Method for preparing SBA(sec-butyl alcohol) through hydrolysis with sec-butyl acetate

A technology of sec-butyl acetate and sec-butanol, which is applied in the fields of hydrolysis preparation, carboxylate/lactone preparation, oxygen-containing compound preparation, etc., can solve the problem that sec-butanol and sec-butyl acetate cannot be separated well, n-butyl Problems such as low conversion rate of olefin per pass and long process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

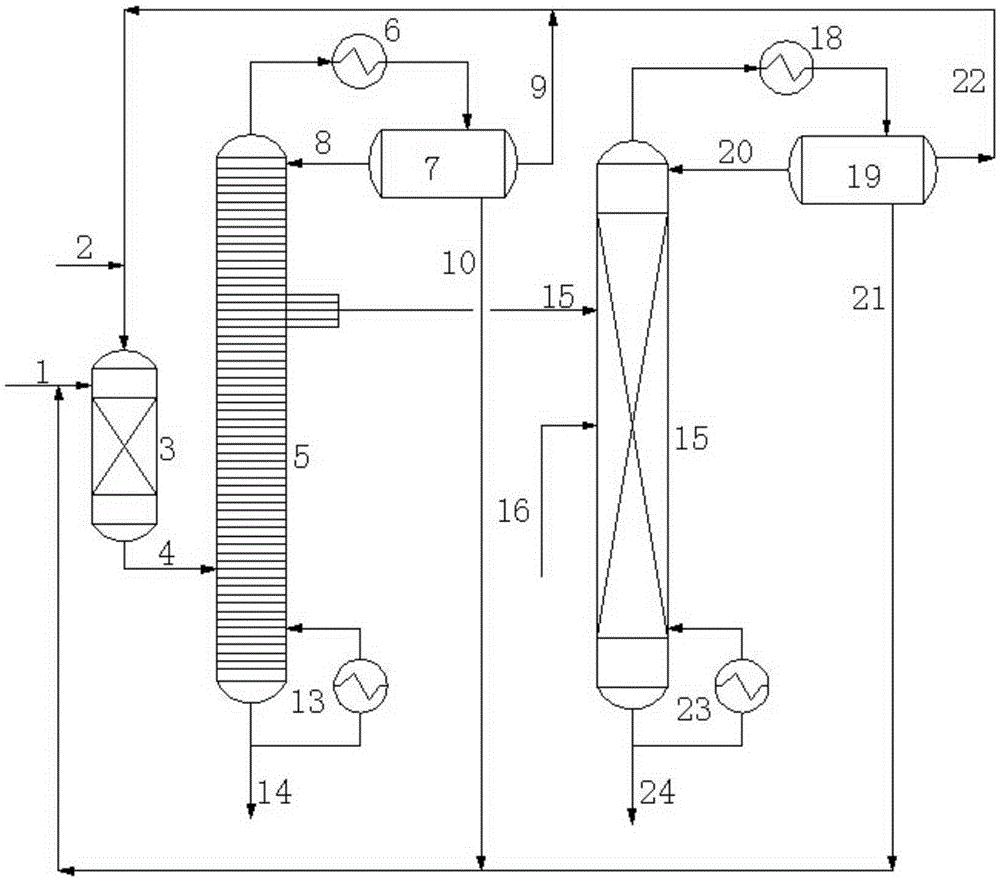

[0071] Such as figure 1 Described, the sec-butyl acetate raw material 2 is sent into the first hydrolysis reactor 3 with the speed of 30t / h, wherein, the sec-butyl acetate is a commercially available product purchased, and the industrial purity is 99.68%, and water 1 is added simultaneously, Among them, the molar ratio of water to sec-butyl acetate is 1.05:1, the temperature of the reactor is 60°C, and the reaction pressure is 1.0 MPa. The mixture 4 of sec-butanol, water and sec-butyl acetate obtained through hydrolysis reaction is 34.9 The speed of t / h is sent into the deacidification tower 5, the deacidification tower is a plate tower, the number of theoretical plates is 60, the feed port of the deacidification tower is arranged at the 35th tray, and the top of the deacidification tower is controlled The pressure is normal pressure, the temperature at the top of the tower is 90°C, and the reflux ratio is 2:1. In the deacidification tower, the separated acetic acid falls in...

