Patents

Literature

34results about How to "Avoid the three wastes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for synthesizing triptorelin from solid phase polypeptide

ActiveCN101357936AConvenient sourceReduce usagePeptide preparation methodsBulk chemical productionSide chainFreeze-drying

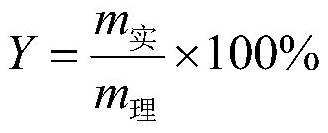

The invention discloses a preparation method of solid phase peptide synthesis triptorelin, which includes the following steps: with Rink Amide AM resins or Rink Amide MBHA resins as starting materials, amino acids with protective groups are sequentially connected according to solid phase synthesis, so as to obtain protective decapeptide resins, and meanwhile crude products are obtained by sequentially removing Fmoc-protective groups and synchronously removing side-chain protective groups and cutting peptides, and triptorelin elaborate products are prepared after the crude products are separated and purified by C18 (or C8 ) column and freeze-dried. The preparation method is stable in technology, convenient in raw and auxiliary material sources, short in production cycle, high in yield, stable in quality, low in production cost and high in transpeptidase yield. Besides, as the preparation method avoids using poisonous reagents, such as hydrogen fluoride, and the like, the pollution of three wastes is low, purification yield is over 25 percent and each step of transpeptidase yield is above 98 percent; the yield after cutting peptides is 78.8 percent and the total yield is 25.4 percent.

Owner:SHANGHAI SOHO YIMING PHARMA

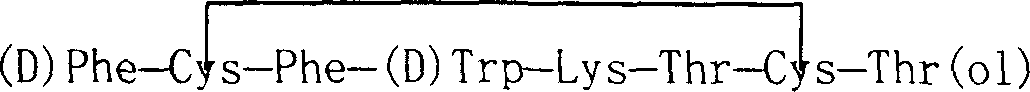

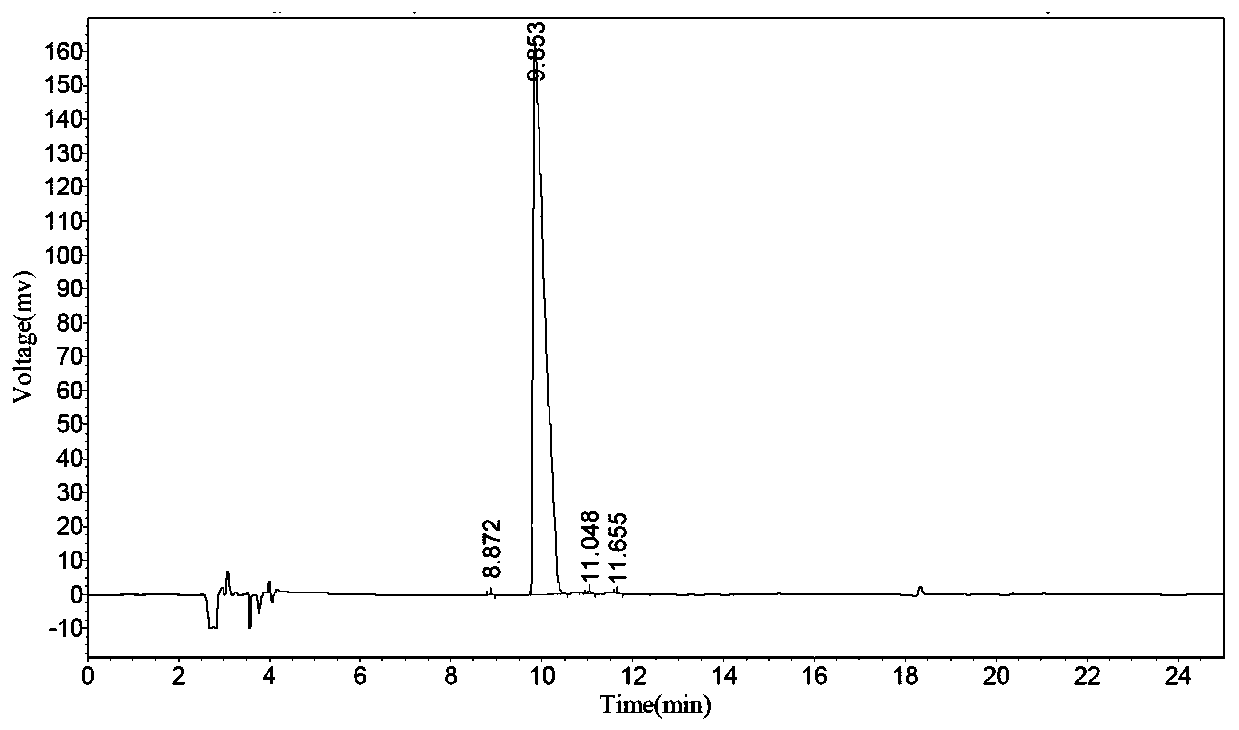

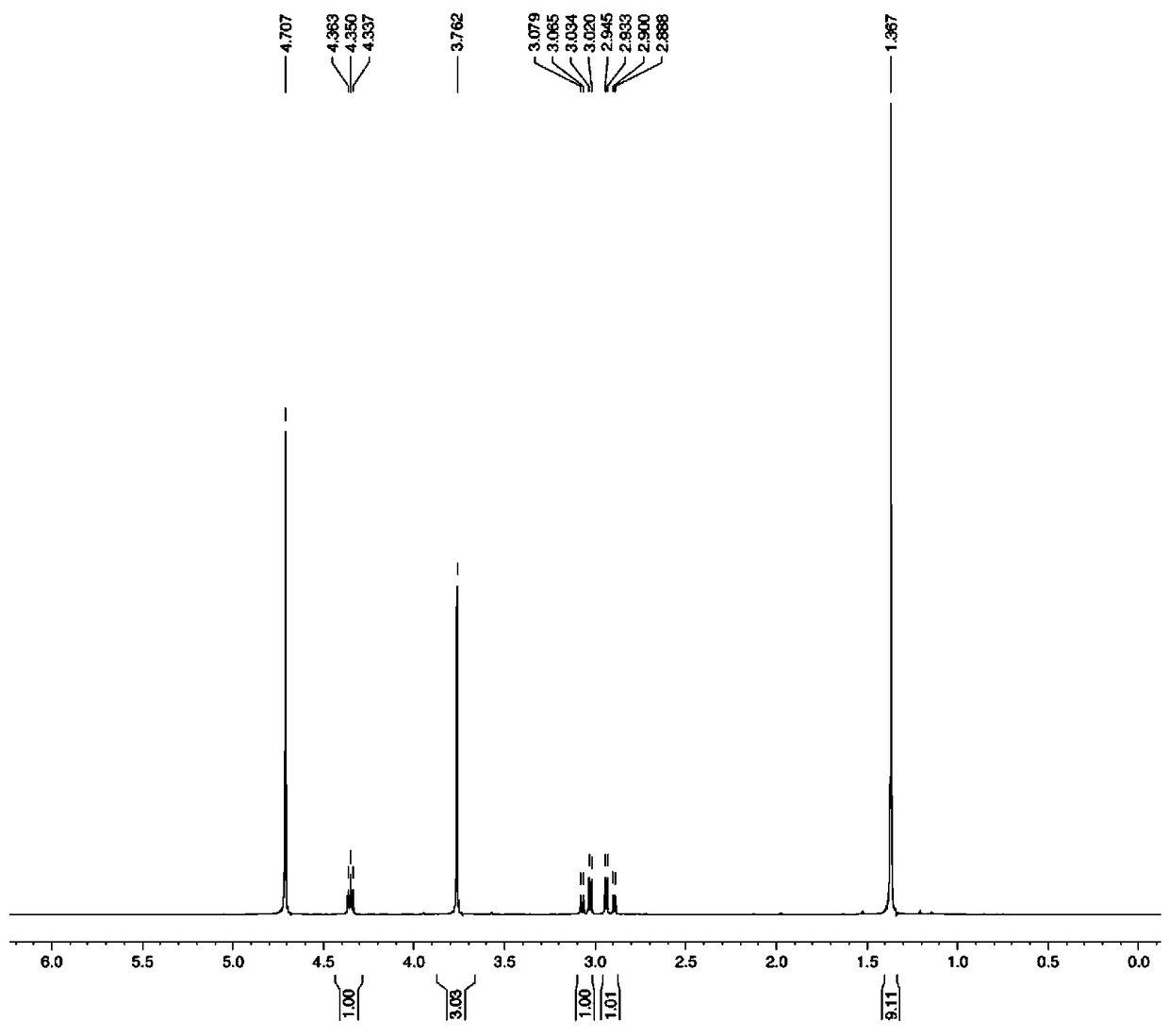

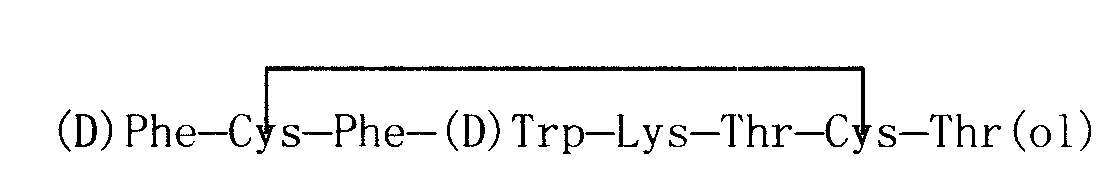

Preparation method of synthesizing octriotide from solid phase polypeptide

ActiveCN1923849AConvenient sourceReduce usagePeptidesBulk chemical productionHydrogen fluorideSide chain

The invention discloses an aoqu-peptide preparing method of solid-phase polypeptide, which comprises the following steps: adopting 2-chloride-trityl resin, 4-methyl trityl resin or 4-methoxyl trityl resin as raw material; connecting amino acid with protective group according to solid-phase synthetic method; obtaining protected octapeptide resin; removing Fmoc-protective group sequently; stripping side-chain protective group; cutting peptide to obtain reduced aoqu-peptide; oxidizing through air under pH 7-11 condition; separating and purifying rought product through C18 (C8) column to produce exquisite.

Owner:SHANGHAI SOHO YIMING PHARMA

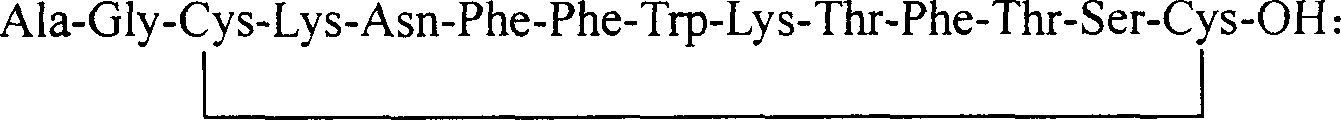

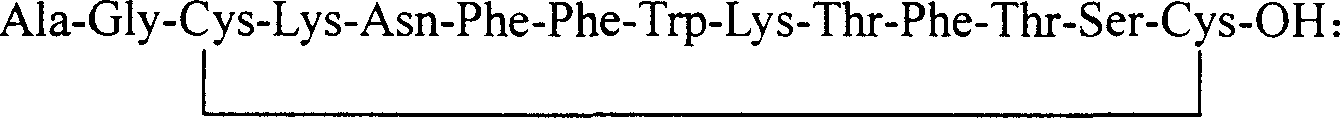

Preparation method of synthesizing growth chalone from solid phase polypeptide

InactiveCN1923851AConvenient sourceReduce usageSomatostatinsPeptide preparation methodsHydrogen fluorideSomatomedin

The invention discloses a chalone preparing method of solid-phase polypeptide, which comprises the following steps: adopting 2-chloride-trityl resin, 4-methyl trityl resin or 4-methoxyl trityl resin as raw material; connecting amino acid with protective group according to solid-phase synthetic method; obtaining protected octapeptide resin; removing Fmoc-protective group sequently; stripping side-chain protective group; cutting peptide to obtain reduced aoqu-peptide; oxidizing through air under pH 7-11 condition; separating and purifying rought product through C18 (C8) column to produce exquisite.

Owner:SHANGHAI SOHO YIMING PHARMA +1

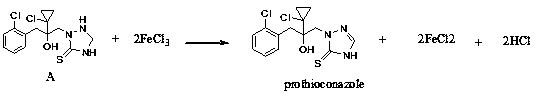

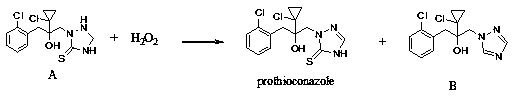

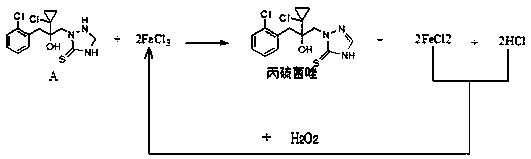

Synthetic method of prothioconazole

ActiveCN111303059AAvoid the three wastesDesulfurization impurities are reducedOrganic chemistryProcess engineeringEnvironmental engineering

The invention relates to a synthetic method of prothioconazole. The method specifically comprises the following steps: oxidizing an intermediate A by ferric chloride to generate prothioconazole and simultaneously generate ferrous chloride and hydrogen chloride, oxidizing the ferrous chloride and the hydrogen chloride by hydrogen peroxide dropwise added into the system to regenerate ferric chloride, continuing to oxidize the intermediate A by the generated ferric trichloride to obtain prothioconazole, and repeating the steps until the intermediate A is completely converted into the prothioconazole. According to the synthesis method of prothioconazole, only a catalytic amount of ferric chloride is needed, a byproduct is water, a large amount of three wastes generated by a traditional ferricchloride oxidation method are avoided, and a mild oxidant ferric chloride is adopted, so that desulfurization impurities are greatly reduced, and the yield is high.

