Preparation method for high-purity alumina

A kind of alumina, high-purity technology, applied in the field of high-purity alumina preparation, can solve the problems of insufficient purity of alumina powder, easy blockage of pipelines, difficult transportation, etc., to reduce preparation costs, good working conditions, and preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

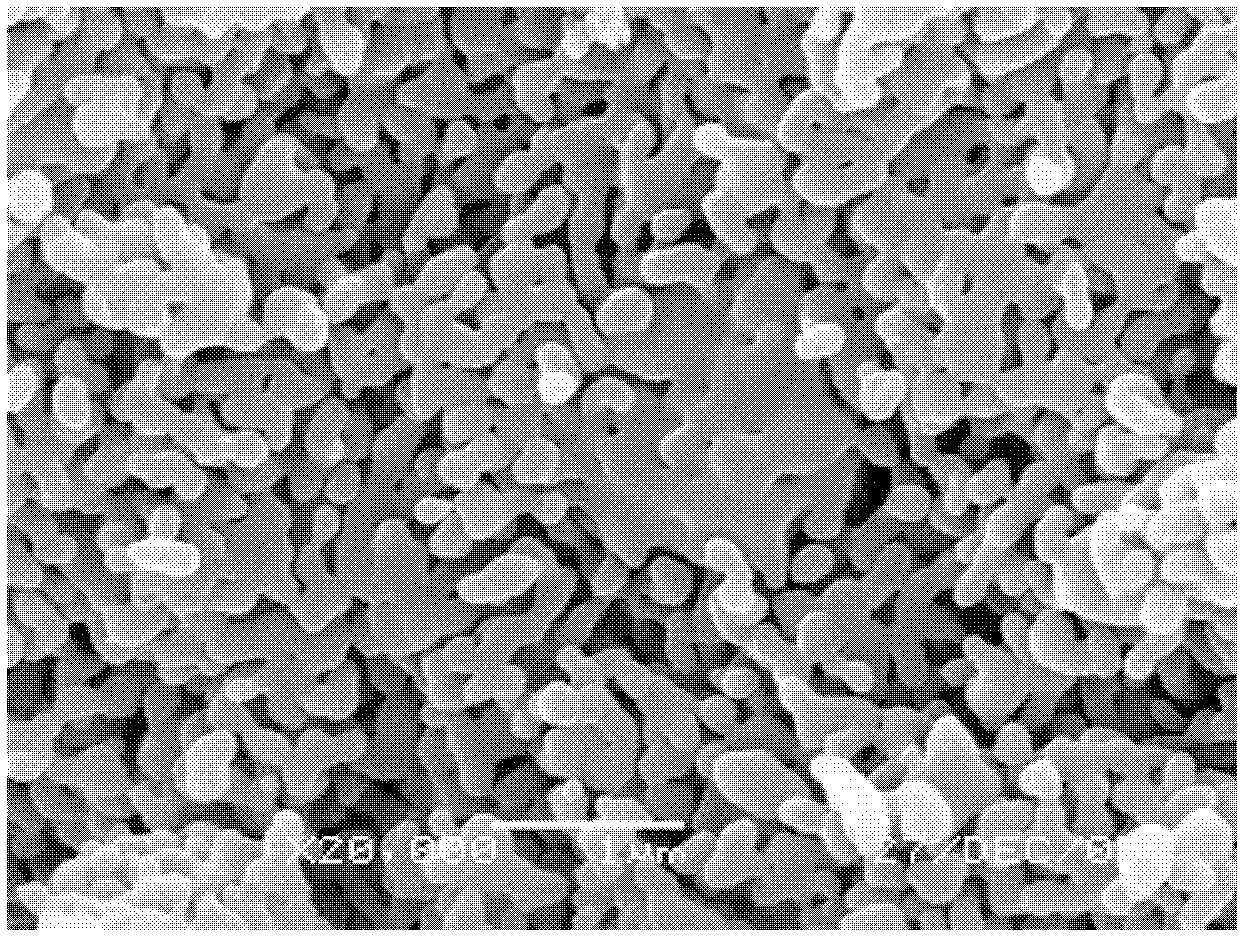

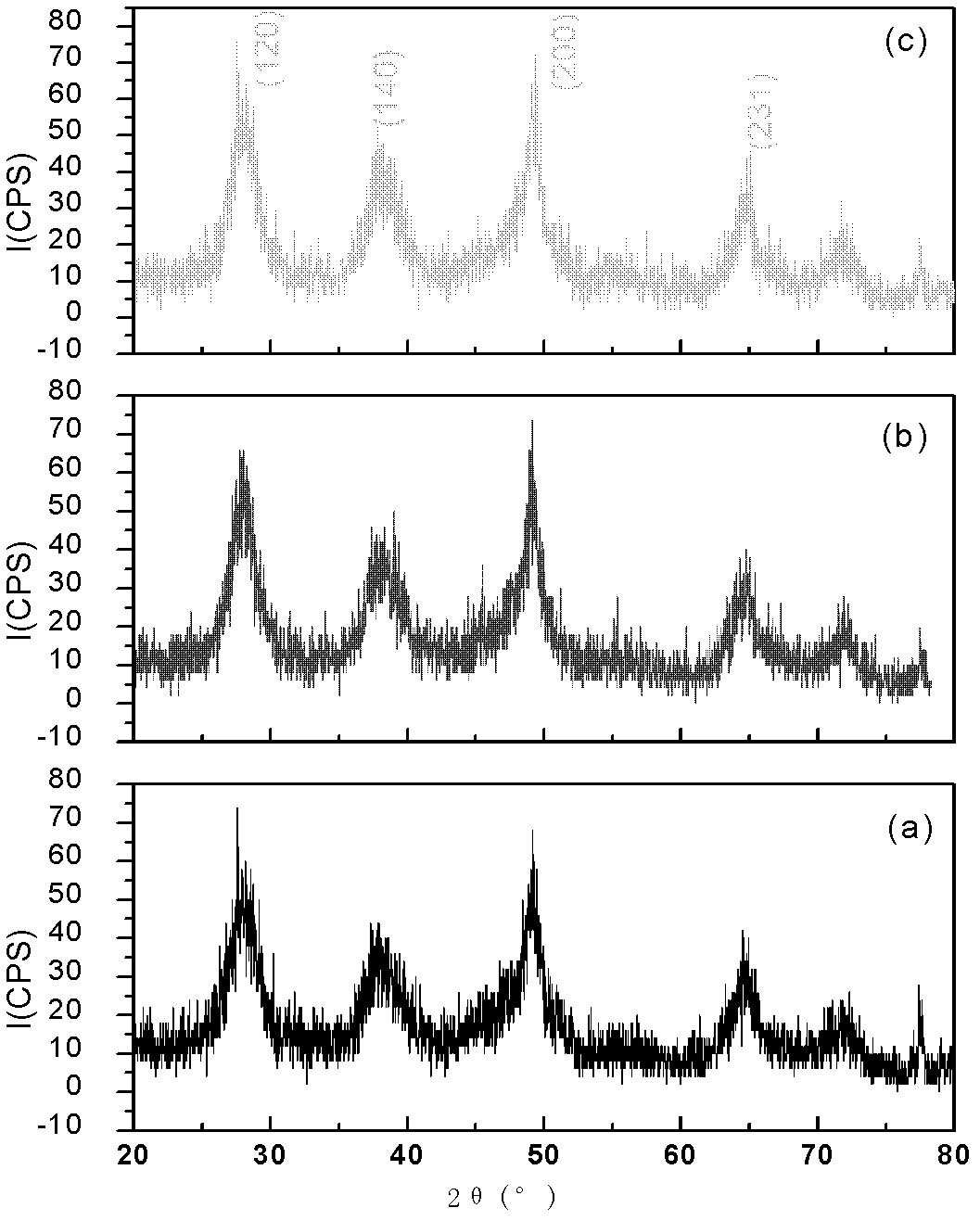

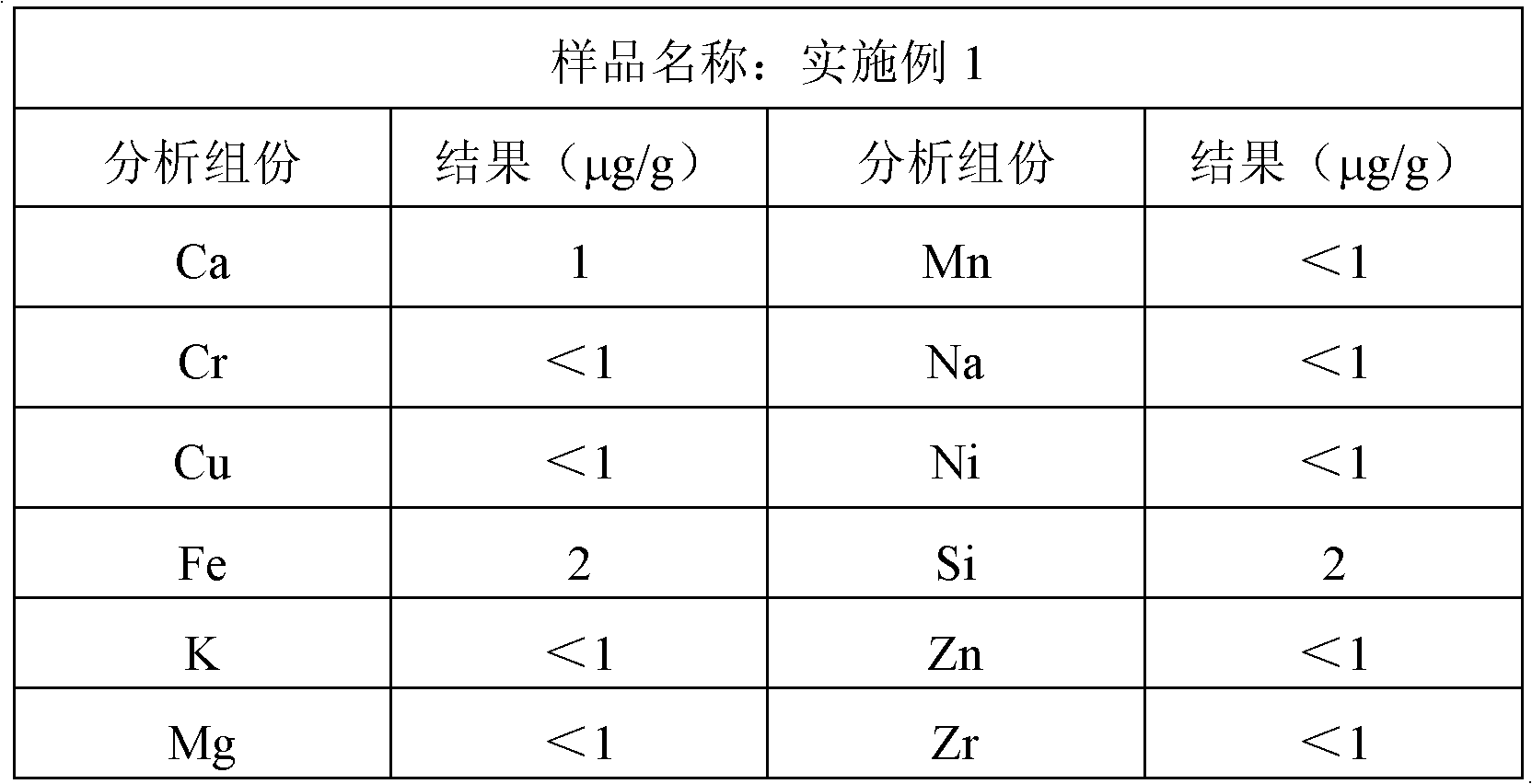

Embodiment 1

[0027] Take 0.5kg of metal aluminum with a purity of 99.996%, 4kg of sec-butanol, HgCl 2 Add 0.1g to the synthesis kettle, heat to 90°C under reflux conditions, react for 6h, and the reaction ends. The resulting mixed solution was filtered and pumped for vacuum distillation at 190° C. and 10 mmHg vacuum to obtain aluminum alkoxide in a liquid state at room temperature. Slowly add 6.67kg of sec-butanol with a water content of 15wt% to the aluminum alkoxide under stirring conditions at room temperature. The molar ratio of aluminum alkoxide to water is kept at 1:3. Distill under high pressure