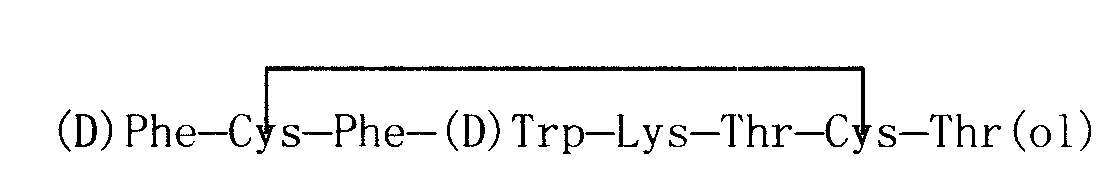

Preparation method of synthesizing octriotide from solid phase polypeptide

A technology for solid-phase peptide synthesis and octreotide, which is applied in the production of peptides and bulk chemicals, and can solve problems such as low yield, environmental pollution, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The list of raw materials adopted in the embodiment and the foregoing process is as follows:

[0073] 1. Synthetic peptide chain

[0074] (1) Preparation of Fmoc-Thr(tBu)-resin:

[0075] Take 50 grams of 2-chloro-trityl resin (100-200 mesh, 1.0mmol / g, 50mmol), soak in DMF for 30 minutes to fully swell the resin, add 44ml DIPEA, 39.7g Fmoc-Thr(tBu)- ol, reacted for 3 hours, then added 50ml of methanol to continue the reaction for 3 hours. Blow dry with nitrogen, and wash the resin three times with DMF. Obtain Fmoc-Thr(tBu)-resin;

[0076] (2) Preparation of Fmoc-Cys(Trt)-Thr-resin:

[0077] Add 800 ml of 20% hexahydropyridine in DMF and react at 25° C. for 30 minutes. Hexahydropyridine was blown and filtered with nitrogen, washed with DMF, anhydrous methanol, and DMF three times respectively, and dried with nitrogen.

[0078] Add Fmoc-Cys(Trt)-OH (MW: 585.7, 200mmol) 117.1g, TBTU (MW: 321, 200mmol) 64.2g, HOBT (MW: 153, 200mmol) 30.6g, NMM 44.4ml (MW = 101.2), ...

Embodiment 2~3

[0106] Adopt the same method and processing condition as embodiment 1, wherein:

[0107] Use 4-methyltrityl resin or 4-methoxytrityl resin as the starting material respectively, connect Fmoc-Thr-ol with the same method as before, then add decapping reagent, react at 25°C for 0.5 hours, Add the mixture of Fmoc-amino acid, TBTU / HBTU and HOBT dissolved in the peptide reagent, react at 25°C for 2 hours, and then undergo reactions such as peptide cutting and oxidation to obtain 16.3g and 14.9g of white loose block products, the yields are respectively 32.0% and 29.2% (in mmol of Fmoc-Thr-resin).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com