Method for refining sec-butyl acetate coarse products through dual-reflux and preparation method of sec-butyl acetate

A technology for sec-butyl acetate and crude products, which is applied in the field of preparation of sec-butyl acetate, can solve problems such as insufficient material exchange, improper operation, and unguaranteed purity of sec-butyl acetate, and achieve sufficient material transfer and improved The effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

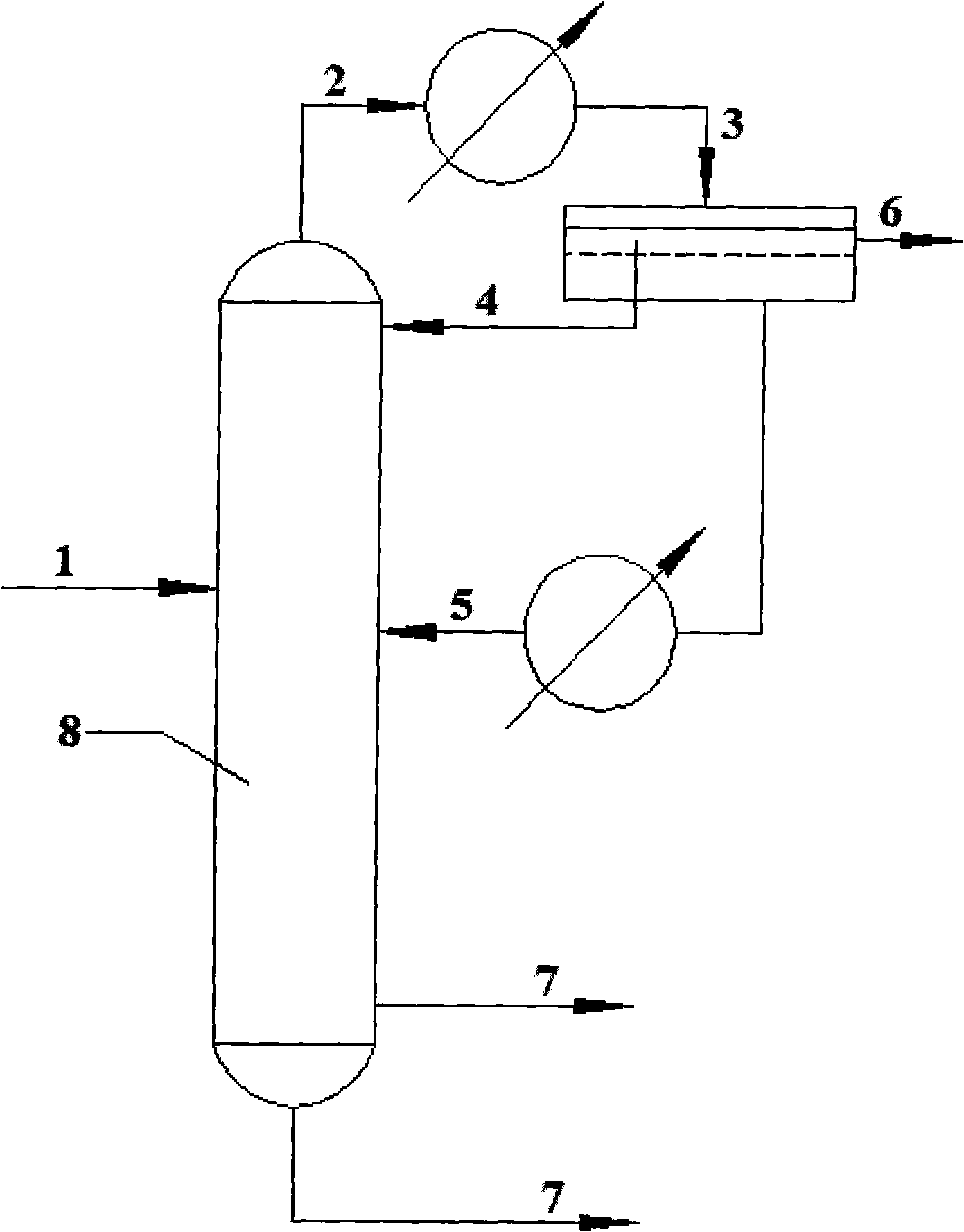

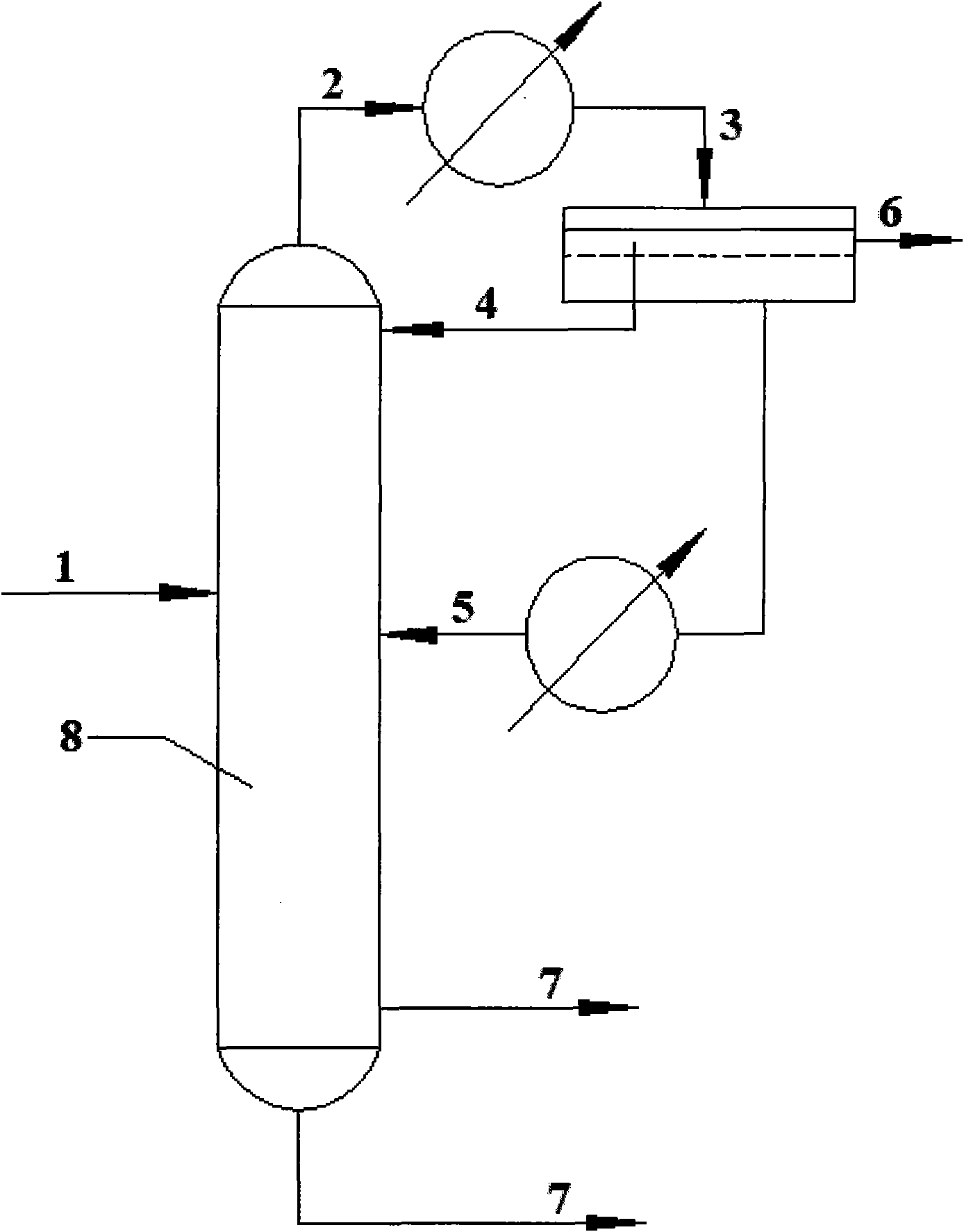

Image

Examples

preparation example Construction

[0042] According to another aspect of the present invention, the present invention also provides a kind of preparation method of sec-butyl acetate, the method comprises the following steps:

[0043] (1) In the presence of a catalyst and under addition reaction conditions, make C 4 Contact reaction of alkenes with acetic acid;

[0044] (2) separate unreacted C from the reaction product obtained in step (1) 4 Olefins, obtained containing sec-butyl acetate, C 5 A mixture of the above hydrocarbons and unreacted acetic acid;

[0045] (3) by azeotropic distillation from said containing sec-butyl acetate, C 5 Separate acetic acid in the mixture of above hydrocarbon and unreacted acetic acid, obtain sec-butyl acetate crude product;

[0046] (4) According to the method for refining sec-butyl acetate by double reflux provided by the invention, refine sec-butyl acetate from the crude product of sec-butyl acetate.

[0047] According to the preparation method of the sec-butyl acetate ...

