Magnesium-aluminum-silicon low-thermal-expansion-coefficient microcrystalline glass material and preparation method thereof

A low thermal expansion coefficient and glass-ceramic technology, applied in the field of electronic ceramic materials, can solve the problems of large thermal expansion coefficient, low thermal expansion coefficient, and high dielectric loss, and achieve low dielectric constant, high bending strength, and low dielectric loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

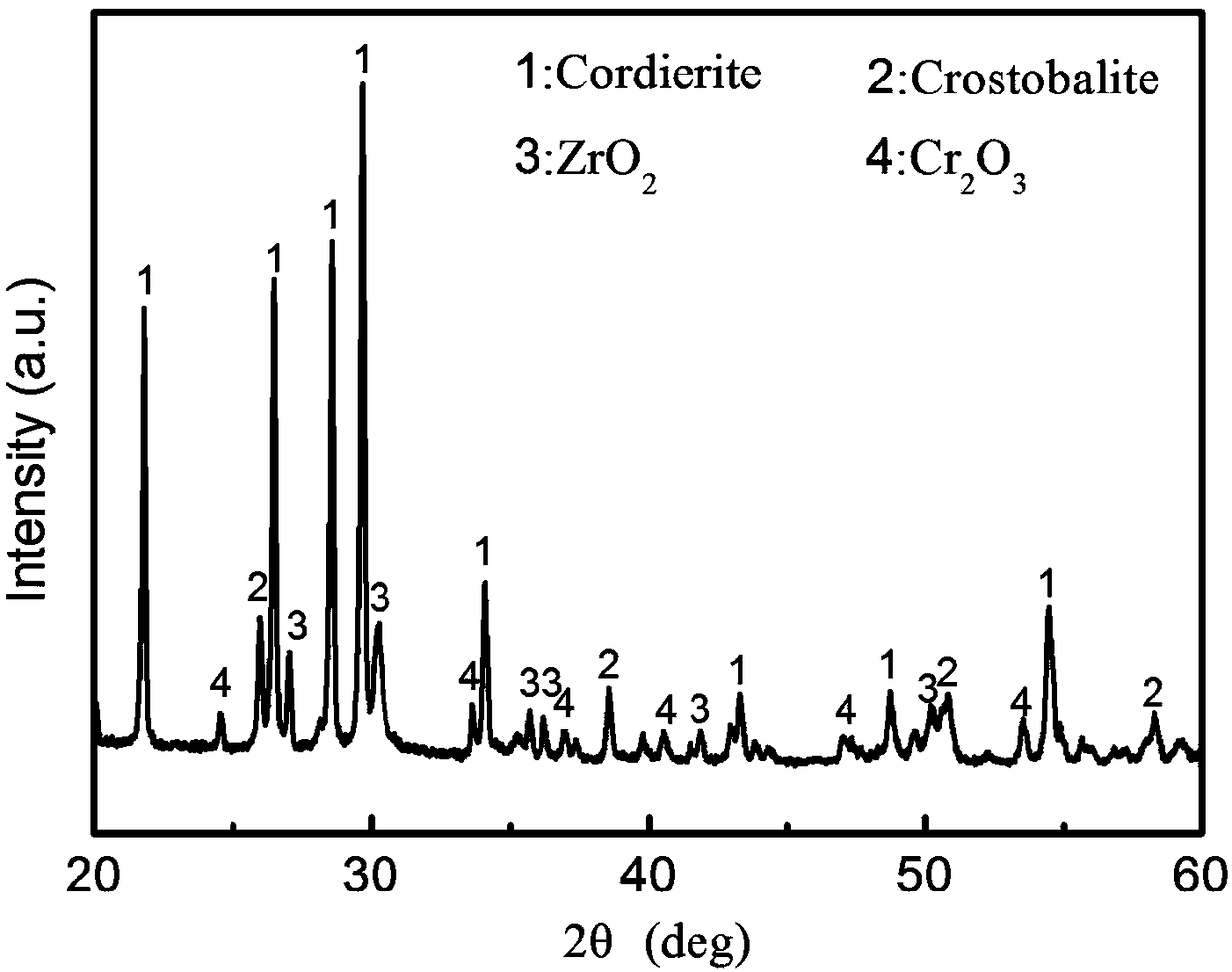

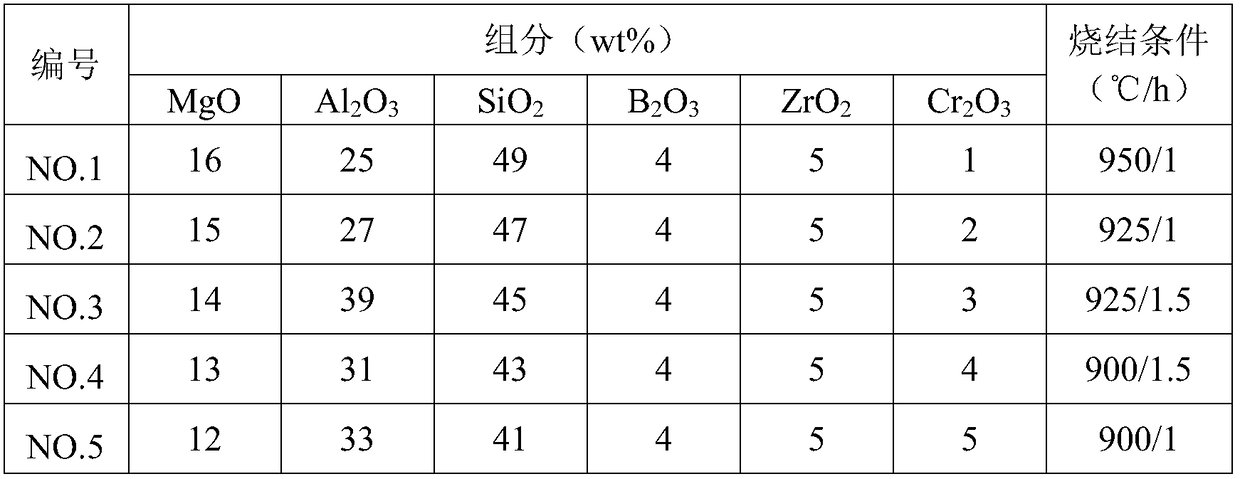

[0031] Accurately calculate MgO and Al according to the formula ratio in the above table 2 o 3 , SiO 2 , ZnO, B 2 o 3 , ZrO 2 The actual amount of various raw materials, after accurate weighing, ball milled for 3 hours to make it evenly mixed and dried; melted the mixture in a crucible, raised the temperature to 1475 ° C for 1 hour, cooled down after the ingredients were melted and clarified, and melted Pour the body into deionized water and water quench to obtain transparent glass slag; the obtained glass slag is wet ball milled and dried to obtain glass powder. According to the basic glass powder and Cr 2 o 3 Accurately weigh Cr with a mass ratio of 100:1 2 o 3 Desired mass, the Cr 2 o 3 Mix and blend into the above glass powder, mill with deionized water and zirconium balls as the medium for 5 hours, dry and sieve to obtain a uniformly dispersed powder; after the powder is granulated and pressed, it is sintered at 950°C And keeping it warm for 1 hour, the magnesiu...

Embodiment 2

