High-strength vermicular cast iron and preparation method thereof

A technology of ductile vermicular cast iron, applied in the field of new high-strength ductile vermicular graphite cast iron and its preparation, can solve the problems that have not been found in literature reports, etc., and achieve the effects of easy control of vermicular treatment, good comprehensive performance of products, and simple operation of preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

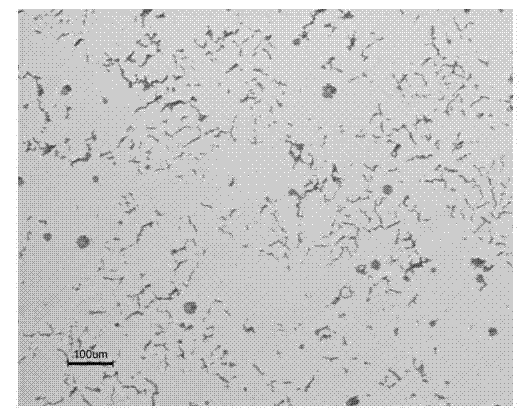

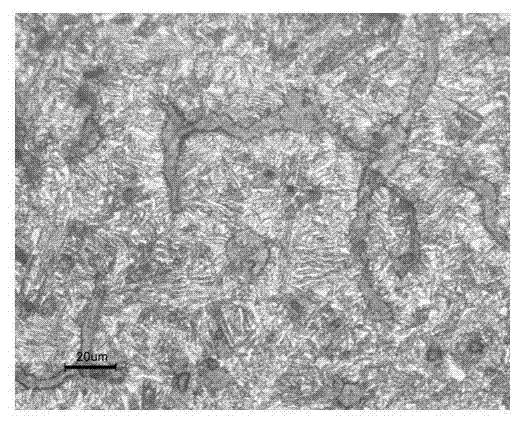

[0024] A high strength and toughness compacted graphite cast iron, its chemical composition is (weight percent): C: 3.6%, Si: 2.4%, Cu: 0.3%, Mo: 0.3%, Mn: 0.5%, Sn: 0.03%, Sb: 0.02 %, the rest is composed of iron and unavoidable impurities. In the vermicularization process, a commercially available rare earth-magnesium-silicon vermicular agent was used as the vermicular agent, the addition amount was 0.8%, the vermicularization temperature was 1475°C, and the vermicularization rate was 85%. Prepared into high strength and toughness compacted graphite iron castings. In the heat treatment process, the casting is kept at 930°C for 2 hours, placed in a salt solution at 350°C for 2 hours, and then air-cooled. The compacted graphite iron casting has excellent comprehensive performance and process formability. The matrix in its metallographic structure is composed of lower bainite and austenite, and the shape of graphite phase is worm-like, see figure 1 and figure 2 . The ...

Embodiment 2

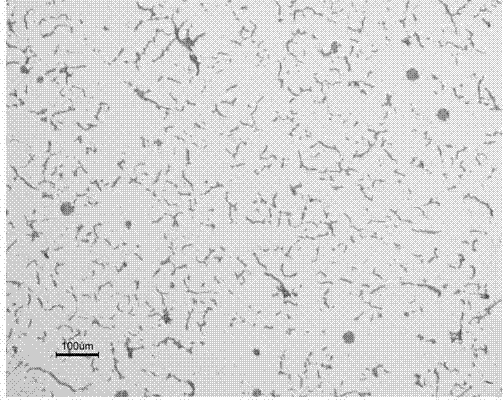

[0028] A high strength and toughness compacted graphite cast iron, its chemical composition is (weight percent): C: 3.8%, Si: 2.1%, Cu: 0.2%, Mo: 0.2%, Mn: 0.2%, Sn: 0.02%, Sb: 0.01 %, the rest is composed of iron and unavoidable impurities. The vermicular agent is a commercially available rare earth-magnesium-silicon vermicular agent, the addition amount is 0.5%, the vermicular temperature is 1450°C, and the vermicular rate is 90%. Prepared into high strength and toughness compacted graphite iron castings. The casting is kept at 900°C for 1.5 hours, put into 330°C salt solution for 1.5h, and then air-cooled to make austenitic and bainite vermicular graphite iron castings. The compacted graphite cast iron casting has excellent comprehensive performance and process formability. The tensile properties at different temperatures are shown in Table 1. The metallographic structure of the compacted graphite cast iron is shown in Table 1. image 3 .

[0029] Table 2

[0030] ...

Embodiment 3

[0032] A high-strength compacted graphite cast iron, its chemical composition is (weight percent): C: 3.6%, Si: 2.6%, Cu: 0.4%, Mo: 0.2%, Mn: 0.6%, Sn: 0.04%, Sb: 0.008 %, the rest is composed of iron and unavoidable impurities. The vermicular agent is a commercially available rare earth-magnesium-silicon vermicular agent, the addition amount is 0.6%, the vermicular temperature is 1500°C, and the vermicular rate is 90%. Prepared into high strength and toughness compacted graphite iron castings. The casting is kept at 950°C for 1.5 hours, put into 360°C salt solution for 3h, and then air-cooled to make austenitic and bainite vermicular graphite iron castings. The tensile properties at different temperatures are shown in Table 3,

[0033] table 3

[0034] temperature(℃) Tensile strength (Mpa) Elongation (%) room temperature 840 3.0 350 827 4.0 550 463 5.0

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com