Method for preparing temperature-resistant and corrosion-resistant aluminum oxide/organic silicon/silicon dioxide hybridized coating

A silicon dioxide, silicone technology, applied in the coating, the device for coating liquid on the surface, the surface pretreatment, etc., can solve the problems of brittleness, high temperature resistance, unsatisfactory aging resistance, high melting viscosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

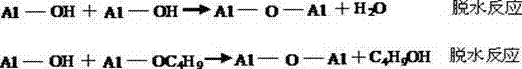

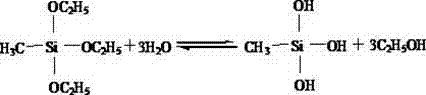

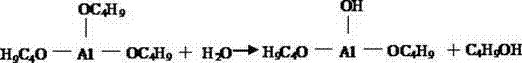

Method used

Image

Examples

Embodiment 1

[0037] Prepare according to the following proportions: ①Preparation of organosilicon / silica hybrid sol The molar ratio of each component is n (tetraethyl orthosilicate): n (methyltriethoxysilane): n (diphenyldiphenyl Methoxysilane)=1:0.3:0.3, n(absolute ethanol): n(distilled water): n(hydrochloric acid): n(total Si)=2.2:0.01:0.002:1, where n(total Si) Indicates the total number of moles of ethyl orthosilicate, methyltriethoxysilane, and diphenyldimethoxysilane added; ② when preparing aluminum sol and mixed hybrid sol, the molar ratio of each component is n (Aluminum sec-butoxide):n(absolute ethanol):n(distilled water):n(chelating agent):n(gelling agent):n(drying control chemical additive) =9:10:1:0.002:3: 5. The amount of modifier added is 40 mg per liter of aluminum sol.

[0038] According to the preparation method in claim 1, the alumina / organosilicon / silicon dioxide hybrid coating is obtained, and the alumina / organosilicon / silicon dioxide hybrid coating is obtained by baki...

Embodiment 2

[0041] Prepare according to the following proportions: ①Preparation of organosilicon / silica hybrid sol The molar ratio of each component is n (tetraethyl orthosilicate): n (methyltriethoxysilane): n (diphenyldiphenyl Methoxysilane)=7:8:2, n(absolute ethanol): n(distilled water): n(hydrochloric acid): n(total Si)=3:0.03:0.005:2, where n(total Si) Indicates the total number of moles of ethyl orthosilicate, methyltriethoxysilane, and diphenyldimethoxysilane added; ② when preparing aluminum sol and mixed hybrid sol, the molar ratio of each component is n (Aluminum sec-butoxide):n(absolute ethanol):n(distilled water):n(chelating agent):n(gelling agent):n(drying control chemical additive) =6:11:2:0.003:4: 3. The amount of modifier added is 50 mg per liter of aluminum sol.

[0042] According to the preparation method in claim 1, the alumina / organosilicon / silicon dioxide hybrid coating is obtained, and the alumina / organosilicon / silicon dioxide hybrid coating is obtained by baking and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com