Preparation method for sec-butyl acetate with product separating technique

A sec-butyl acetate and process technology, which is applied in the field of preparation of sec-butyl acetate, can solve problems affecting product purification, increase energy consumption, flash tower temperature, high pressure, etc., and achieve product separation process simplification and production cost reduction , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Using strong acid ion exchange resin as catalyst, commercially available ZH-100 type. A total amount of 250 Kg of catalyst was charged into the reaction section of the catalytic distillation column, and thus a catalyst layer was obtained.

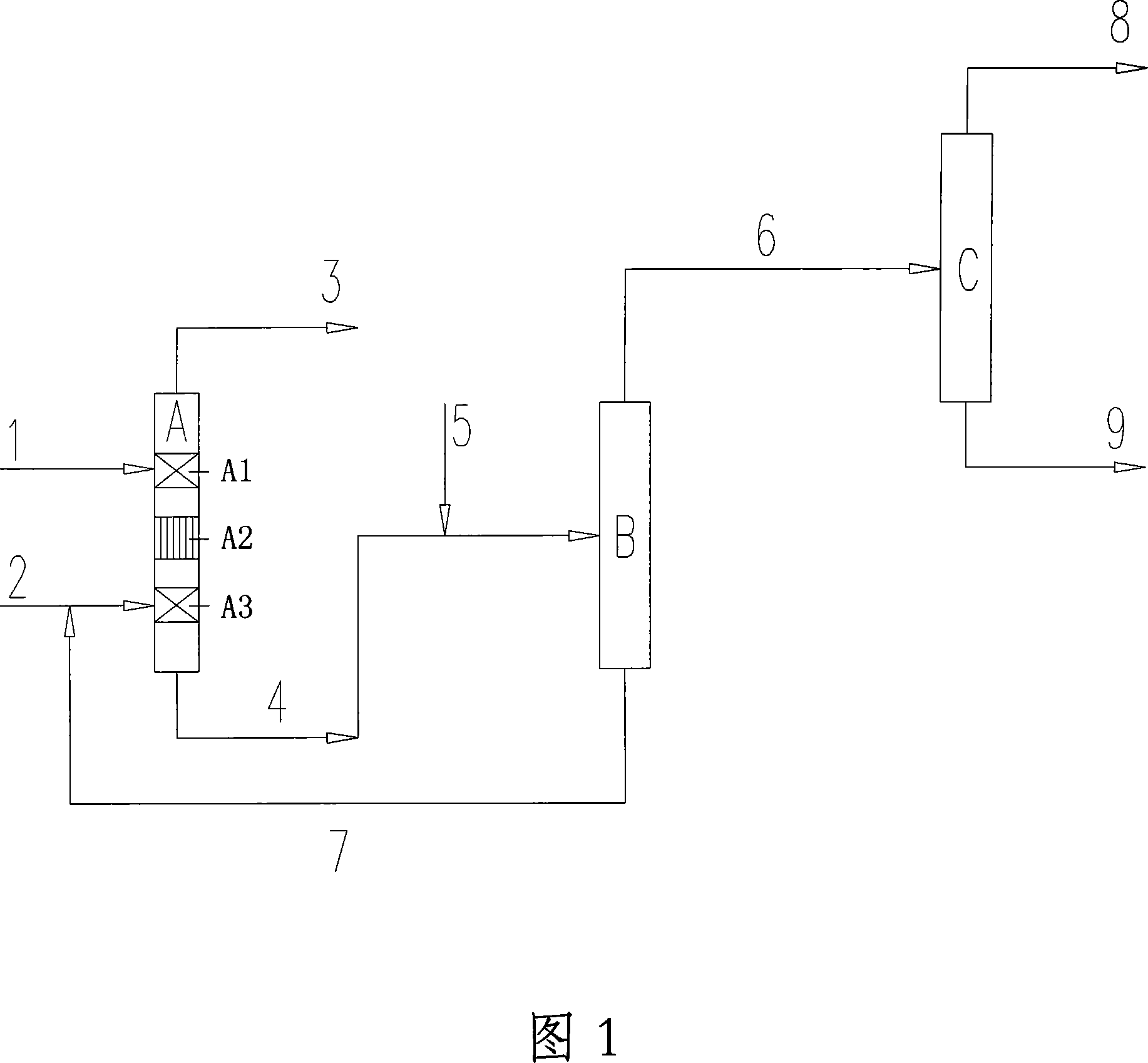

[0024] As shown in Figure 1, acetic acid 1, mixed C 4 2 respectively enter the tower from the upper rectifying section A1 and the lower stripping section A3 of the catalytic distillation column A, the two are in countercurrent contact on the catalyst surface of the reaction section A2, and the acetic acid 1 and the mixed C 4 2 The reaction generates sec-butyl acetate, and the unreacted mixed C 4 3 is distilled from the top of the column, and the product mixture 4 is discharged from the bottom of the column.

[0025]The operating conditions of catalytic distillation tower A are: tower top pressure 0.65MPa, tower top temperature 50 ℃, reaction section A2 middle temperature 100 ℃, tower kettle temperature 180 ℃, reflux ratio is 5, ...

Embodiment 2

[0031] As shown in Figure 1, strong acid ion exchange resin is used as catalyst, commercially available ZH-100 type. A total amount of 250 Kg of catalyst was charged into the reaction section of the catalytic distillation column, and thus a catalyst layer was obtained.

[0032] Acetic acid 1, mixed C 4 2 respectively enter the tower from the upper rectifying section A1 and the lower stripping section A3 of the catalytic distillation column, the two are in countercurrent contact on the catalyst surface of the reaction section A2, and the acetic acid 1 and the mixed C 4 2 The reaction generates sec-butyl acetate, and the unreacted mixed C 4 3 is distilled from the top of the column, and the product mixture 4 is discharged from the bottom of the column.

[0033] The operating conditions of catalytic distillation tower A are: tower top pressure 0.5 MPa, tower top temperature 55 ℃, reaction section A2 middle temperature 60 ℃, tower kettle temperature 160 ℃, reflux ratio is 0.5,...

Embodiment 3

[0039] As shown in Figure 1, strong acid ion exchange resin is used as catalyst, commercially available ZH-100 type. A total amount of 250 Kg of catalyst was charged into the reaction section of the catalytic distillation column, and thus a catalyst layer was obtained.

[0040] Acetic acid 1, mixed C 4 2 respectively enter the tower from the upper rectifying section A1 and the lower stripping section A3 of the catalytic distillation column A, the two are in countercurrent contact on the catalyst surface of the reaction section A2, and the acetic acid 1 and the mixed C 4 2 The reaction generates sec-butyl acetate, and the unreacted mixed C 4 3 is distilled from the top of the column, and the product mixture 4 is discharged from the bottom of the column.

[0041] The operating conditions of catalytic distillation tower A are: tower top pressure 0.35 MPa, tower top temperature 65 ℃, reaction section A2 middle temperature 110 ℃, tower kettle temperature 185 ℃, reflux ratio is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com