Salted egg white protein polypeptide containing enteral nutrition and preparation method thereof

A technology of enteral nutritional preparations and albumin, which is applied in the field of nutritional food preparations, can solve the problems of limited functional components of nutritional preparations, and achieve the effects of promoting digestion and absorption, enhancing immunity, and facilitating digestion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh a certain amount of salted egg white powder, configure it into an aqueous solution with a substrate concentration of 5%, conduct heating pretreatment at 90°C and pH 8, and continue magnetic stirring for 15 minutes. Then add 3500U / g trypsin, enzymatically hydrolyze in a constant temperature water bath at 45°C for 4 hours, add sodium hydroxide dropwise and stir continuously during this period to ensure that the pH is stable; Centrifuge for 15 minutes, take the supernatant and debitterize, decolorize, and deodorize with activated carbon, and then vacuum freeze-dry to make salted egg white protein polypeptide powder.

[0032] Weigh 5g of salted egg white protein polypeptide powder, 40g of soybean protein, 100g of maltodextrin, 20g of medium chain triglyceride, 15g of fruit and vegetable powder, 10g of oligosaccharide, 5g of arginine, and 20g of konjac powder.

[0033] Stir and mix fruit and vegetable powder and maltodextrin in advance, respectively encapsulate medium-...

Embodiment 2

[0035] A certain amount of salted egg white powder was weighed, prepared into a solution with a substrate concentration of 7%, and subjected to heating pretreatment at 90°C and pH 8, and continued magnetic stirring for 15 minutes. Then add trypsin and papain, the amount of enzyme added is 3500U / 0.4g and 4000U / 0.6g respectively, enzymatic hydrolysis in a constant temperature water bath at 55°C for 5 hours, during which sodium hydroxide is continuously added dropwise and stirred to ensure that the pH is stable; enzymatic hydrolysis After the end, the enzyme was inactivated in a boiling water bath at 100°C for 10 minutes, and after cooling, it was centrifuged at 4000r / min for 15 minutes. The supernatant was debittered, decolorized and deodorized with activated carbon, and then vacuum freeze-dried to make salted egg white polypeptide powder.

[0036] Weigh 10g of salted egg white protein polypeptide powder, 35g of soybean protein, 110g of maltodextrin, 15g of medium chain triglycer...