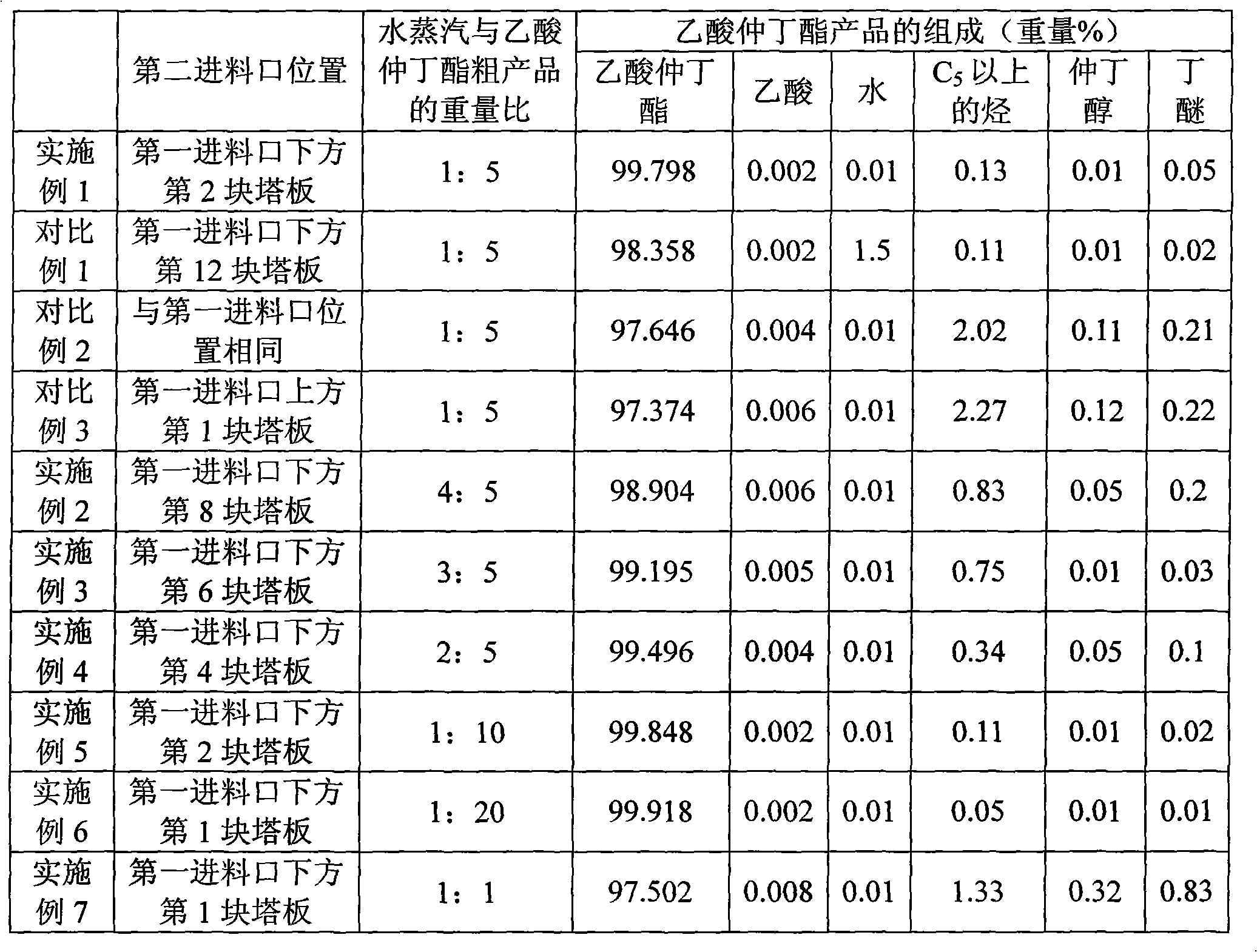

Embodiment 1

[0055] This embodiment is used to illustrate the method for refining the crude product of sec-butyl acetate by double reflux and the preparation method of sec-butyl acetate provided by the present invention.

[0056] (1) Preparation of sec-butyl acetate crude product

[0057] With 100 grams of strongly acidic ion exchange resin catalyst (sulfonated styrene-divinylbenzene type resin, specific surface area 30m 2 / g, average particle diameter is 1.0mm, pore volume 0.25mL / g) is loaded in the fixed-bed reactor (φ 32 * 4 * 1000mm), acetic acid is passed in the fixed-bed reactor continuously with the speed of 1000 grams / hour, Will C 4 Olefin mixture (mass composition: n-butane 36.2%, trans-butene 39.5%, n-butene 4.2%, cis-butene 20.1%) was continuously fed into the fixed-bed reactor at a speed of 800 g / hour. Circulating water with a temperature of 80° C. was passed into the jacket of the reactor to control the reaction temperature, and the gauge pressure of the system was controlle...

Embodiment 2

[0080] This embodiment is used to illustrate the method for refining the crude product of sec-butyl acetate by double reflux and the preparation method of sec-butyl acetate provided by the present invention.

[0081] (1) Preparation of sec-butyl acetate crude product

[0082] With 100 grams of strongly acidic ion exchange resin catalyst (sulfonated styrene-divinylbenzene type resin, specific surface area 30m 2 / g, average particle diameter is 1.0mm, pore volume 0.25mL / g) is loaded in the fixed-bed reactor (φ 32 * 4 * 1000mm), acetic acid is passed in the fixed-bed reactor continuously with the speed of 900 grams / hour, Will C 4Olefin mixture (mass composition: isobutane 39.0%, n-butane 9.7%, trans-butene 20.1%, n-butene 17.5%, butene 13.7%) is continuously fed into the fixed-bed reactor at a speed of 800 g / hour middle. Circulating water with a temperature of 80° C. was passed into the jacket of the reactor to control the reaction temperature, and the gauge pressure of the sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com