Treatment method for phosphoric acid arsenic-removed slag

A treatment method and arsenic removal technology, applied in chemical instruments and methods, arsenic compounds, inorganic chemistry, etc., can solve the problems of waste of resources and increase the burden on enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

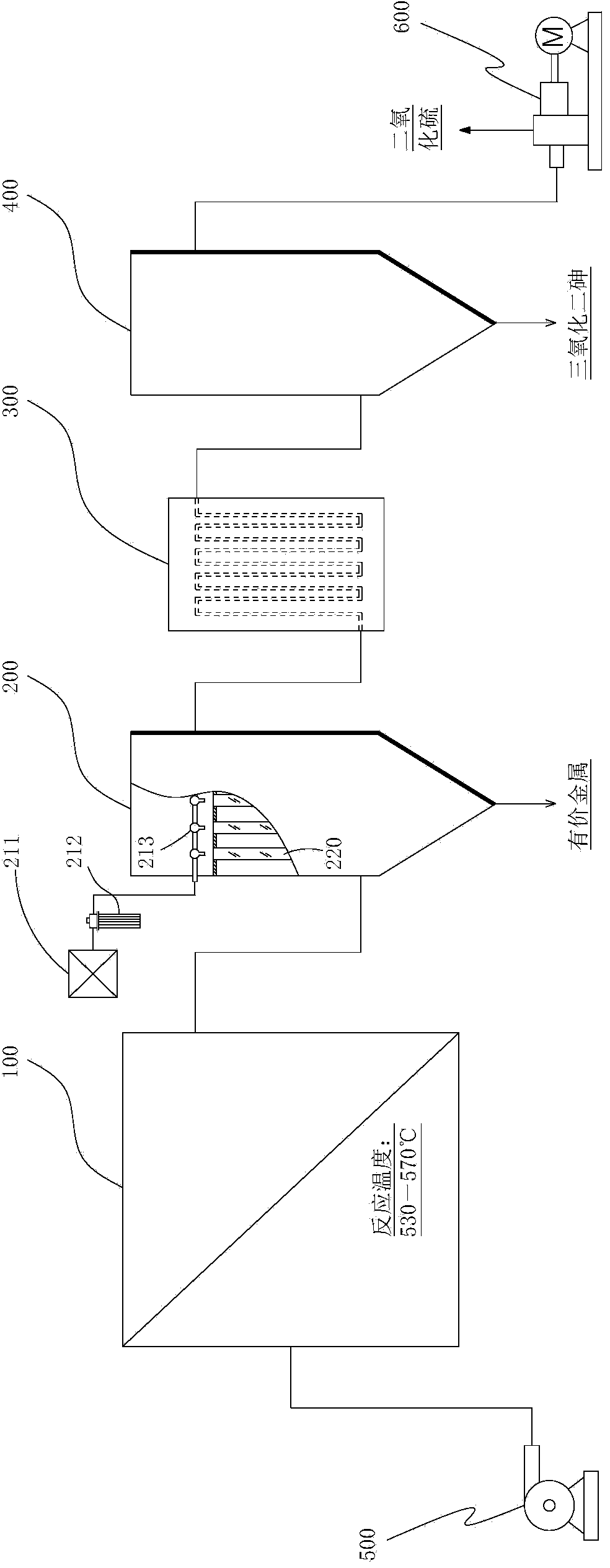

Embodiment 1

[0013] A phosphoric acid production enterprise produces primary phosphoric acid by thermal method. In order to remove arsenic in primary phosphoric acid, a de-arsenic tower is installed in the production process, and P is added to the de-arsenic tower. 2 S 5 React with primary phosphoric acid to generate more stable As 2 S 3 , so as to achieve the purpose of arsenic removal. The waste residue generated in the arsenic removal tower is the phosphoric acid arsenic removal residue to be treated in this embodiment. After inspection, the phosphoric acid dearsenic slag contains As2 S 3 10.32%, Pb1.46mg / kg, Cr2.12mg / kg, Ni2.89mg / kg, Cd0.254mg / kg. Now the phosphoric acid dearsenic slag is dried (the water content is reduced to about 10%), and sent to the rotary kiln for oxidation and roasting, such as figure 1 As shown, the air is blown into the rotary kiln through the blower 500, and the reaction temperature is controlled by the joint control of the ventilation speed and the detec...

Embodiment 2

[0015] The phosphoric acid dearsenic slag is the same as in Example 1. Now the phosphoric acid dearsenic slag is dried (the water content is reduced to about 10%), and sent to the rotary kiln for oxidation and roasting, such as figure 1 As shown, the air is blown into the rotary kiln through the blower 500, and the reaction temperature is controlled by the joint control of the ventilation speed and the detection temperature in the kiln, and the reaction temperature is strictly controlled at 530-570°C, so that As 2 S 3 Reacts with oxygen and fully converts to As 2 o 3 and SO 2 Gas; before sending the high-temperature furnace gas produced by the rotary kiln into the first flue gas filter 200, first inject inert preheating gas into the first flue gas filter 200 through the blowback device 213 to filter the first flue gas The sintered inorganic porous material filter element in the device 200 is preheated to about 150°C, and then the high-temperature dust-containing furnace ga...

Embodiment 3

[0017] The phosphoric acid dearsenic slag is the same as in Example 1. Now the phosphoric acid dearsenic slag is dried (the water content is reduced to about 10%), and sent to the rotary kiln for oxidation and roasting, such as figure 1 As shown, the air is blown into the rotary kiln through the blower 500, and the reaction temperature is controlled by the joint control of the ventilation speed and the detection temperature in the kiln, and the reaction temperature is strictly controlled at 530-570°C, so that As 2 S 3 Reacts with oxygen and fully converts to As 2 o 3 and SO 2 Gas; before sending the high-temperature furnace gas produced by the rotary kiln into the first flue gas filter 200, first inject inert preheating gas into the first flue gas filter 200 through the blowback device 213 to filter the first flue gas The sintered inorganic porous material filter element in the device 200 is preheated to about 200°C, and then the high-temperature dust-containing furnace ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com