A feeding and mixing process and equipment for emulsified asphalt plant cold recycling

A technology for emulsified asphalt and process equipment, applied in the field of material feeding and mixing process and equipment, can solve the problems of high maintenance and maintenance costs, poor road quality, unstable quality of finished materials, etc., so as to reduce maintenance and maintenance costs and improve road quality. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

[0021] The steps of the feeding and mixing process of emulsified asphalt plant mixed cold regeneration of the present invention are as follows: select new aggregates; add or not add water to the new aggregates according to the water content of the new aggregates, and perform pre-stirring; A small amount of emulsified asphalt is sprayed and stirred until the surface of the new aggregate is covered with a small amount of asphalt, so that it has the characteristics of old asphalt pavement milling materials; then add asphalt pavement milling old materials, cement and Mineral powder, spray water, and pre-mix at the same time; finally, spray emulsified asphalt into the mixture, and fully stir until the emulsified asphalt regenerated finished material is formed.

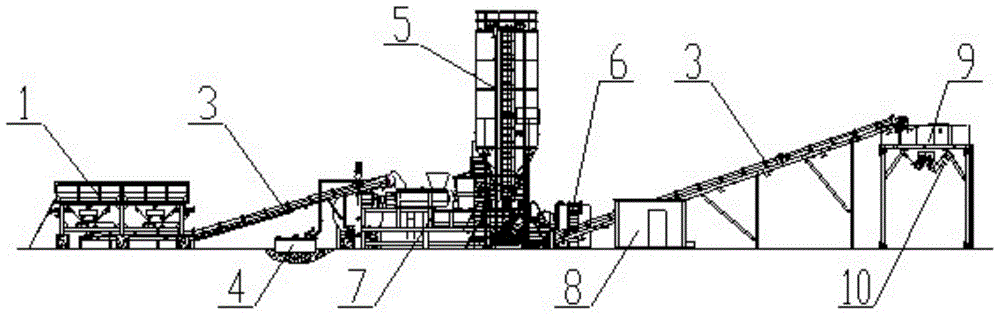

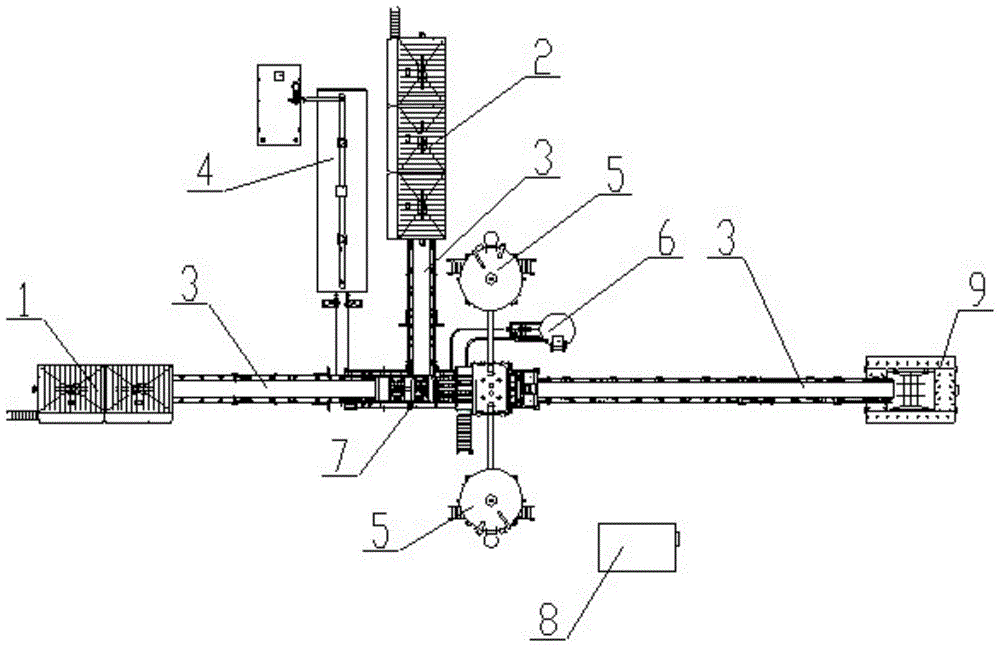

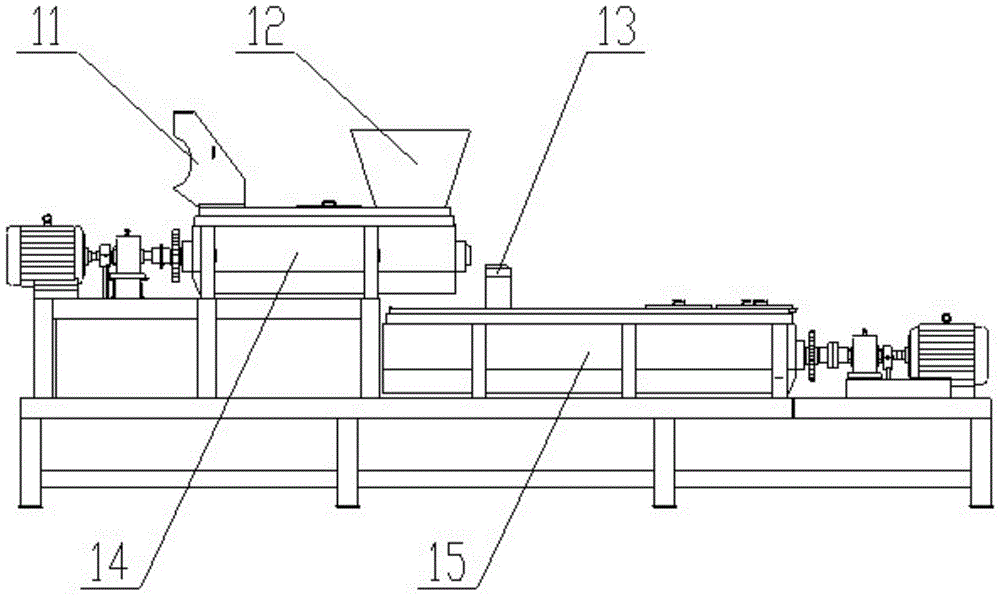

[0022] Such as Figure 1 to Figure 4 As shown in the present invention, a kind of emulsified asphalt factory mixed co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com