Patents

Literature

137results about How to "Safety hazard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

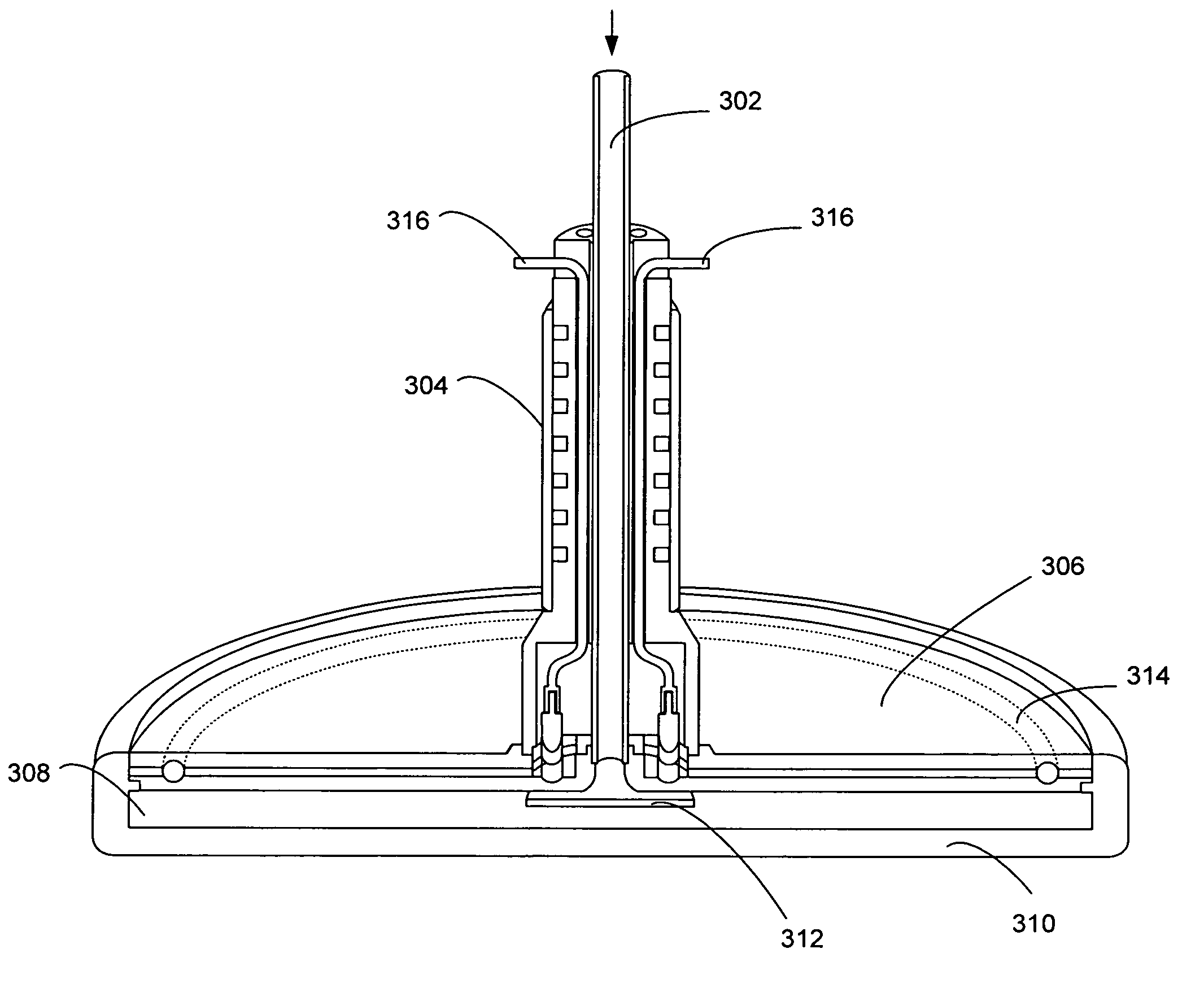

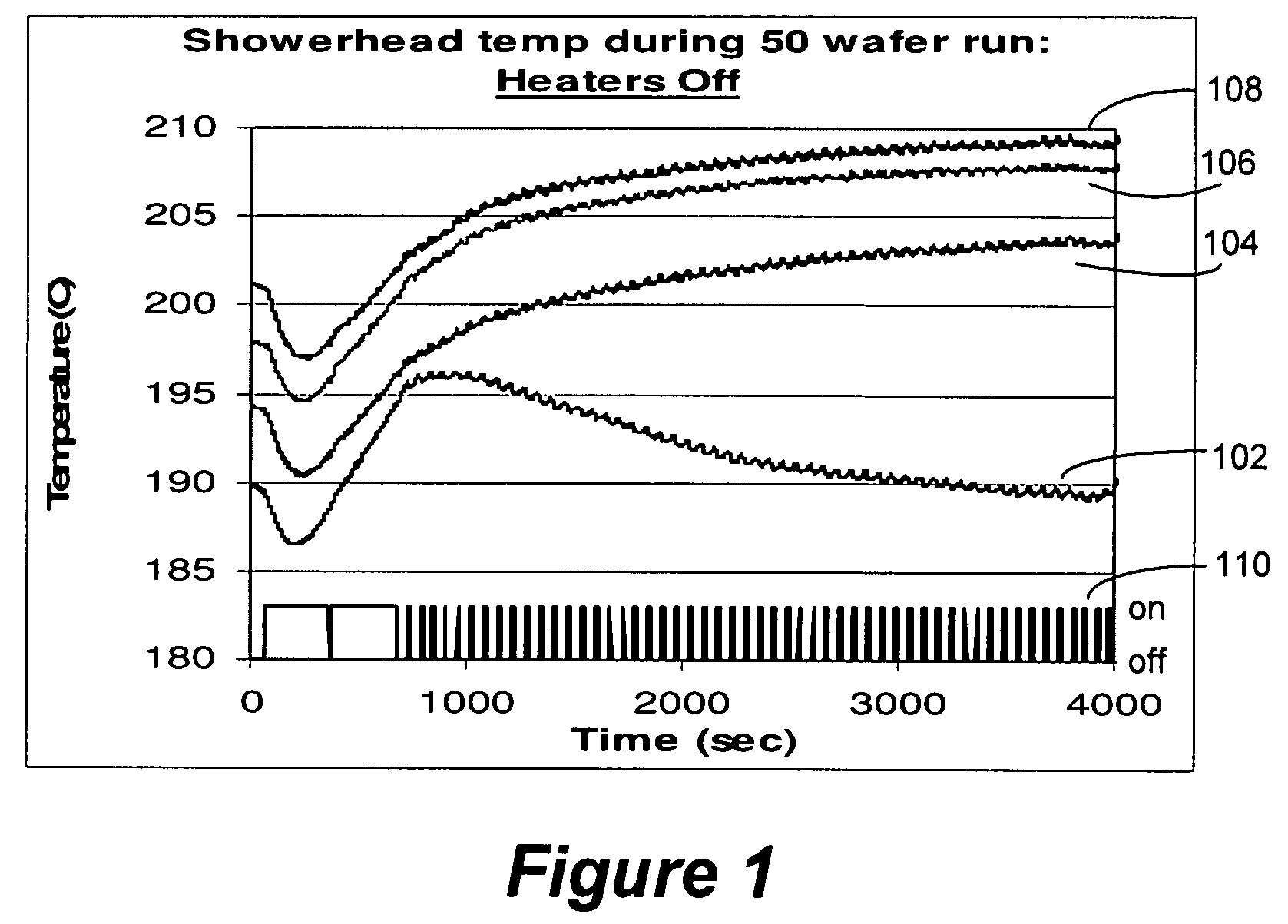

Temperature controlled showerhead

ActiveUS20090095220A1Precise and stable temperature controlRapid responseLiquid surface applicatorsElectric discharge tubesTemperature controlControl system

