Application for waste scrap in carbon fiber/glass fiber composite material production process and products thereof

A glass fiber and composite material technology, applied in the direction of synthetic resin layered products, layered products, plastic recycling, etc., can solve the problems of troublesome production process, high cost, environmental pollution, etc., and achieve the effect of saving cost and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

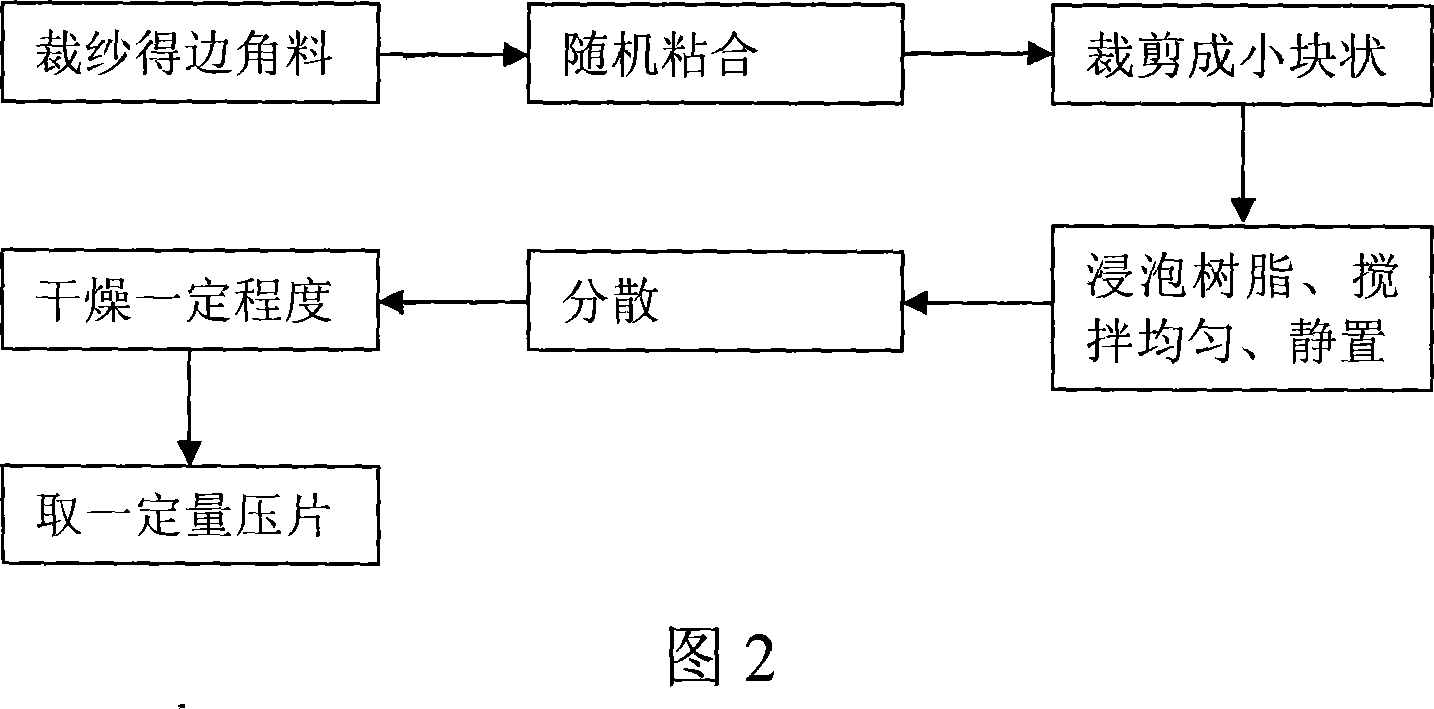

[0035] Take 1 kg of carbon fiber composite material leftovers, paste all the leftovers together by hand, then cut the material into 2cm×2cm small squares with a yarn cutting machine, add epoxy resin at a weight ratio of 1:2, mix evenly and let it stand for 1 After hours, the material was poured into the kneader and kneaded for 2 hours. Take out the kneaded material, bake it at 50°C for 10 minutes, and finally press the tablet with a hydraulic press, and the thickness of the tablet is about 4mm.

