Wind-driven generator electrothermal ice melting rotor blade, electrothermal chip and forming device and method

A technology for wind turbines and electric heating chips, which is applied to wind turbine components, electric heating devices, wind turbines, etc., can solve problems such as damage to generator sets, icing of rotor blades of wind turbines, damage to wind turbines, etc., to prevent The effect of icing, strong integration and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0101] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

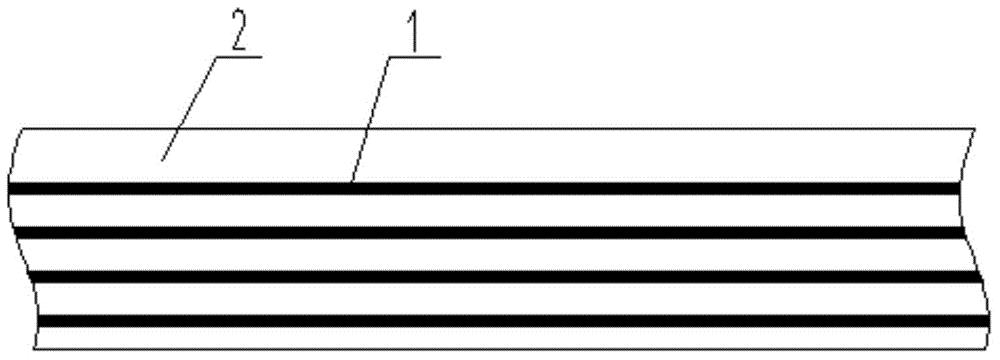

[0102] like figure 1 As shown, the present invention provides an electrothermal chip for electrothermal ice-melting rotor blades of a wind power generator, including a glass fiber cloth 2 with a thickness of 0.4 to 0.8 cm, and a carbon fiber bundle 1 is sewn on the glass fiber cloth 2, and the carbon fiber bundle 1 Use 12-36K carbon fiber bundles.

[0103] The glass fiber cloth 2 is provided with at least two carbon fiber bundles 1 arranged in parallel at intervals, and the distance between the at least two carbon fiber bundles 1 is determined according to the heat generation requirements in practical applications. In this embodiment, The spacing between the carbon fiber bundles 1 is set at 1-2 cm.

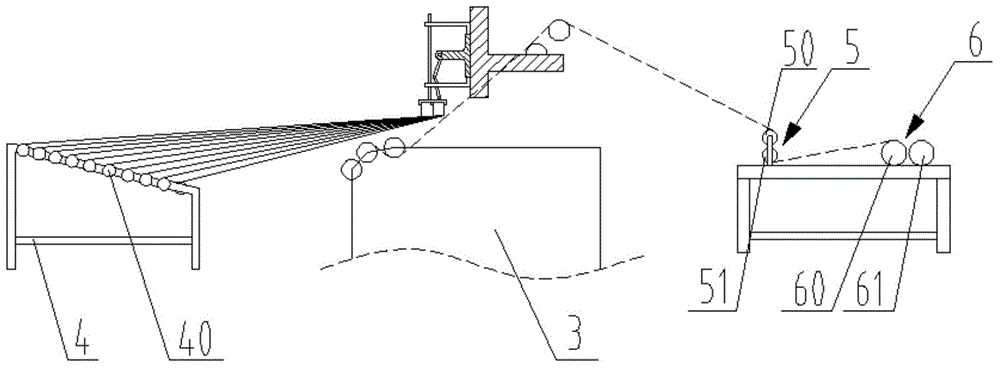

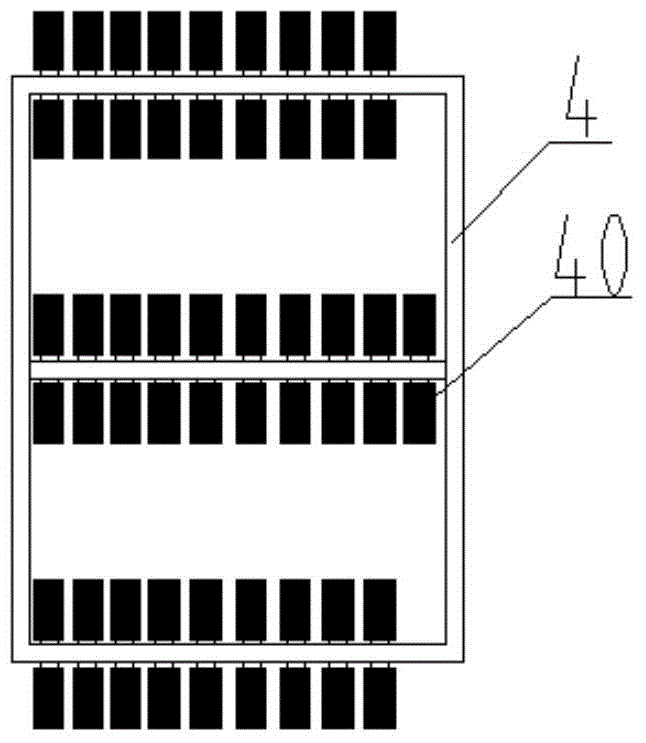

[0104] like Figure 15 , Figure 16 As shown, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com