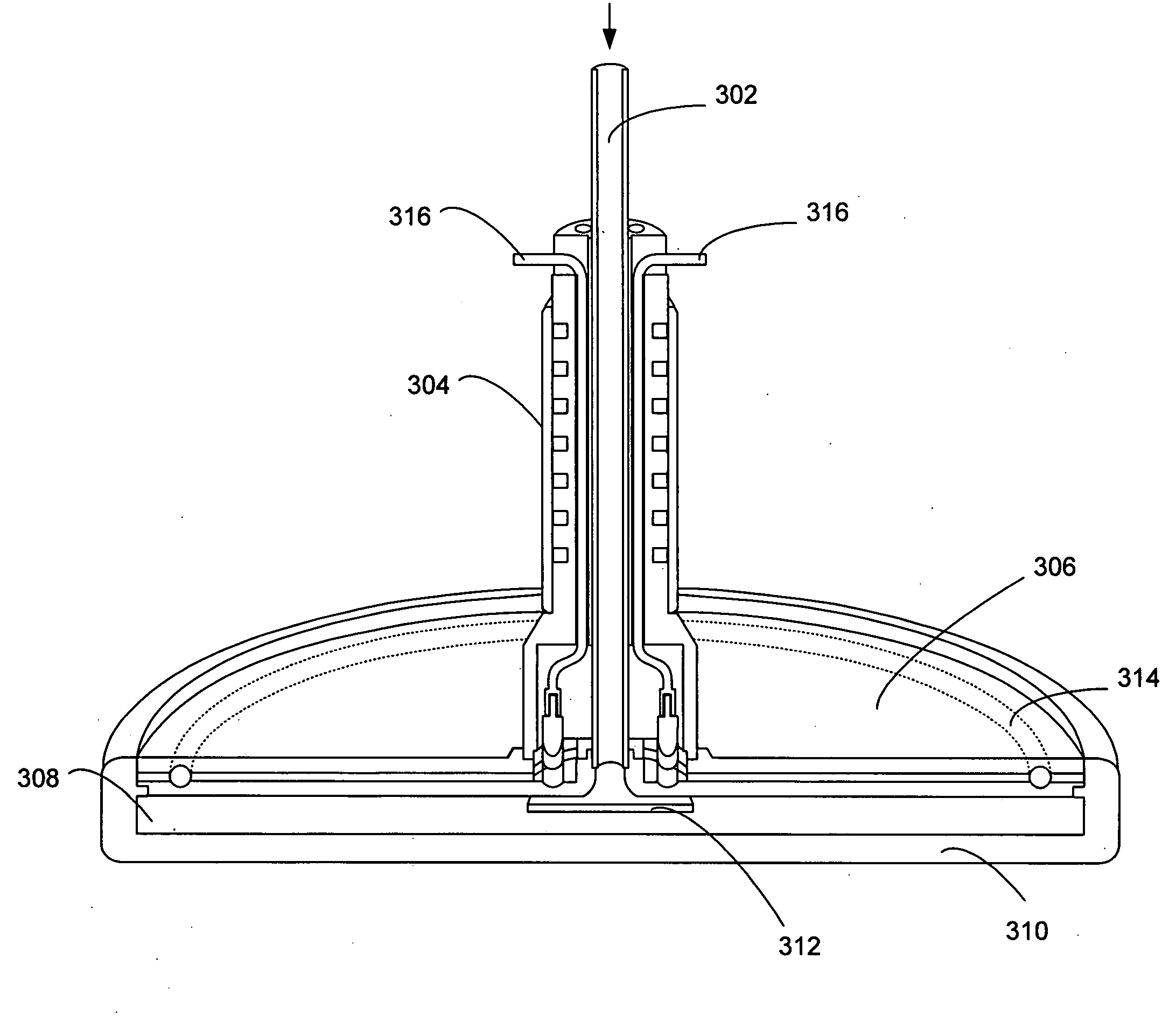

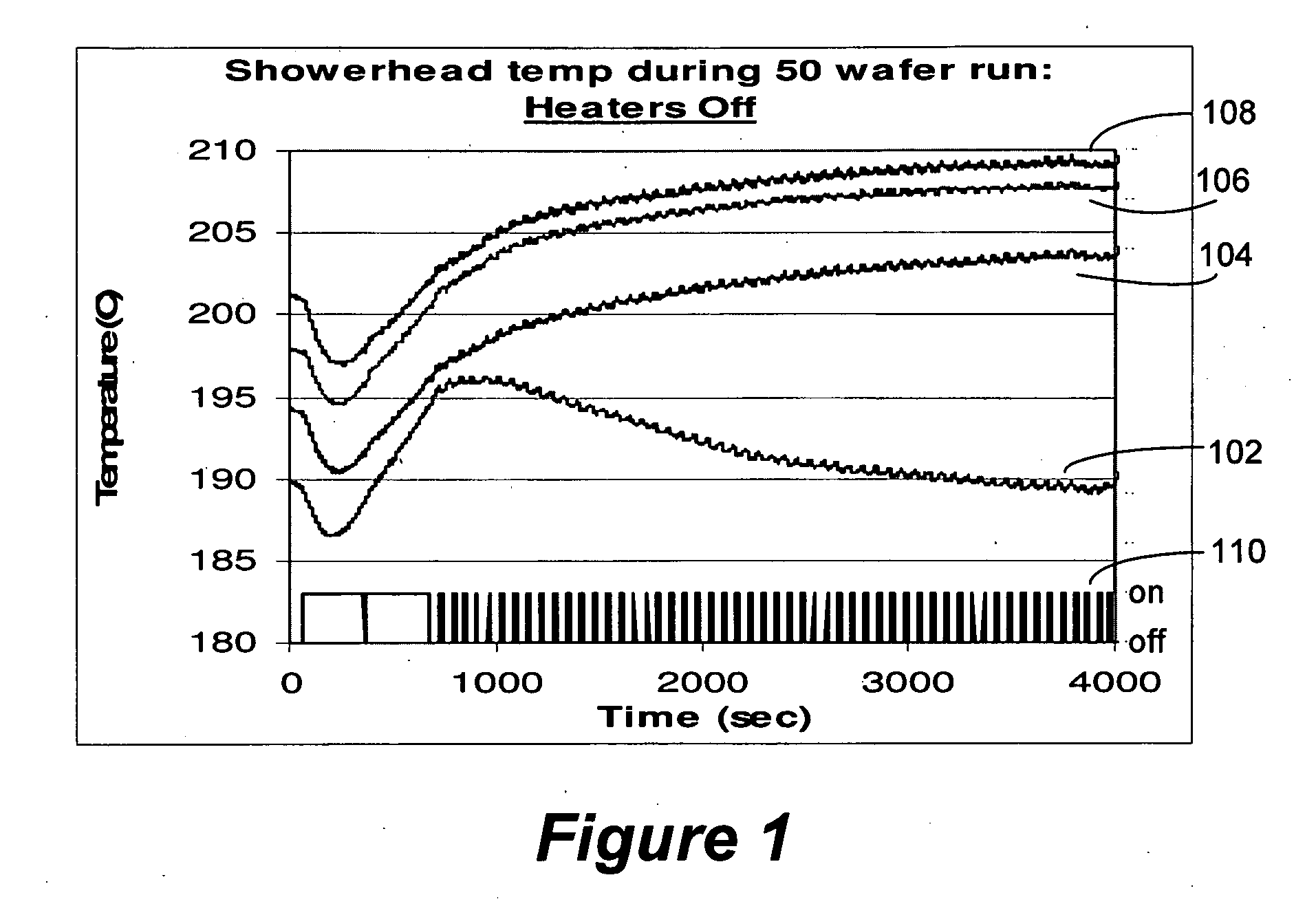

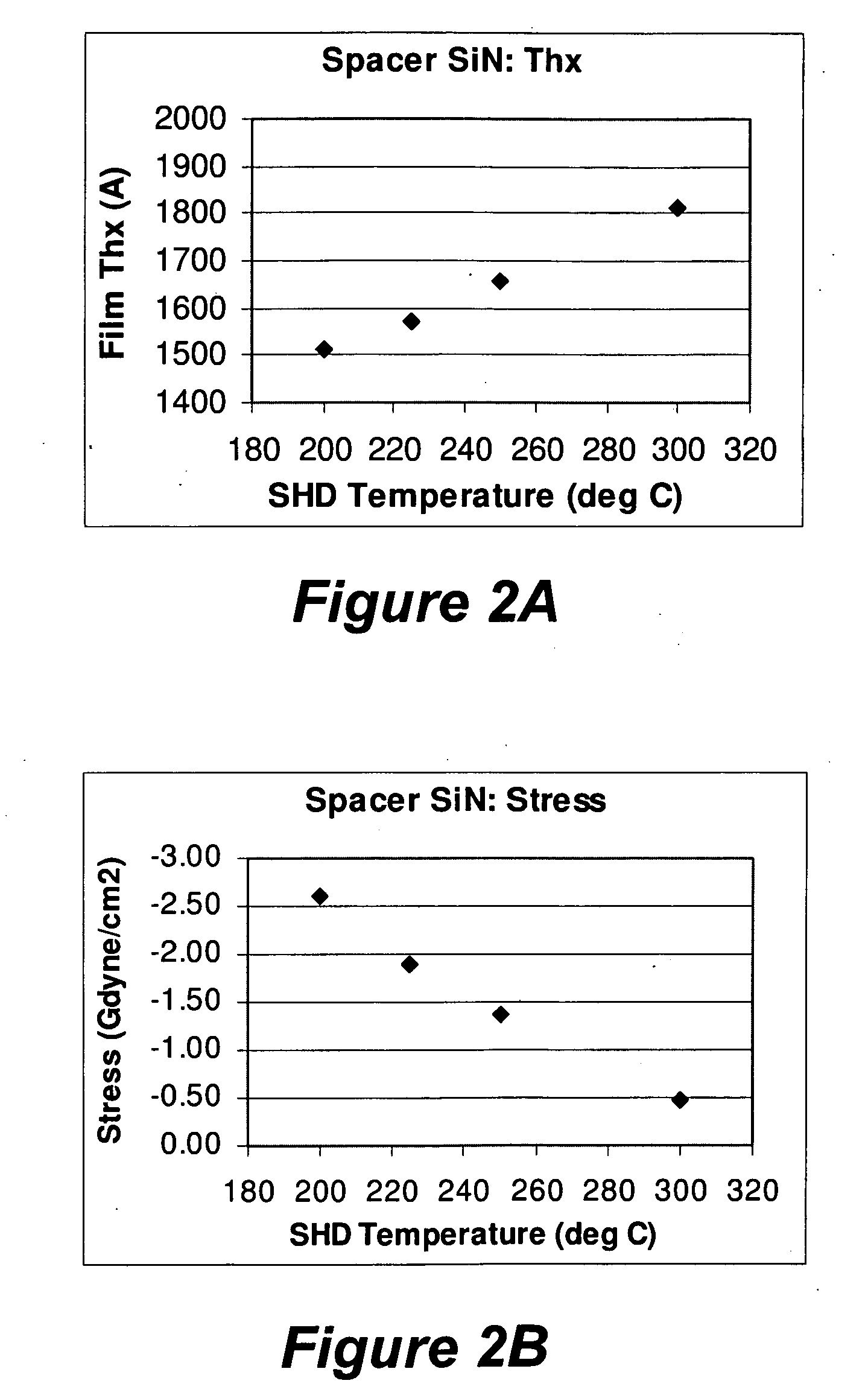

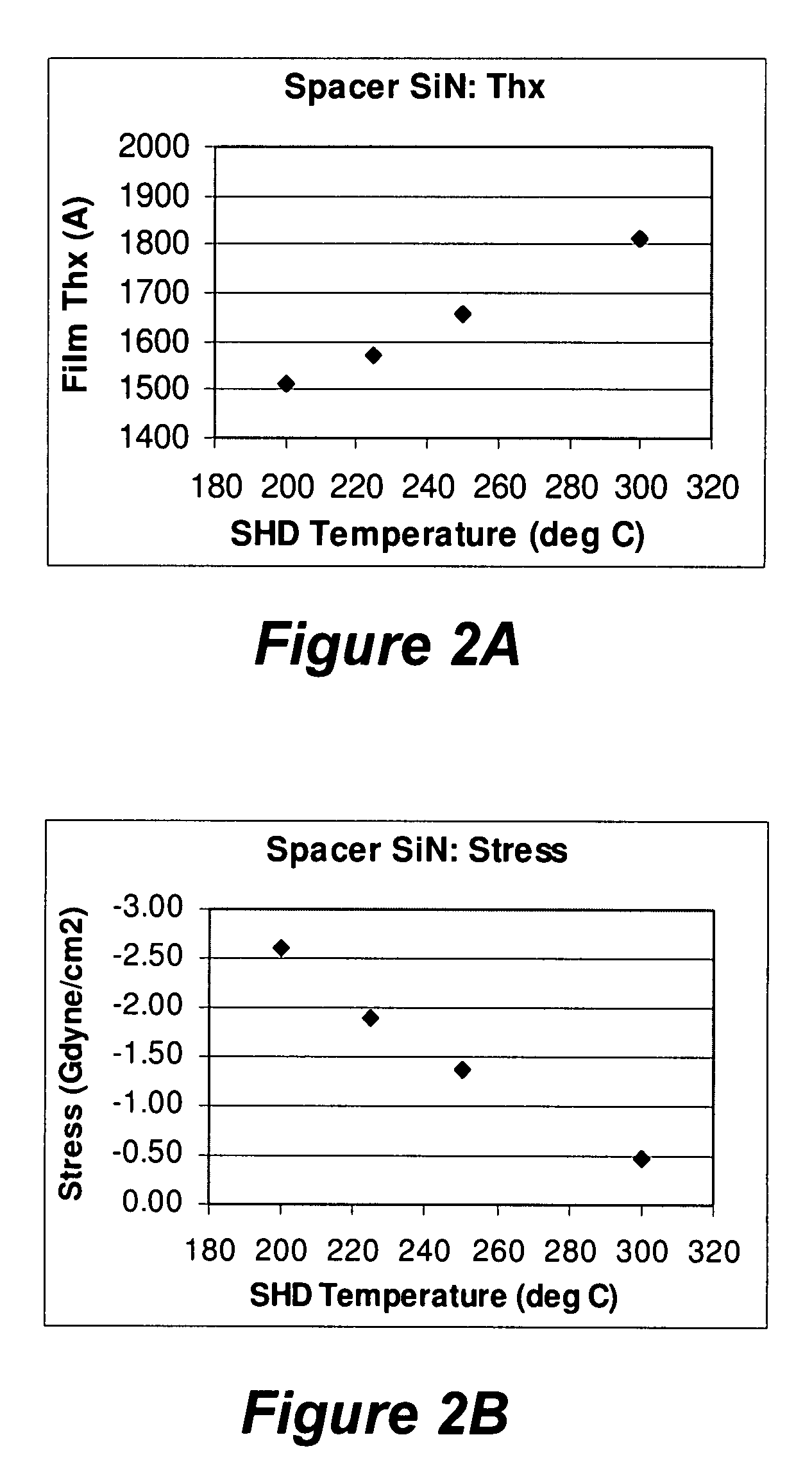