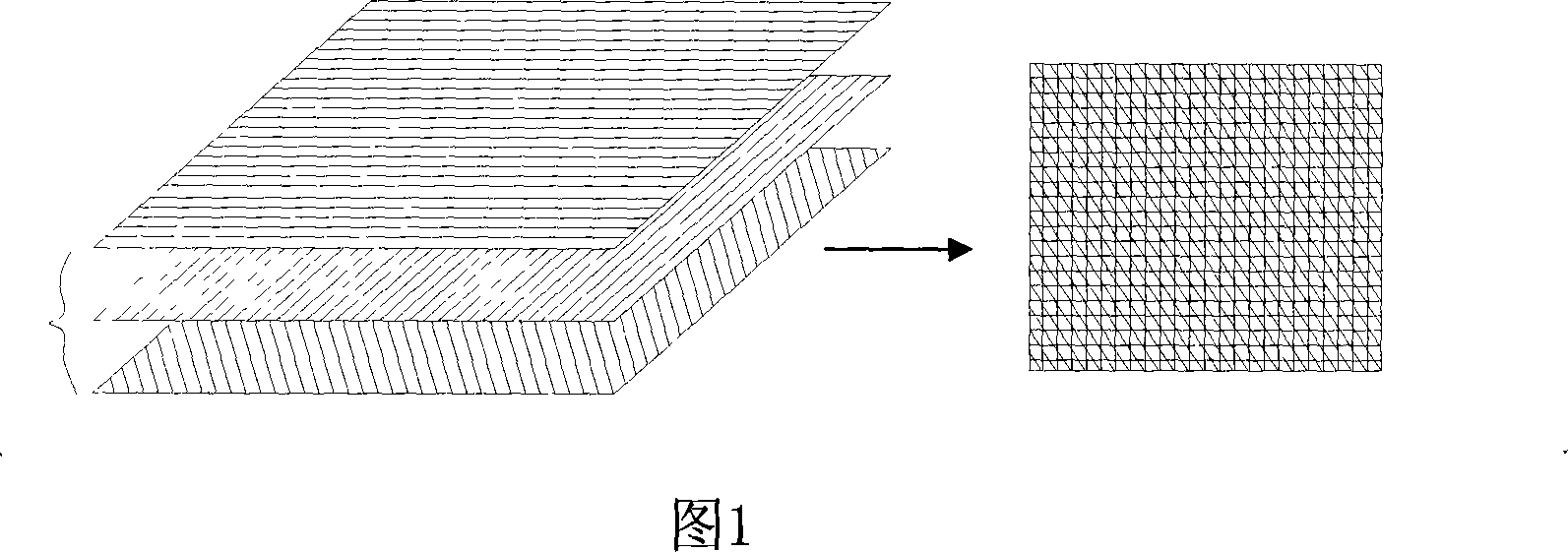

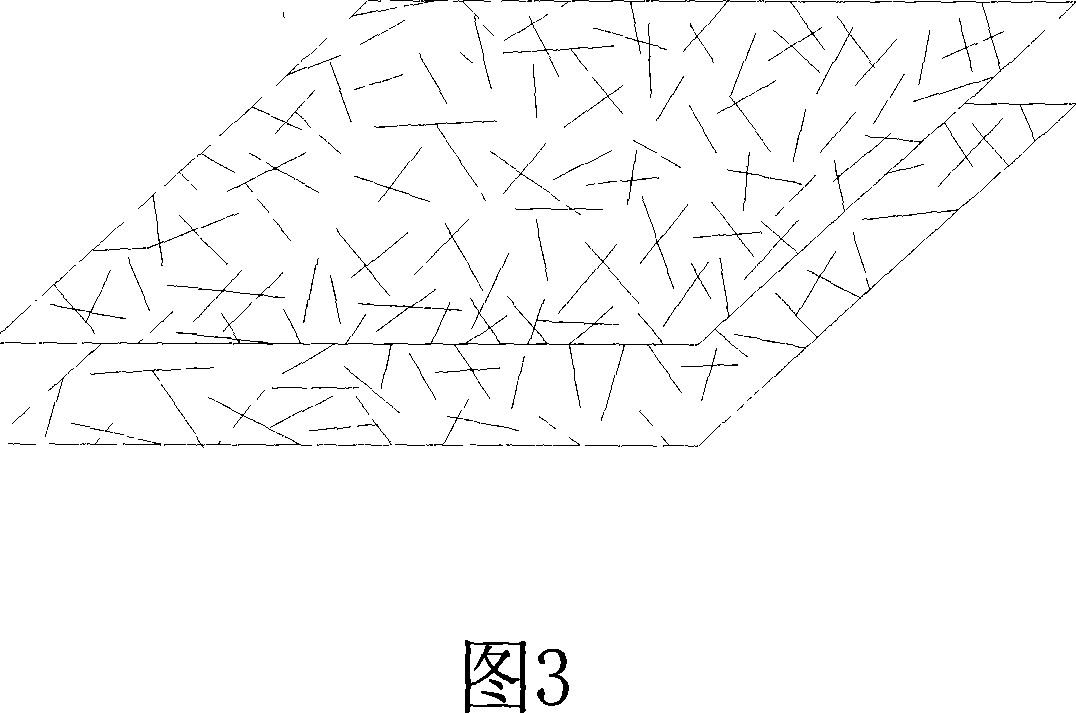

[0036] Take several new carbon fiber composite sheets with the above-mentioned pressed fiber directions randomly dispersed and press them together to form a different-directional fiber layer; then take a number of ordinary carbon fiber or glass fiber yarn sheets with the fiber directions in the same direction and regular distribution Zhang, staggered (makes the fiber direction of each sheet to be at a certain angle) and pressed into the same direction fiber layer, and then laminate the di...

Embodiment 2

[0039] Take 1 kg of glass fiber composite material leftovers, paste all the leftovers together manually, then cut the material into 2cm×2cm small squares with a yarn cutter, add epoxy resin according to the weight ratio of 1:2, stir evenly and then stand still For 1 hour, the material was poured into the kneader and kneaded for 2 hours. Take out the kneaded material, bake it at 50°C for 10 minutes, and finally press the tablet with a hydraulic press, and the thickness of the tablet is about 4mm.

[0040] Take several new glass fiber composite sheets with the above pressed fiber directions randomly dispersed and press them together to form a different-directional fiber layer; then take ordinary glass fiber or carbon fiber yarn sheets with the fiber directions in the same direction and regular distribution Several sheets, staggered (makes the fiber direction of each sheet at a certain angle) are pressed into the same direction fiber layer, and then the different direction fiber laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com