Device and method for separating n-methylpyrrolidine, water and tetrahydrofuran

A technology of methylpyrrolidine and tetrahydrofuran, which is applied in the field of separation of N-methylpyrrolidine in water and tetrahydrofuran devices, can solve the problems of high energy consumption, low yield and high production cost, and achieve the effect of eliminating three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

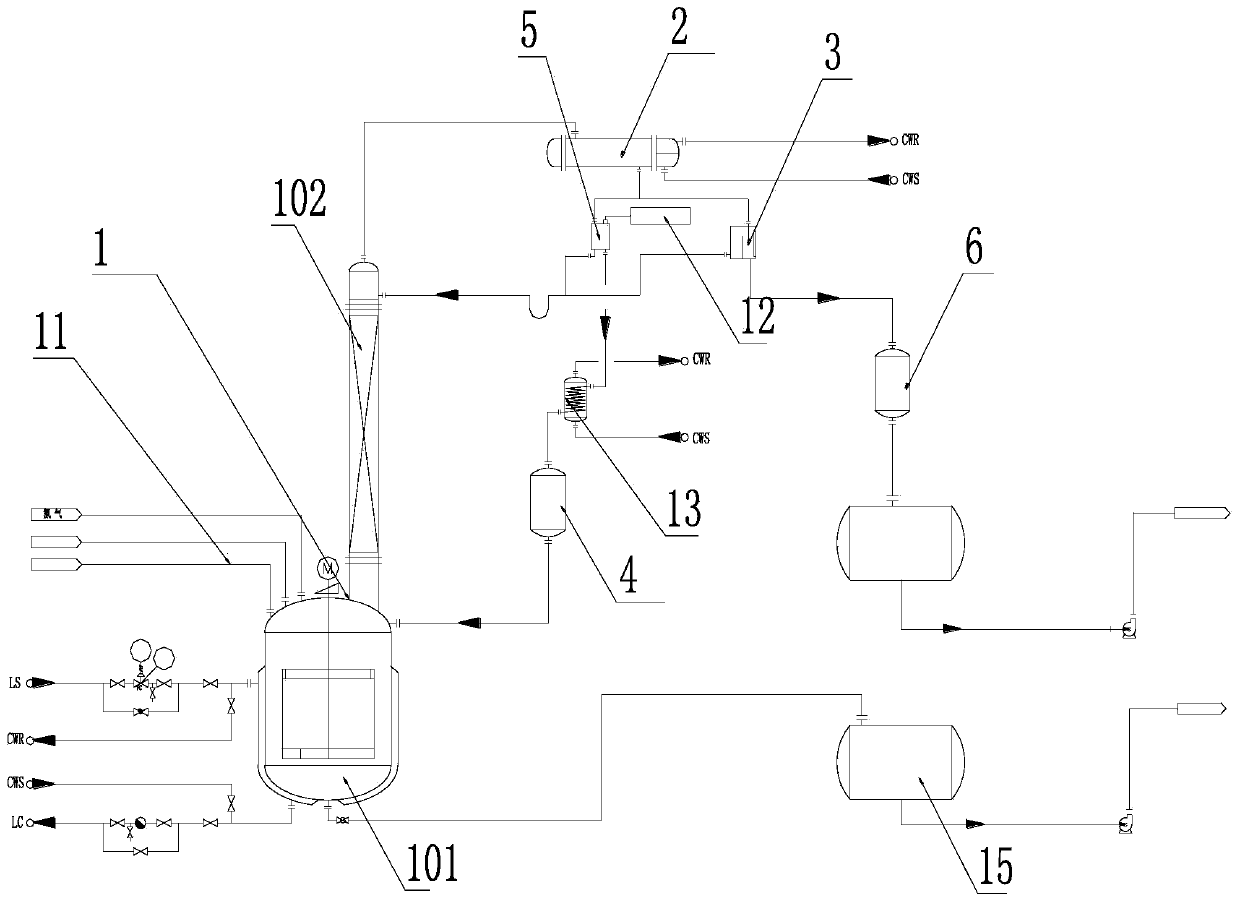

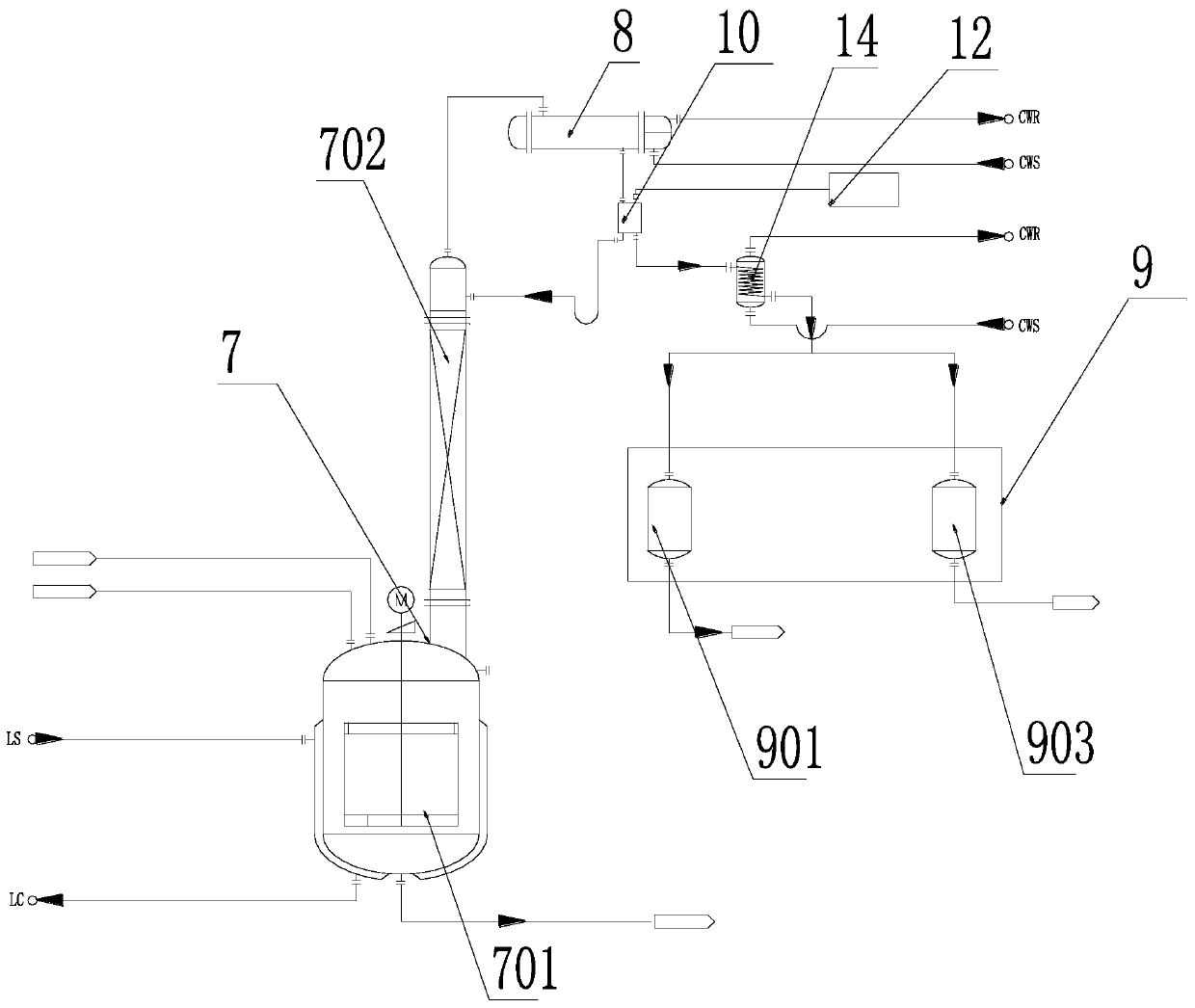

[0063] The raw material and the entrainer are added into the rough steaming tower 102 still 101 at one time with a ratio of 0.02:1. In this embodiment, the entraining agent adopts n-hexane, and the rough steaming tower 102 still 101 heats the raw material to make The raw material turns into steam, and the raw material steam rises to the top of the rough steaming tower 102, and then enters the first condenser 2 connected with the rough steaming tower 102 for condensation. After the phase changes into liquid, a part of it enters the phase separation tank 3 , the other part enters the reflux head, wherein the raw material entering the reflux head is regulated by the reflux ratio controller 12, a part returns to the rough distillation tower 102 tower top, and the other part returns through the first cooler 13 and the first fraction receiving tank 4 In the crude steaming tower 102 still 101, enter the raw material in the phase separation tank 3 to carry out phase separation, wherein...

Embodiment approach 2

[0066] The raw material and the entrainer are added into the crude distillation tower 102 and the kettle 101 at one time at a ratio of 0.2:1. In this embodiment, the entrainer is a mixture of 2-methylpentane and cyclohexane, which is roughly steamed The tower 102 and the still 101 heat the raw material to turn the raw material into steam, and the raw material steam rises to the top of the rough steaming tower 102, and then enters the first condenser 2 connected to the rough steaming tower 102 for condensation, and the phase changes After the liquid, part of it enters the phase separation tank 3, and the other part enters the reflux head, wherein the raw material entering the reflux head is regulated by the reflux ratio controller 12, and part of it returns to the top of the rough distillation tower 102, and the other part passes through the first cooling The device 13 and the first fraction receiving tank 4 are returned to the crude distillation tower 102 still 101, and the raw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com