Embodiment 2

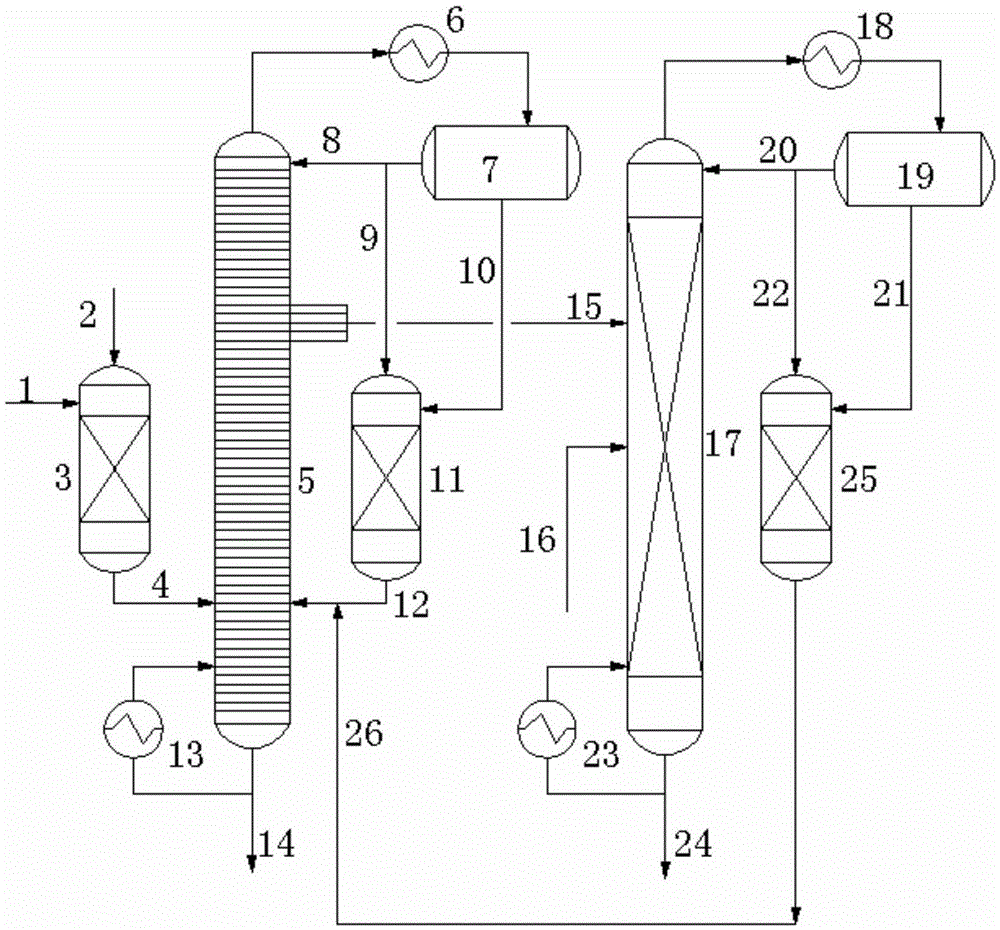

[0074] Such as figure 2 Described, the sec-butyl acetate raw material 2 is sent into the first hydrolysis reactor 3 with the speed of 30t / h, wherein, the sec-butyl acetate is a commercially available product purchased, and the industrial purity is 99.85%, and water 1 is added simultaneously, Among them, the molar ratio of water to sec-butyl acetate is 1.0:1, the temperature of the reactor is 70°C, and the reaction pressure is 0.6MPa. The mixture 4 of sec-butanol, water and sec-butyl acetate obtained through hydrolysis reaction is 34.7 The speed of t / h is sent into the deacidification tower 5, the deacidification tower is a plate tower, the number of theoretical plates is 40, the feed port of the deacidification tower is arranged at the 22nd tray, and the top of the deacidification tower is controlled The pressure is normal pressure, the temperature at the top of the tower is 60°C, and the reflux ratio is 10:1. In the deacidification tower, the separated acetic acid falls int...

