Butanone preparation and refining method

A refining method and technology of methyl ethyl ketone, which is applied in the field of preparation and refining of methyl ethyl ketone, can solve problems such as product surplus, and achieve the effects of short process, high purity of raw materials, and uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

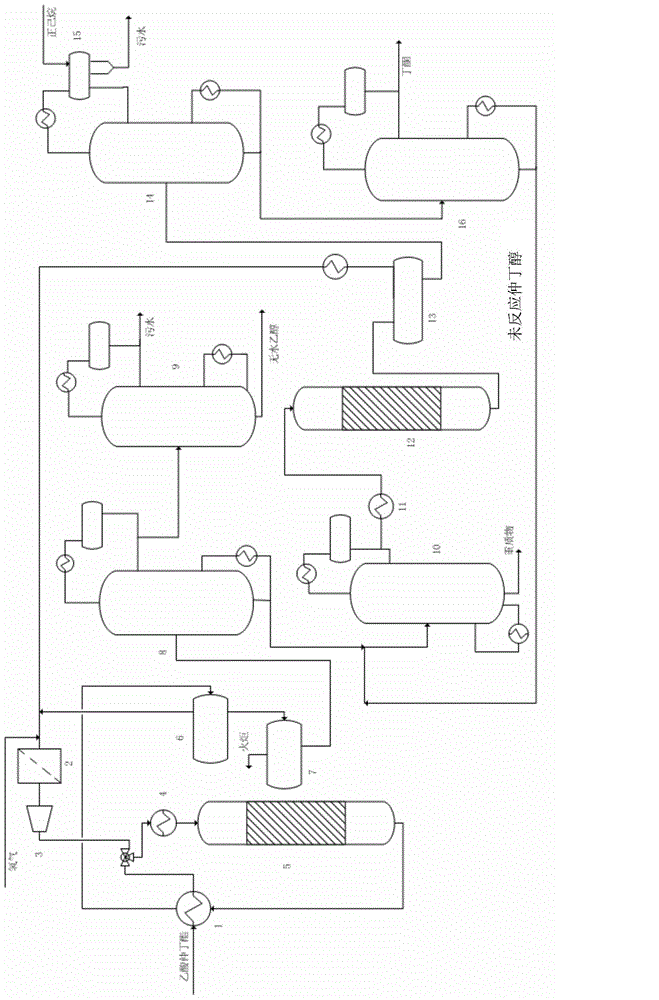

Method used

Image

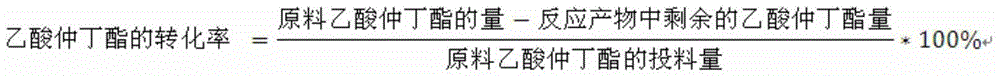

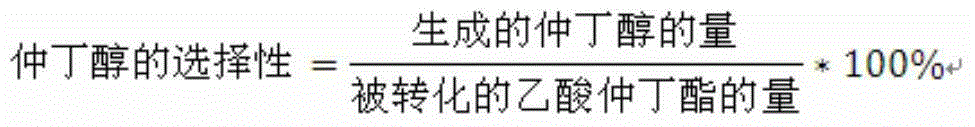

Examples

preparation example Construction

[0057] In the present invention, the hydrogenation catalyst is prepared according to conventional methods. For example, the preparation method of the copper-chromium catalyst may include: adopting the method of excessive impregnation, the excess carrier γ-Al 2 o 3 Add it to the mixed solution of copper nitrate and chromium nitrate prepared according to a certain atomic ratio, soak it at room temperature for 20 hours, filter out the excess solution, dry the filter residue in an oven at 120°C for 12 hours, and then roast it in a muffle furnace to obtain copper - Chromium catalyst. The carrier includes γ-Al 2 o 3 , BaO-γ-Al 2 o 3 , MgO-γ-Al 2 o 3 Wait. The Cu / Cr atomic ratio in the copper nitrate and chromium nitrate solution is 1-30, the calcination temperature is 300-600°C, and the calcination time is 3-9h.

[0058] In the present invention, the dehydrogenation copper-zinc catalyst is prepared according to conventional methods. For example, the preparation method of t...

Embodiment 1

[0068] This embodiment is used to illustrate the preparation method of butanone of the present invention.

[0069] (1) Preparation of hydrogenation catalyst

[0070] Prepared according to the Cu / Cr atomic ratio of 2.35. Take copper nitrate (Cu(NO 3 ) 2 3H2O) 70g and chromium nitrate (Cr(NO 3 ) 3 9H 2O) 50g were dissolved in water at 50°C respectively to form a mixed aqueous solution, weighed 12g of carrier γ-Al2O3 and added to the solution, maintained in an incubator at 25°C for 20h. Ordinary filtration was used to remove excess solution, and the filtrate was dried in an oven at 120°C for 12 hours, and then calcined in a muffle furnace for 5 hours at 500°C to obtain a copper-chromium catalyst. Then take 4 parts by weight of the copper-chromium catalyst and 1 part by weight of alumina particles and mix evenly.

[0071] (2) Preparation of sec-butanol

[0072] The hydrogenation reactor is a small stainless steel fixed bed reactor. The inner diameter of the reaction chamb...

Embodiment 2

[0082] This embodiment is used to illustrate the preparation method of butanone of the present invention. Butanone was prepared according to the method of Example 1, the difference being the preparation of the hydrogenation catalyst. The copper-nickel catalyst is formulated according to the Cu / Ni atomic ratio of 12, and the loading is preferably such that alumina accounts for 50% of the total weight of the catalyst.

[0083] It can be known by calculation that the conversion rate of sec-butanol is 97.2%, the selectivity of butanone is 97.8%, and the purity of product butanone is 99.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com