Method for producing feed additive from livestock and poultry breeding wastewater and purifying breeding wastewater to reclaimed water

A feed additive, livestock and poultry breeding technology, applied in chemical instruments and methods, animal feed, animal feed, etc., can solve problems such as heavy metal content exceeding the standard, and achieve the goal of reducing water consumption, high nutritional value, reducing breeding costs and antibiotic consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and the embodiments given in the accompanying drawings. The production technique of the present invention is easy to implement for those skilled in the art.

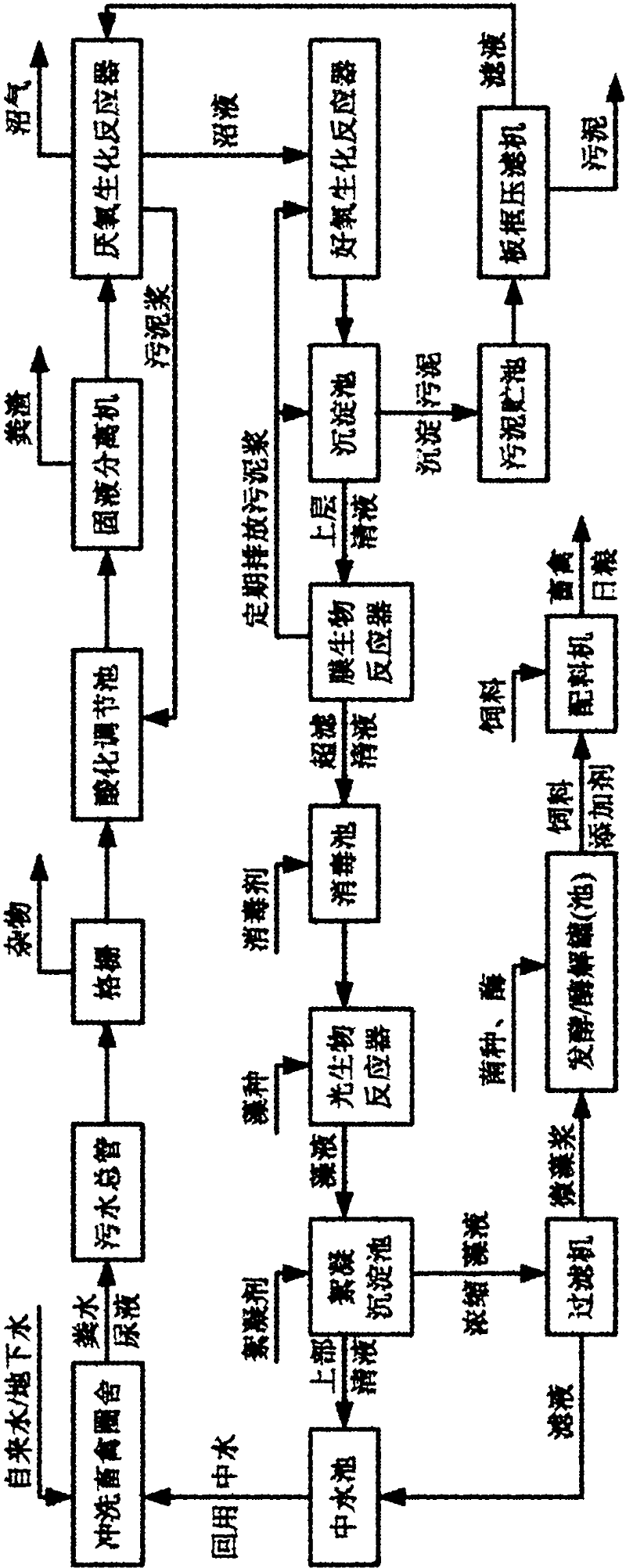

[0042] refer to figure 1 , the method of the present invention comprises the following steps:

[0043] a. Anaerobic-Aerobic Treatment of Livestock and Poultry Breeding Wastewater

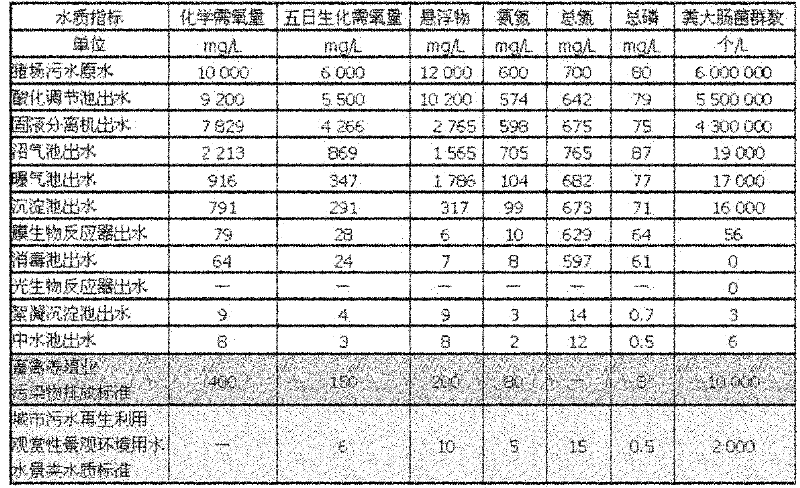

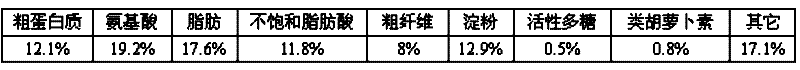

[0044] The feces produced by flushing the livestock and poultry pens and the urine excreted by the livestock and poultry enter the sewage main pipe of the livestock and poultry farm, and then enter the acidification adjustment tank after removing large floating objects and other mechanical impurities through the grid to adjust the sewage water volume, water quality, pH value, add part of the activated sludge slurry produced in the front of the subsequent anaerobic biochemical reactor to the rear of the acidification adjustment tank, dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com