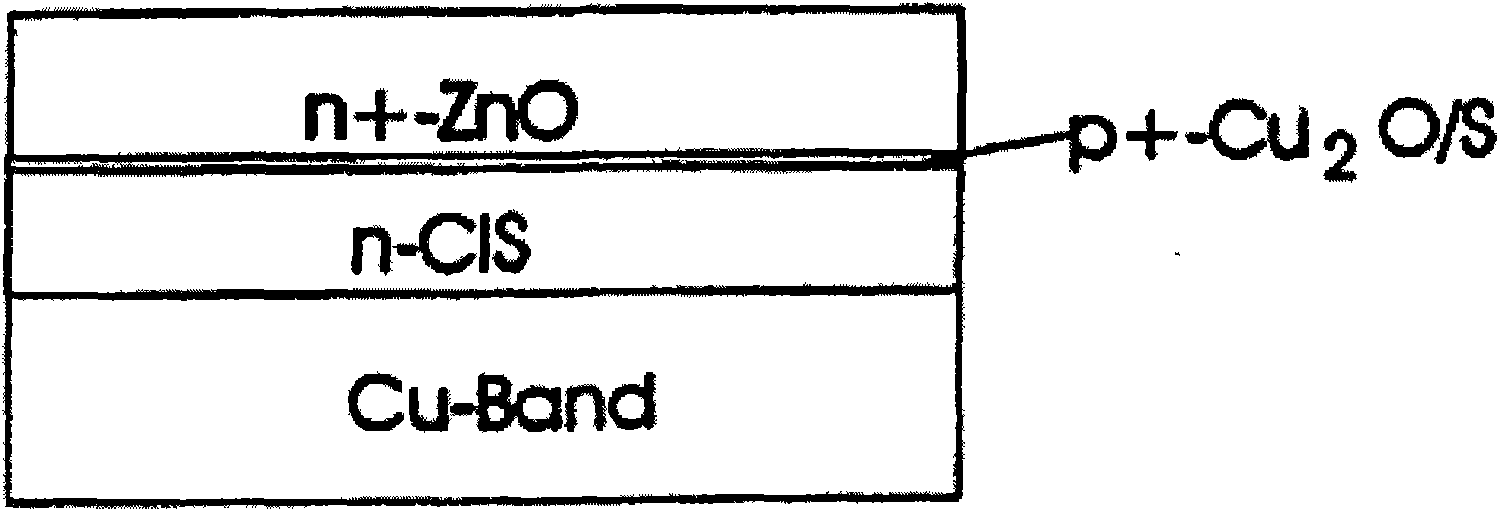

Thin film solar cell as well as base band and preparation method thereof

A solar cell, thin film technology, used in circuits, photovoltaic power generation, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

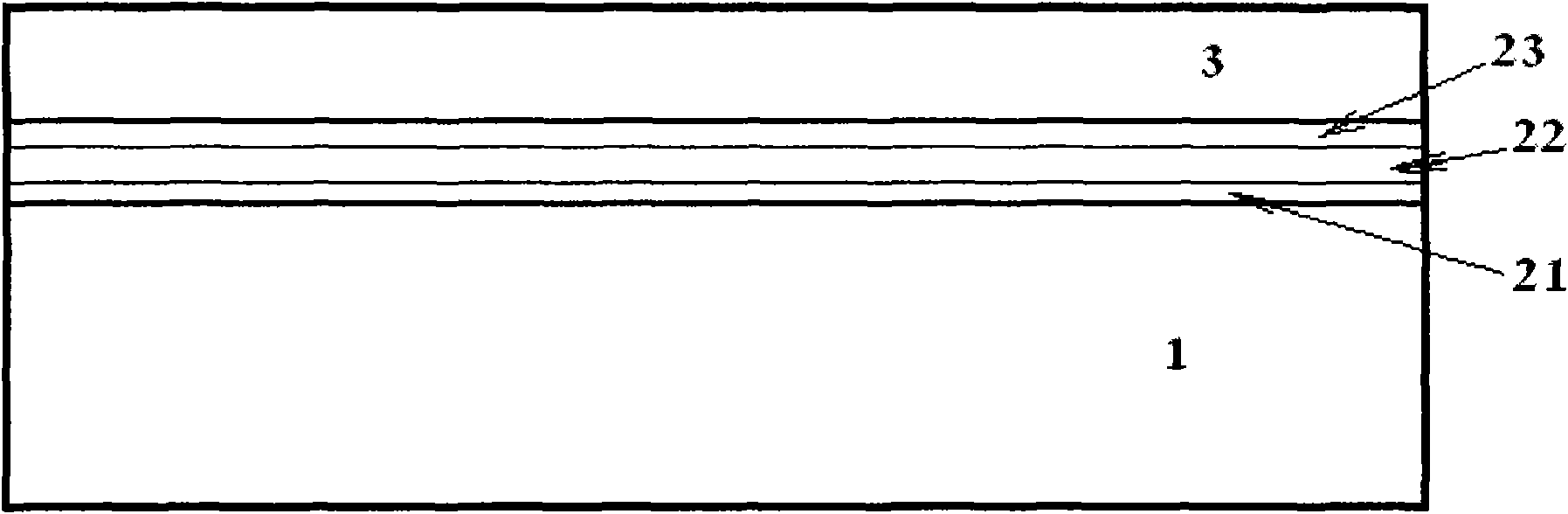

[0106] Embodiment 1: Preparation of thin-film solar cell substrate

[0107] The preparation of thin-film solar cell base tape is mainly through roll-to-roll continuous electroplating. The main steps are as follows:

[0108] The first step is to carry out continuous degreasing and water washing on the brass strip;

[0109] In the second step, the brass strip is continuously electroplated with nickel and washed with water;

[0110] The third step is to continuously electroplate copper on the nickel-plated brass strip and wash it with water;

[0111] The fourth step is to dry and coil the electroplated strip.

[0112] The thickness of the coating can be controlled by controlling the electroplating current and the time that the base tape stays in the electroplating tank by controlling the continuous tape speed to control the electroplating time, so as to achieve the purpose of controlling the thickness of the coating. For example, control the current density to 0.5A / cm 2 , T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com