Method for recycling waste lithium battery module

A technology for waste lithium batteries and lithium batteries, which is applied in battery recycling, recycling technology, recycling by waste collectors, etc., to achieve the effect of improving the recycling rate and the method is simple and easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Through the following examples, the present invention can be explained in detail, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention, and the present invention is not limited to the following examples.

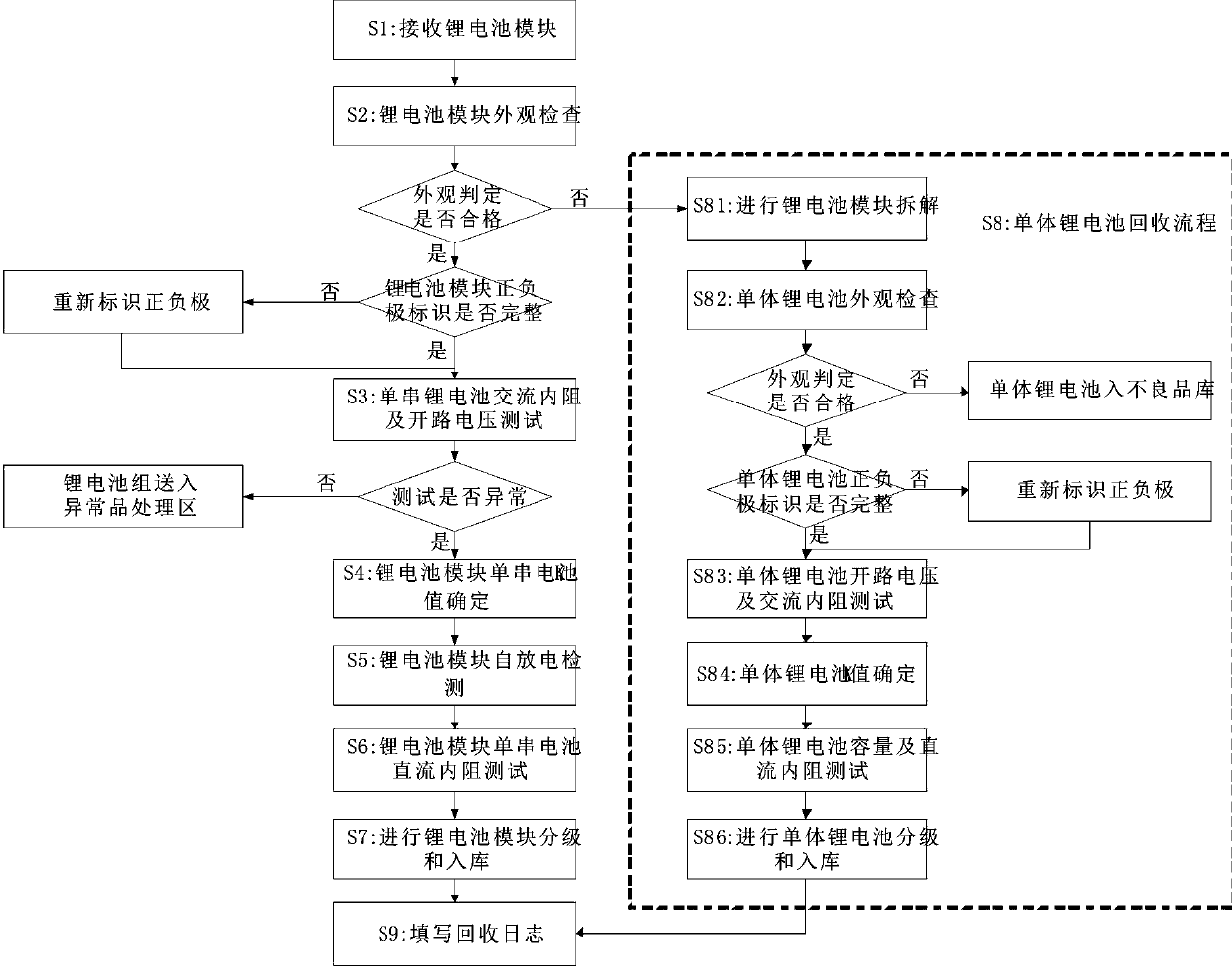

[0046] like figure 1 As shown, a method for recycling waste lithium battery modules of the present invention comprises the following steps:

[0047] S1: Receive lithium battery module;

[0048] Place the lithium battery module to be recycled in the battery basic performance test area, and place the lithium battery module in the correct position and direction.

[0049] S2: Appearance inspection of lithium battery module;

[0050] Check the appearance and size of the lithium battery module. It is required that the shell of the lithium battery module is intact, without deformation, cracks, or leakage. The surface should be smooth and free of trauma. If it does not meet the requirements of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com