Etherified C4 superimposition esterification cogeneration method of isooctane and sec-butyl acetate

A technology of sec-butyl acetate and C4 after ether, which is applied in the production field of sec-butyl acetate, can solve the problems of no mention of production volume, unfavorable esterification reaction, high energy consumption, etc., to expand the scope of raw material procurement and reduce procurement Indicators, the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

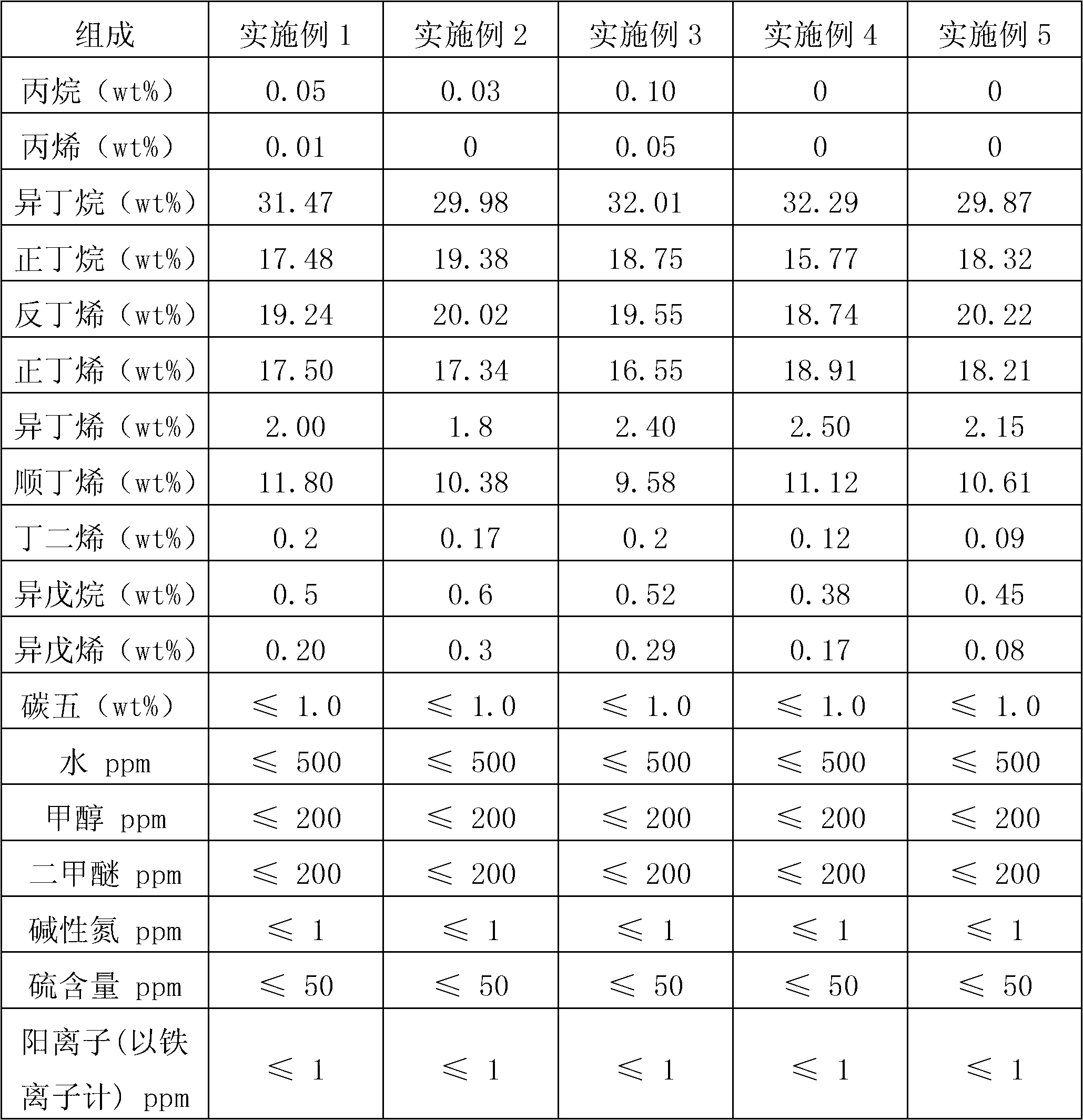

[0032] (1) Lamination reaction: The C4 raw material after ether with an isobutene content of 2.0wt% and a methanol content ≤ 1.5 times the isobutene content is passed through a reactor equipped with Amberlyst 15 resin catalyst at a reaction temperature of 66°C and a pressure of 1.6Mpa Carry out superposition reaction under certain reaction conditions, distill superposition reaction product, obtain the refined C4 raw material of isobutene content≤0.0945wt% at the top of the distillation tower, obtain the carbooctaolefin mainly based on isooctene at the bottom of the tower;

[0033] (2) Esterification reaction: the refined C4 raw material and acetic acid are mixed and preheated, then passed through an esterification reactor equipped with an esterification heteropolyacid catalyst, under the reaction conditions of a temperature of 75°C and a pressure of 1.4Mpa The reaction produces sec-butyl acetate.

Embodiment 2

[0035] (1) Lamination reaction: The C4 raw material after ether passes through the reactor equipped with Y series catalysts, and the lamination reaction is carried out under the reaction conditions of the reaction temperature of 90°C and the pressure of 0.8Mpa. The feed space of the lamination reaction is Speed is 1.0h -1 , the superimposed reaction product is distilled, the top of the distillation tower obtains a refined C4 raw material with an isobutene content of 0.0744wt%, and the bottom of the tower obtains carbon octaolefins mainly composed of isooctene;

[0036] (2) Esterification reaction: the refined C4 raw material and acetic acid are mixed and preheated and passed through an esterification reactor equipped with an esterification heteropolyacid catalyst. The molar ratio of acetic acid to refined C4 is 3, and the esterification The feed space velocity of the reaction is 0.8h -1 , under the reaction conditions of temperature 110°C and pressure 1.0Mpa, the reaction p...

Embodiment 3

[0038] (1) Superimposition reaction: the isobutene content is 2.4wt%, the methanol content is ≤ 1.5 times the isobutene content, and the C4 raw material after ether is passed through a reactor equipped with a Keggin structure heteropolyacid catalyst composed of a mixture of tungstic acid and molybdic acid , the superposition reaction is carried out under the reaction conditions that the reaction temperature is 80°C and the pressure is 1.2Mpa, and the superposition reaction product is distilled, and the refined C4 raw material with an isobutene content of 0.0984wt% is obtained at the top of the distillation tower, and the isooctyl Alkene-based carbon octaolefins;

[0039] (2) Esterification reaction: the refined C4 raw material and acetic acid are mixed and preheated and passed through an esterification reactor equipped with an esterification heteropolyacid catalyst. The molar ratio of acetic acid to refined C4 is 2.5. Under the reaction conditions of 90°C and pressure of 1.2Mp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com