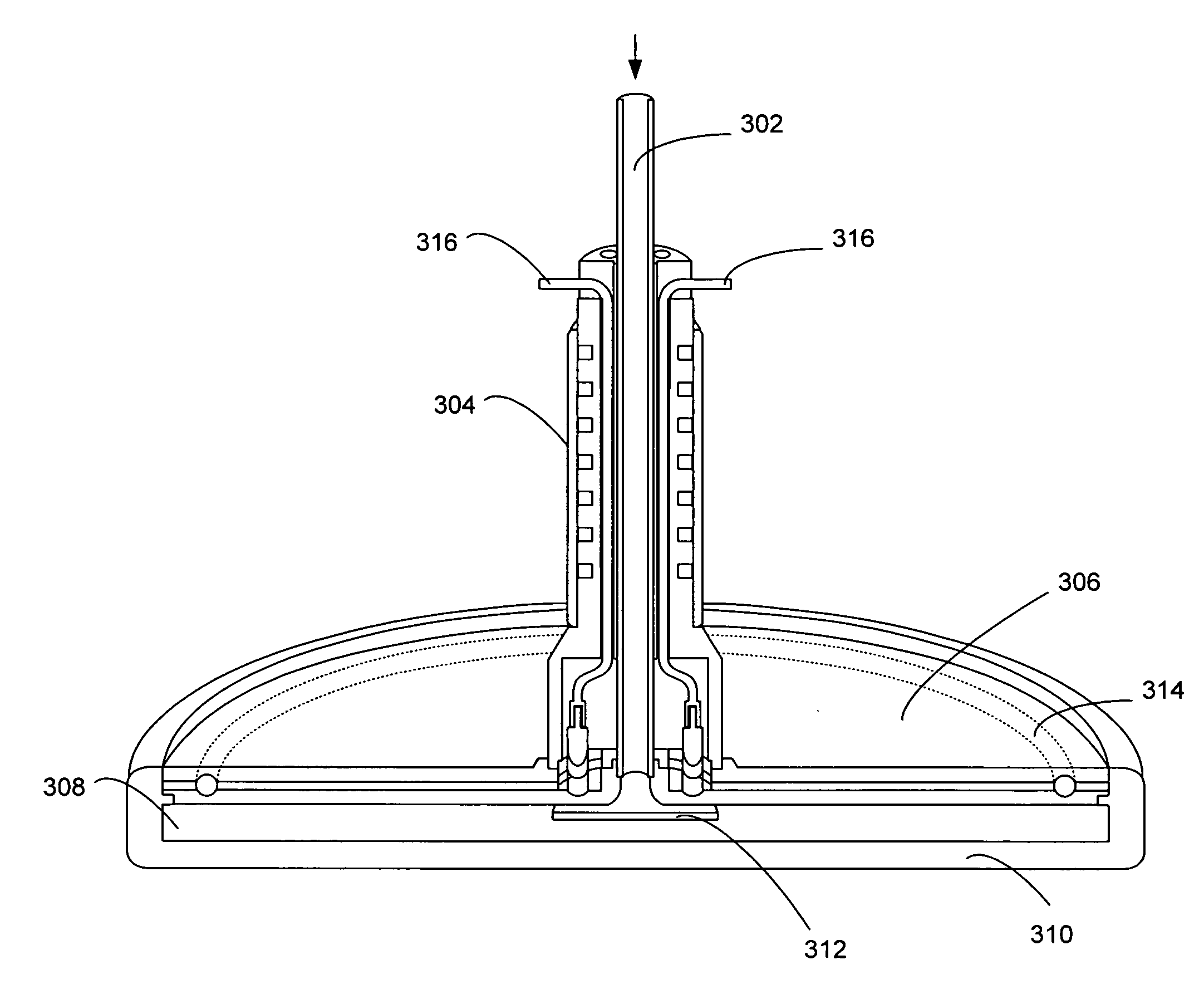

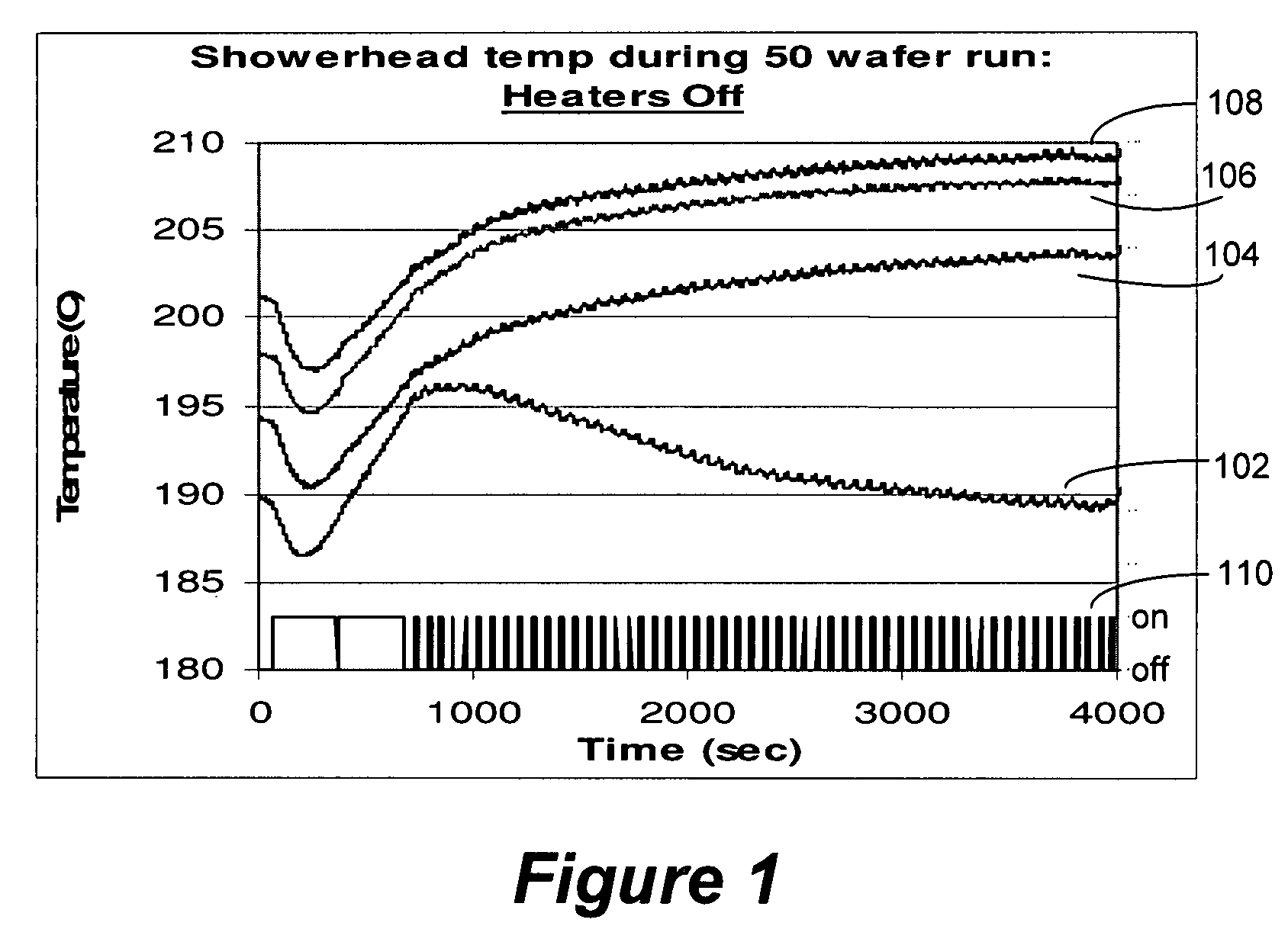

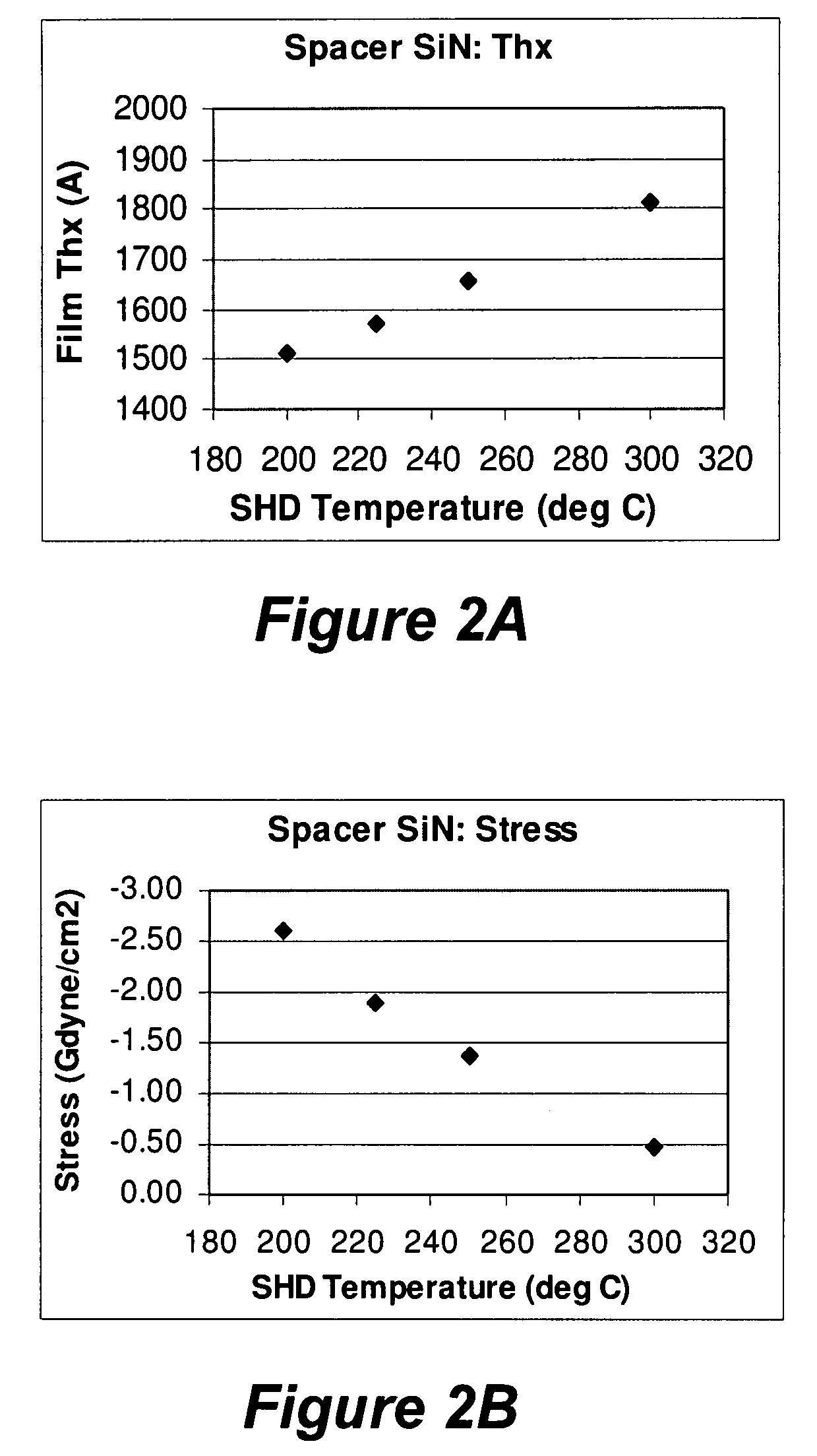

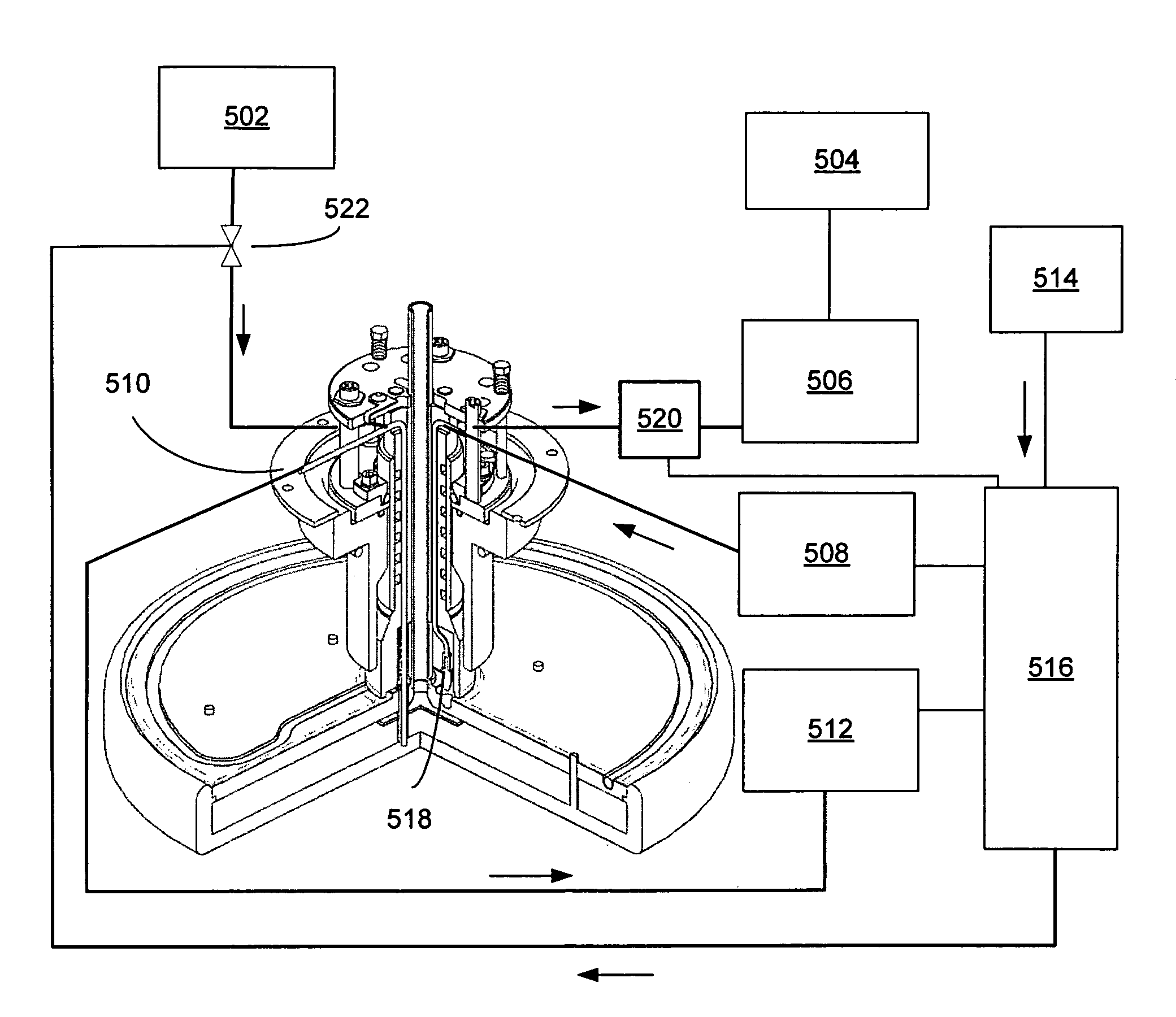

