ACS (acrylonitrile-chlorinated polyethylene-styrene) resin composition and method for preparing same

A resin composition and resin technology are applied in the field of resin composition and its preparation, which can solve the problems of large amount of three wastes, serious environmental pollution and high equipment requirements, and achieve the effects of low industrialization cost, convenient process operation and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Add 90Kg chlorinated polyethylene resin, 10Kg compatibilizer 1 ethylene-methyl acrylate-maleic anhydride, 0.5Kg antioxidant and 0.8Kg heat stabilizer to a high-speed mixer and stir for 15 minutes before discharging to obtain mixture A . Add the mixture from the main feeding port of the twin-screw extruder, and extrude and granulate through the twin-screw extruder. Obtain chlorinated polyethylene resin masterbatch.

[0050] 90Kg of SAN resin, 10Kg of compatibilizer 2 styrene-acrylonitrile-glycidyl methacrylate, and 0.3Kg of antioxidant were put into a high-speed mixer and stirred for 20 minutes to obtain mixture B. Add mixture B from the main feeding port of the twin-screw extruder, extrude and granulate through the twin-screw extruder, control the temperature of the barrel of the extruder to 180-230°C, and the screw speed to 200-600rpm. pellets to obtain SAN resin masterbatches.

[0051] 35Kg chlorinated polyethylene resin masterbatch, 63KgSAN resin masterbatch, 0.05...

Embodiment 2-4

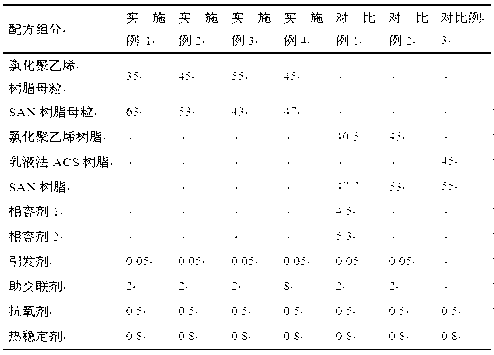

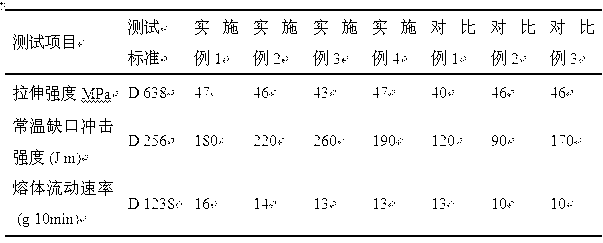

[0053] In order to reflect the characteristics of the above-mentioned ACS resin composition better, the present invention has used embodiment 2-3, has compared different chlorinated polyethylene resin masterbatch consumption, different SAN resin masterbatch consumption, different auxiliary crosslinking agent consumption to product The impact of performance, the specific material formulation is shown in Table 1, and the steps are the same as in Example 1.

Embodiment 5

[0066] Add 80Kg chlorinated polyethylene resin, 20Kg compatibilizer 1 ethylene-methyl acrylate-maleic anhydride, 0.3Kg antioxidant and 0.5Kg heat stabilizer to a high-speed mixer and stir for 15 minutes before discharging to obtain mixture A . Add the mixture from the main feeding port of the twin-screw extruder, and extrude and granulate through the twin-screw extruder. Obtain chlorinated polyethylene resin masterbatch.

[0067] 90Kg of SAN resin, 10Kg of compatibilizer 2 styrene-acrylonitrile-glycidyl methacrylate, and 0.3Kg of antioxidant were put into a high-speed mixer and stirred for 20 minutes to obtain mixture B. Add mixture B from the main feeding port of the twin-screw extruder, extrude and granulate through the twin-screw extruder, control the temperature of the barrel of the extruder to 180-230°C, and the screw speed to 200-600rpm. pellets to obtain SAN resin masterbatches.

[0068] 30Kg chlorinated polyethylene resin masterbatch, 70KgSAN resin masterbatch, 0.02...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com