Method for separating sec-butyl acetate from mixture after reaction of acetic acid and butylene or mixture of C4

A kind of sec-butyl acetate and the technology after the reaction are applied in the field of separating sec-butyl acetate, which can solve the problems of increasing equipment investment, operating energy consumption, and increasing equipment corrosion, so as to reduce equipment investment and operating costs, reduce corrosion, and prolong use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

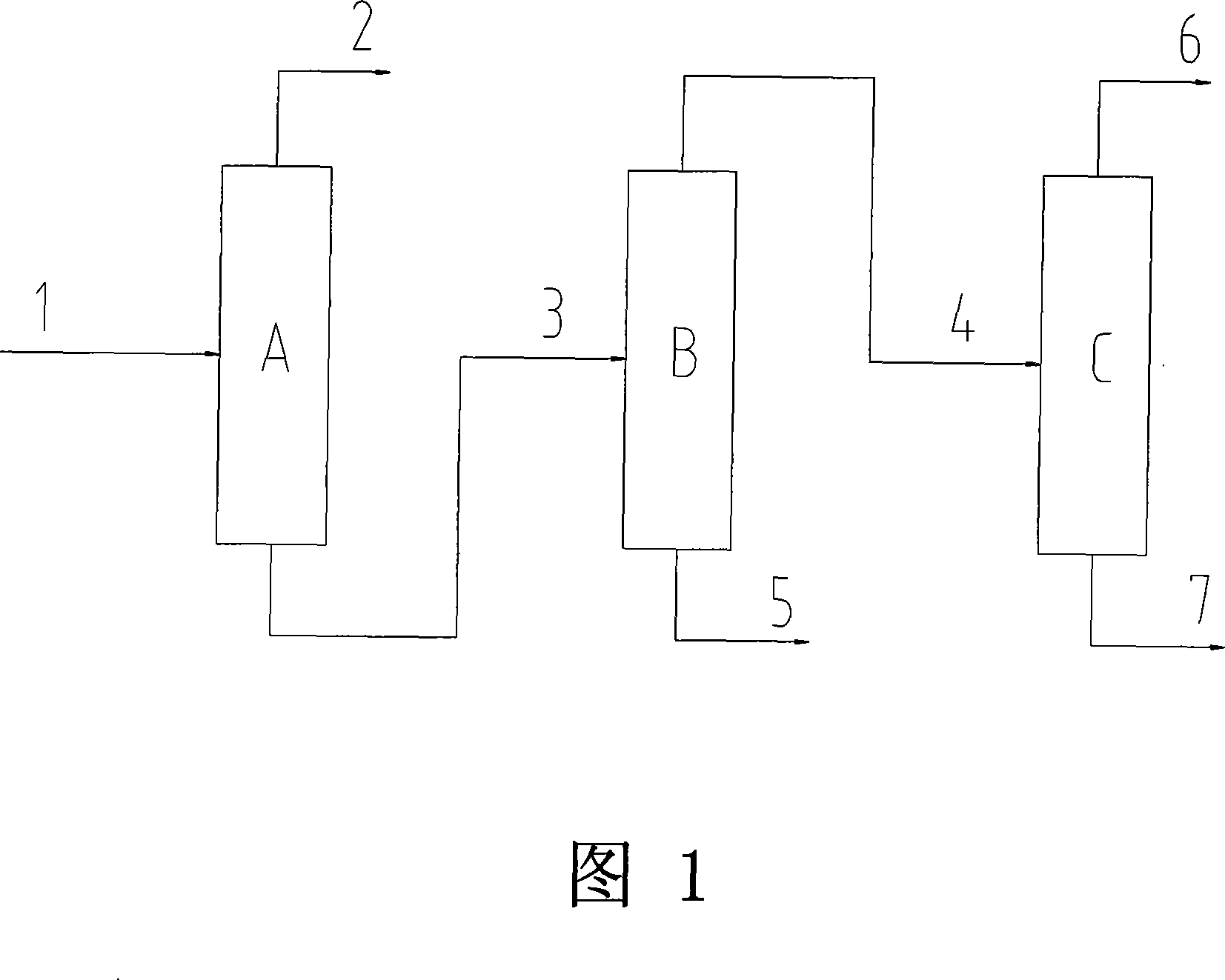

[0025] Referring to accompanying drawing 1, after acetic acid and mixed C4 react the gained mixture, its mass composition is sec-butyl acetate 45.65%, acetic acid 37.07%, hydrocarbons and other substances 17.28%, this mixture 1 imports flash column A. The temperature at the bottom of the flash tower A is 180.5°C, the temperature at the top of the tower is 56°C, and the pressure is 0.65MPa. The product 3 is obtained at the bottom of the flash tower A, and its mass composition is: 52.10% of sec-butyl acetate, 43.39% of acetic acid, 4.51% of hydrocarbons and other substances. The remaining hydrocarbons 2 are output from the top of the tower.

[0026] The bottom material 3 of the flash tower is input into the separation column B of acetic acid and sec-butyl acetate. The temperature at the bottom of the acetic acid and sec-butyl acetate separation tower B is 122°C and the pressure is 108KPa; the temperature at the top of the tower is 112°C and the pressure is 100KPa. The mass com...

Embodiment 2

[0030] Referring to accompanying drawing 1, the mixture 1 after the reaction of acetic acid and mixing C4, its mass composition is sec-butyl acetate 51.44%, acetic acid 35.95%, hydrocarbons and other substances 12.61%, and this mixture 1 is imported flash column A. The temperature at the bottom of the flash tower A is 165°C, the temperature at the top of the tower is 65°C, and the pressure is 0.48MPa. The product 3 is obtained at the bottom of the flash tower A, and its mass composition is: 55.98% of sec-butyl acetate, 40.29% of acetic acid, 3.73% of hydrocarbons and other substances. Part of the hydrocarbons 2 is output from the top of the flash tower A.

[0031] The bottom material 3 of the flash tower A enters the acetic acid and sec-butyl acetate separation tower B. The pressure at the bottom of the acetic acid and sec-butyl acetate separation tower B is 6.3Kpa, the temperature is 47°C, the pressure at the top of the tower is 5Kpa, and the temperature is 35°C. The overhe...

Embodiment 3

[0035] Referring to accompanying drawing 1, the mixture 1 after the reaction of acetic acid and mixed C4, its mass composition is sec-butyl acetate 48.21%, acetic acid 33.85%, hydrocarbons and other substances 17.94%, this mixture 1 is input flash column A. The temperature at the bottom of the flash tower A is 178° C., the temperature at the top of the tower is 55° C., and the pressure is 0.50 MPa. The product 3 is obtained at the bottom of flash tower A, and its mass composition is: 55.48% of sec-butyl acetate, 38.96% of acetic acid, 5.56% of hydrocarbons and other substances. Part of the hydrocarbons 2 is output from the top of the flash tower A.

[0036] The bottom material 3 of the flash tower A enters the acetic acid and sec-butyl acetate separation tower B. The pressure at the bottom of the acetic acid and sec-butyl acetate separation tower B is 80Kpa, the temperature is 89°C, the pressure at the top of the tower is 76Kpa, and the temperature is 76°C. The overhead dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com