Owner:JIANGYIN SULI CHEM

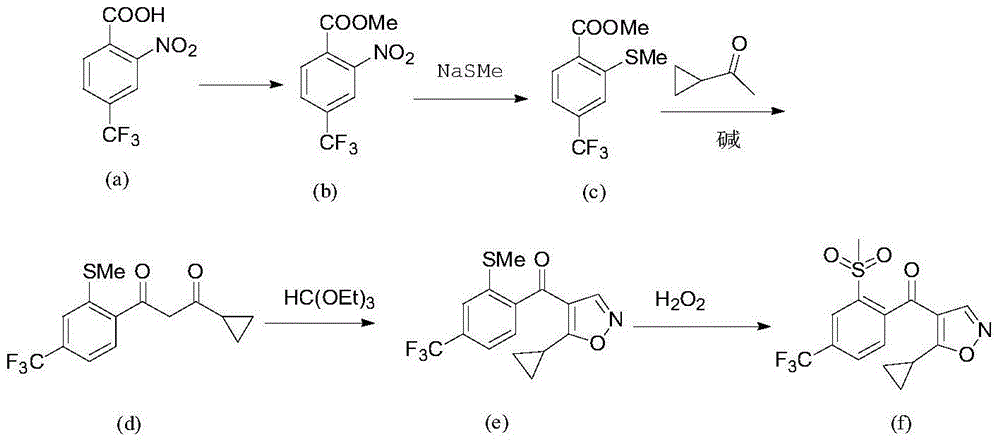

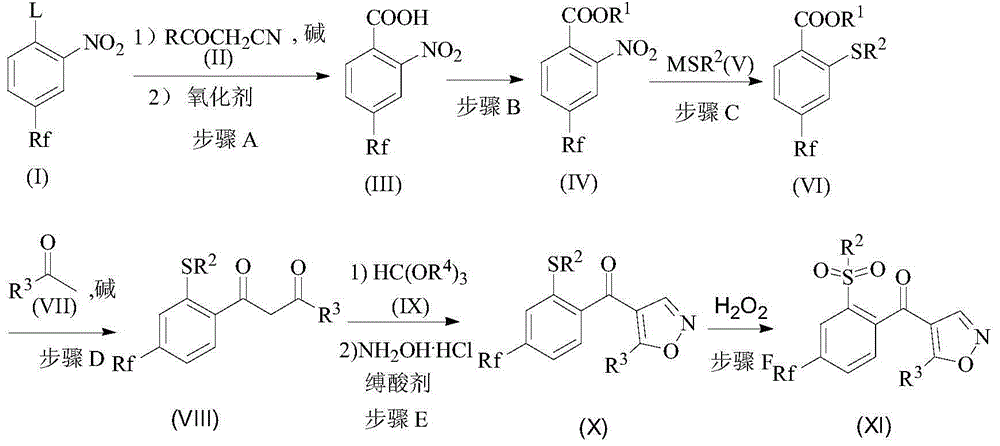

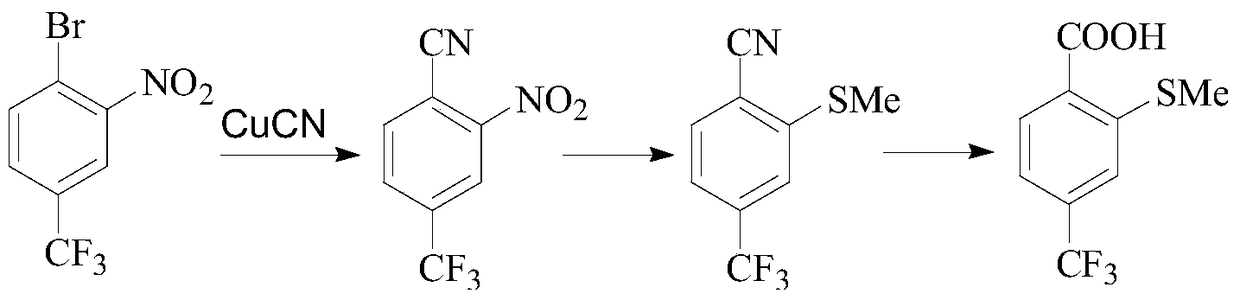

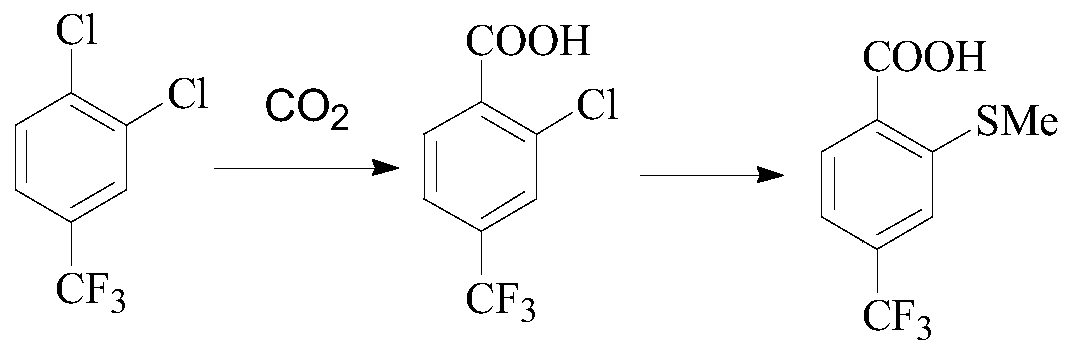

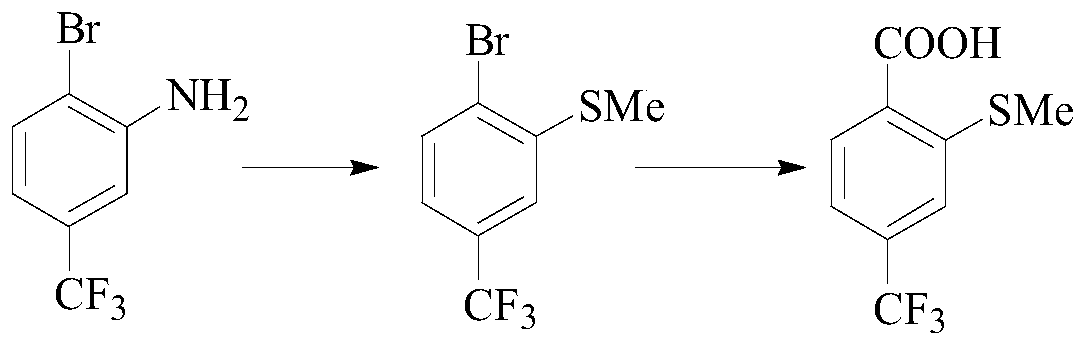

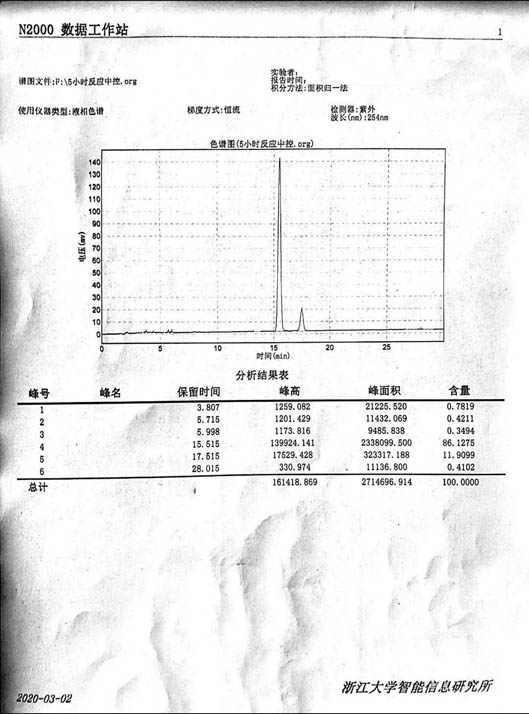

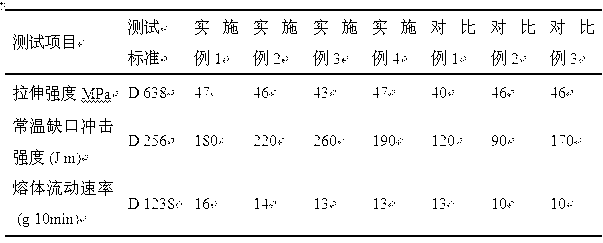

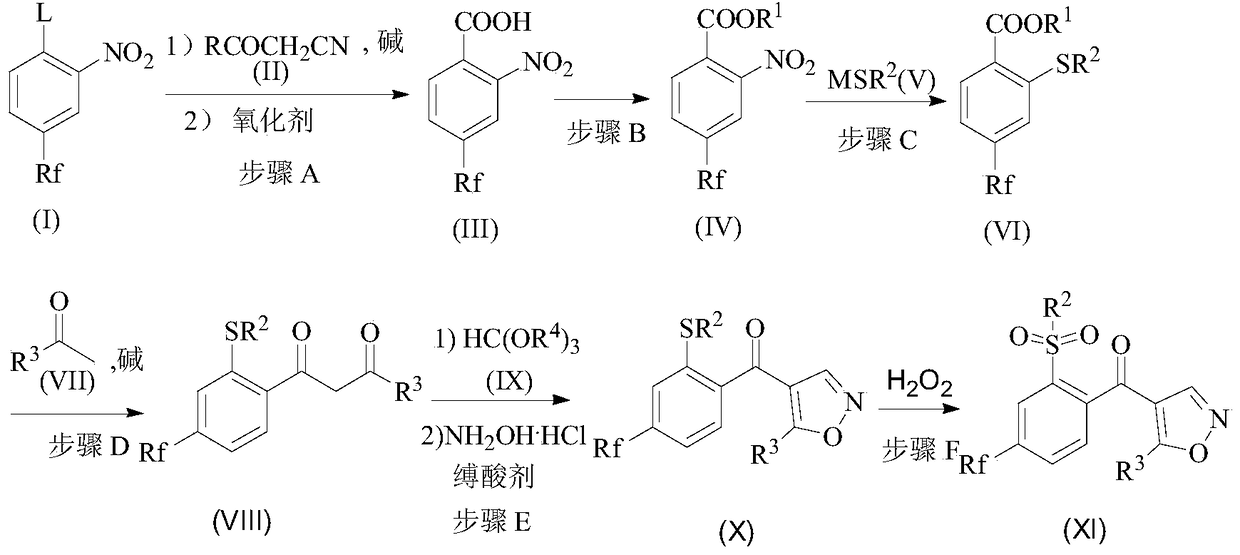

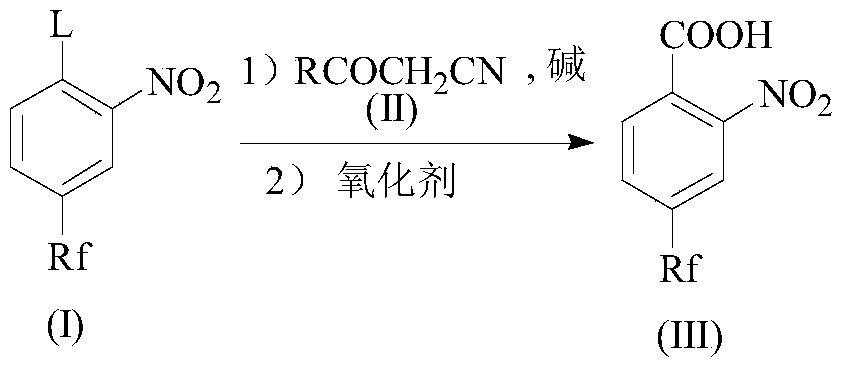

Preparation method of isoxazole compound and isoxazole compound intermediate

ActiveCN105712944AMild reaction conditionsSafe reaction conditionsOrganic compound preparationSulfide preparationHydroxylamine HydrochlorideMethyl Ketone

