Preparation of sec-butyl acetate

A technology of sec-butyl acetate and acetic acid, which is applied in the field of preparation of sec-butyl acetate, can solve the problems of low product purity, low selectivity, easy deactivation of catalysts, etc., and achieves high separation efficiency, simple process, and reduced superposition. product effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

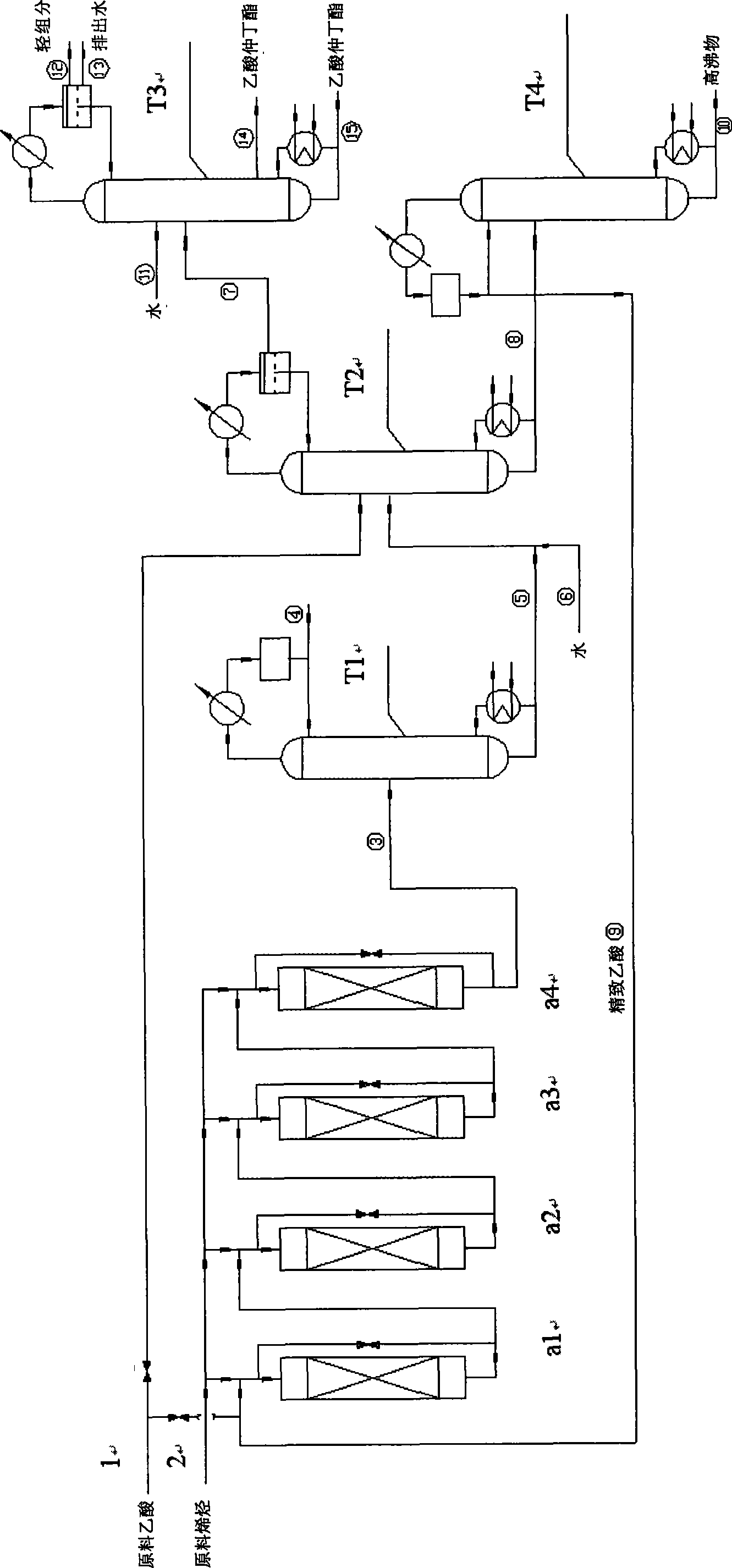

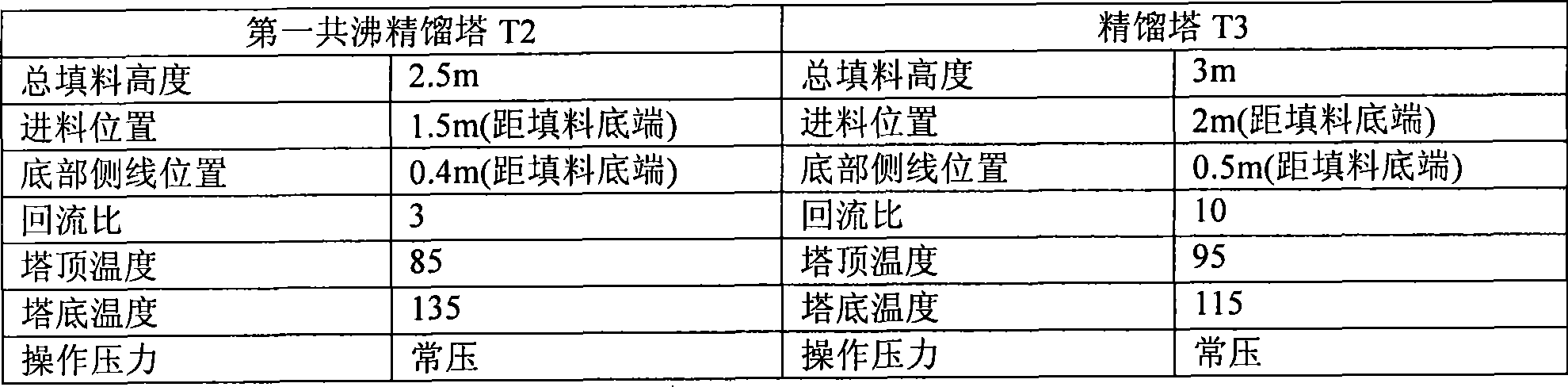

[0030] The preparation method of sec-butyl acetate provided by the invention can be carried out continuously or batchwise. When the preparation method of the sec-butyl acetate is performed batchwise, preferably, the C 4 The method that olefin is contacted with acetic acid several times comprises adding all said acetic acid in the reaction vessel once, and then adding C 4 Olefin was added to the reaction vessel in portions. When the preparation method of the sec-butyl acetate is carried out in a continuous manner, preferably, as figure 1 shown, the C 4 The method that olefins are contacted with acetic acid several times comprises that all acetic acid is directly passed into the first reactor according to the material flow direction of acetic acid, and the C 4 The olefins are divided into several strands and passed into the first reactor and a plurality of reactors connected in series with the first reactor, so that C 4 Alkenes are contacted and reacted with acetic acid in m...

Embodiment 1

[0103] This embodiment is used to illustrate the preparation method of sec-butyl acetate provided by the invention.

