Piping exchange station for the incoming and outgoing system of the oil depot tank area

A technology of exchange station, inbound and outbound, applied in the field of piping exchange station, it can solve the problems of incompatibility of pumps, chemical reaction explosion, quality change, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

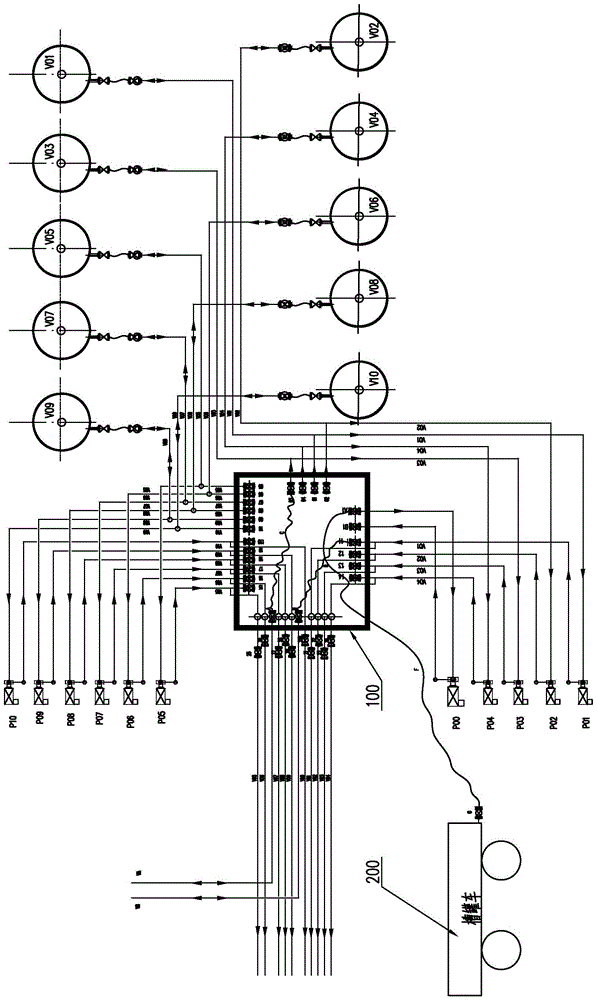

[0014] figure 1 Among them, including storage tanks V01-V10, dock loading and unloading ship inlet and outlet pipelines VA, VB, piping exchange station 100, tank trucks 200, delivery pumps P01-P10, loading and unloading ship control valves A, B, storage tank control valves 01-10, Delivery pump control valves 11-110, delivery line control valves 21-210, hoses C, D, F, etc.

[0015] Such as figure 1 Shown, the present invention is a kind of piping exchange station that is used for the import and export system of the tank area of the oil depot. The present invention will be illustrated by taking 10 storage tanks as examples below.

[0016] The import and export system of the oil depot tank area includes 10 storage tanks V01-V10, the dock loading and unloading ship inlet and outlet pipelines VA, VB, piping exchange station 100, delivery pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com