Combination treatment system of oil sludge cracking and thermal desorption of polluted soil

A treatment system and technology for polluted soil, applied in the field of sludge cracking and polluted soil thermal desorption combined treatment system, can solve the problems of large waste gas, low environmental impact, large energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

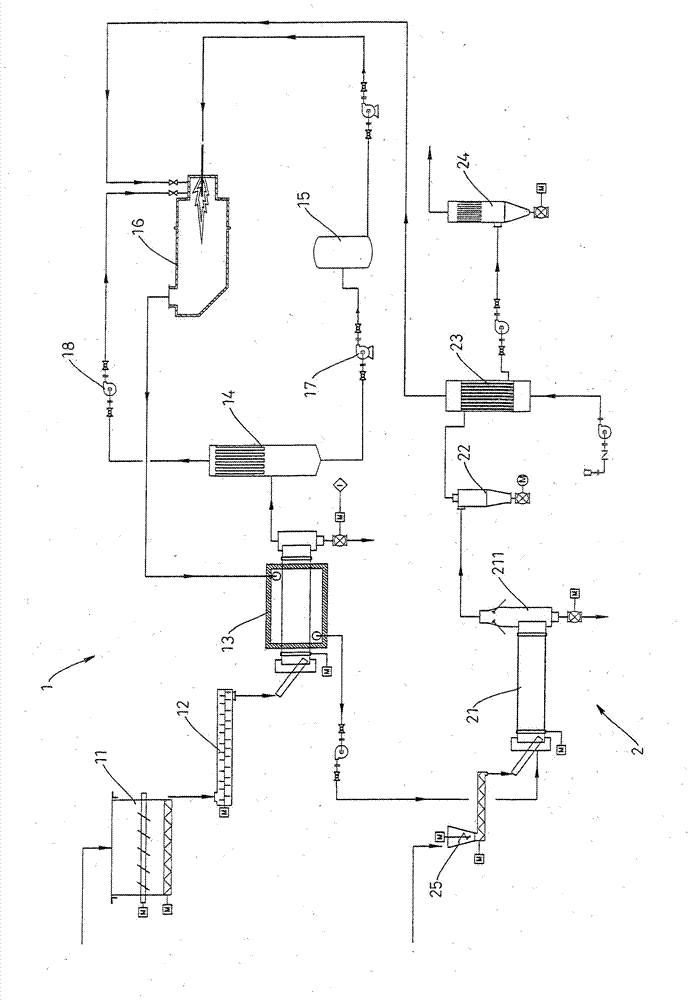

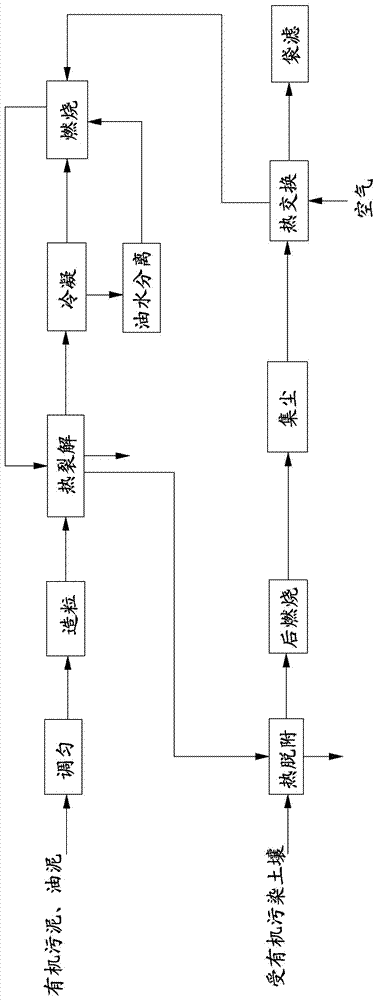

[0023] Please also see figure 1 , figure 2 , the present invention is mainly composed of: an oil sludge thermal cracking treatment system 1 and a contaminated soil thermal desorption treatment system 2. Wherein, the oil sludge thermal cracking treatment system 1 comprises: a sludge homogeneous tank 11, a granulator 12, a thermal cracking furnace 13, a condenser 14, an oil-water separation tank 15 and a hot blast stove 16, which can be For petrochemical wastes such as organic sludge and oil sludge, first send them into the sludge homogenization tank 11 and mix them thoroughly to adjust their quality, which can help stabilize subsequent processing operations; and after the dispersibility is adjusted by the granulator 12, the The thermal cracking furnace 13 is provided with a spiral blade, which can be rotated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com