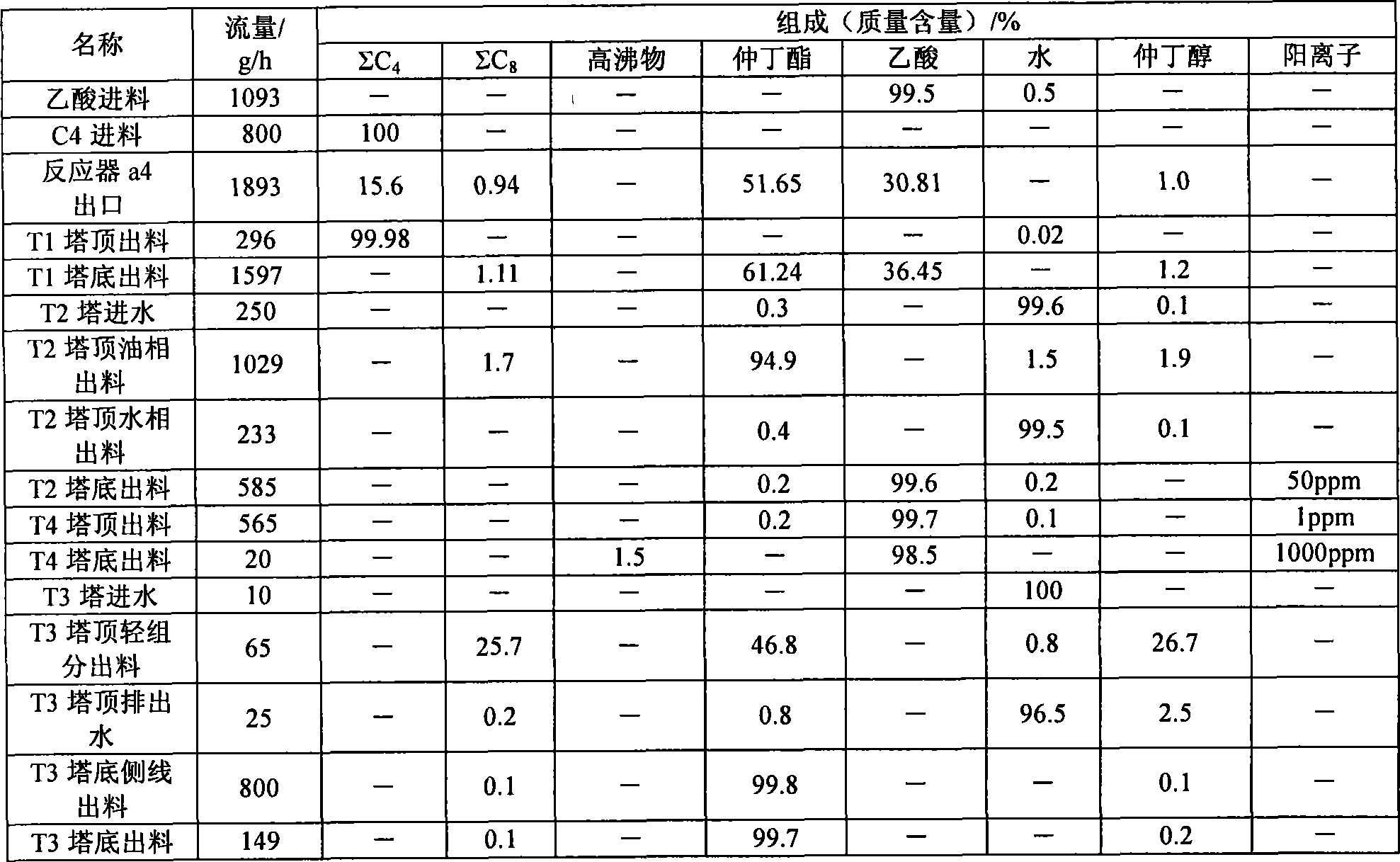

[0104] In four fixed-bed reactors, 100 grams of resin-assembled cesium phosphotungstic acid salt catalyst (prepared according to the method of Example 1 disclosed by CN1781598A, the assembled amount of cesium phosphotungstic acid cesium salt is 19.8% by weight) is loaded into each of the four fixed-bed reactors, and acetic acid is The speed of 1093 grams / hour is continuously passed in the first fixed-bed reactor a1, C 4 Olefin mixture (mass composition: n-butane 36.2%, trans-butene 39.5%, n-butene 4.2%, butene 20.1%) is divided into four strands at 240 g / h, 240 g / h, 160 g / h, The speed of 160 g / h enters in the first fixed bed reactor a1, the second fixed bed reactor a2, the third fixed bed reactor a3 and the fourth fixed bed reactor a4, C 4 The total feed rate of olefin mixture is 800 g / h, acetic acid and C 4 The total molar ratio of olefins is 2. Circulating...

Embodiment 2

[0127] This embodiment is used to illustrate the preparation method of sec-butyl acetate provided by the invention

[0128] 100 grams of strongly acidic ion-exchange resin catalysts (sulfonated styrene-divinylbenzene type resins, total exchange capacity of 5.0mmolH + / g, the bulk density is 700g / L, and the specific surface area is 40m 2 / g, average pore diameter 30nm, pore volume 0.4mL / g), acetic acid is passed in the first fixed-bed reactor a1 continuously with the speed of 893 grams / hour, C 4 Olefin mixture (mass composition: isobutane 38.5%, n-butane 9.4%, trans-butene 20.1%, n-butene 17.5%, isobutene 0.5%, butene 13.7%, butadiene 0.3%) divided into four strands respectively Enter the first fixed-bed reactor a1, the second fixed-bed reactor a2, the third fixed-bed reactor a3 and the fourth fixed bed reactor a4, C 4 The total feed rate of olefin mixture is 800 g / h, acetic acid and C 4The molar ratio of the total amount of the olefin mixture was 2. Circulating water with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com