High-impact high-stiffness polypropylene rotational molding material and preparation method thereof

A polypropylene, high-rigidity technology, applied in the field of high-impact and high-rigidity polypropylene rolling plastic and its preparation, can solve the problems of poor low temperature resistance and creep resistance, limited space for material performance improvement, etc. achieve the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

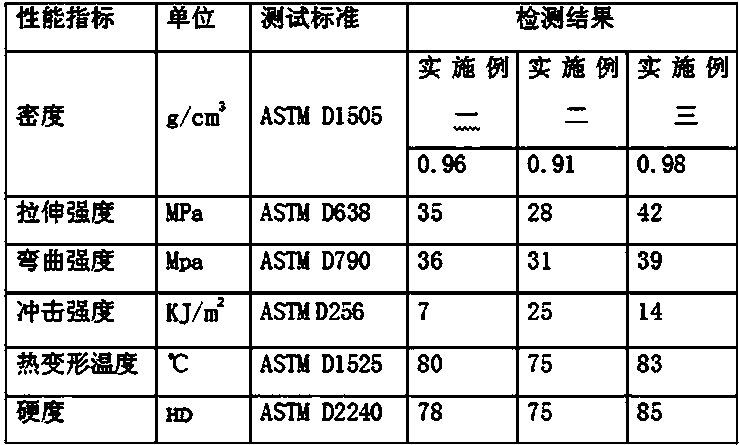

Examples

Embodiment 1

[0031] Embodiment 1: A high-impact and high-rigidity polypropylene rolling plastic is composed of the following raw materials measured in parts by mass:

[0032] Polypropylene 100

[0033] Ethylene-octene copolymer 5

[0034] Compound antioxidant 0.4

[0035] Nano Talc 5

[0036] Ethylene bis stearamide 0.4

[0037] γ-Aminopropyltriethoxysilane 0.1.

[0038] The composite antioxidant is made by mixing phosphite antioxidant 168 and hindered phenolic antioxidant 1010 at a weight ratio of 1:0.3.

[0039] A preparation method of high-impact high-rigidity polypropylene rolling plastic is carried out according to the following steps: 0.1 part of γ-aminopropyltriethoxysilane is mixed with 5 parts of nanometer talcum powder in a high-speed mixer for 5 minutes; mixed with Nano talcum powder of γ-aminopropyltriethoxysilane and 100 parts of polypropylene, 5 parts of ethylene-octene copolymer, 0.4 parts of composite antioxidant, 0.4 parts of ethylene bisstearamide, at medium spee...

Embodiment 2

[0040] Embodiment 2: A high-impact and high-rigidity polypropylene rolling plastic is composed of the following raw materials measured in parts by mass:

[0041] Polypropylene 100

[0042] HDPE 25

[0043] 2,5-Dimethyl-2,5-bis(tert-butylperoxy)hexane 0.04

[0044] Triallyl isocyanurate 0.06

[0045]Ethylene-octene copolymer 5

[0046] Compound antioxidant 0.3

[0047] Ethylene bis stearamide 0.2.

[0048] The composite antioxidant is made by mixing phosphite antioxidant 168 and hindered phenolic antioxidant 1010 at a weight ratio of 1:0.5.

[0049] A preparation method of high-impact high-rigidity polypropylene rolling plastic is carried out according to the following steps:

[0050] Step 1: Pre-dry the high-density polyethylene in an oven with a set temperature of 80°C until the moisture content is lower than 600ppm, and grind it to 50 meshes for later use.

[0051] Step 2: Mix 0.04 parts of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane and 0.06 parts of triallyl isocya...

Embodiment 3

[0053] Embodiment 3: A high-impact and high-rigidity polypropylene rolling plastic is composed of the following raw materials measured in parts by mass:

[0054] Polypropylene 100

[0055] HDPE 12.5

[0056] Linear Low Density Polyethylene 12.5

[0057] Dicumyl peroxide 0.04

[0058] Triallyl isocyanurate 0.06

[0059] Ethylene-octene copolymer 6

[0060] Compound antioxidant 0.3

[0061] Nano Talc 8

[0062] Ethylene bis stearamide 0.4

[0063] γ-Aminopropyltriethoxysilane 0.2.

[0064] The composite antioxidant is made by mixing phosphite antioxidant 168 and hindered phenolic antioxidant 1010 at a weight ratio of 1:0.7.

[0065] A preparation method of high-impact high-rigidity polypropylene rolling plastic is carried out according to the following steps:

[0066] Step 1: 12.5 parts of high-density polyethylene and 12.5 parts of linear low-density polyethylene were pre-dried in an oven with a set temperature of 80°C until the moisture content was lower than 600ppm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com