A method for preparing 1-fluoronaphthalene by electrochemical fluorination

A fluorination method and electrochemical technology, applied in the field of electrochemistry, can solve the problems of increasing the concentration of nitrous acid, difficult operation, poor temperature control, etc., and achieve simple and easy production process, low equipment requirements, and high safety factor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Materials: naphthalene 100g, acetonitrile 900g, tetramethylammonium fluoride hydrofluoride 2000g

[0032] Operation: Pour anhydrous acetonitrile into the electrolytic cell, the room temperature is 16 degrees Celsius, add naphthalene under stirring at 1000 rpm, after dissolving, add tetramethylammonium fluoride hydrofluoride, connect the power supply, platinum as the anode material, carbon Make cathode material, power on (constant voltage 2V, current 2-10mA), 10 hours of sampling and control, no product.

Embodiment 2

[0034] Materials: naphthalene 100g, acetonitrile 900g, pyridine hydrofluoride 2000g

[0035] Operation: Pour anhydrous acetonitrile into the electrolytic cell, the room temperature is 16 degrees Celsius, add naphthalene under stirring at 1000 rpm, after dissolving, add pyridine hydrofluoride, connect the power supply, use platinum as the anode material, and carbon as the cathode material, and power on (Constant voltage 2V, current 2-10mA), 10-hour sampling control, no product.

Embodiment 3

[0037] Materials: 900g acetonitrile, 100g naphthalene, 2000g triethylamine trihydrofluoride

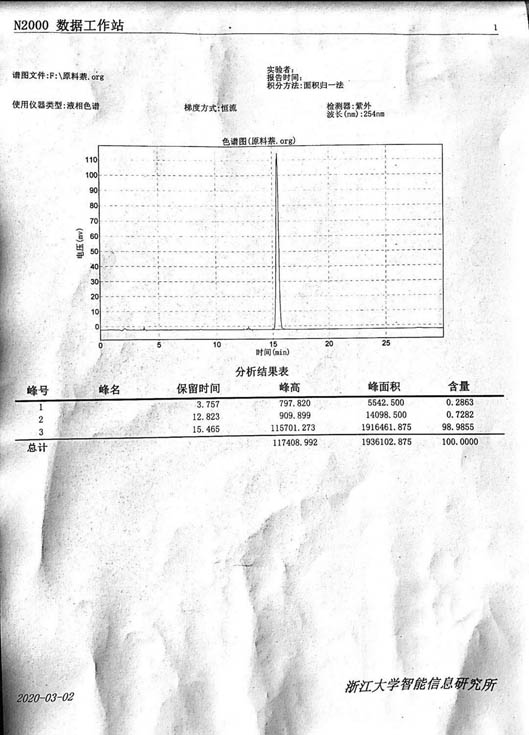

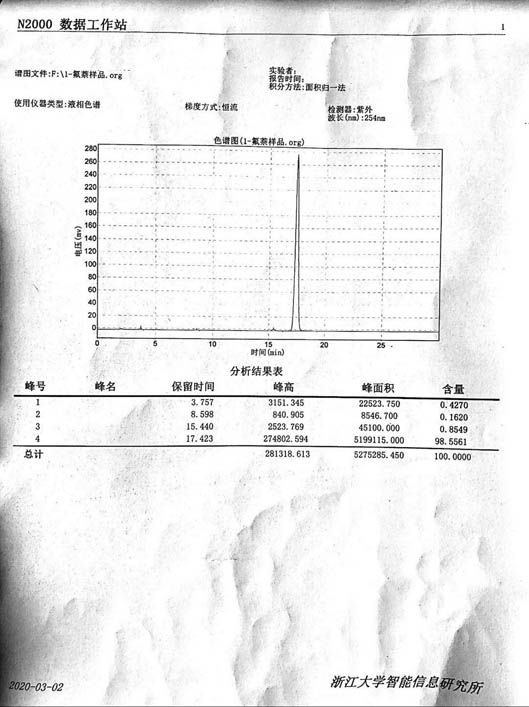

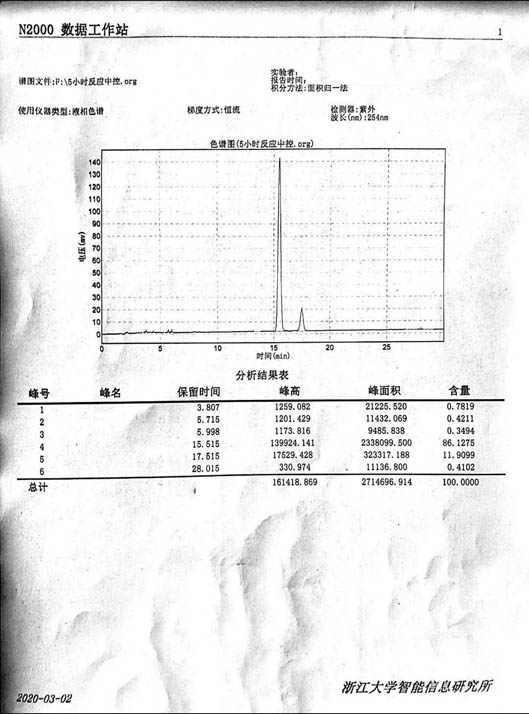

[0038] Operation: Pour anhydrous acetonitrile into the electrolytic cell, the room temperature is 16 degrees Celsius, add naphthalene under stirring at 1000 rpm, after dissolving, add triethylamine trihydrofluoride, connect the power supply, use platinum as the anode material, and carbon as the cathode Materials, electricity (constant voltage 2V, current 2-10mA), after 10 hours of reaction, the yield of 1-fluoronaphthalene reached 25%. (See Figure 1-7 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com