Prediction method for flow temperature of mixed coal liquid slag based on raw coal ash components

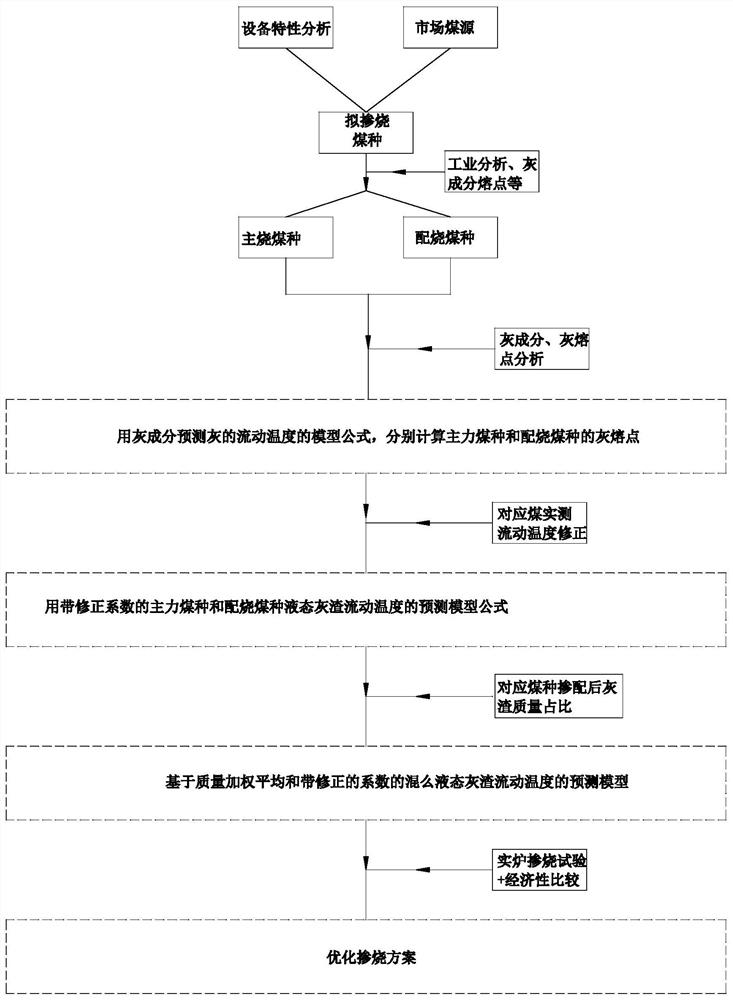

A technology of flow temperature and prediction method, which is applied in the direction of prediction, data processing application, instrument, etc. It can solve the problems of strong lag of test results, high consumption of manpower, material and financial resources, and poor flow of slag, and achieve model boundary data acquisition Simple and convenient, improve safety and economy, eliminate the effect of poor slag discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

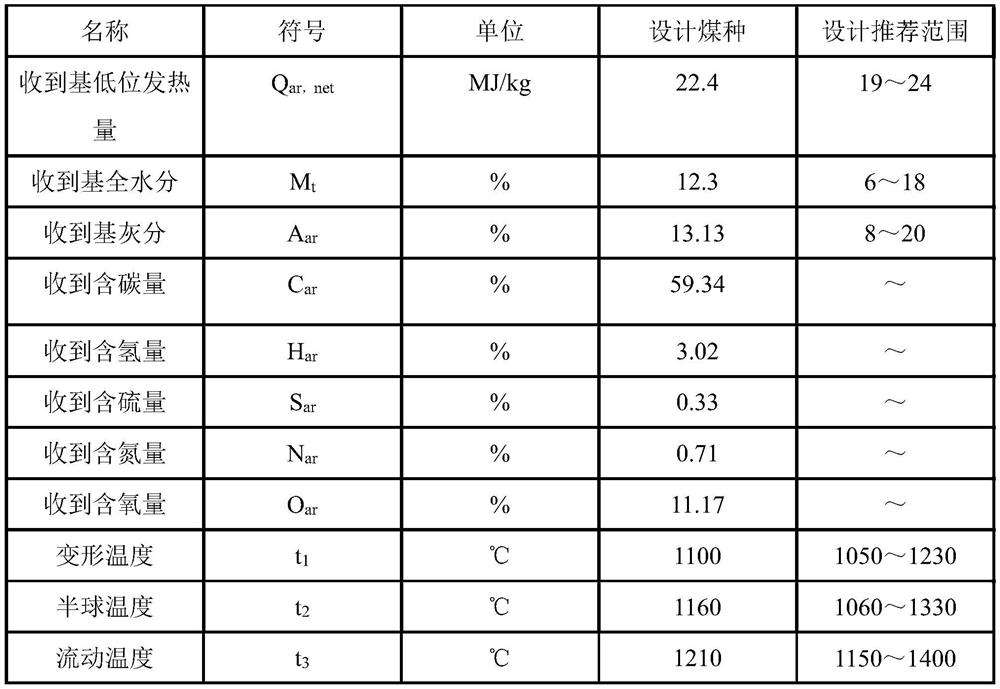

[0061] According to the characteristics of the equipment, a certain liquid slag discharge boiler includes swirl burner, cyclone combustion, slag catcher with slag catcher and slag discharge with slag outlet. Its designed coal combustion characteristics are shown in Table 1 below. It can be seen that the boiler equipment is suitable for burning bituminous coal with high calorific value and low ash melting point. According to the characteristics of its equipment and the market coal supply situation and the preliminary selection of potential candidates for blending coal type A as the main type of coal for burning, and coal B as the type of coal for blending, its quality and characteristic parameters are shown in Table 2. The reason is that the main indicators of the coal quality characteristics of A coal are close to the design coal quality, especially the low ash melting point and other values are relatively close to the design coal type, and can be fully burned through practic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com