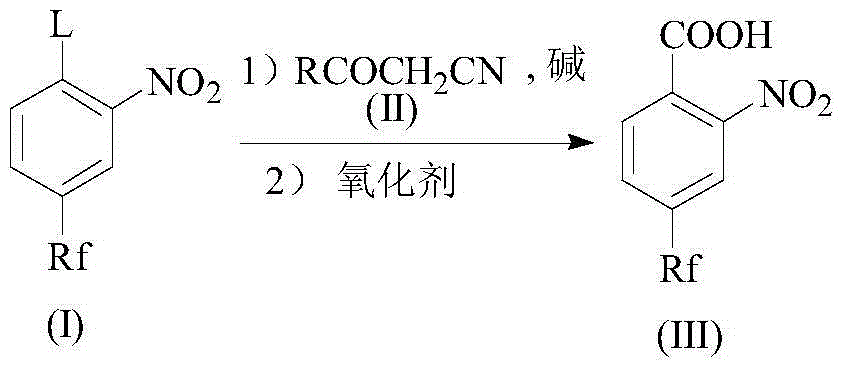

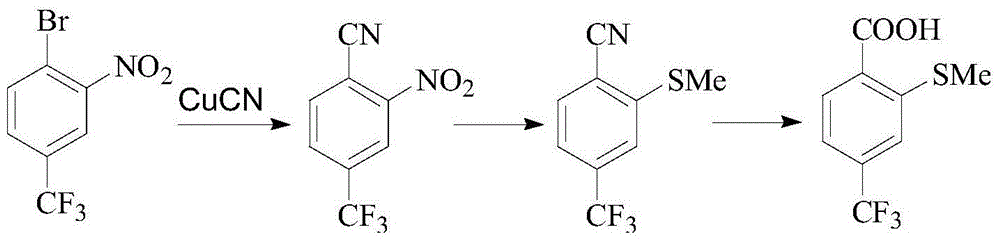

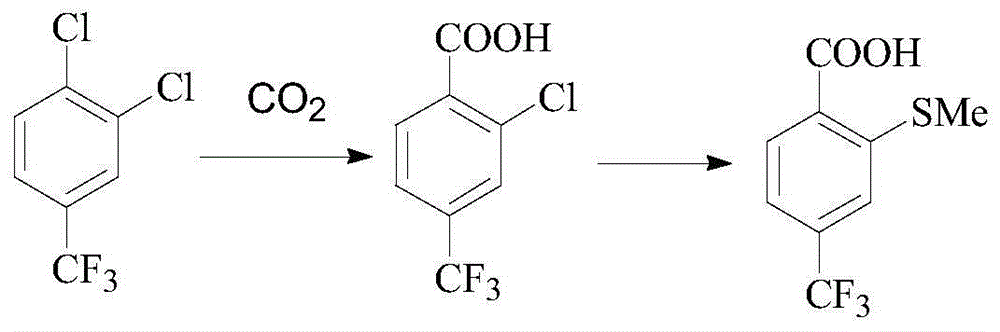

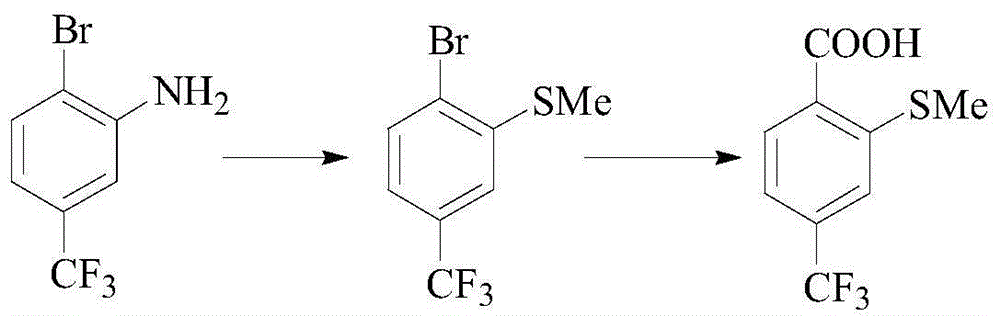

The present invention discloses a preparation method of an isoxazole compound and an isoxazole compound intermediate. According to the method, an intermediate acid (III) is prepared by substitution reaction of a compound (I) as a raw material and a compound (II) in the presence of a base and then oxidation reaction; an intermediate (IV) is prepared by methyl esterification of the intermediate acid (III); an intermediate (VI) is prepared by thionation of the intermediate (IV); an intermediate (VIII) is prepared by condensation of the intermediate (VI) and cyclopropyl methyl ketone under basic conditions; an intermediate (X) is prepared by ene-etherification reaction of the intermediate (VIII) and ortho-formate and then cyclization with hydroxylamine hydrochloride; and the isoxazole compound (XI) is prepared by oxidation of methylthio groups of the intermediate (X) by hydrogen peroxide. Raw materials are readily available, yield is high, purity is high, three-waste is low, cost is low, and the preparation method has good industrial value.

Owner:ZHEJIANG ZHUJI UNITED CHEM

Solid phase polypeptide synthesis preparation method for leuprorelin

ActiveCN1865280BConvenient sourceReduce usagePeptide preparation methodsBulk chemical productionHydrogen fluorideLeuprorelin

The invention discloses a bright-ala-ruilin preparing method of solid-phase polypeptide, which comprises the following steps: adopting Wang resin or CTC resin as original material to connect amino with protective group to produce protective nonapeptide resin; removing Fmoc-protective group sequently; proceeding side-chain protective group synchronizingly and cutting peptide; connecting ethylaminethrough ethylamine-to-HOBT to produce crude product; proceeding separation and purifying through C18 (or C8) pillar to produce fine bright-ala-ruilin. The invention avoids the utility of poisonous agent, which improves the purifying, peptide connecting and obtaining rate.

Owner:SHANGHAI SOHO YIMING PHARMA

Preparation method for preparing chitosan by utilizing snow crab shells

ActiveCN111138563AMake full use of the valueAvoid the three wastesOrganic compound preparationCarboxylic acid salt preparationEnvironmental engineeringCitric acid

A preparation method for preparing chitosan by utilizing snow crab shells relates to the technical field of preparation methods of high-viscosity chitosan, and particularly belongs to a preparation method for preparing chitosan by utilizing fresh snow crab shells. Crab shell pretreatment: taking 200 parts (by mass) of fresh snow crab shells, and crushing the fresh snow crab shells; decalcifying the crab shells: adding 600-1000 parts by mass of a citric acid solution with the mass percent concentration of 5-10% into the crab shells, soaking for 6-15 hours, filtering, washing the crab shells obtained by filtering by using water as a washing solution, and combining washing residual liquid with a filtrate to obtain a mixture for storage; extracting organic calcium: filtering the mixture through a plate frame, and drying filter residues to obtain calcium citrate; and collecting the residual mixed solution for later use after subsequent treatment. Three wastes are avoided in the whole production process, and zero waste, zero emission and high-value utilization are realized. A high-temperature strong-alkali deproteinization procedure is not needed, so that energy conservation, environmental protection and stable product quality are realized. The product has high viscosity and good quality.

Owner:SHANDONG MEIJIA GROUP

Preparation method of sulfophenyl pyrazolone and intermediate thereof

ActiveCN105646356AMild reaction conditionsSafe reaction conditionsSulfonic acid esters preparationEsterification reactionHydrolysis

The invention discloses a preparation method of sulfophenyl pyrazolone. The method consists of: taking a compound (I) as the raw material, in the presence of alkali, subjecting the compound (I) and a compound (II) to substitution reaction, then conducting oxidation by an oxidizing agent to obtain a compound (III), esterfying the compound (III) to obtain a compound (IV), subjecting the compound (IV) to thionation to obtain a compound (VI), conducting oxidation and hydrolysis (or hydrolysis, oxidation) on the compound (VI) to obtain a compound (VII), subjecting the compound (VII) to acyl chlorination, subjecting the obtained acyl chloride (VIII) and 1, 3-dimethyl-5-hydroxypyrazole to esterification reaction so as to obtain a compound (IX), and finally carrying out rearrangement on the compound (IX) to obtain a compound (X). The method provided by the invention has the advantages of cheap and easily available raw materials, high reaction conversion rate, few three wastes, and is beneficial to industrial production.

