Preparation method of orientation LTL type molecular sieving membrane for gas separation

A gas separation and molecular sieve technology, applied in separation methods, semi-permeable membrane separation, dispersed particle separation, etc., can solve the problems of non-orientation of membrane, easy crystallographic orientation degree, narrow secondary growth and crystallization interval, etc. Easy-to-control, repeatable, and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a method for preparing an oriented LTL molecular sieve membrane for gas separation, the main steps of which include:

[0034] Carrier selection and pretreatment: The carrier material provides a surface for carrying seed crystals, which then grow to form a film. The carrier material is any material on which seeds can be deposited, and the surface area of the carrier material is 1 cm 2 ~400cm 2 . The thickness of the carrier may be any thickness as long as it provides the required strength without affecting its application. The shape of the carrier can be any geometric configuration, such as circular, square, and polygonal. Preferred supports coated with an orientation seed layer are metal sheets, dense substrates, porous substrates and oxide substrates which can be of any geometry. More preferred supports are stainless steel, quartz or graphite with smooth surfaces and porous inorganic porous materials or alloys. Preferred porous supports in...

Embodiment 1

[0049] (1) The molar ratio of the synthetic solution used for secondary growth is: 1.0Al 2 o 3 : 25SiO 2 : 10K 2 O: 800H 2 O. The preparation process of the secondary growth synthesis liquid is similar to the process of preparing the seed crystal synthesis gel. Only different raw materials were used in this step, which are listed in Table 1.

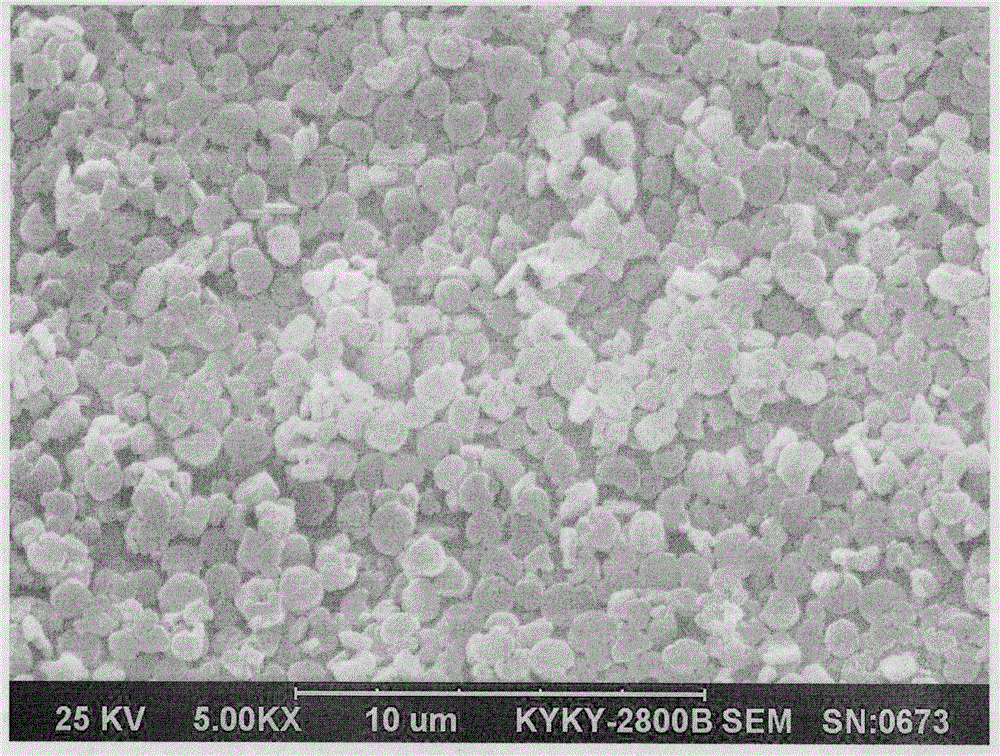

[0050] (2) Put the stainless steel carrier assembled with the c-axis orientation seed layer into the high-pressure synthesis kettle obliquely, pour the above-mentioned secondary growth synthesis liquid, and seal; crystallize at 180°C for 48h; cool, take out the carrier, wash and dry , the oriented LTL molecular sieve membrane was obtained on a stainless steel carrier, and the physical photo is as follows figure 2 shown. Its SEM photo and x-ray diffraction spectrum are as follows image 3 and Figure 4 As shown, it is proved that the obtained LTL-type molecular sieve membrane is continuous, dense and highly c-axis oriented.

Embodiment 2

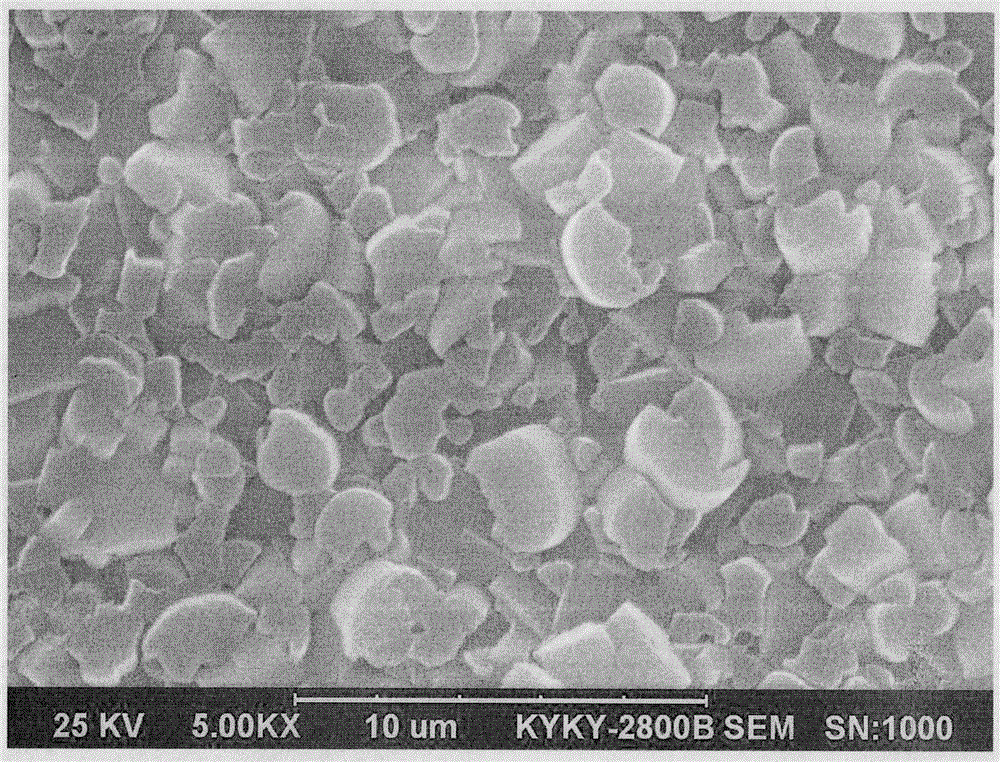

[0052] The operation is the same as in Example 1, and the molar ratio of the secondary synthesis solution becomes 1.0Al 2 o 3 : 25SiO 2 : 10K 2 O: 300H 2 O, the materials used are listed in Table 1. The SEM photo of the oriented LTL molecular sieve membrane obtained on the surface of the stainless steel carrier is as follows Figure 5 shown. It can be seen that the content of water in the synthetic solution has a significant effect on the growth of the film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com