Method for recovering dilute acetic acid by virtue of extraction-azeotropic distillation of sec-butyl acetate

A technology of sec-butyl acetate and azeotropic distillation, applied in the field of chemical production, can solve problems such as low separation efficiency, and achieve the effects of simple replacement process, strong water-carrying ability, and small loss of entrainer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

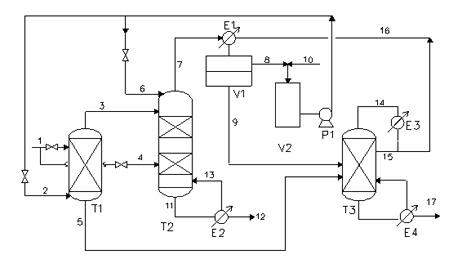

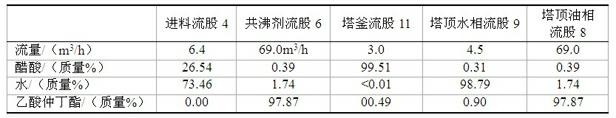

[0035] Such as figure 1 As shown, the flow rate sent to the top of the extraction tower through line 1 is 6m 3 / h, dilute acetic acid solution with acetic acid concentration of 26.54%, the flow rate sent from pipeline 2 to the bottom of the extraction tower is 17.5m 3 / h, the concentration is 97.87% sec-butyl acetate, after countercurrent extraction in the extraction tower T1, the flow rate of the extraction phase at the top of the tower is 1.851 m 3 / h, containing 9.077% acetic acid, the flow rate of the raffinate phase in the tower kettle is 4.008m 3 / h contains 0.7% acetic acid concentration. The extract phase (stream 3) from the top of the extraction tower is sent to the 25th theoretical plate of the azeotropic distillation column, and the raffinate phase (stream 5) from the bottom of the tower is sent to the solvent recovery tower T3 to recover the solvent therein. The flow rate of 69.0 m is added to the top of the azeotropic distillation column T2 through the pipeline...

Embodiment 2

[0037] Such as figure 1 As shown, the flow rate sent to the top of the extraction tower through line 1 is 6m 3 / h, the concentration of acetic acid is 10% dilute acetic acid solution, and the flow rate sent from pipeline 2 to the bottom of the extraction tower is 17.5m 3 / h, the concentration is 97.79% sec-butyl acetate, after countercurrent extraction in the extraction tower T1, the flow rate of the extraction phase at the top of the tower is 17.935 m 3 / h, containing 3.6% acetic acid, the flow rate of the raffinate phase in the tower kettle is 5.255m 3 / h contains 0.3% acetic acid concentration. The extract phase (stream 3) from the top of the extraction tower is sent to the 25th theoretical plate of the azeotropic distillation column, and the raffinate phase (stream 5) from the bottom of the tower is sent to the solvent recovery tower T3 to recover the solvent therein. Adding flow to the top of azeotropic distillation column T2 through line 6 is 31.5m 3 / h, the concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com