Owner:ZHEJIANG ZHUJI UNITED CHEM

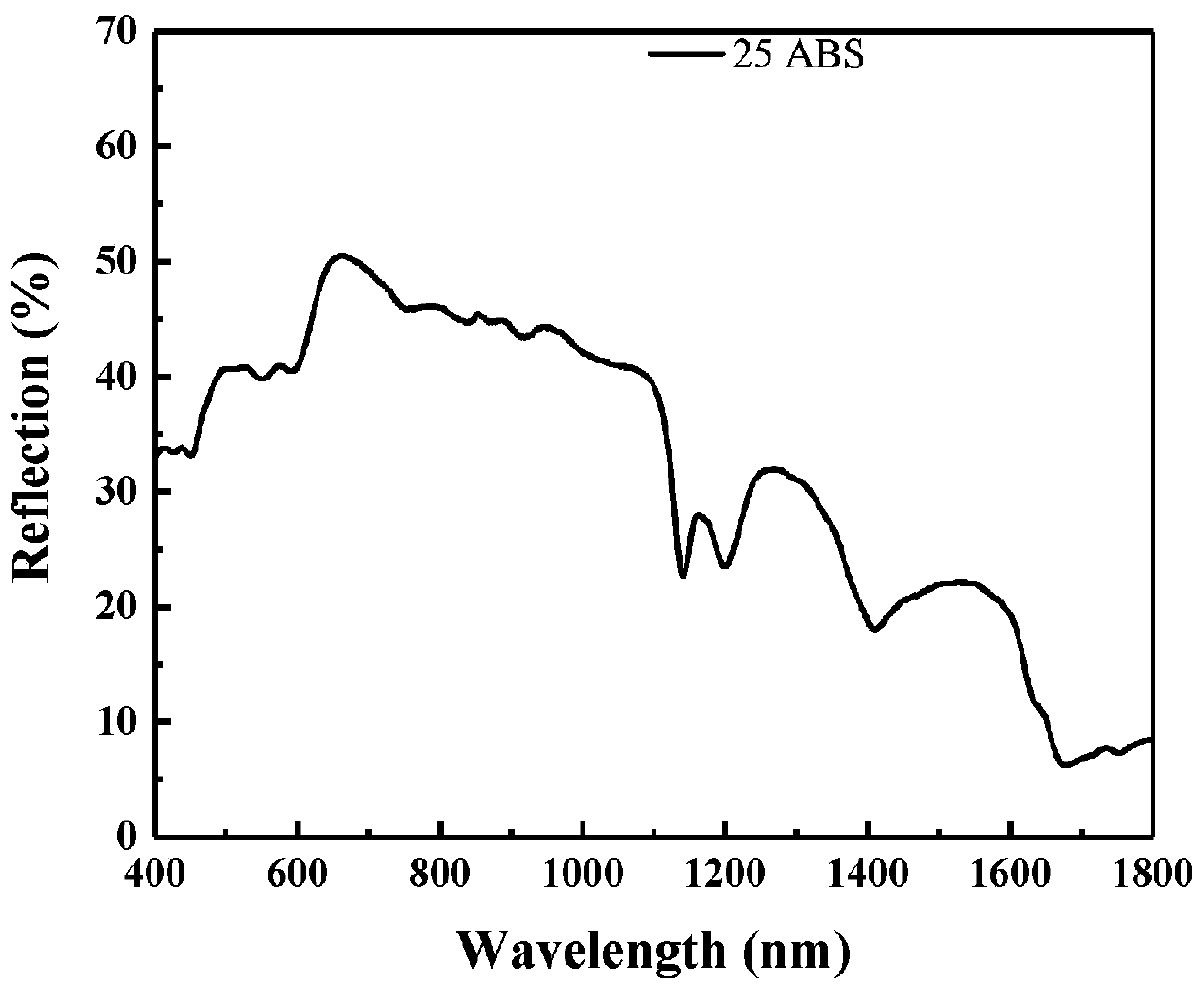

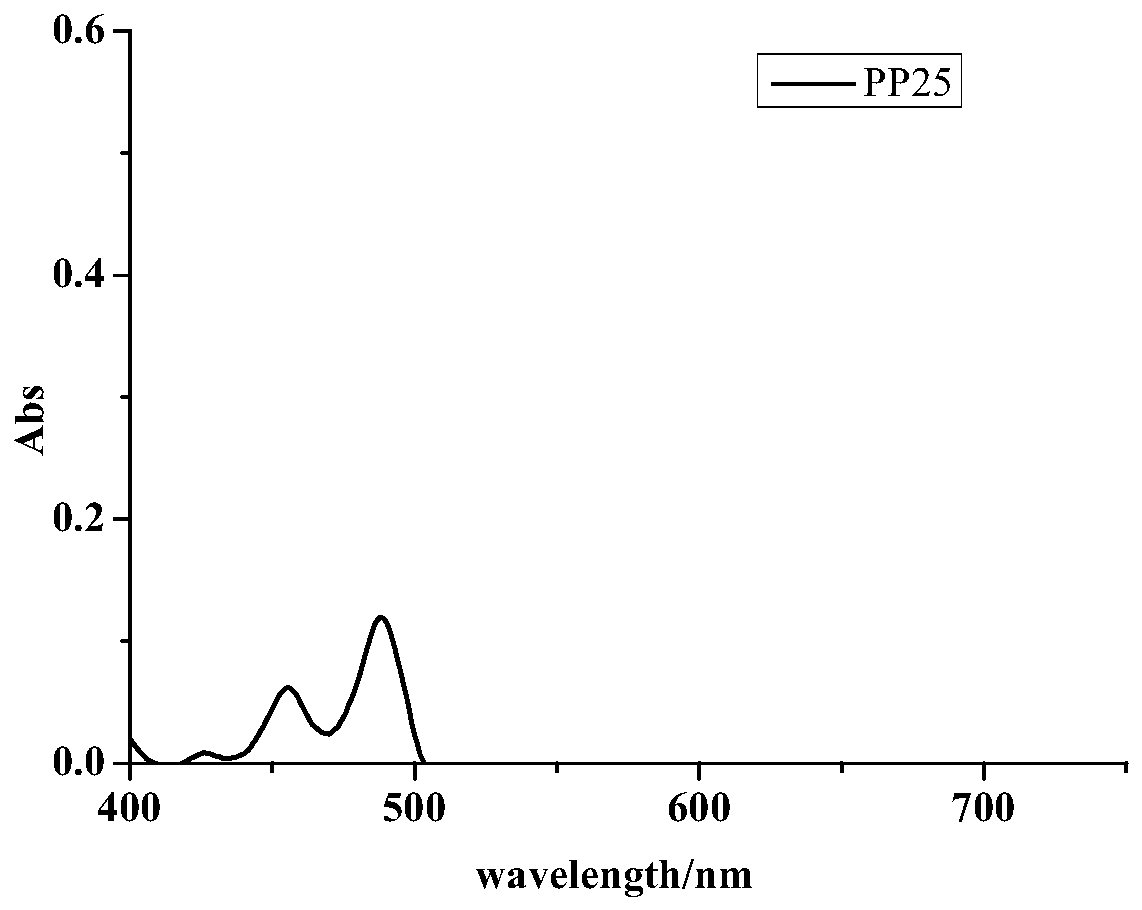

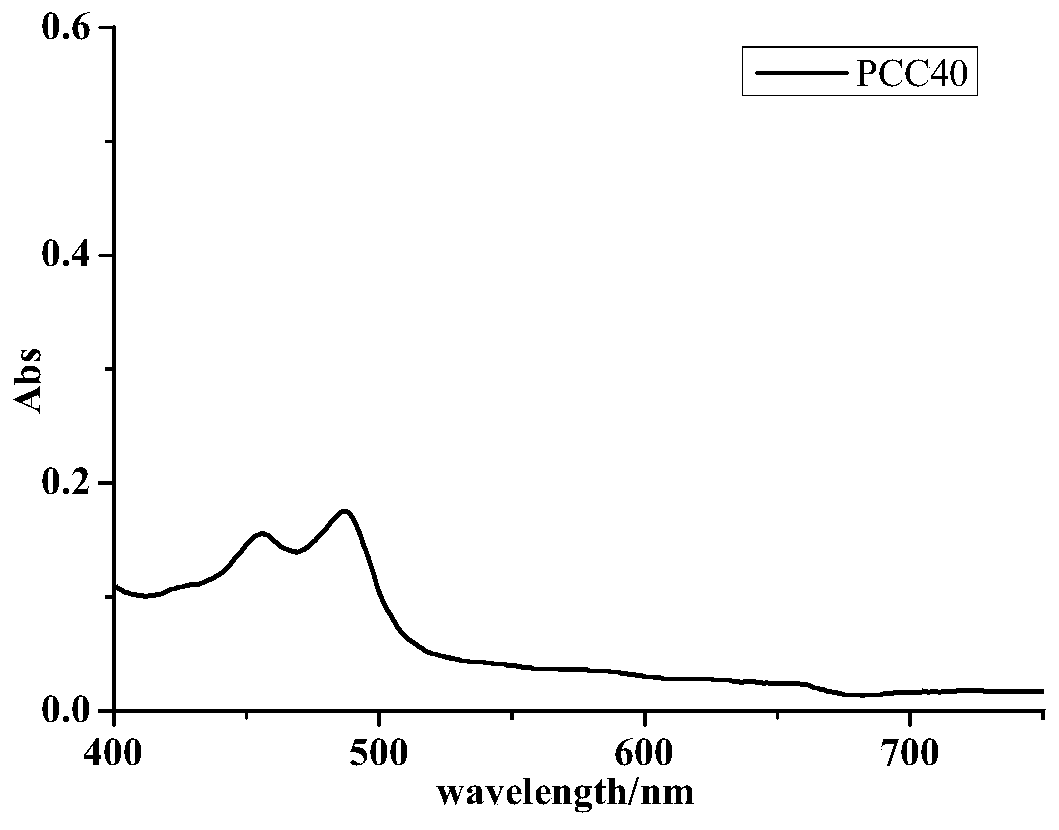

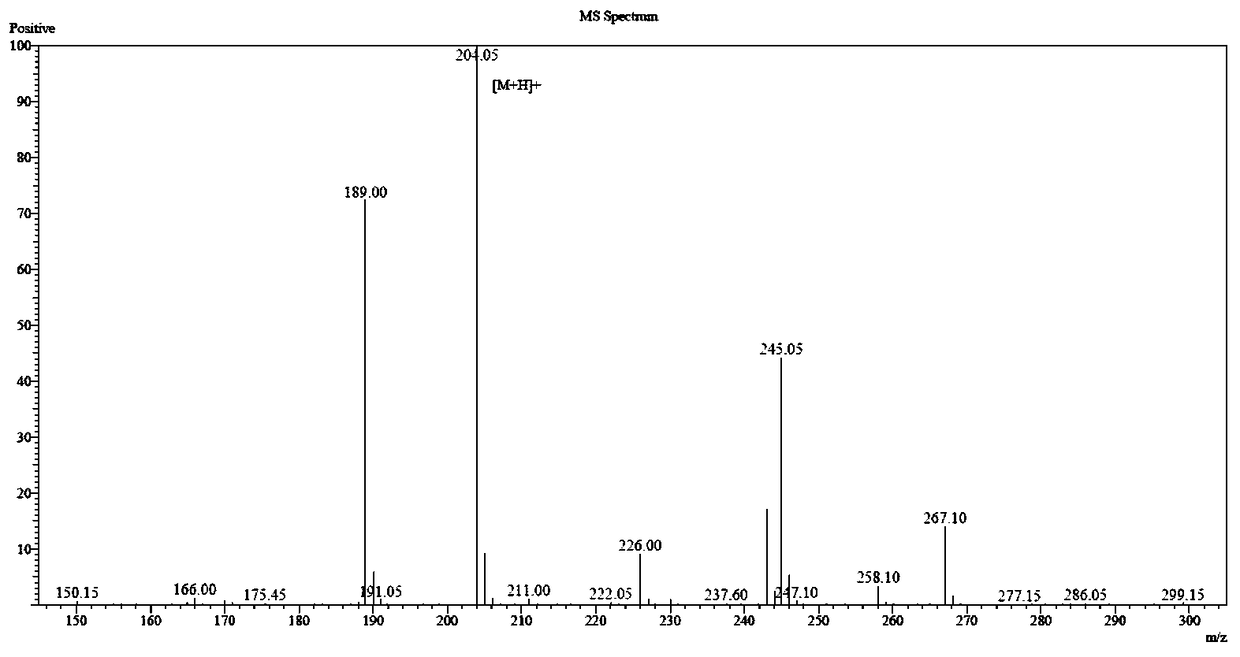

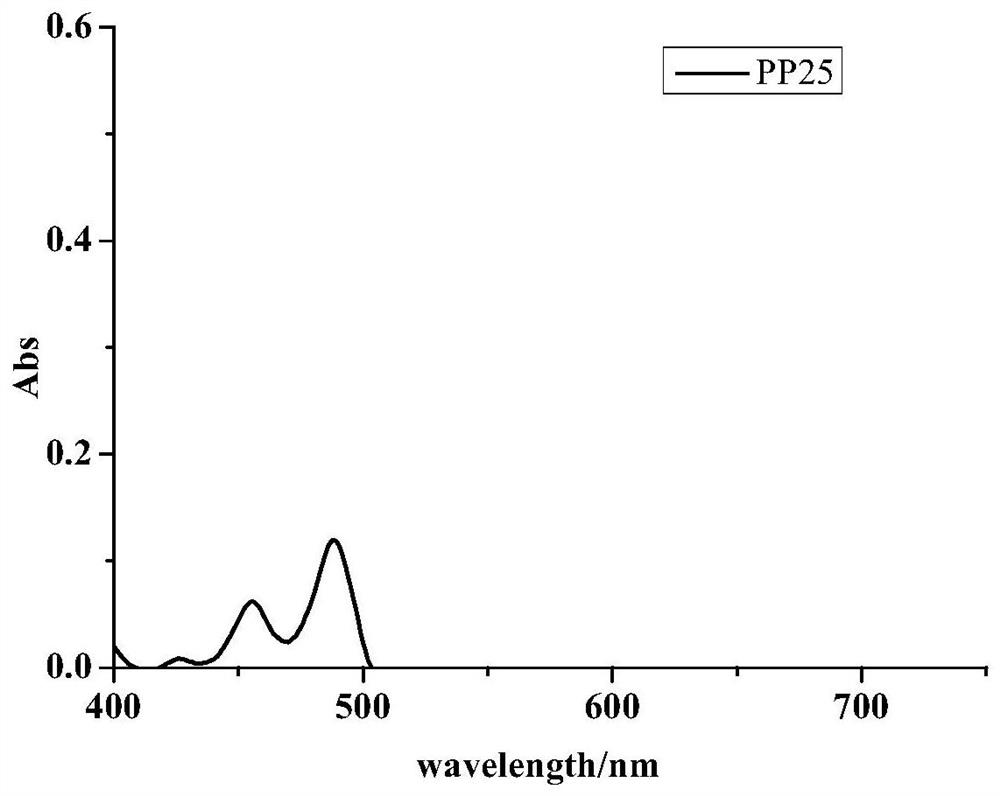

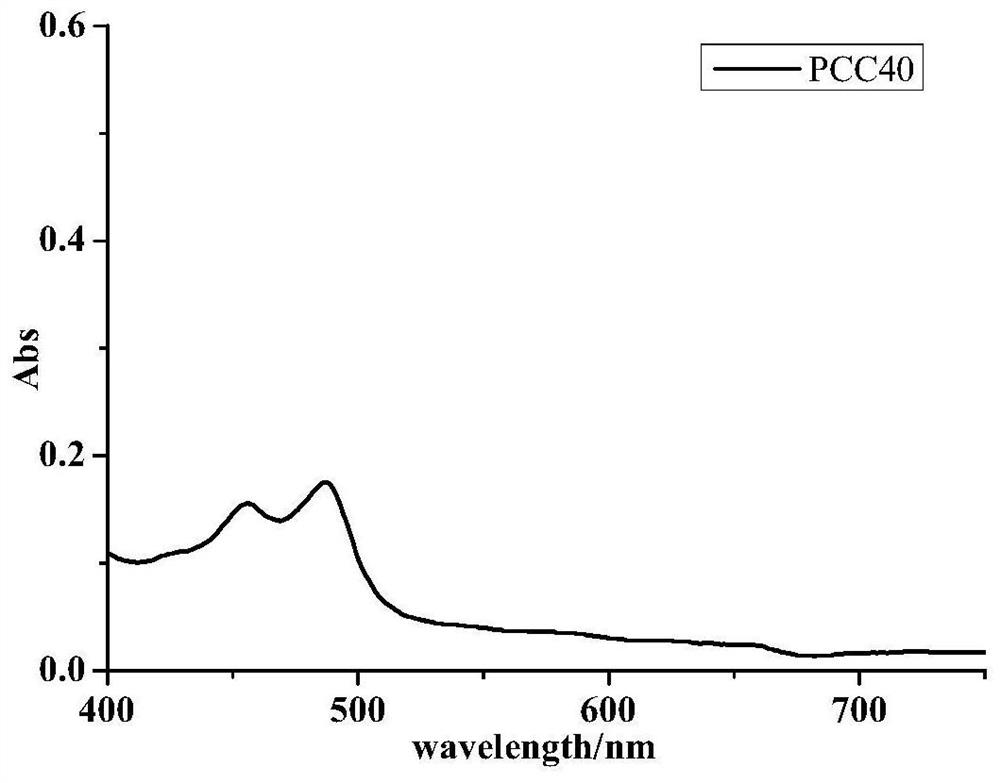

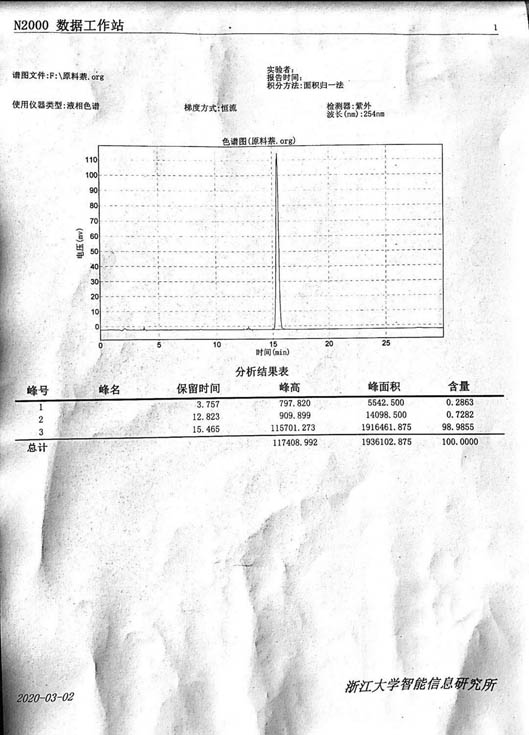

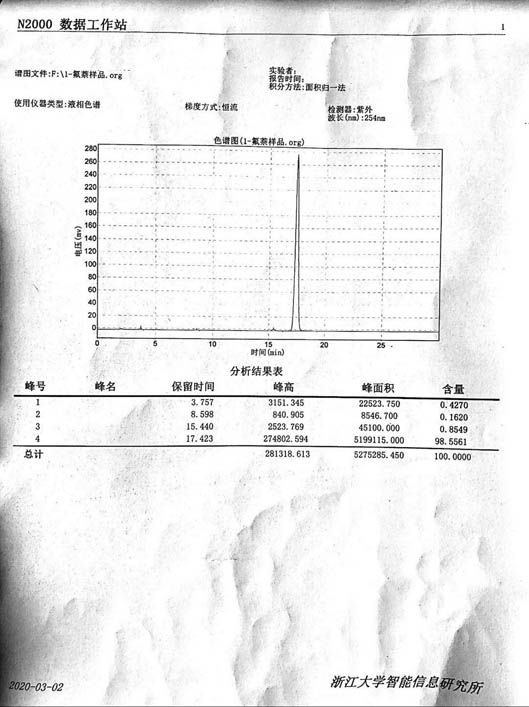

Polymer material wrappage of pigment yellow 138 or derivative of pigment yellow 138, preparation method of polymer material wrappage, and downstream product of polymer material wrappage

ActiveCN110790982AGood dispersionAvoid the three wastesInksOrganic dyesOrganic acidPerylene derivatives

The invention relates to a polymer material wrappage of pigment yellow 138 or a derivative of pigment yellow 138, a preparation method of the polymer material wrappage, and a downstream product of thepolymer material wrappage. The method comprises the following steps: mixing a monoanhydride aromatic compound, an 8-aminoquinaldine compound, a solid organic acid and a thermoplastic polymer material; adjusting the reaction molar ratio of the raw materials and the mass content of pigment yellow 138 or the derivative of pigment yellow 138 in a final product so as to realize extruding or kneading of an obtained mixture and obtain the polymer material wrappage of pigment yellow 138 or the derivative of pigment yellow 138 in one step. The raw material reactants of pigment yellow 138 or the derivative of pigment yellow 138 have better dispersity in the high polymer material; therefore, pigment yellow 138 or the derivative of pigment yellow 138 can be directly generated and uniformly dispersedin the high polymer material in the extrusion or kneading process, no solvent is required to be added in the process, separation and purification are not required after the reaction is finished, the generation of three wastes in the traditional synthesis process of pigment yellow 138 or the derivative is avoided, the process flow is greatly simplified, and the energy consumption is reduced.

