Wet desulphurization technology and system using coal ash

A technology of wet desulfurization and fly ash, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of no good solutions for treatment and comprehensive recycling, and achieve no secondary pollution, The effect of low running cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

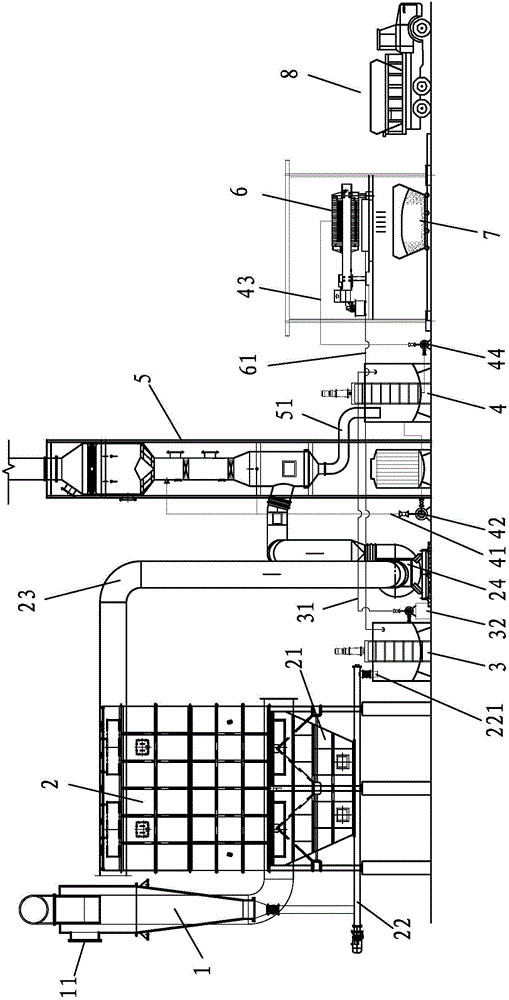

Image

Examples

Embodiment Construction

[0036] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0037] The invention relates to a wet desulfurization process using fly ash, which mainly includes the following steps:

[0038] 1) Collect the ultra-fine fly ash in the flue gas after boiler combustion, and transport the collected ultra-fine fly ash to the liquid making pool; the ultra-fine fly ash contains active oxides;

[0039] 2) The active oxides in the ultrafine fly ash fully react with a certain proportion of water in the liquid making tank to obtain an alkaline solution;

[0040] 3) Transport the alkaline solution obtained in step 2 to the desulfurization circulation pool;

[0041] 4) The alkaline solution in the desulfurization circulation pool circulates between the desulfurization tower and the desulfurization circulation pool. The alkaline solution transported from top to bottom in the desulfurization tower and the rising flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com