Production process of high-purity abamectin fine powder

A technology of abamectin and production process, which is applied to the preparation of sugar derivatives, sugar derivatives, and sugar derivatives, etc., can solve the problems of high production cost, many times of recrystallization of refined powder, large consumption of ethanol, etc. Good social and economic benefits, improve product quality, and reduce solvent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

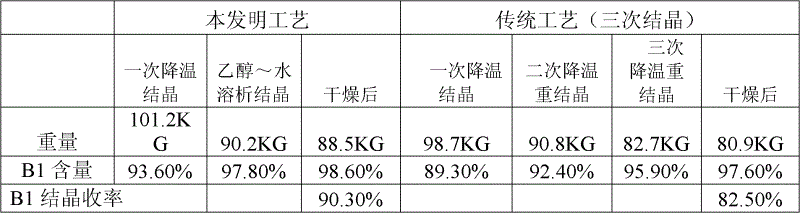

Examples

Embodiment 1

[0051] A, get 1000 kilograms of water content in 18% abamectin fermented liquid dry mycelium, add 4000 kilograms (4 tons) of sec-butyl acetate at every turn by mass ratio 1: 4 and carry out three extractions, merge three extractions Liquid (12000 kilograms) 12 tons of sec-butyl acetate extracts; This step replaces the technique that adopts ethanol solution to extract dry mycelia in the traditional process with sec-butyl acetate, and solvent consumption is few, extraction rate is high;

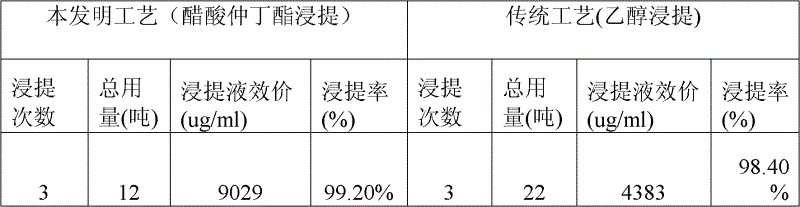

[0052] The comparative effect is shown in Table 1

[0053]

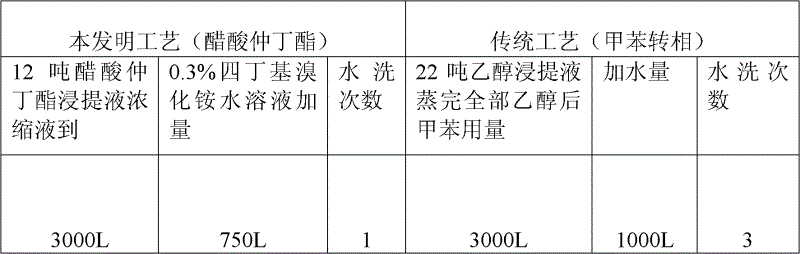

[0054] B. After heating and concentrating the extraction solution in step A to 3000 liters, add 750 liters of 0.3% tetrabutylammonium bromide aqueous solution for 1 washing and layering;

[0055] The specific comparison results are shown in Table 2. The operation steps are simplified to provide a guarantee for improving the yield. Tetrabutylammonium bromide can be washed once to remove more impurities;

[0056] Table 2

[0057] ...

Embodiment 2

[0067] A, get 1000 kilograms of water content in 18% abamectin fermented liquid dry mycelium, be by mass ratio: 1: 5, add 5 tons of sec-butyl acetate at every turn and carry out three extractions, merge three extractions (15000 kilograms) 15 tons of 2-butyl acetate extracts; This step replaces ethanol solution leaching dry mycelia solvent consumption in the traditional technique with 2-butyl acetate, and the leaching rate is high,

[0068] The comparative effect is shown in Table 4

[0069]

[0070] B. After heating and concentrating the extract in step A to 3000 liters, add 750 liters of 0.4% tetrabutylammonium bromide aqueous solution for 1 washing and layering; see Table 5 for specific comparative effects, and the operation steps are simplified to improve the yield Guarantee that more impurities can be removed by washing with tetrabutylammonium bromide once;

[0071] The results are shown in Table 5 below

[0072] table 5

[0073]

[0074] C. Distill out all the se...

Embodiment 3

[0081] A, get 1000 kilograms of water content in 18% abamectin fermented liquid dry mycelia, be by mass ratio: 1: 3 add 3000 kilograms of sec-butyl acetate (3 tons) at every turn and carry out three extractions, merge three times 9000 kg (9 tons) of sec-butyl acetate extract of the extract;

[0082] This step replaces the ethanol solution in the traditional process with sec-butyl acetate to extract the dry mycelium with less solvent consumption and high extraction rate.

[0083] The comparative effect is shown in Table 7

[0084]

[0085] B. After heating and concentrating the extraction solution in step A to 3000 liters, add 750 liters of 0.6% tetrabutylammonium bromide aqueous solution for 1 washing and layering;

[0086] The specific comparison results are shown in Table 8. The operation steps are simplified to provide a guarantee for improving the yield. Tetrabutylammonium bromide can be washed once with water to remove more impurities.

[0087] Table 8

[0088]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com