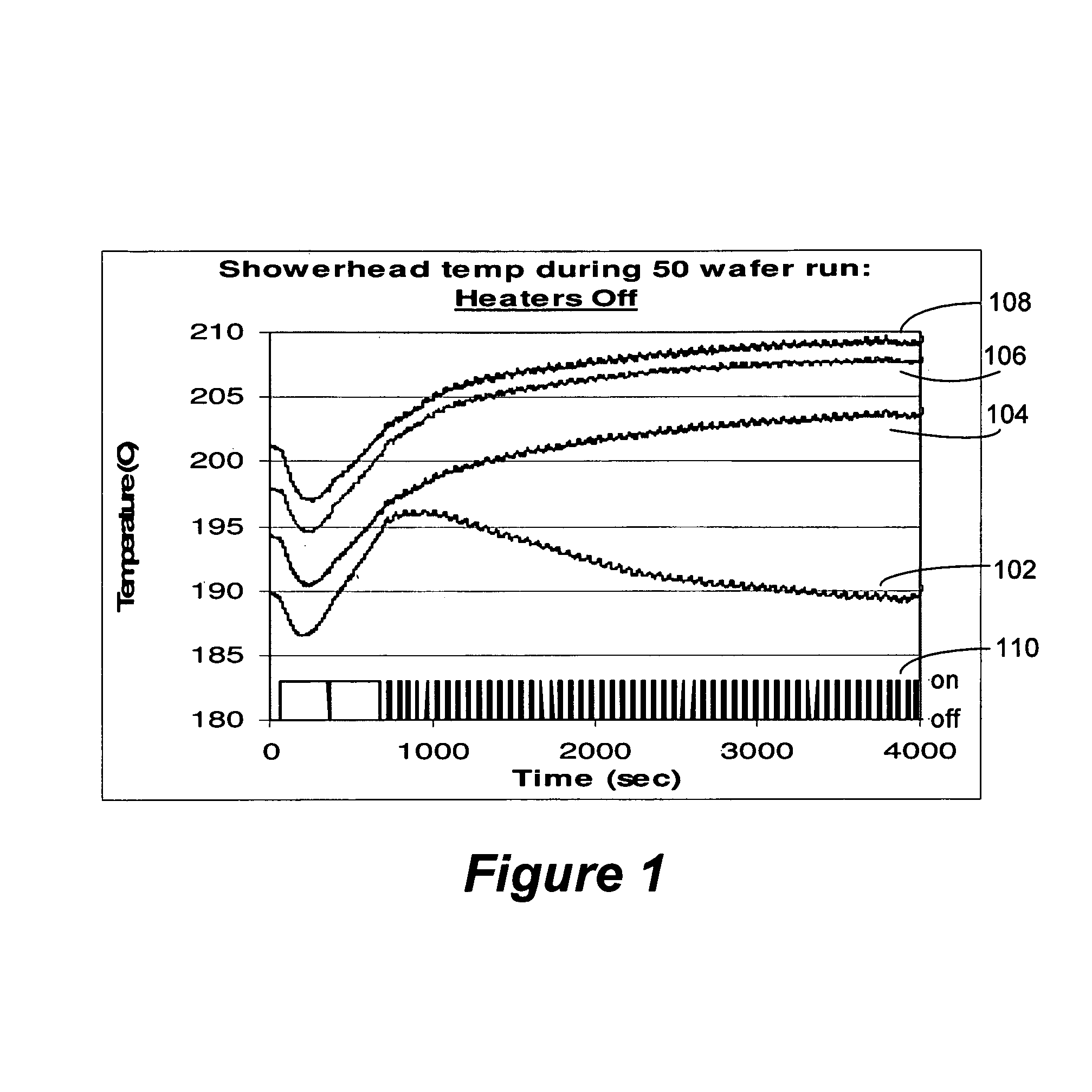

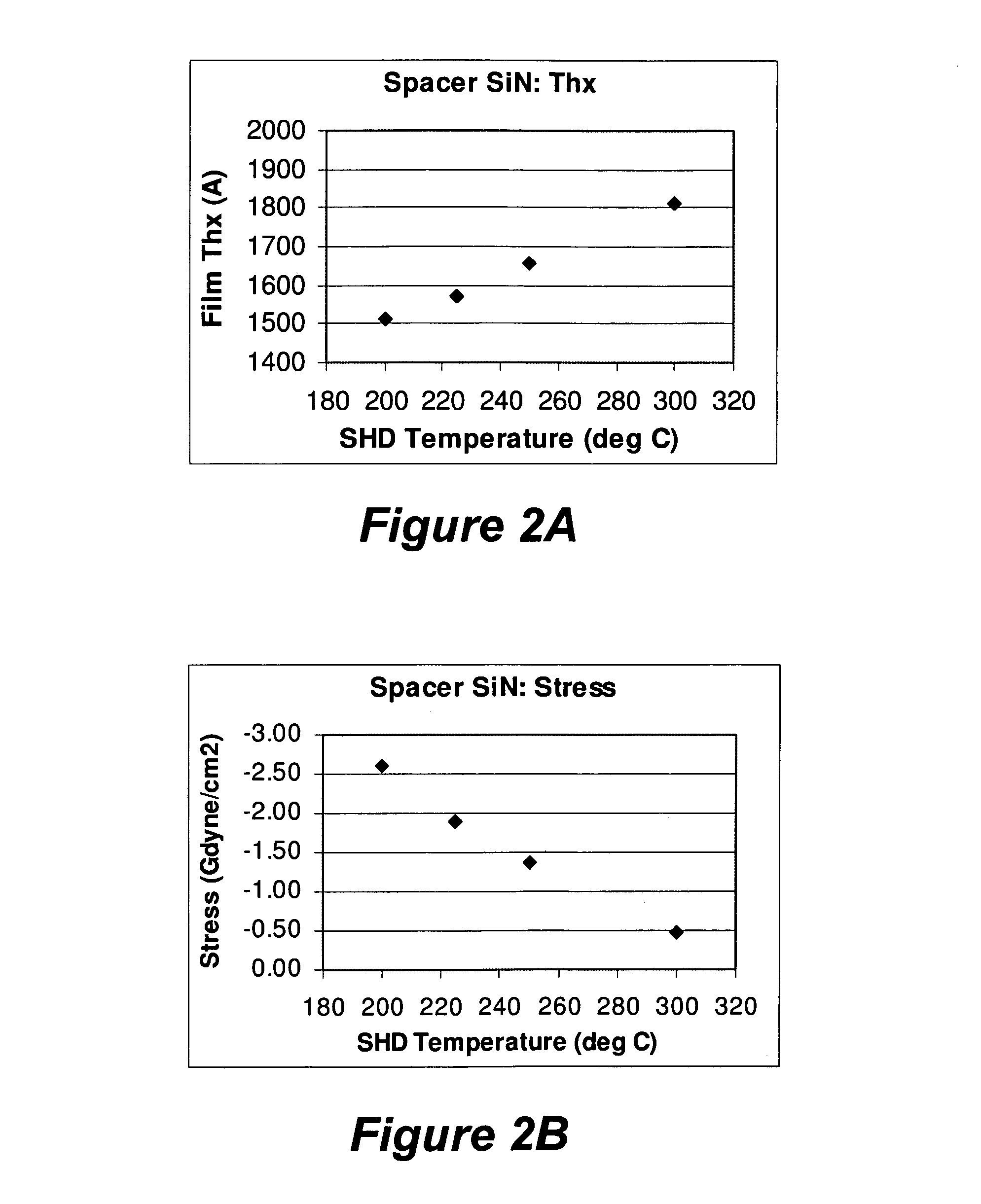

A temperature controlled showerhead for chemical vapor deposition (CVD) chambers enhances heat dissipation to enable accurate temperature control with an electric heater. Heat dissipates by conduction through a showerhead stem and fluid passageway and radiation from a back plate. A temperature control system includes one or more temperature controlled showerheads in a CVD chamber with fluid passageways serially connected to a heat exchanger.

