Coating with protection and color alteration functions

A coating and functional technology, applied in the field of coatings with protection and color-changing functions, can solve the problems of difficult stripping, low coating adhesion, and leakage of the coating, and achieves the reduction of toluene toxicity and environmental damage, and excellent acid resistance. Alkali and weather resistance, the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1 Preparation coating

[0051]The formula is: thermoplastic styrene butadiene rubber A SBS792: 200 kg, thermoplastic styrene butadiene rubber B SEBS501: 100 kg, sec-butyl acetate 400 kg, 120# solvent oil 400 kg, xylene 400 kg, C9 petroleum resin 50 kg, antioxidant 8 kg, 8 kg of UV absorber, 7 kg of light stabilizer, 18 kg of fumed silica, and 5 kg of defoamer.

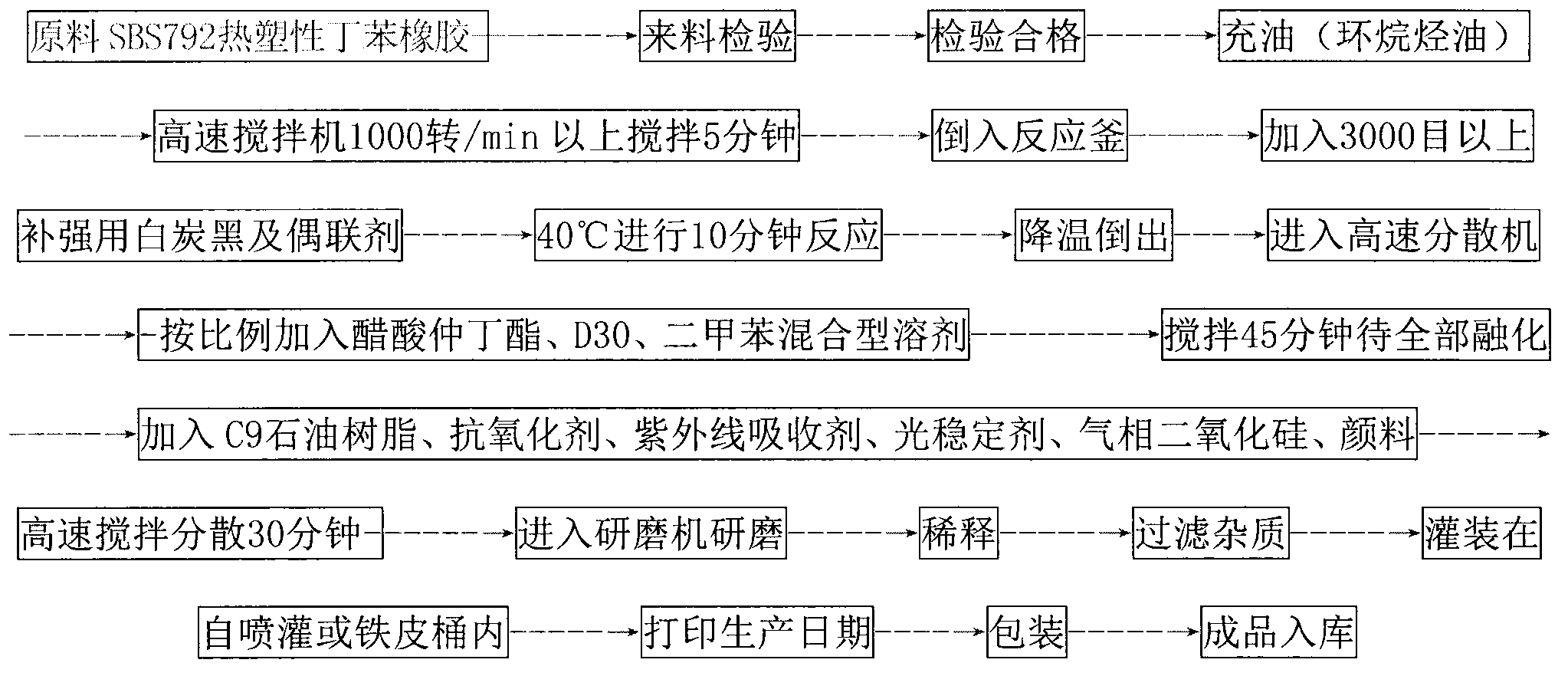

[0052] The preparation method is: (flow process such as figure 1 shown)

[0053] (1) Take thermoplastic styrene-butadiene rubber A SBS792, SEBS YH-501, add naphthenic oil, stir with a high-speed disperser at a speed ≥ 1000 rpm for 5 minutes, and then pour it into the reaction kettle;

[0054] (2) Add sec-butyl acetate, D30 solvent oil and xylene, and stir for 45 minutes at a speed ≥ 1000 rpm until completely dissolved;

[0055] (3) Add C9 petroleum resin, antioxidant, ultraviolet absorber, light stabilizer, fumed silica and defoamer, disperse for 30 minutes at a linear speed of 20m / s, enter the gri...

Embodiment 2

[0061] Embodiment 2 preparation coating

[0062] The formula is: thermoplastic styrene butadiene rubber A SBS792: 200 kg, thermoplastic styrene butadiene rubber B SEBS501: 100 kg, sec-butyl acetate 400 kg, 120# solvent oil 400 kg, xylene 400 kg, C9 petroleum resin 50 kg, antioxidant 8 kilograms, 8 kilograms of ultraviolet absorbers, 7 kilograms of light stabilizers, 18 kilograms of fumed silica, 5 kilograms of defoamers, 32 kilograms of pigments (the pigment color is black).

[0063] The preparation method is:

[0064] (1) Take thermoplastic styrene-butadiene rubber A SBS792, SEBS YH-501, add naphthenic oil, stir with a high-speed disperser at a speed ≥ 1000 rpm for 5 minutes, and then pour it into the reaction kettle;

[0065] (2) Add sec-butyl acetate, D30 solvent oil and xylene, and stir for 45 minutes at a speed ≥ 1000 rpm until completely dissolved;

[0066] (3) Add C9 petroleum resin, antioxidant, ultraviolet absorber, light stabilizer, fumed silica, defoamer and pigme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com