Owner:DONGGUAN UNIV OF TECH

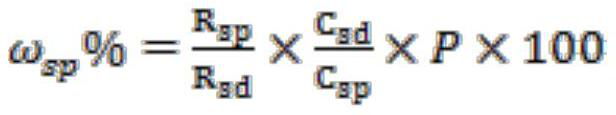

Preparation method of polypeptide raw material aspartic acid beta-tert-butyl ester alpha-methyl ester hydrochloride

InactiveCN108997155AFew synthetic stepsSuitable for mass productionOrganic compound preparationAmino-carboxyl compound preparationTert butylTetrahydrofuran

The invention discloses a preparation method of a polypeptide raw material aspartic acid beta-tert-butyl ester alpha-methyl ester hydrochloride, and mainly solves the technical problems of complex original process, long period, low yield, high cost, high dangerousness and inadaptation for mass production. The preparation method comprises the following steps: firstly, suspending aspartic acid in dry tetrahydrofuran, to prepare aspartic lactonic anhydride hydrochloride under the action of phosphorus oxychloride; secondly, suspending aspartic lactonic anhydride hydrochloride in methanol, carryingout a reaction to obtain aspartic acid alpha-methyl ester hydrochloride, and adjusting the pH value by triethylamine to make aspartic acid alpha-methyl ester separated out; thirdly, suspending aspartic acid alpha-methyl ester in dichloromethane, introducing isobutylene, dropwise adding concentrated sulfuric acid, and carrying out sealed reaction treatment, to obtain an oily substance aspartic acid beta-tert-butyl ester alpha-methyl ester; and fourthly, dissolving the oily substance aspartic acid beta-tert-butyl ester alpha-methyl ester in ethyl ether and dropwise adding ethyl ether-hydrochloric acid gas, to obtain the final product aspartic acid beta-tert-butyl ester alpha-methyl ester hydrochloride.

Owner:GL BIOCHEM SHANGHAI +1

Preparation method of synthesizing octriotide from solid phase polypeptide

ActiveCN1923849BConvenient sourceReduce usagePeptidesBulk chemical productionHydrogen fluorideSide chain

The invention discloses an aoqu-peptide preparing method of solid-phase polypeptide, which comprises the following steps: adopting 2-chloride-trityl resin, 4-methyl trityl resin or 4-methoxyl trityl resin as raw material; connecting amino acid with protective group according to solid-phase synthetic method; obtaining protected octapeptide resin; removing Fmoc-protective group sequently; strippingside-chain protective group; cutting peptide to obtain reduced aoqu-peptide; oxidizing through air under pH 7-11 condition; separating and purifying rought product through C18 (C8) column to produce exquisite.

Owner:SHANGHAI SOHO YIMING PHARMA

3,5-dichloro-2-pentanone preparation method

ActiveCN109265329AReduce usageSimple processPreparation from heterocyclic compoundsSulfonyl chlorideOrganic solvent

The invention relates to the field of fine chemicals, and discloses a 3,5-dichloro-2-pentanone preparation method, which comprises: making alpha-acetyl-gamma-butyrolactone contact sulfonyl chloride ina solvent-free system to carry out a chlorination reaction, mixing the material obtained by the chlorination reaction with water, adding hydrochloric acid to the obtained mixture in a dropwise manner, and carrying out a ring-opening reaction. According to the present invention, the solvent-free one-pot reaction is achieved by using the cheap industrial chemicals as the raw materials, such that the process operation is simplified, the three-waste and the production cost are reduced, and the pollution caused by the use of the metal catalyst is avoided.

Owner:NUTRICHEM LAB CO LTD

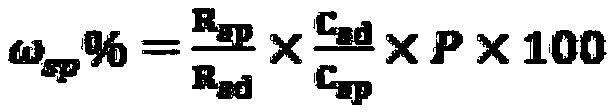

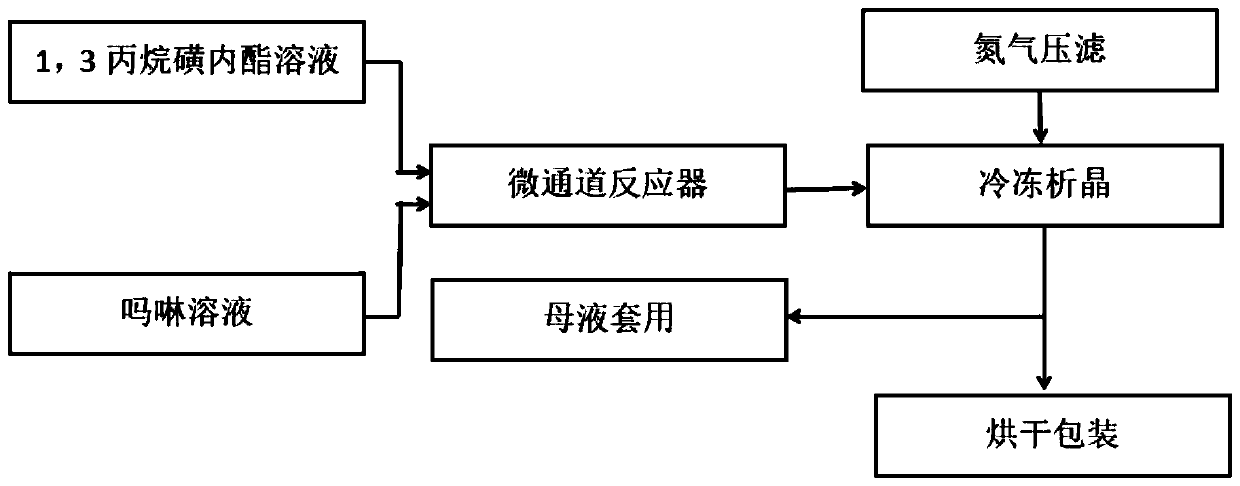

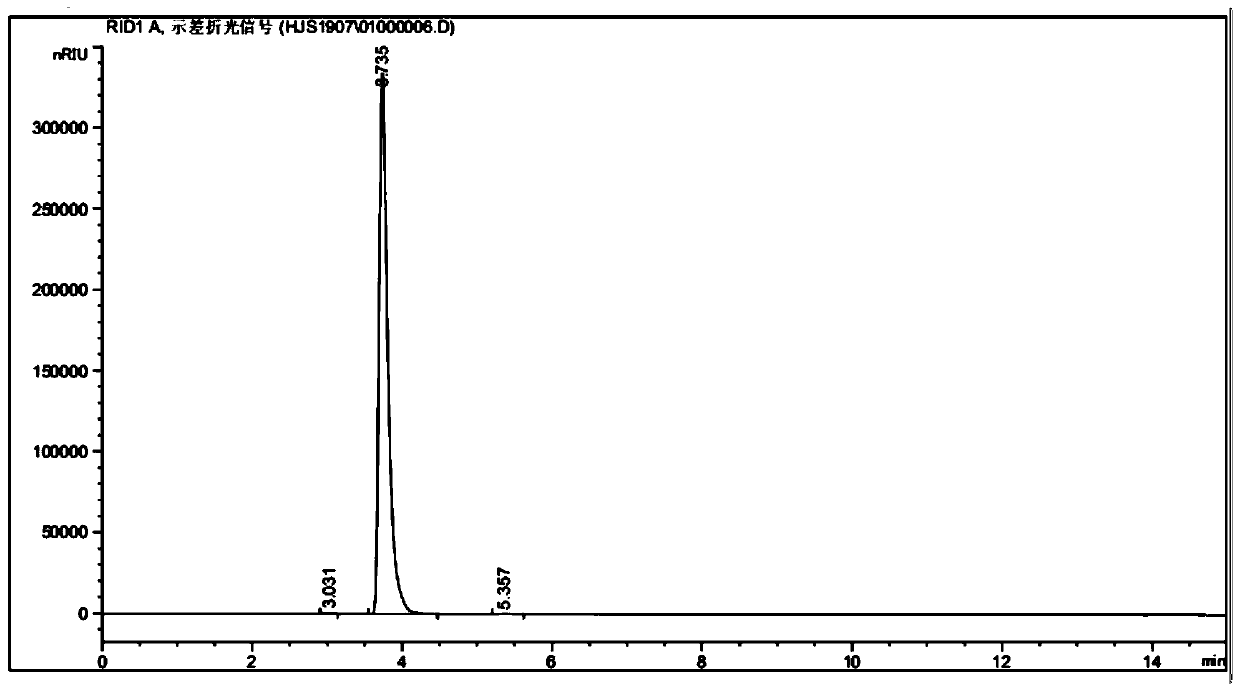

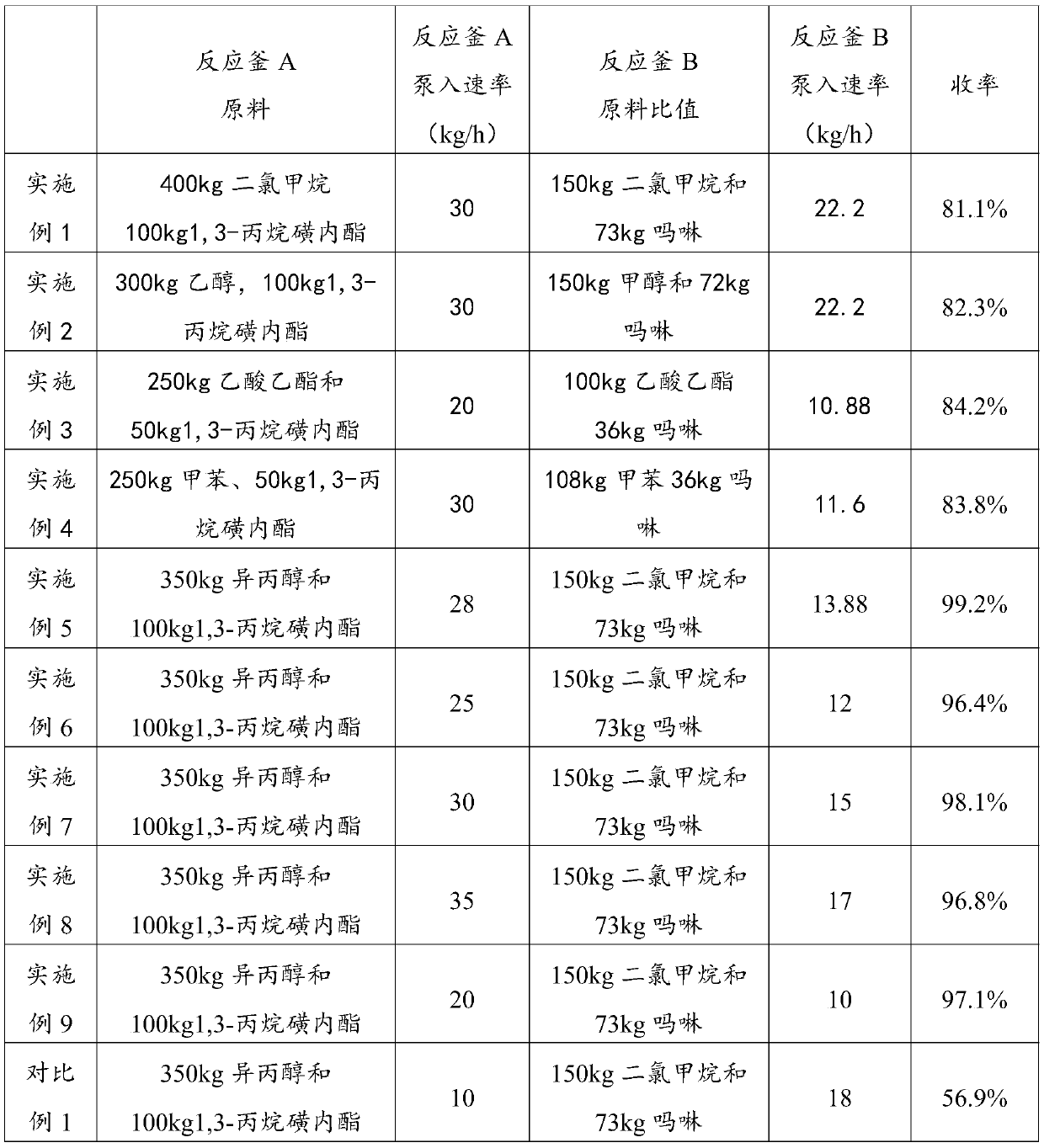

Preparation method of 3-morpholinopropanesulfonic acid

ActiveCN110981831AHigh yieldThe operation process is simple and stable and controllableOrganic chemistryMorpholinePhysical chemistry

The invention provides a preparation method of 3-morpholinopropanesulfonic acid, wherein the preparation method comprises the steps: dissolving 1,3-propanesultone with an organic solvent A to obtain an organic solution containing 1,3-propanesultone, and dissolving morpholine with an organic solvent B to obtain an organic solution containing morpholine, wherein the molar ratio of the 1,3-propanesultone to the morpholine is 1:1; respectively pumping the organic solution containing 1,3-propanesultone and the organic solution containing morpholine into a micro-channel reactor at the same time, andcarrying out a reaction to obtain a reaction solution, wherein the pumping speed of the organic solution containing 1,3-propanesultone is 20-35 kg / h, and the pumping speed of the organic solution containing morpholine is 10-25 kg / h; and separating out a 3-morpholinopropanesulfonic acid crude product from the obtained reaction solution by adopting freezing crystallization, then introducing nitrogen, and carrying out filter pressing to obtain the 3-morpholinopropanesulfonic acid finished product. According to the method, 1,3-propanesultone and morpholine are used as raw materials, the micro-channel reactor is adopted, and reaction conditions are set, so that the yield of the product can be greatly increased.