to distill off excess alcohol to obtain aluminum hydroxide powder. Calcined at 1200° C. for 3 hours to obtain alumina powder with a purity of 99.999%. Such as figure 2 As shown in a, each diffraction peak is the characteristic diffraction peak of alumina. The aluminum oxide powder was analyzed by atomic spectroscopy quantitative analysis technology, and the test results are shown in Tabl...

Embodiment 2

[0029] Get 0.75kg of metal aluminum with a purity of 99.996%, 4.5kg of sec-butanol, HgCl 2 Add 0.3g into the synthesis kettle, heat to 90°C under reflux conditions, react for 6h, and the reaction ends. The resulting mixed solution was filtered and pumped for vacuum distillation at 190° C. and 10 mmHg vacuum to obtain aluminum alkoxide in a liquid state at room temperature. Slowly add 13.33kg of sec-butanol with a water content of 15wt% into the aluminum alkoxide under stirring conditions at room temperature. The molar ratio of aluminum alkoxide to water is kept at 1:4. Distill under high pressure to distill off excess alcohol to obtain aluminum hydroxide powder. Calcined at 1200° C. for 3 hours to obtain alumina powder with a purity of 99.999%. Such as figure 2 As shown in b, each diffraction peak is a characteristic diffraction peak of alumina.

Embodiment 3

[0031] Take 1.25kg of metal aluminum with a purity of 99.996%, 3.75kg of sec-butanol, HgCl 2 Add 0.2g into the synthesis kettle, heat to 90°C under reflux conditions, react for 6h, and the reaction ends. The resulting mixed solution was filtered and pumped for vacuum distillation at 190° C. and 10 mmHg vacuum to obtain aluminum alkoxide in a liquid state at room temperature. At room temperature, 33.33 kg of sec-butanol with a water content of 15 wt% was slowly added to the aluminum alkoxide under stirring conditions, and the molar ratio of the aluminum alkoxide to water was kept at 1:6. Distill under high pressure to distill off excess alcohol to obtain aluminum hydroxide powder. Calcined at 1200° C. for 3 hours to obtain alumina powder with a purity of 99.999%. Such as figure 2 As shown in c, each diffraction peak is a characteristic diffraction peak of alumina.

[0032] Table 1

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com