Embodiment 3

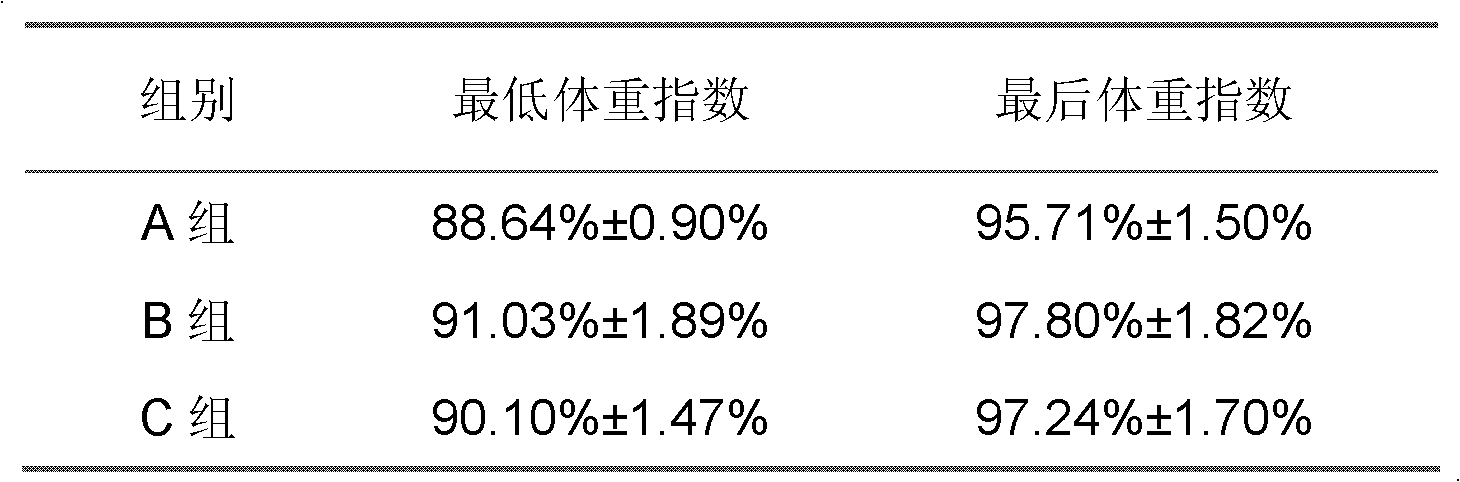

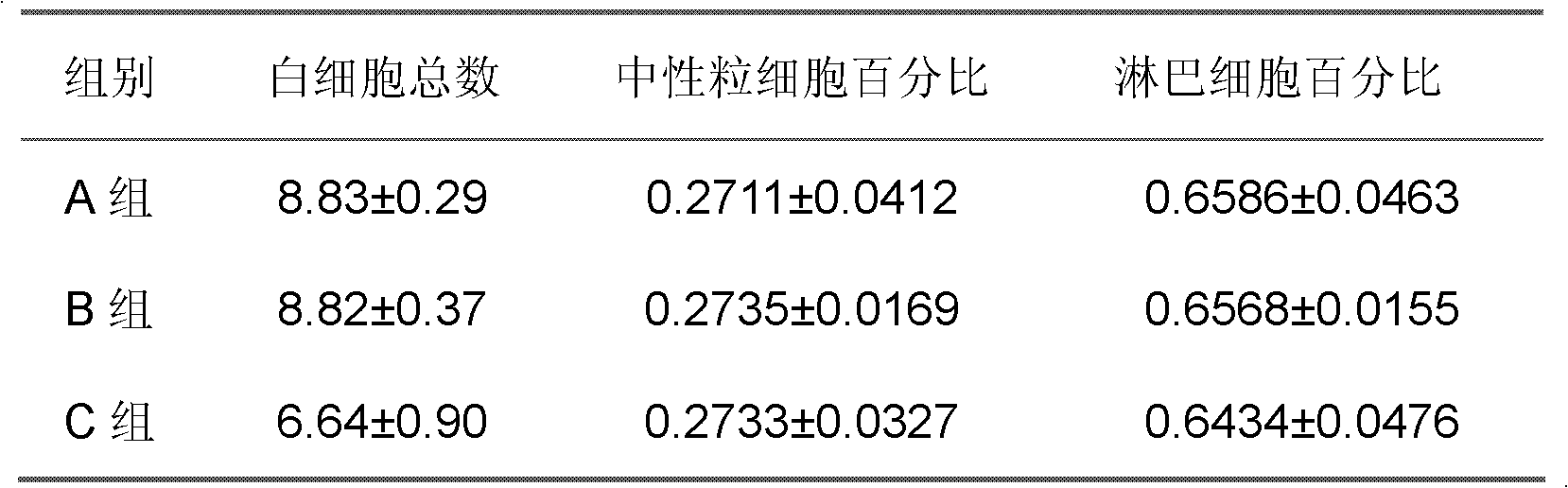

[0039] Effects of enteral nutrition preparations on the body weight of SD rats:

[0040] Clean-grade Sprague-Dawley (SD) female rats, fed for one week, aged 6-7 weeks, weighing 250g-270g, were provided by the Experimental Animal Center of Jilin University.

[0041] Establishment of animal burn model: intraperitoneal anesthesia was injected with 1% pentobarbital sodium (0.4ml / 100g), and the anesthetized rat was fixed on a rat operating board. Open 1cm on both sides of the spine on the back, mark the two ends of the head and tail parallel to the spine, each with a side length of 1.5cm and an area of 2.25cm 2 The square preprocessing marks the line. The back hair was clipped, and the back hair was depilated with 8% sodium sulfide preparation. Cover the marked line on the back with alcohol gauze of the same area, protect the surrounding skin with wet gauze, ignite the alcohol gauze and let it burn for 15 seconds, then cover it with saline gauze to form 4 square burn wounds. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com