High-strength low-thermal-expansion-coefficient microcrystalline glass and preparation method thereof

A low thermal expansion coefficient, glass-ceramic technology, used in glass manufacturing equipment, glass molding, manufacturing tools and other directions, can solve the problems of high thermal expansion coefficient, low bending strength, large dielectric loss, etc., to achieve simple process, bending resistance, etc. The effect of high strength and low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

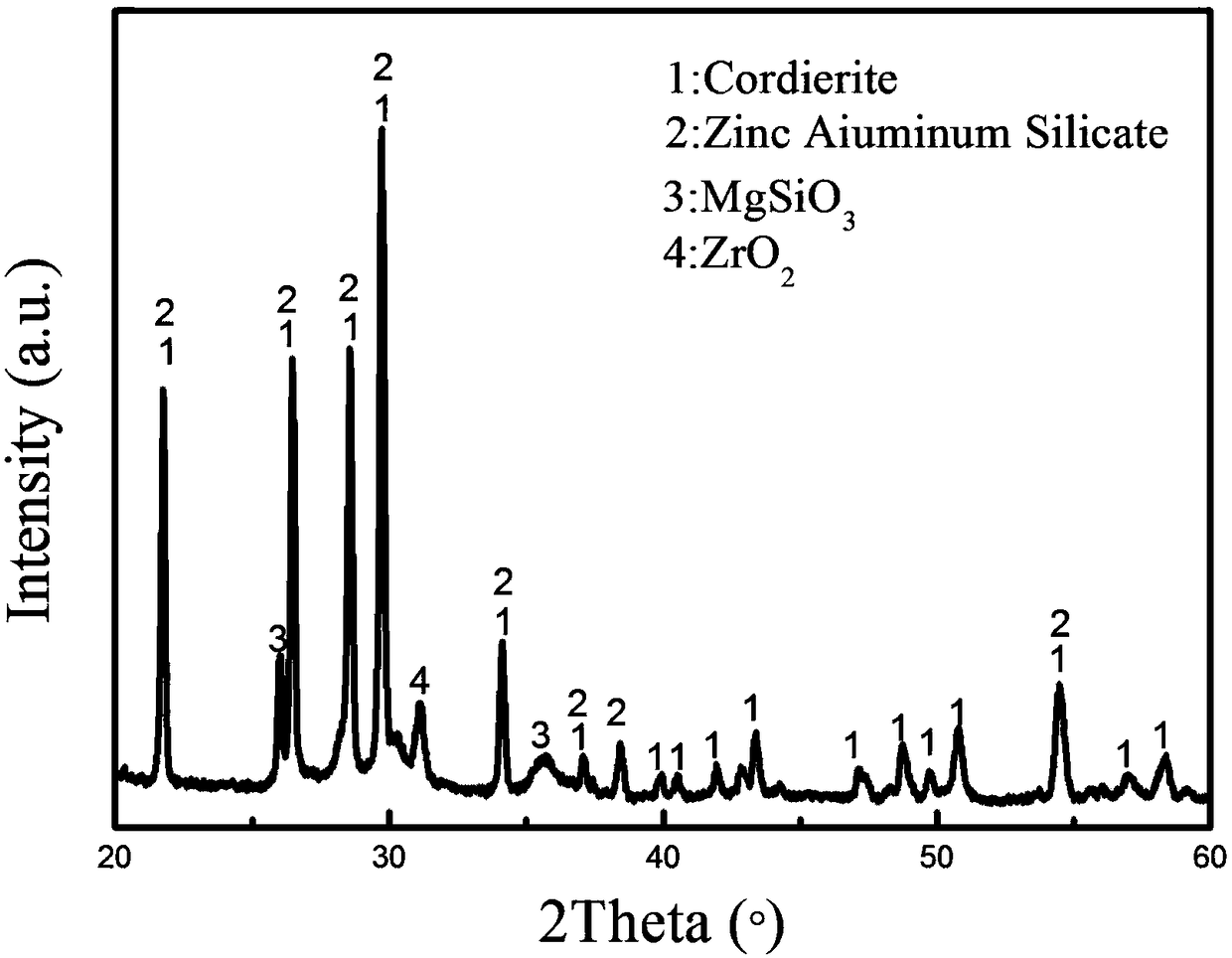

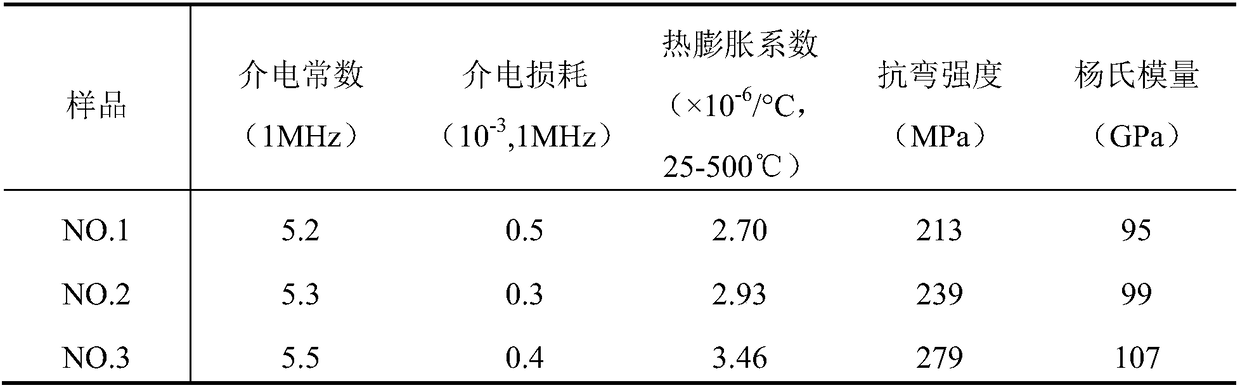

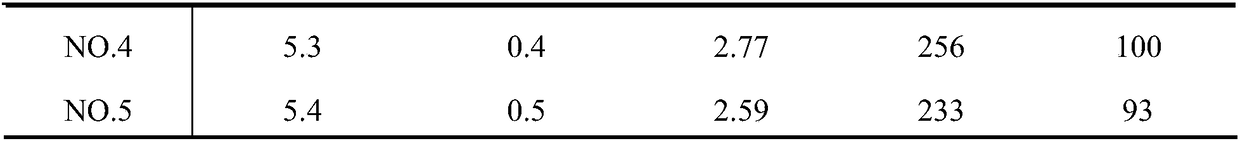

Embodiment 1

[0026] This embodiment provides a high-strength low thermal expansion coefficient glass-ceramics, its composition is: MgO is 15wt%, Al 2 o 3 27wt%, SiO 2 48wt%, B 2 o 3 3wt%, ZnO 2wt%, ZrO 2 5wt%, accurately calculate the corresponding actual amount of hydroxide, wet ball mill for 2 hours, mix evenly and dry, put in a crucible and melt at 1450°C for 1 hour, water quench to get glass slag, and ball mill the glass slag for 1 hour After drying to obtain glass powder, the glass powder was wet ball milled with deionized water for 7 hours to obtain a uniformly dispersed powder, the powder was granulated with acrylic acid as a binder, pressed and molded, sintered at 900 ° C and kept for 1 Hours, high-strength and low thermal expansion coefficient glass-ceramics can be obtained, and its mechanical properties, dielectric properties and thermal properties are shown in the following table.

Embodiment 2