Owner:湖北吉和昌化工科技有限公司

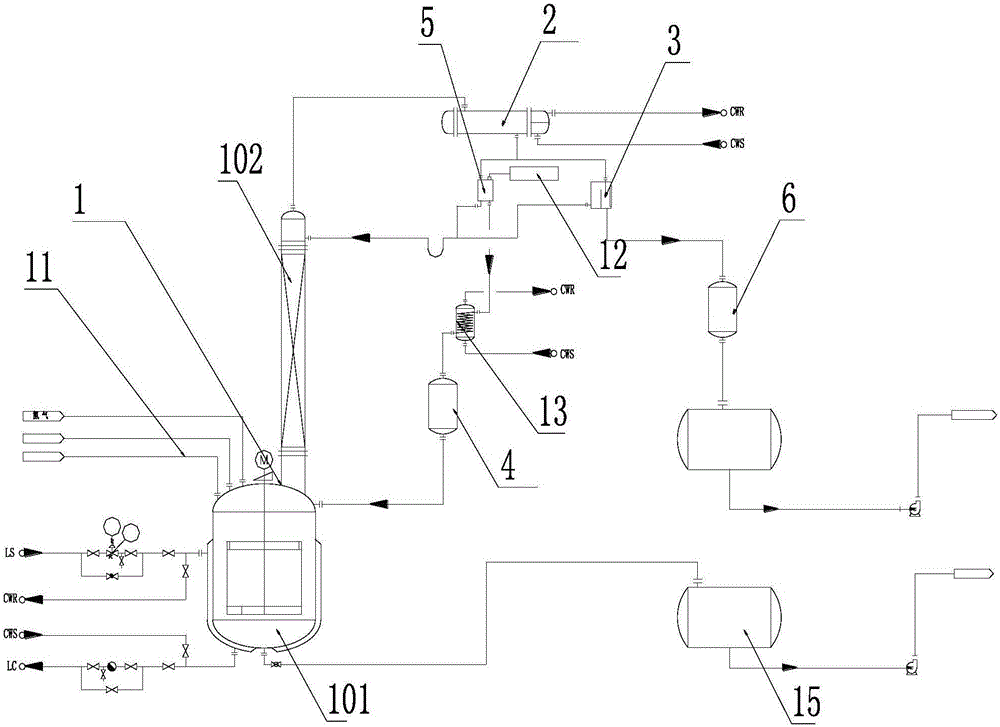

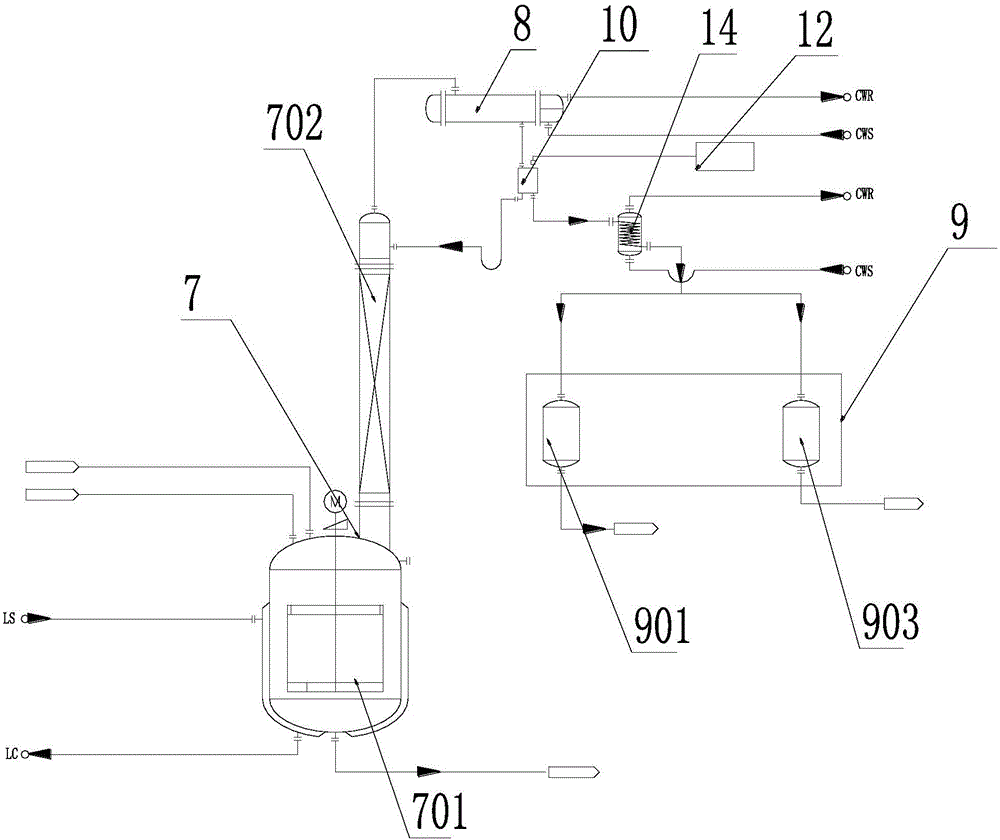

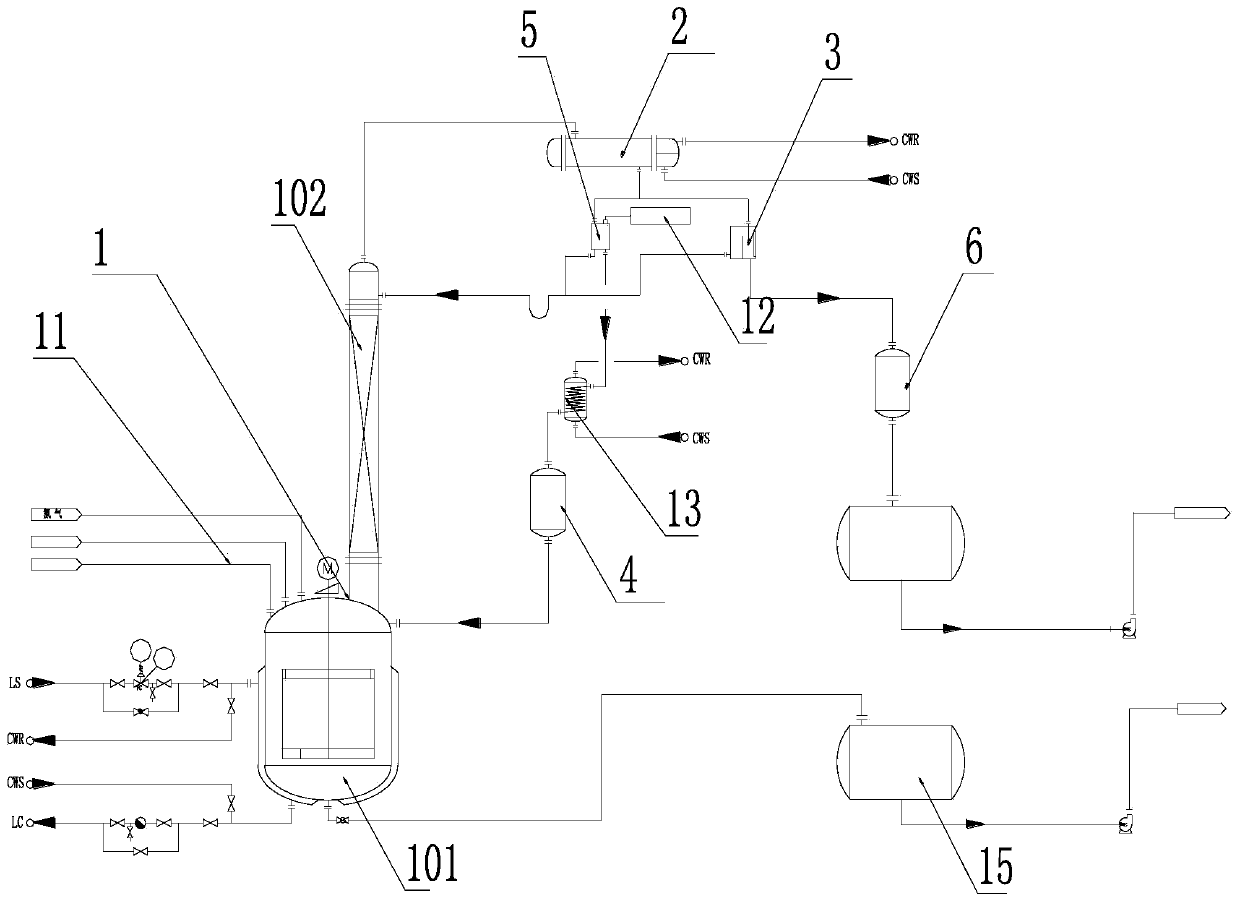

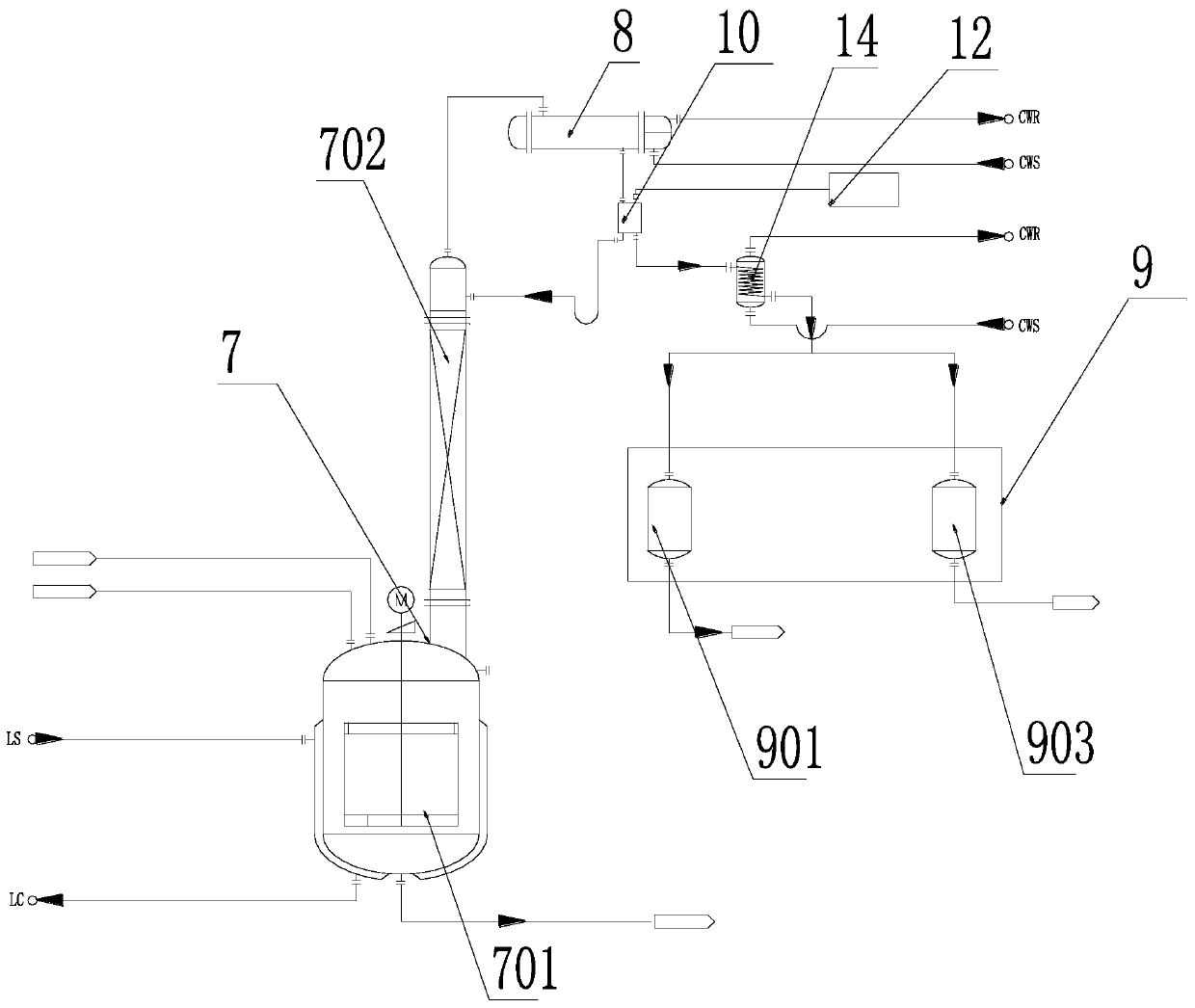

Device and method for separating N-methylpyrrolidine, water and tetrahydrofuran

ActiveCN105061363ASolve the problem of energy consumptionSettlement yieldOrganic chemistryPhase splittingProcess engineering

Provided are a device and method for separating N-methylpyrrolidine, water and tetrahydrofuran. The device comprises a crude product dehydration working section and a product refining working section. The crude product dehydration working section comprises a crude product intermittent column, a first condenser, a phase splitting tank, a backflow head and the like. The crude product intermittent column comprises a crude steaming column reactor and a crude steaming column. The product refining working section comprises a refining intermittent column, a second condenser, a transition cut fraction receiving tan and a product receiving tank. The refining intermittent column comprises a rectifying column reactor and a rectifying column located at the top of the rectifying column reactor. The crude product dehydration working section is communicated with the rectifying column reactor of the product refining working section through a crude product storage tank communicated with the crude steaming column reactor. A two-column intermittent rectifying process is adopted in the method, water and tetrahydrofuran are taken out through the crude product intermittent column, left raw materials are purified through the product refining working section, and high-purity N-methylpyrrolidine is obtained. The problems that a traditional device and technique are large in energy consumption, low in yield, high in production cost and troublesome in aftertreatment are solved.

