Method for producing hydrogen through lignite chemical looping gasification based on steel slag oxygen carrier

A technology of oxygen carrier and chemical chain, applied in the field of industrial solid waste resource utilization, to achieve the effect of good oxygen transfer performance, wide source of raw materials, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

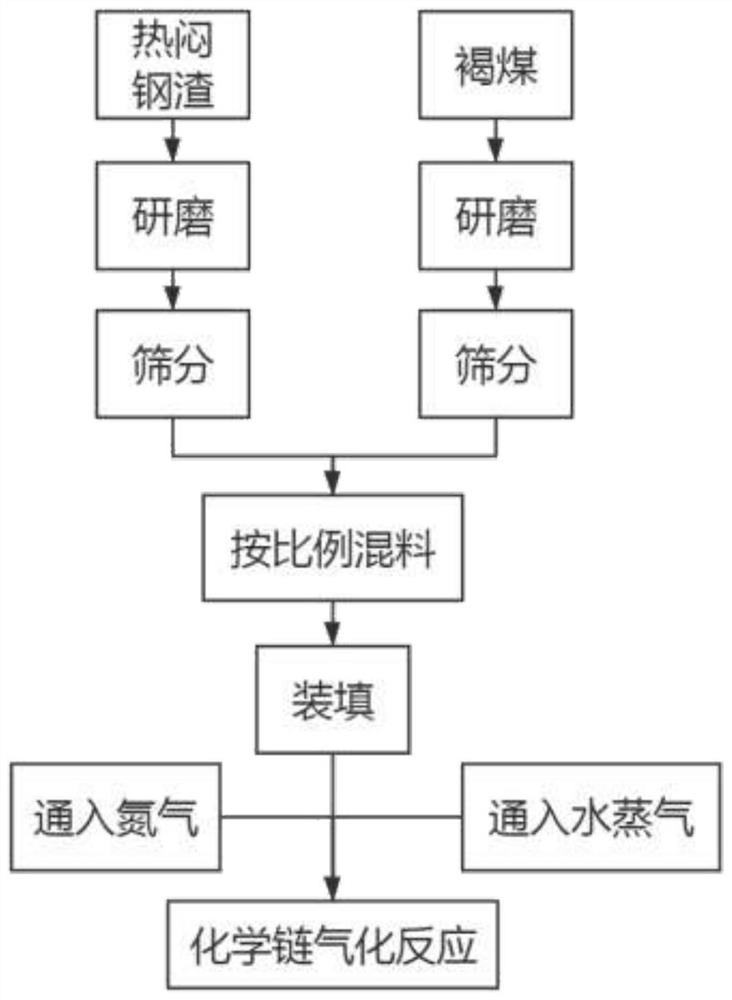

[0030] Embodiment 1: a kind of method based on the lignite chemical chain gasification hydrogen production of steel slag oxygen carrier, it carries out according to the following steps:

[0031] Step 1. Grinding hot stuffy steel slag and lignite respectively, and sieving to below 120 mesh;

[0032] Step 2, weighing 18.5g of hot stuffy steel slag and lignite 18.5g ground and screened in step 1 by mass percentage;

[0033] Step 3, dry mixing the hot stuffy steel slag and lignite taken in step 2 in a three-dimensional mixer for 20 minutes;

[0034] Step 4, filling the mixed material in step 3 in the reactor, so that the gas can fully contact with the material and pass through the material;

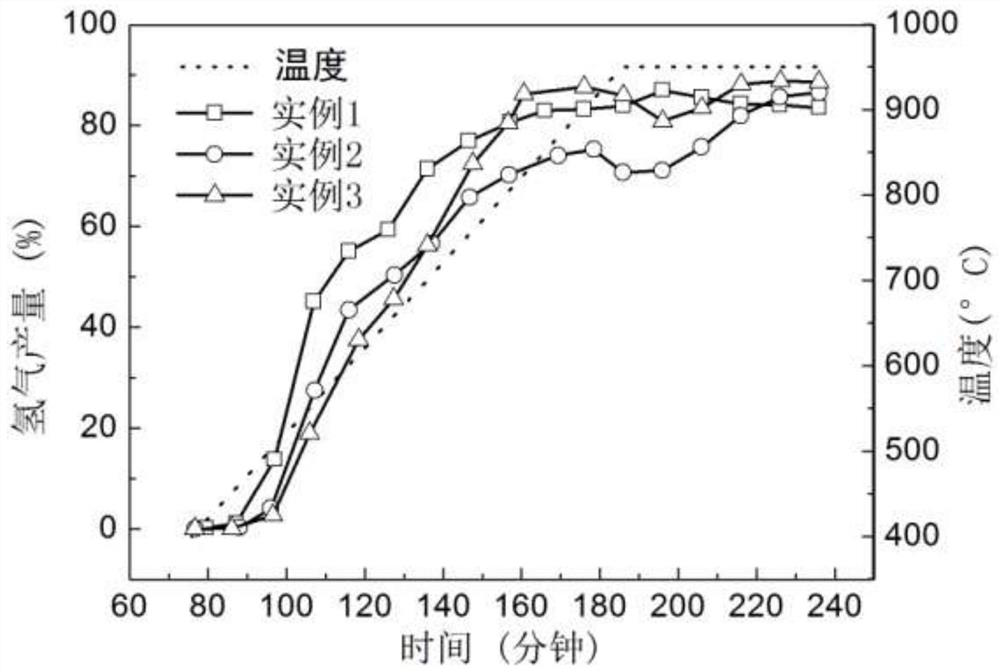

[0035] Step 5. Under a nitrogen atmosphere of 100mL / min, feed water vapor into the reactor, raise the temperature to 950°C at a rate of 5°C / min, and continue the reaction at 950°C for 2 hours to obtain a hydrogen content of ≥86%.

Embodiment 2

[0036] Embodiment 2: a kind of method based on the lignite chemical chain gasification hydrogen production of steel slag oxygen carrier, it carries out according to the following steps:

[0037] Step 1. Grinding hot stuffy steel slag and lignite respectively, and sieving to below 120 mesh;

[0038] Step 2, take by mass percentage 3.7g and lignite 14.8g that are ground and sieved in step 1;

[0039] Step 3, dry mixing the hot stuffy steel slag and lignite taken in step 2 in a three-dimensional mixer for 20 minutes;

[0040] Step 4, filling the mixed material in step 3 in the reactor, so that the gas can fully contact with the material and pass through the material;

[0041] Step 5. Under a nitrogen atmosphere of 100mL / min, feed water vapor into the reactor, raise the temperature to 950°C at a rate of 5°C / min, and continue the reaction at 950°C for 2 hours to obtain a hydrogen content of ≥86%.

Embodiment 3

[0042] Embodiment 3: a kind of method based on the lignite chemical chain gasification hydrogen production of steel slag oxygen carrier, it carries out according to the following steps:

[0043] Step 1. Grinding hot stuffy steel slag and lignite respectively, and sieving to below 120 mesh;

[0044] Step 2, taking by mass percentage 7.4g and lignite 11.1g ground and screened in step 1;

[0045] Step 3, dry mixing the hot stuffy steel slag and lignite taken in step 2 in a three-dimensional mixer for 20 minutes;

[0046] Step 4, filling the mixed material in step 3 in the reactor, so that the gas can fully contact with the material and pass through the material;

[0047] Step 5. Under a nitrogen atmosphere of 100mL / min, feed water vapor into the reactor, raise the temperature to 950°C at a rate of 5°C / min, and continue the reaction at 950°C for 3 hours to obtain a hydrogen content of ≥88%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com