Method for cleaning silicon material

A silicon material and cleaning technology, which is applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems that impurities on the surface of silicon materials cannot be completely removed, and alleviate the shortage of silicon material resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

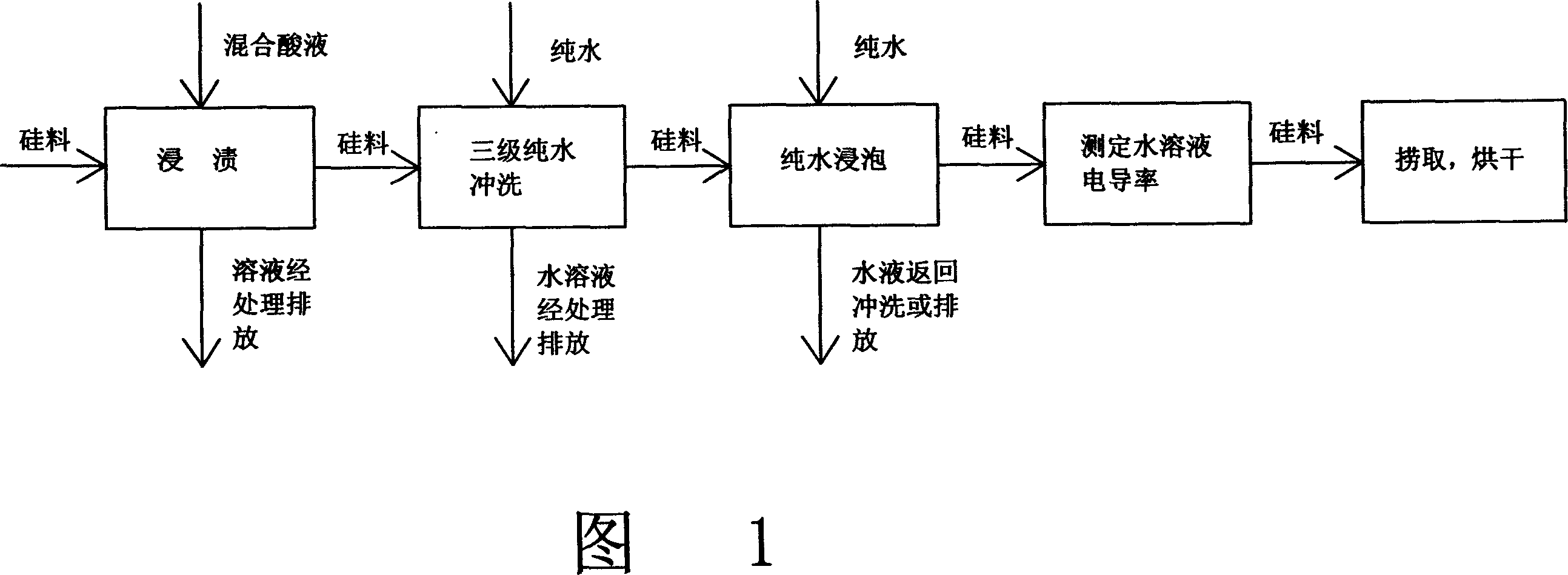

[0020] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] Prepare an acid solution tank that contains hydrofluoric acid with a concentration of 40% and a nitric acid solution with a concentration of 65% in a ratio of 1:8 to form an acid solution, and immerse the waste silicon material in the above-mentioned mixed acid solution for 2 minutes . During this process, the silicon material reacts with the mixed acid solution, , the surface layer of the silicon material is completely corroded, and the metal impurities and organic dirt contained in the surface layer are removed; then, the silicon material treated with the acid solution is rinsed three times with pure water (deionized water), and the surface of the silicon material is further cleaned. The silicon material is soaked in the pure water tank, and the compressed air is bubbled to fully release the residual impurities of the silicon material. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com