Owner:NOVELLUS SYSTEMS

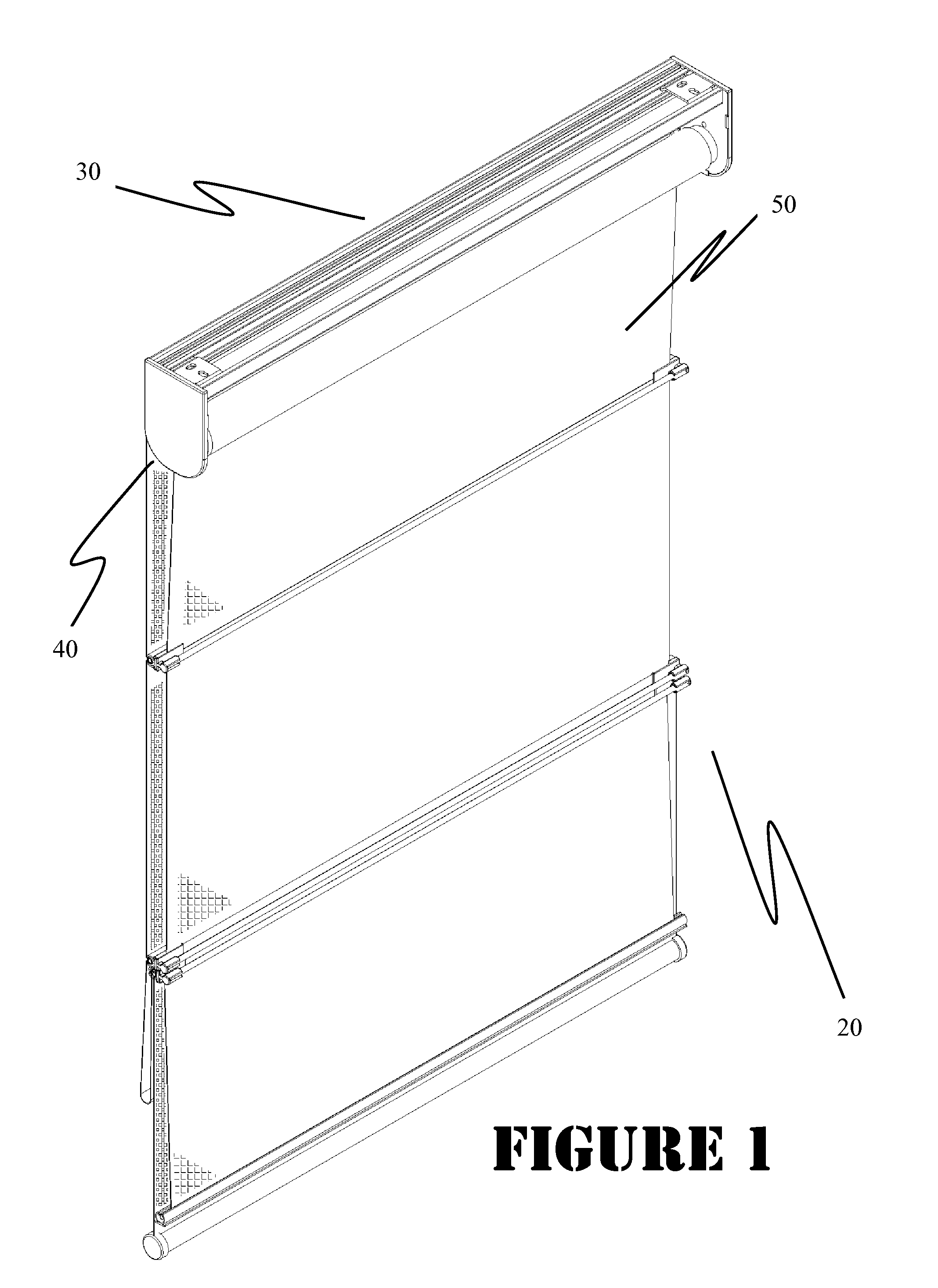

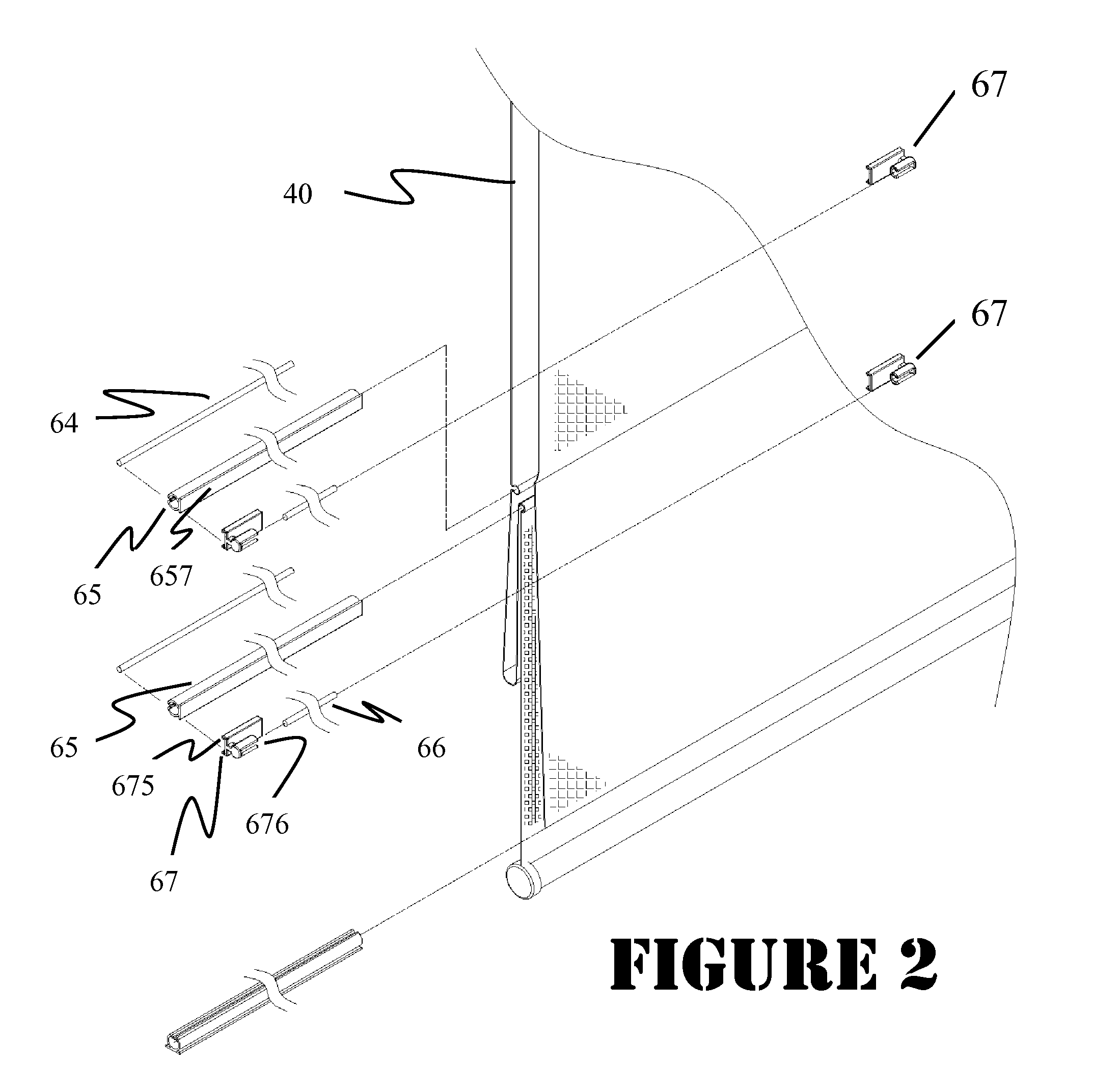

