Method for removing heavy hydrocarbon from reaction product of preparation of sec-butyl acetate

A technology of sec-butyl acetate and reaction product, which is applied in the field of removing heavy hydrocarbons in the reaction product of preparing sec-butyl acetate, can solve problems such as no method for removing heavy hydrocarbons, no mention, etc., to reduce energy consumption and material consumption , The effect of improving product quality and improving operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

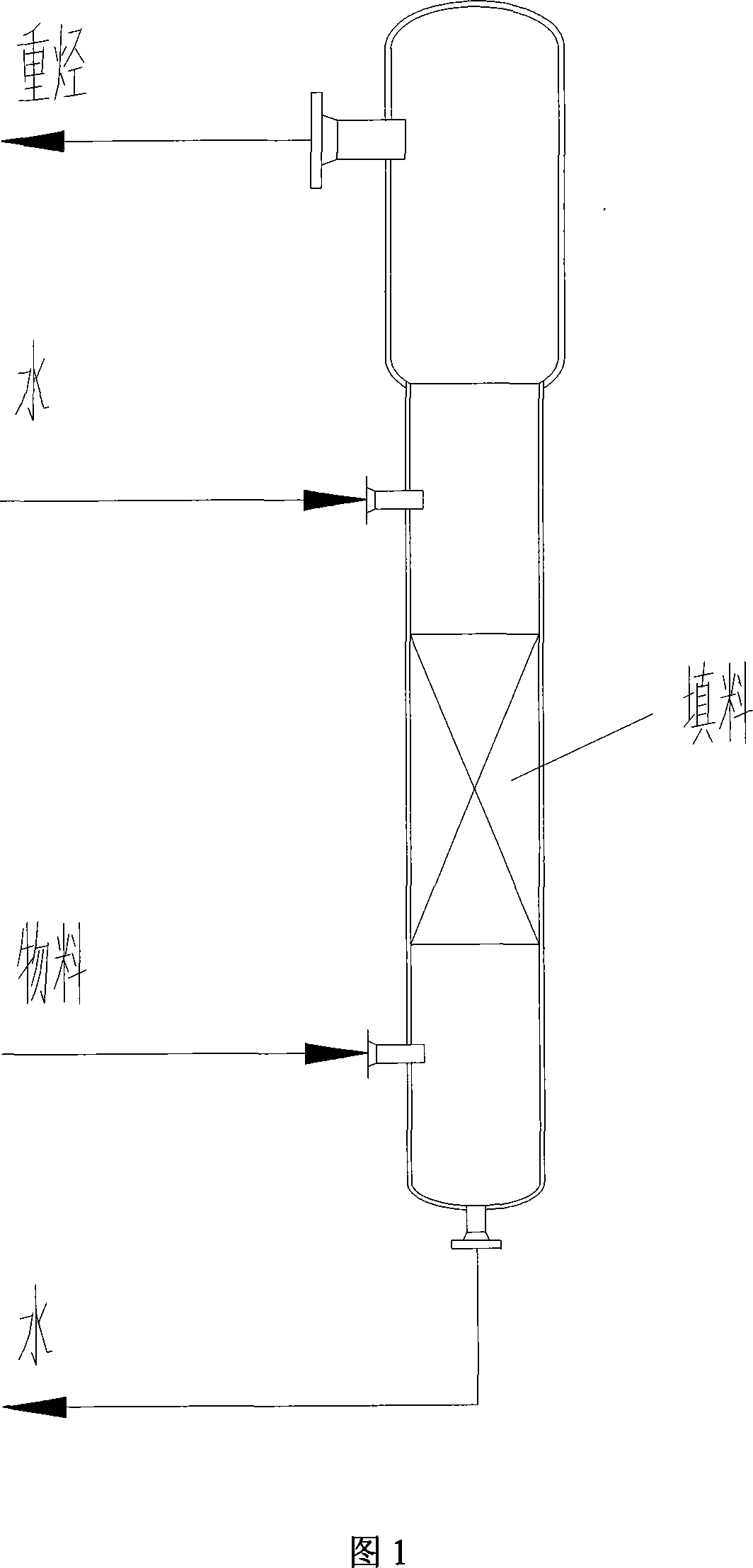

[0021] In the previous process, the reaction mixture is removed from unreacted C4 and light components, and then mixed with water, using water as an entrainer to azeotropically separate acetic acid and sec-butyl acetate, at the bottom of the azeotropic distillation column That is the heavy hydrocarbon enrichment area. Referring to Fig. 1, the material drawn from the bottom of the azeotropic rectification tower enters the lower part of the heavy hydrocarbon water washing tower, and the mass flow rate of the material is 100Kg / hr. Water is injected into the upper part of the heavy hydrocarbon water washing tower, and the water mass flow rate is 800Kg / hr (the ratio of the mass flow rate of water to the material mass flow rate is 8). After the reverse contact between water and materials, heavy hydrocarbons are discharged from the top of the heavy hydrocarbon washing tower, and water is pumped out from the bottom of the heavy hydrocarbon washing tower and reinjected into the system....