Embodiment 3

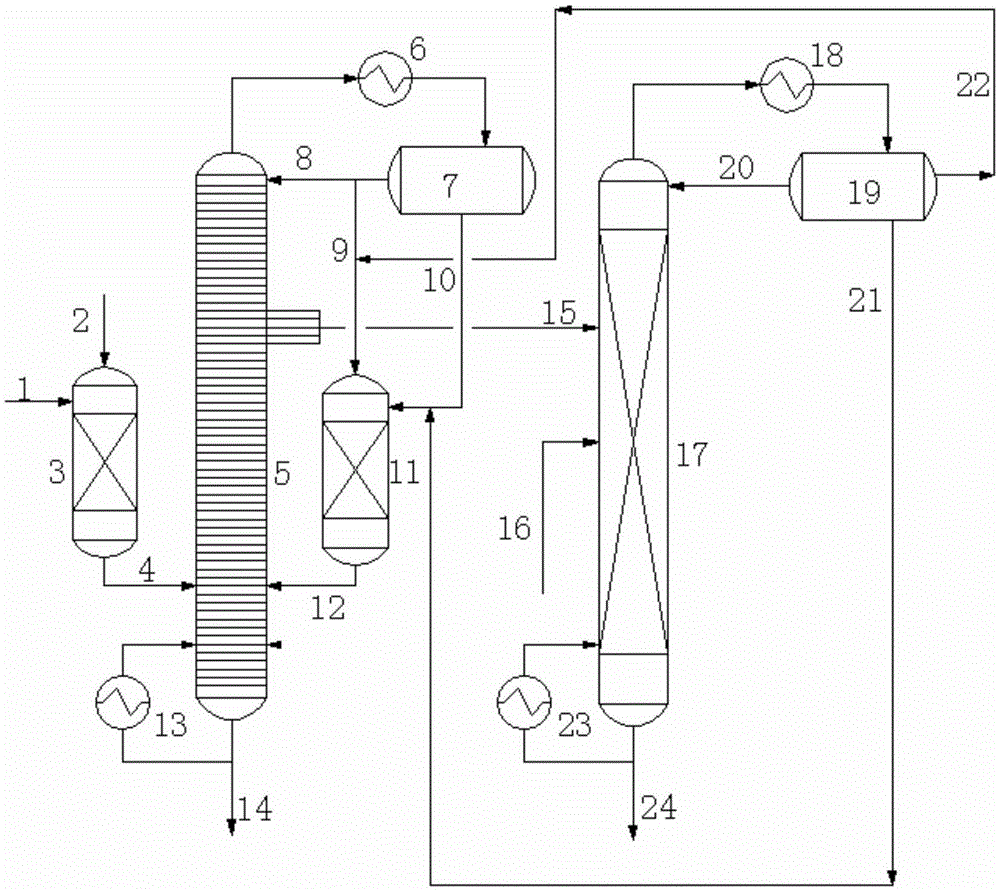

[0077] Such as image 3 Described, the sec-butyl acetate raw material 2 is sent into the first hydrolysis reactor 3 with the speed of 30t / h, wherein, sec-butyl acetate is a commercially available product purchased, and the industrial purity is 99.57%, and water 1 is added simultaneously, Among them, the molar ratio of water to sec-butyl acetate is 1.2:1, the temperature of the reactor is 80°C, and the reaction pressure is 0.6MPa. The mixture 4 of sec-butanol, water and sec-butyl acetate obtained through hydrolysis reaction is 35.6 The speed of t / h is sent into the deacidification tower 5, the deacidification tower is a plate tower, the number of theoretical plates is 50, the feed inlet of the deacidification tower is arranged at the 30th tray, and the top of the deacidification tower is controlled The pressure is normal pressure, the temperature at the top of the tower is 85°C, and the reflux ratio is 8:1. In the deacidification tower, the separated acetic acid falls into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com