[0028] This embodiment provides a kind of glass-ceramics with high strength and low coefficient of thermal expansion, its composition is: MgO is 13wt%, Al 2 o 3 29wt%, SiO 2 46wt%, B 2 o 3 3wt%, ZnO 3wt%, ZrO 2 6wt%, accurately calculate the corresponding actual amount of hydroxide, wet ball mill for 2 hours, mix evenly and dry, put in a crucible and melt at 1450°C for 1 hour, get glass slag after water quenching, and ball mill the glass slag for 1 hour After drying to obtain glass powder, the glass powder was wet ball milled with deionized water for 7 hours to obtain a uniformly dispersed powder, the powder was granulated with acrylic acid as a binder, pressed and molded, sintered at 900 ° C and kept for 1.5 Hours, high-strength and low thermal expansion coefficient glass-ceramics can be obtained, and its mechanical properties, dielectric properties and thermal properties are shown in the following table.

Embodiment 3

[0030] This embodiment provides a kind of glass ceramics with high strength and low coefficient of thermal expansion, its composition is: MgO is 11wt%, Al 2 o 3 31wt%, SiO 2 44wt%, B 2 o 3 3wt%, ZnO 4wt%, ZrO 2 7wt%, accurately calculate the actual amount of hydroxide, wet ball mill for 2 hours, mix evenly and dry, put in a crucible and melt at 1475°C for 1 hour, water quench to get glass slag, and ball mill the glass slag for 1 hour After drying to obtain glass powder, the glass powder was wet ball milled with deionized water for 6 hours to obtain a uniformly dispersed powder, the powder was granulated with acrylic acid as a binder, pressed and molded, sintered at 875 ° C and kept for 1.5 Hours, high-strength and low thermal expansion coefficient glass-ceramics can be obtained, and its mechanical properties, dielectric properties and thermal properties are shown in the following table.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com