Pigment yellow 138 or its derivative polymer material wrapping, its preparation method and its downstream products

A technology of polymer materials and derivatives, applied in the field of pigments, can solve the problems of unusable and unavoidable generation of a large amount of waste acid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A method for preparing a polymer material wrapping of Pigment Yellow 138 or its derivatives in one embodiment, comprising the following steps:

[0036] The monoacid anhydride aromatic compound, 8-aminoquinaldine compound, solid organic acid and thermoplastic polymer material are mixed, extruded or kneaded to obtain the polymer material wrapping of Pigment Yellow 138 or its derivatives.

[0037] Wherein, 8-aminoquinaldine compound, structure is as shown in formula (I):

[0038] R1, R2, R3, R4 and R5 are each independently H, methyl, ethyl, alkoxy, alkylthio or halogen.

[0039] Monoacid anhydride aromatic compound, the structure is as shown in formula (II):

[0040] X is an aromatic group (such as benzene ring, naphthalene, pyrene, anthracene, phenanthrene, etc.) or a halogenated derivative of an aromatic group.

[0041] Further, the 8-aminoquinaldine compound is one of the following compounds:

[0042] R1', R2', R3', R4', R5', R6' are each independently methy...

Embodiment 1

[0075]

[0076] Mix (40g, 140mmol) tetrachlorophthalic anhydride, (11g, 70mmol) 8-aminoquinaldine, (3g, 16mmol) citric acid and 0.5kg PMMA, extrude the reaction in a single-screw extruder, cool and dry and cut into pellets , to obtain PMMA masterbatch of yellow pigment yellow 138.

[0077] After grinding the PMMA masterbatch of Pigment Yellow 138 prepared in Example 1, toner particles are obtained, and its size distribution spectrum is as follows: Figure 4 shown. Tested by Malvern particle size analyzer, D50=4.09 μm, D99=10.6 μm.

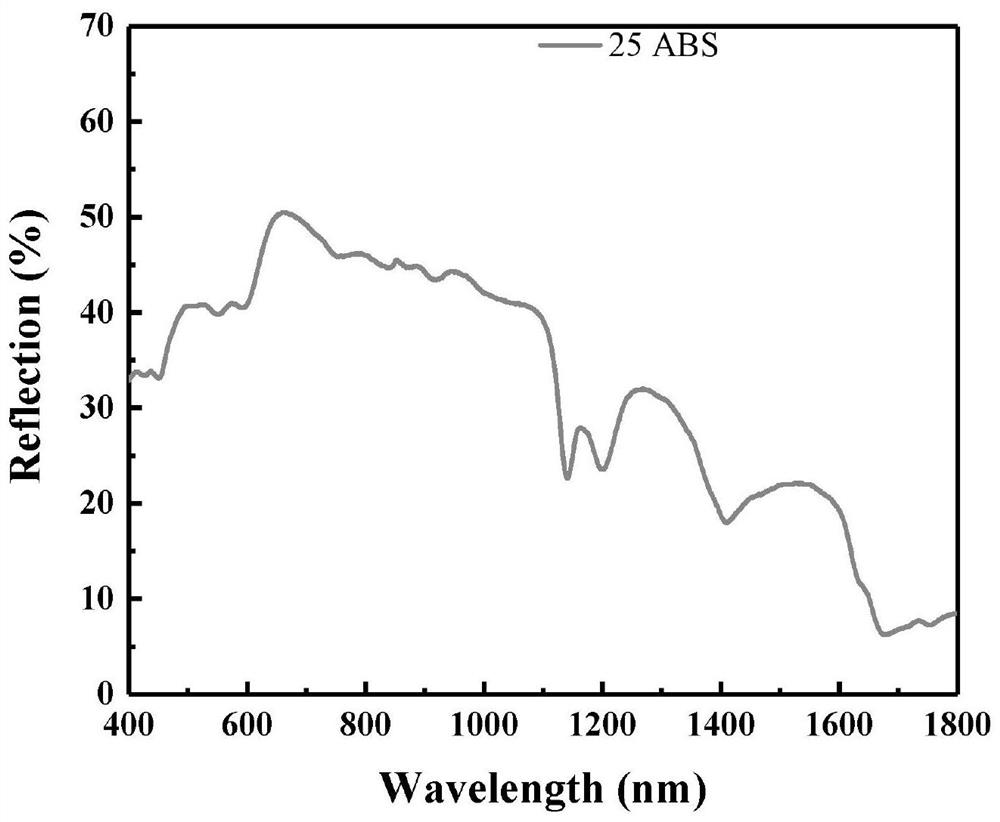

[0078] figure 1 The reflectance spectrogram of the PMMA color masterbatch crude product of the pigment yellow 138 prepared by embodiment 1 is mixed with ABS and injected into a sheet, by figure 1 It can be seen that the plastic sheet exhibits similar absorption spectrum properties to traditional pigment yellow.

Embodiment 2

[0080] Mix (40g, 140mmol) tetrachlorophthalic anhydride, (11g, 70mmol) 8-aminoquinaldine, (3g, 16mmol) citric acid and 0.5kg PC, extrude the reaction in a twin-screw extruder, cool and dry and cut into pellets , to obtain yellow pigment yellow 138 PC masterbatch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com