Embodiment 2

[0024] In the previous process, the reaction mixture is removed from unreacted C4 and light components, and then mixed with water, using water as an entrainer to azeotropically separate acetic acid and sec-butyl acetate, at the bottom of the azeotropic distillation column That is the heavy hydrocarbon enrichment area. Referring to Fig. 1, the material drawn from the bottom of the azeotropic rectification tower enters the lower part of the heavy hydrocarbon water washing tower, and the mass flow rate of the material is 100Kg / hr. Water is injected into the upper part of the heavy hydrocarbon water washing tower, and the water mass flow rate is 150Kg / hr (the ratio of the mass flow rate of water to the material mass flow rate is 1.5). After the reverse contact between water and materials, heavy hydrocarbons are discharged from the top of the heavy hydrocarbon washing tower, and water is pumped out from the bottom of the heavy hydrocarbon washing tower and reinjected into the syste...

Embodiment 3

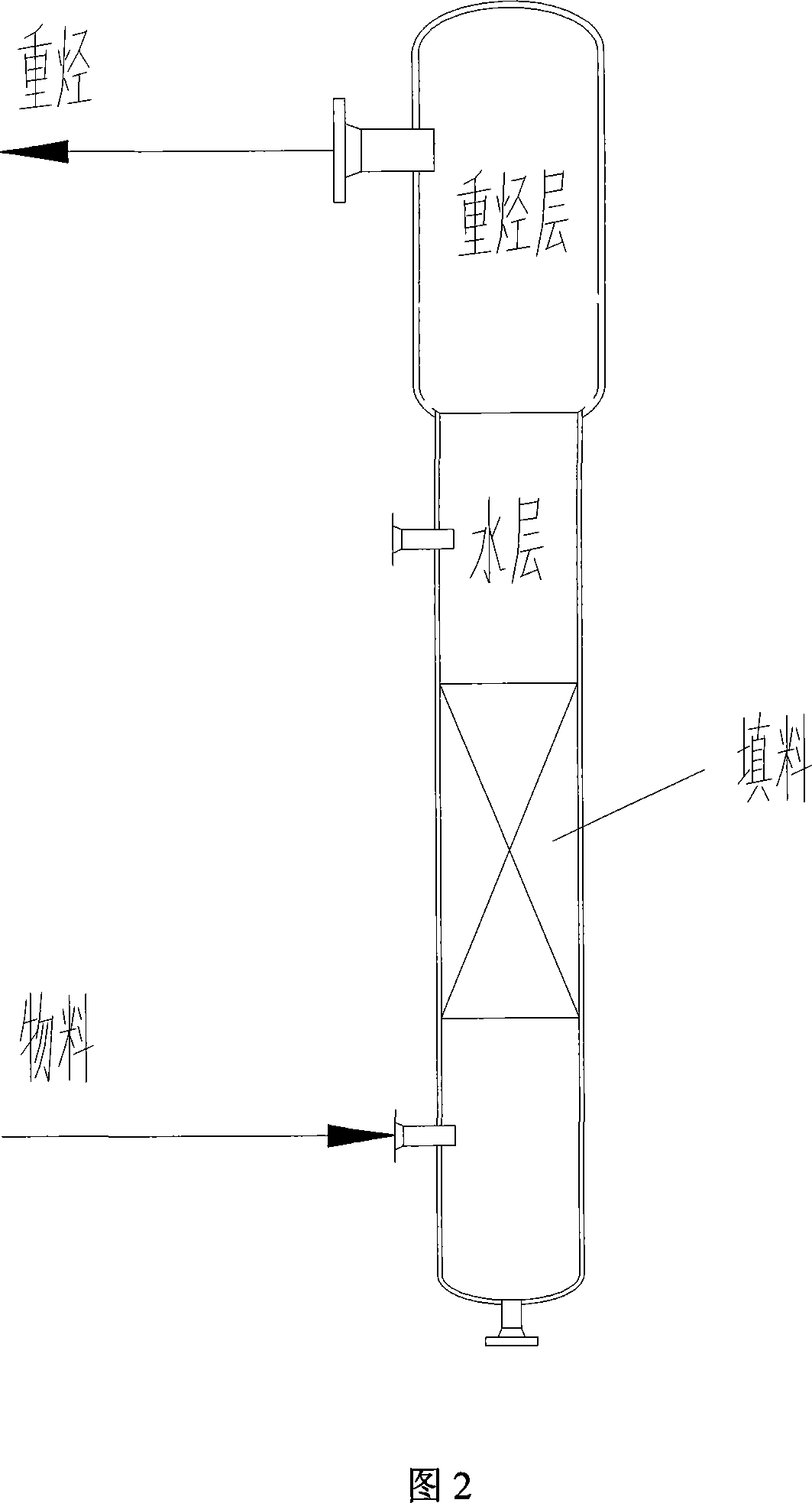

[0029] In the previous process, the reaction mixture is removed from unreacted C4 and light components, and then mixed with water, using water as an entrainer to azeotropically separate acetic acid and sec-butyl acetate, at the bottom of the azeotropic distillation column That is the heavy hydrocarbon enrichment area. Referring to Fig. 2, extracting material from the bottom of the azeotropic rectification tower enters the lower part of the heavy hydrocarbon washing tower that water is housed in the tower, and the material mass flow rate is 100Kg / hr; The material mass flow ratio is 0. When the material is poured into the tower, the heavy hydrocarbon will be discharged from the top of the heavy hydrocarbon washing tower after the water fully contacts with the material. When the acid content in the heavy hydrocarbon is greater than 0.5%, the water in the heavy hydrocarbon washing tower is injected into the system, and water is replenished to the heavy hydrocarbon washing tower. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com