[0034] Accurately calculate MgO and Al according to the formula ratio in the above table 2 o 3 , SiO 2 , ZnO, B 2 o 3, ZrO 2 The actual amount of various raw materials, after being accurately weighed, ball milled for 3 hours to make it evenly mixed and dried; melted the mixture in a crucible, raised the temperature to 1475°C and kept it for 1.5 hours, cooled down after the ingredients were melted and clarified, and melted Pour the body into deionized water and water quench to obtain transparent glass slag; the obtained glass slag is wet ball milled and dried to obtain glass powder. According to the basic glass powder and Cr 2 o 3 Accurately weigh Cr with a mass ratio of 100:2 2 o 3 Desired mass, the Cr 2 o 3 Mix and blend into the above glass powder, mill with deionized water and zirconium balls for 6 hours, dry and sieve to obtain a uniformly dispersed powder; the powder is sintered at 925°C after granulation and compression molding And keeping it warm for 1 hour, t...

Embodiment 3

[0037] Accurately calculate MgO and Al according to the formula ratio in the above table 2 o 3 , SiO 2 , ZnO, B 2 o 3 , ZrO 2 The actual amount of various raw materials, after being accurately weighed, ball milled for 3 hours to make it evenly mixed and dried; melted the mixture in a crucible, raised the temperature to 1450°C and kept it for 1.5 hours, cooled down after the ingredients were melted and clarified, and melted Pour the body into deionized water and water quench to obtain transparent glass slag; the obtained glass slag is wet ball milled and dried to obtain glass powder. According to the basic glass powder and Cr 2 o 3 Accurately weigh Cr with a mass ratio of 100:3 2 o 3 Desired mass, the Cr 2 o 3 Mix and blend into the above glass powder, mill with deionized water and zirconium balls for 6 hours, dry and sieve to obtain a uniformly dispersed powder; the powder is sintered at 925°C after granulation and compression molding And keeping it warm for 1.5 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com