Owner:烟台国邦化工机械科技有限公司

Method for synthesizing triptorelin from solid phase polypeptide

ActiveCN101357936BConvenient sourceReduce usagePeptide preparation methodsBulk chemical productionFreeze-dryingSide chain

The invention discloses a preparation method of solid phase peptide synthesis triptorelin, which includes the following steps: with Rink Amide AM resins or Rink Amide MBHA resins as starting materials, amino acids with protective groups are sequentially connected according to solid phase synthesis, so as to obtain protective decapeptide resins, and meanwhile crude products are obtained by sequentially removing Fmoc-protective groups and synchronously removing side-chain protective groups and cutting peptides, and triptorelin elaborate products are prepared after the crude products are separated and purified by C18 (or C8 ) column and freeze-dried. The preparation method is stable in technology, convenient in raw and auxiliary material sources, short in production cycle, high in yield, stable in quality, low in production cost and high in transpeptidase yield. Besides, as the preparation method avoids using poisonous reagents, such as hydrogen fluoride, and the like, the pollution of three wastes is low, purification yield is over 25 percent and each step of transpeptidase yield is above 98 percent; the yield after cutting peptides is 78.8 percent and the total yield is 25.4 percent.

Owner:SHANGHAI SOHO YIMING PHARMA

A kind of preparation method of sulfophenylpyrazolone and its intermediate

ActiveCN105646356BMild reaction conditionsSafe reaction conditionsSulfonic acid esters preparationThio-Chloride

The invention discloses a preparation method of sulfophenylpyrazolone. The method uses compound (I) as a raw material, carries out a substitution reaction with compound (II) in the presence of a base, and then undergoes oxidation with an oxidant to prepare compound (III), compound (III) is esterified to obtain compound (IV), compound ( IV) Compound (VI) is obtained by thioreaction, compound (VI) is then oxidized, hydrolyzed (or hydrolyzed, oxidized) to obtain compound (VII), and compound (VII) is subjected to acid chloride to obtain acid chloride (VIII) and 1 , 3-dimethyl-5-hydroxypyrazole undergoes an esterification reaction to obtain compound (IX), and finally compound (IX) is rearranged to obtain compound (X). The beneficial effects of the invention are mainly reflected in the following: the raw materials are cheap and easy to obtain, the reaction conversion rate is high, the three wastes are few, and the industrial production is favorable.

Owner:ZHEJIANG ZHUJI UNITED CHEM

Device and method for separating n-methylpyrrolidine, water and tetrahydrofuran

ActiveCN105061363BHigh yieldApplication rate increasedOrganic chemistryPhase splittingProcess engineering

Provided are a device and method for separating N-methylpyrrolidine, water and tetrahydrofuran. The device comprises a crude product dehydration working section and a product refining working section. The crude product dehydration working section comprises a crude product intermittent column, a first condenser, a phase splitting tank, a backflow head and the like. The crude product intermittent column comprises a crude steaming column reactor and a crude steaming column. The product refining working section comprises a refining intermittent column, a second condenser, a transition cut fraction receiving tan and a product receiving tank. The refining intermittent column comprises a rectifying column reactor and a rectifying column located at the top of the rectifying column reactor. The crude product dehydration working section is communicated with the rectifying column reactor of the product refining working section through a crude product storage tank communicated with the crude steaming column reactor. A two-column intermittent rectifying process is adopted in the method, water and tetrahydrofuran are taken out through the crude product intermittent column, left raw materials are purified through the product refining working section, and high-purity N-methylpyrrolidine is obtained. The problems that a traditional device and technique are large in energy consumption, low in yield, high in production cost and troublesome in aftertreatment are solved.

Owner:烟台国邦化工机械科技有限公司

The preparation method of 3,5-dichloro-2-pentanone

ActiveCN109265329BReduce usageSimple processPreparation from heterocyclic compoundsSulfonyl chloridePtru catalyst

The invention relates to the field of fine chemical industry, and discloses a preparation method of 3,5-dichloro-2-pentanone, which is characterized in that the preparation method comprises: contacting α-acetyl-γ-butyrolactone and sulfuryl chloride in a system without a solvent to perform a chlorination reaction, then mixing the material obtained by the chlorination reaction with water, and adding hydrochloric acid dropwise to the obtained mixture to perform a ring-opening reaction. By using cheap industrial chemicals as raw materials, the method realizes a one-pot reaction without organic solvents, simplifies the process operation, reduces three wastes and production costs, and avoids the pollution caused by the use of metal catalysts.

Owner:NUTRICHEM LAB CO LTD

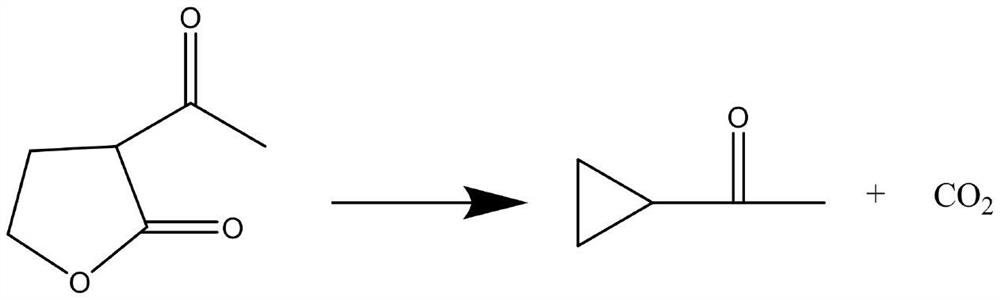

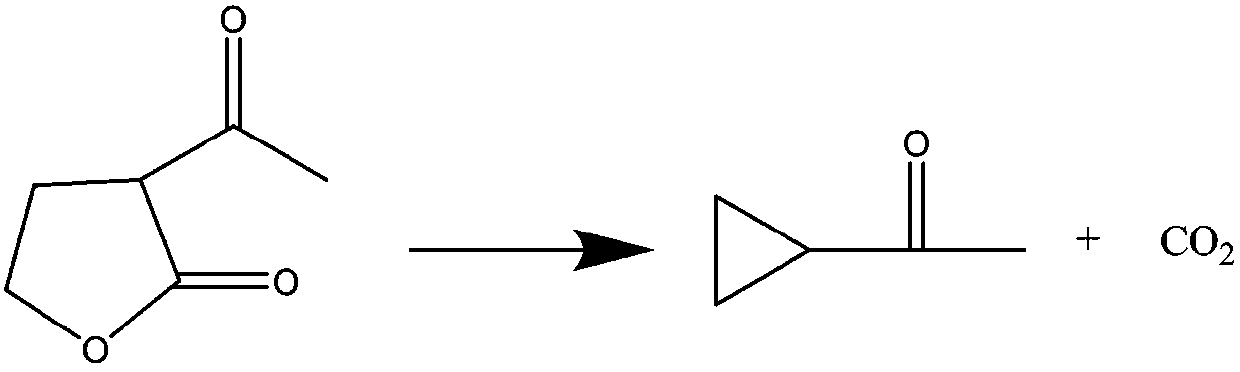

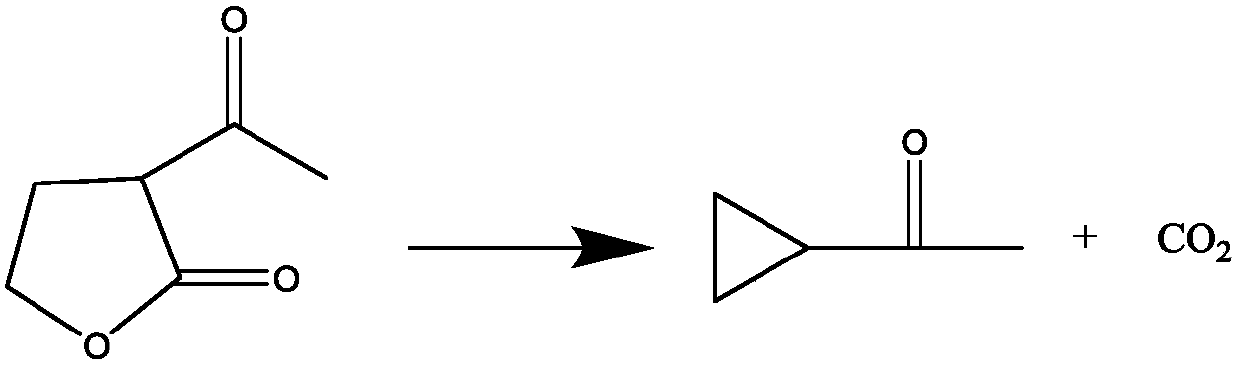

A kind of new preparation method of cyclopropanone

ActiveCN109678688BHigh reactivityLow costPreparation from heterocyclic compoundsPhysical chemistryKetone

Owner:JIANGSU YUXIANG CHEM

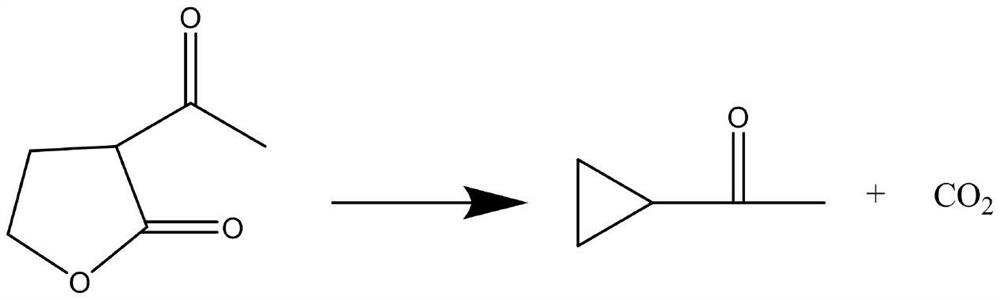

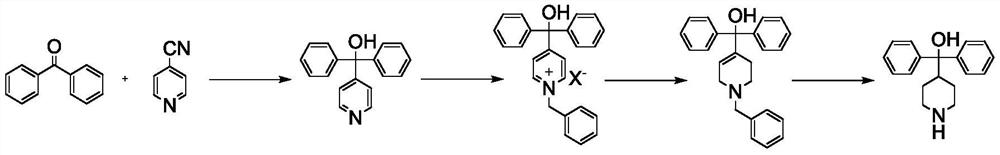

Preparation method of alpha, alpha-diphenyl-4-piperidine methanol

ActiveCN112724070AReduce manufacturing costAvoid corrosionOrganic chemistryBulk chemical productionCombinatorial chemistryBenzophenone

The invention discloses a preparation method of alpha, alpha-diphenyl-4-piperidine methanol, which comprises the following steps of by using benzophenone and 4-cyanopyridine as raw materials, carrying out free radical coupling reaction under the action of alkali metal to obtain alpha, alpha-diphenyl-4-piperidine methanol, reacting the obtained alpha, alpha-diphenyl-4-pyridine methanol with a benzylation reagent to generate N-benzyl-alpha, alpha-diphenyl-4-pyridine methanol, carrying out hydroboration reduction on the N-benzyl-alpha, alpha-diphenyl-4-pyridine methanol to obtain (1-benzyl-1, 2, 3, 6-tetrahydropyridine-4-yl)benzhydrol, ane enabling (1-benzyl-1, 2, 3, 6-tetrahydropyridine-4-yl)benzhydrol to be subjected to catalytic hydrogenation and debenzylation protection to obtain alpha, alpha-diphenyl-4-piperidine methanol. The method has the advantages of cheap and accessible raw materials, high reaction yield and high controllability, and is suitable for industrial production requirements.

