Acrylonitrile-ethylene-styrene (AES) resin composition and preparation method thereof

A resin composition and resin technology, applied in the field of resin composition and its preparation, can solve the problems of large three-waste treatment, serious environmental pollution, and high equipment requirements, and achieve the effects of low industrialization cost, convenient process operation, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

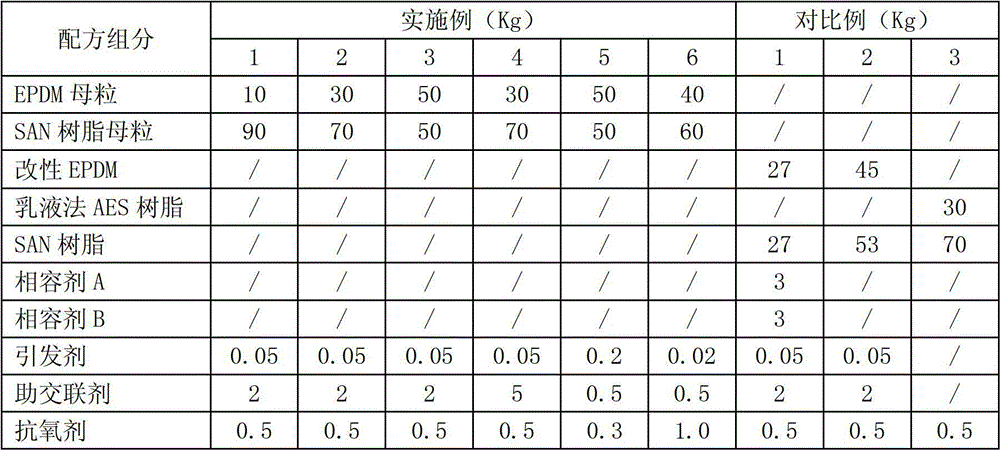

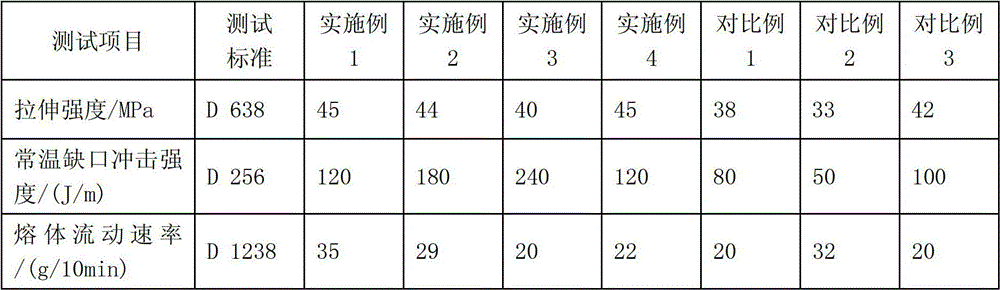

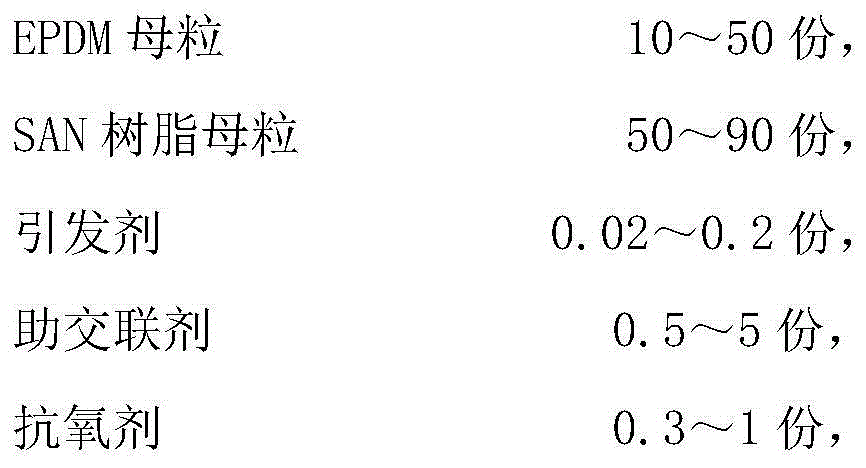

[0045]The AES resin composition of this embodiment includes each component and its parts by weight as shown in Table 1. Its preparation method is as follows:

[0046] 1. Preparation of EPDM masterbatch

[0047] 90Kg modified EPDM (maleic anhydride EPDM, wherein the EPDM content is 95wt%), 10Kg compatibilizer A ethylene-methyl acrylate-maleic anhydride (among them, the MAH content is 1wt%) and 0.5Kg antioxidant Add it into a high-speed mixer and stir for 15 minutes before discharging to obtain mixture A. Add the mixture A from the main feeding port of the twin-screw extruder, and extrude and granulate through the twin-screw extruder. pellets to obtain EPDM masterbatches.

[0048] 2. Preparation of SAN resin masterbatch

[0049] 90Kg SAN resin (weight-average molecular weight 100,000-150,000, of which, the content of acrylonitrile is 33wt%), 10Kg of compatibilizer B styrene-acrylonitrile-glycidyl methacrylate (of which, the content of GMA is 5wt%), 0.5 The Kg antioxidant wa...

Embodiment 2~4

[0053] In order to better reflect the characteristics of the above-mentioned AES resin composition, the present invention uses Examples 2 to 4 to compare the impact of different EPDM masterbatch dosages, different SAN resin masterbatch dosages, and different crosslinking assistant dosages on product performance, The specific component formula is shown in Table 1, and the steps are the same as in Example 1.

Embodiment 5

[0055] The AES resin composition of this embodiment includes each component and its parts by weight as shown in Table 1. Its preparation method is as follows:

[0056] 1. Preparation of EPDM masterbatch

[0057] Mix 80Kg of modified EPDM (brominated EPDM, sulfonated EPDM and chlorinated EPDM with a mass ratio of 1:1:1, wherein the content of EPDM is 88wt% to 92wt%), 20Kg of compatibilizer A (compatibilizer A is: MAH content is 10wt% ethylene-butyl acrylate-maleic anhydride and GMA content is 1wt% ethylene-butyl acrylate-glycidyl methacrylate, the mass ratio of the two can be any ratio, preferably in the present embodiment 1:2) and 1Kg antioxidant were added to a high-speed mixer and stirred for 5 minutes before discharging to obtain mixture A. Add the mixture A from the main feeding port of the twin-screw extruder, and extrude and granulate through the twin-screw extruder. pellets to obtain EPDM masterbatches.

[0058] 2. Preparation of SAN resin masterbatch

[0059] 80Kg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com