Owner:南京方生和医药科技有限公司

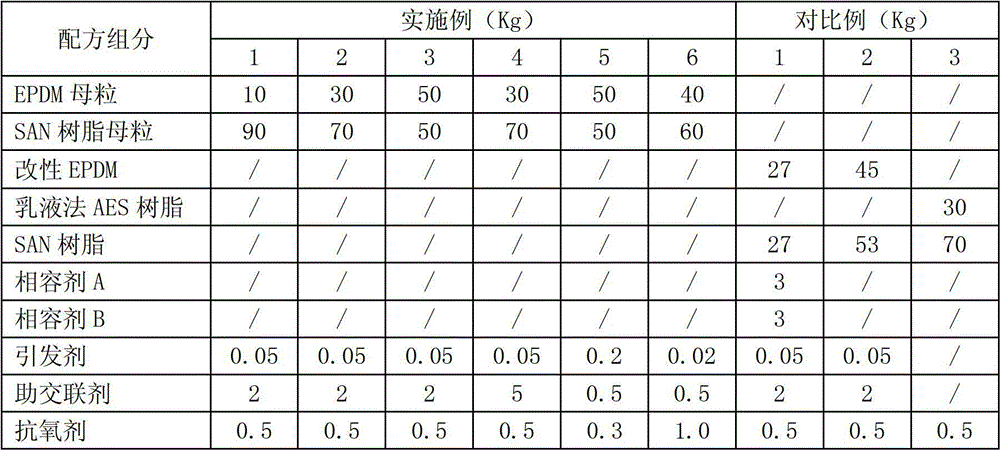

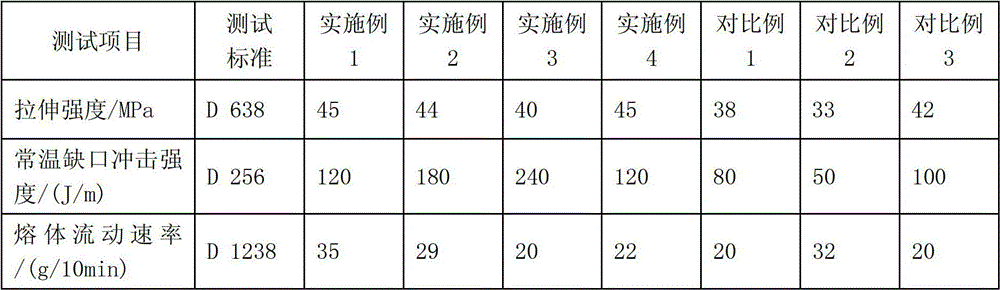

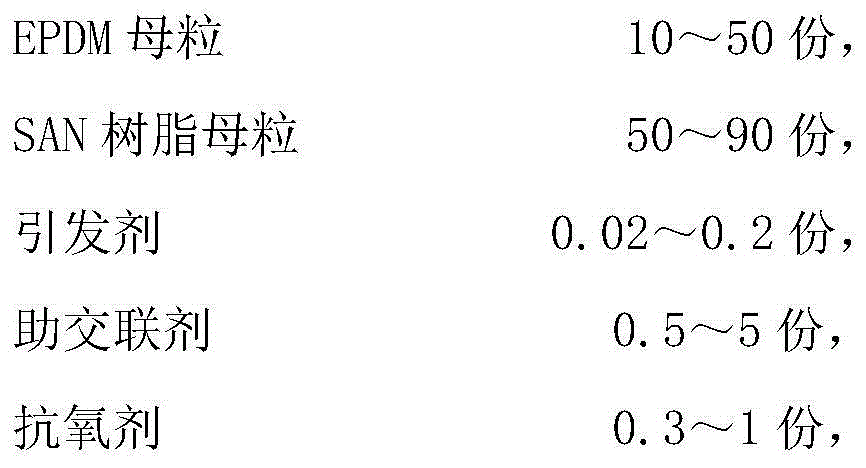

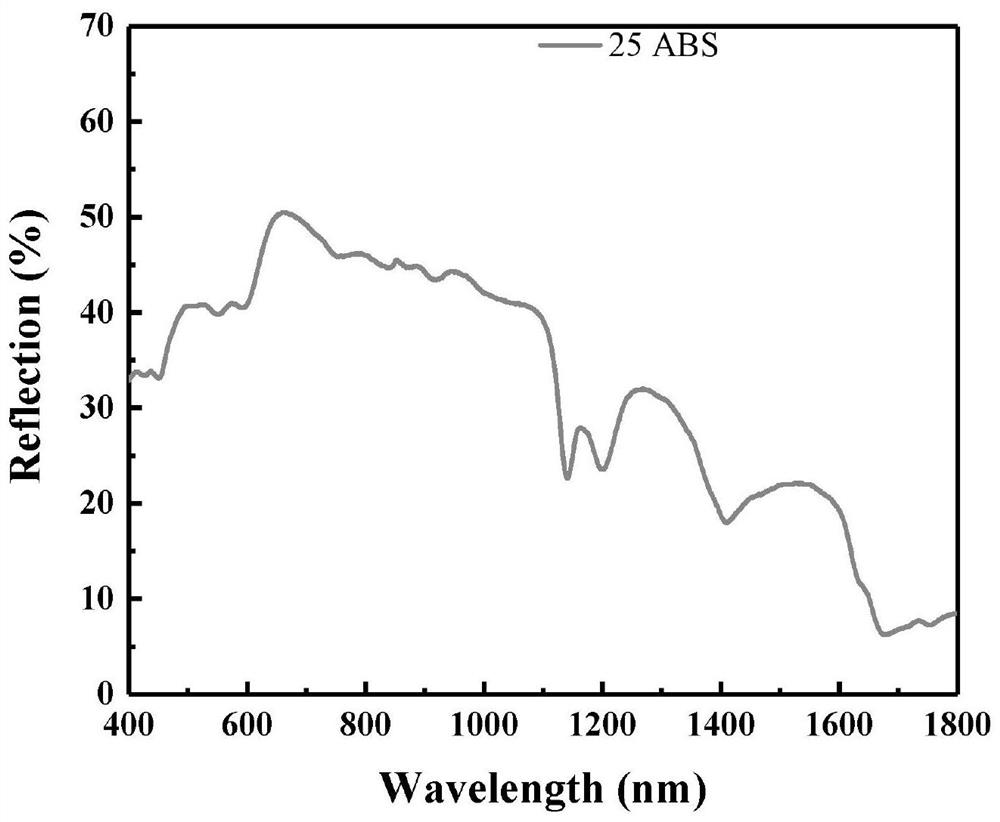

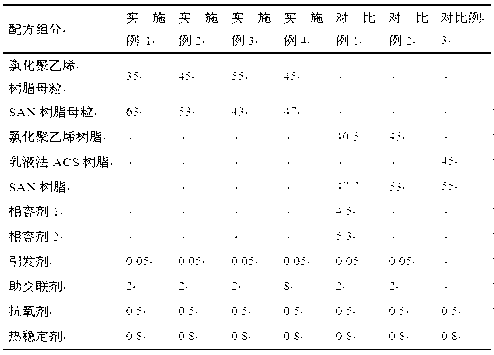

Acrylonitrile-ethylene-styrene (AES) resin composition and preparation method thereof

ActiveCN102898759BSimple process controlLow cost of industrializationGlycidyl methacrylateAntioxidant

The invention discloses an acrylonitrile-ethylene-styrene (AES) resin composition and a preparation method thereof. The composition comprises the following components in parts by weight: 10 to 50 parts of ethylene-propylene-diene monomer (EPDM) master batch, 50 to 90 parts of styrene-acrylonitrile (SAN) resin master batch, 0.02 to 0.2 part of initiator, 0.5 to 5 parts of co-crosslinker, and 0.3 to 1 part of antioxidant. The composition is prepared by adopting a reactive extrusion grafting method; and a compatilizer containing maleic anhydride (MAH) active functional groups, a compatilizer containing glycidyl methacrylate (GMA) active functional groups and modified EPDM and SAN resin are respectively prepared into the master batches, then other raw materials are added, the raw materials are stirred and mixed, and the mixture is extruded and granulated to form a sample. The reactive extrusion grafting method is environment-friendly, simple in equipment and convenient to operate; and the prepared composition has excellent weather resistance, low-temperature impact resistance, chemical corrosion resistance, size stability and processing performance, and can be applied to outdoor products such as building materials, sports equipment, communication equipment shells and automotive parts.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Spraying-free metal effect material and preparation method thereof

The invention belongs to the technical field of spraying-free materials, and particularly relates to a spraying-free metal effect material and a preparation method thereof. A spraying-free metal effect material is prepared from the following raw materials: an acrylate copolymer, an acrylate polymer, a polystyrene series high-molecular polymer, metal powder and an antioxidant. The spraying-free metal effect material prepared by the invention can solve the problem about the overall stability of the system and the dispersing performance and wettability of metal powder, pearl powder and the like in the system, can better imitate the appearance of the coating effect of metals such as aluminum, bronze, red copper, gold or bronze, is low-carbon and environment-friendly, avoids the problems of three wastes and huge energy consumption, and has lower cost and high economic benefit.

Owner:上海英耀塑胶材料有限公司

Preparation method of chitosan produced from snow crab shell

ActiveCN111138563BMake full use of the valueAvoid the three wastesOrganic compound preparationCarboxylic acid salt preparationGlycanEnvironmental engineering

The invention discloses a method for preparing chitosan by using snow crab shells, relates to the technical field of preparation methods for high-viscosity polysaccharides, and in particular belongs to a method for preparing chitosan by using fresh snow crab shells. Crab shell pretreatment: take 200 parts ("parts" are in mass units, the same below) fresh snow crab shells and crush them; crab shell decalcification: add 600-1000 parts of citric acid solution with a mass percentage concentration of 5-10% to the crab shells , soaked for 6 to 15 hours, filtered, and water was used as a washing liquid to wash the filtered crab shells, and the washing residual liquid was combined with the filtrate to obtain a mixture for retention; extracting organic calcium: filtering the mixture through a plate frame, and drying the filter residue to obtain calcium citrate; The remaining mixed liquid is collected for reuse after subsequent treatment; the three wastes are eliminated in the entire production process, and zero waste, zero discharge, and high-value utilization are realized. Without high temperature and strong alkali deproteinization process, energy saving, environmental protection, and stable product quality. The product has high viscosity and good quality.

Owner:SHANDONG MEIJIA GROUP

Pigment yellow 138 or its derivative polymer material wrapping, its preparation method and its downstream products

The application relates to a polymer material wrapping of Pigment Yellow 138 or its derivatives, its preparation method and its downstream products. The method is by mixing monoacid anhydride aromatic compounds, 8-aminoquinaldine compounds, solid organic acids and thermoplastic polymer materials, and adjusting the reaction molar ratio between each raw material and the amount of Pigment Yellow 138 or its derivatives in the final product. Mass content, so that their mixture can be extruded or kneaded, one step to obtain the polymer material wrapping of Pigment Yellow 138 or its derivatives, because the raw material reactants of Pigment Yellow 138 or its derivatives have better presence in polymer materials Excellent dispersibility, so they can be directly generated and uniformly dispersed in polymer materials during extrusion or kneading, and this process does not require adding any solvent, and does not require separation and purification after the reaction, avoiding the traditional pigment yellow 138 or its derivatives The generation of three wastes in the process of compound synthesis greatly simplifies the process and reduces energy consumption.

Owner:DONGGUAN UNIV OF TECH

A method for preparing 1-fluoronaphthalene by electrochemical fluorination

InactiveCN111286749BEasy to operateMild conditionsElectrolysis componentsElectrolytic organic productionElectrochemical fluorinationReagent

The invention relates to a method for preparing 1-fluoronaphthalene by electrochemical fluorination, which comprises the following steps: adding a solvent into an electrolytic cell, turning on the stirring, adding substrate naphthalene, adding a fluorine source after completely dissolving, and connecting electrode sheets, Turn on the power supply, stir and react at a constant temperature to obtain 1-fluoronaphthalene. The invention has simple equipment, low equipment requirements, mild fluorination reaction conditions, no highly toxic or dangerous reagents, and can reduce pollution.

Owner:石家庄保利农化工有限公司

ACS (acrylonitrile-chlorinated polyethylene-styrene) resin composition and method for preparing same

ActiveCN102153830BSimple process controlLow cost of industrializationMasterbatchGlycidyl methacrylate

The invention discloses ACS (acrylonitrile-chlorinated polyethylene-styrene) resin composition and a method for preparing the same. The ACS resin composition comprise the following components in parts by weight: 30-60 parts of chlorinated polyethylene resin masterbatch, 40-70 parts of SAN (styrene acrylonitrile) resin masterbatch, 0.02-0.2 part of initiator, 0.5-5 parts of assistant cross-linking agent, 0.3-1 part of antioxidant and 0.5-1.5 pars of heat stabilizer. The ACS resin composition is prepared by adopting a method of grafting by reactive extrusion according to the following steps: preparing masterbatches respectively from a compatibilizer containing an MAH (maleic anhydride) active functional group, a compatibilizer containing a GMA (glycidyl methacrylate) active functional group, chlorinated polyethylene resin and SAN resin, adding other raw materials, stirring and mixing, and extruding and granulating to obtain a sample. The method of grafting through reactive extrusion is more environmental friendly, the equipment is simple, the process is more convenient to operate, and the prepared ACS resin composition has excellent weather resistance and good anti-static properties, dimensional stability and processing performance.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

A kind of preparation method of isoxazole compound and its intermediate

ActiveCN105712944BMild reaction conditionsSafe reaction conditionsOrganic compound preparationSulfide preparationIndustrial waste waterFormate

Disclosed is a preparation method for an isoxazole compound and an intermediate thereof, the method comprising: a compound (I), as the starting material, is subjected to a substitution reaction with a compound (II) in the presence of a base, and subsequently to an oxidation reaction to prepare an intermediate acid (III); the intermediate acid (III) is methyl esterified to obtain an intermediate (IV); the intermediate (IV) is subjected to thionation to obtain an intermediate (VI); the intermediate (VI) is condensed with cyclopropyl methanone under a basic condition to obtain an intermediate (VIII); the intermediate (VIII) is subjected to alkene etherification reaction with ortho-formate and cyclized with hydroxylamine hydrochloride to obtain an intermediate (X); the methylthio of the intermediate (X) is oxidized by hydrogen peroxide to obtain isoxazole compound (XI). The starting material used in the present preparation method is readily available, and the preparation method has high productivity and purity, produces less industrial waste water, gas and residue, and has low cost and good industrial value.

Owner:ZHEJIANG ZHUJI UNITED CHEM

Rust remover and use method thereof

PendingCN114250476AReduce storageReduce riskBacteriaMicroorganism based processesBiotechnologyThiobacillus ferrooxidans

The invention discloses a rust remover and a use method thereof. The rust remover comprises (a) metabolites of microorganisms; or (b) a microorganism and a microorganism culture solution; wherein the microorganisms comprise thiobacillus thiooxidans and / or acidithiobacillus caldus. According to the scheme, the metabolite produced by culturing the microorganisms in the microorganism culture solution contains sulfuric acid, the sulfuric acid can react with the metal oxide and the corrosion layer, so that the metal oxide and the corrosion layer generate ions to be dissolved, and compared with direct use of the sulfuric acid, three wastes produced by mass production of the sulfuric acid are avoided; therefore, the pollution to the environment and the danger of storage and transportation of sulfuric acid are reduced.

Owner:HUBEI ENG UNIV

Novel preparation method of cyclopropyl methyl ketone

ActiveCN109678688AHigh selectivityHigh activityPreparation from heterocyclic compoundsIonHigh selectivity

The invention discloses a novel preparation method of cyclopropyl methyl ketone. The preparation method comprises the following steps: an ionic liquid is added to a microwave reactor, stirring is started, and microwave heating is started to increase the temperature to 100-140 DEG C; 2-acetylbutyrolactone is added slowly and continuously at 100-140 DEG C, a catalytic cracking reaction of the ionicliquid is promoted by microwaves, and a cracked product cyclopropyl methyl ketone is withdrawn through a distillation column continuously. The ionic liquid is promoted by the microwaves for catalyticcracking of the raw material 2-acetylbutyrolactone, high selectivity is realized when the reaction is performed under the conditions, impurities are almost avoided in the reaction, the content of cyclopropyl methyl ketone obtained with the method is higher than 99% and the total reaction yield is higher than 98%, which are both far higher than those obtained in the traditional method and in literature report. Production of three wastes in the reaction process is completely avoided, and the environment is protected; danger probably caused in a high-temperature production process is avoided, higher safety is realized, and operation efficiency can be increased.

Owner:JIANGSU YUXIANG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com