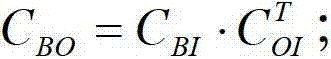

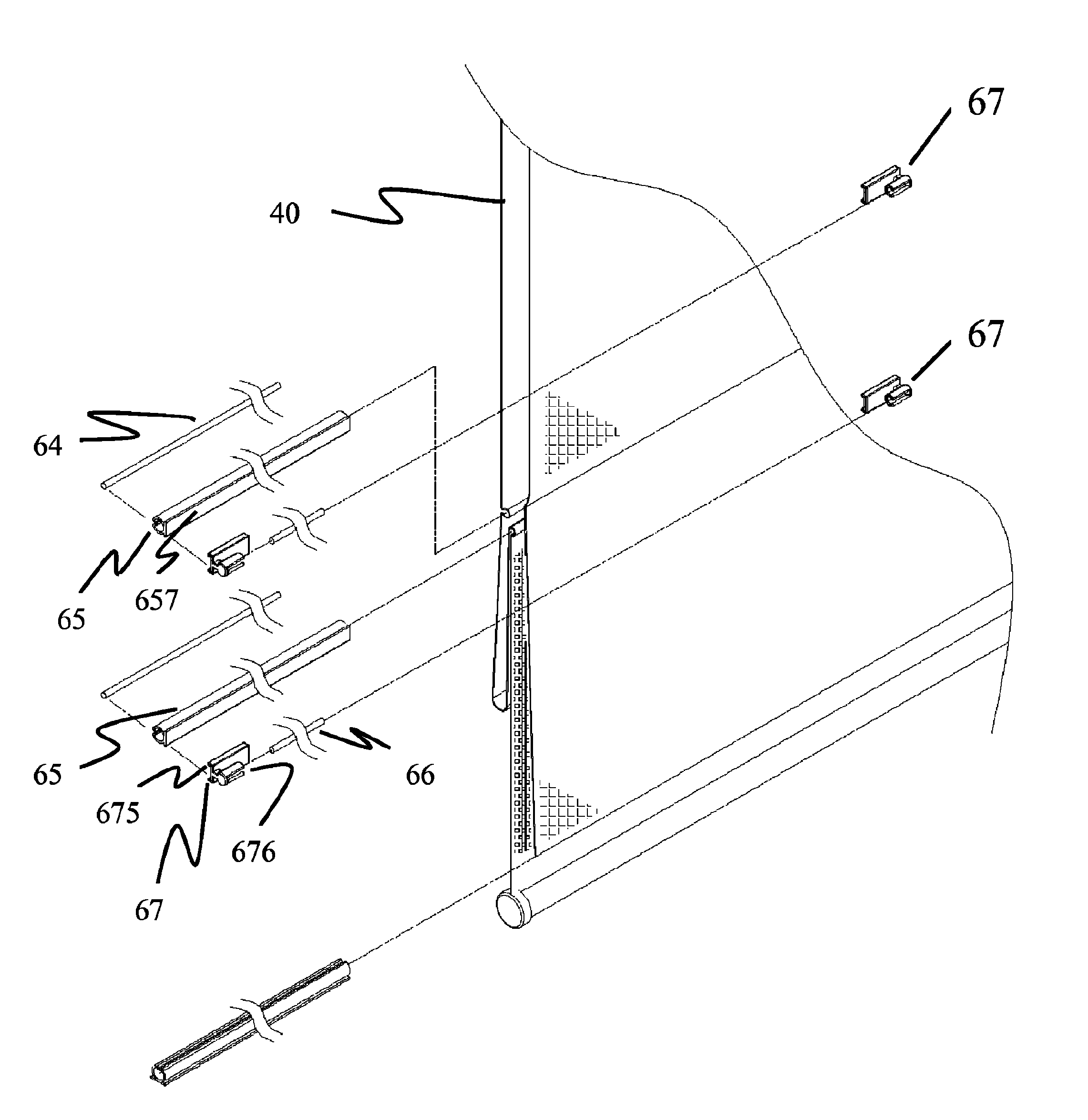

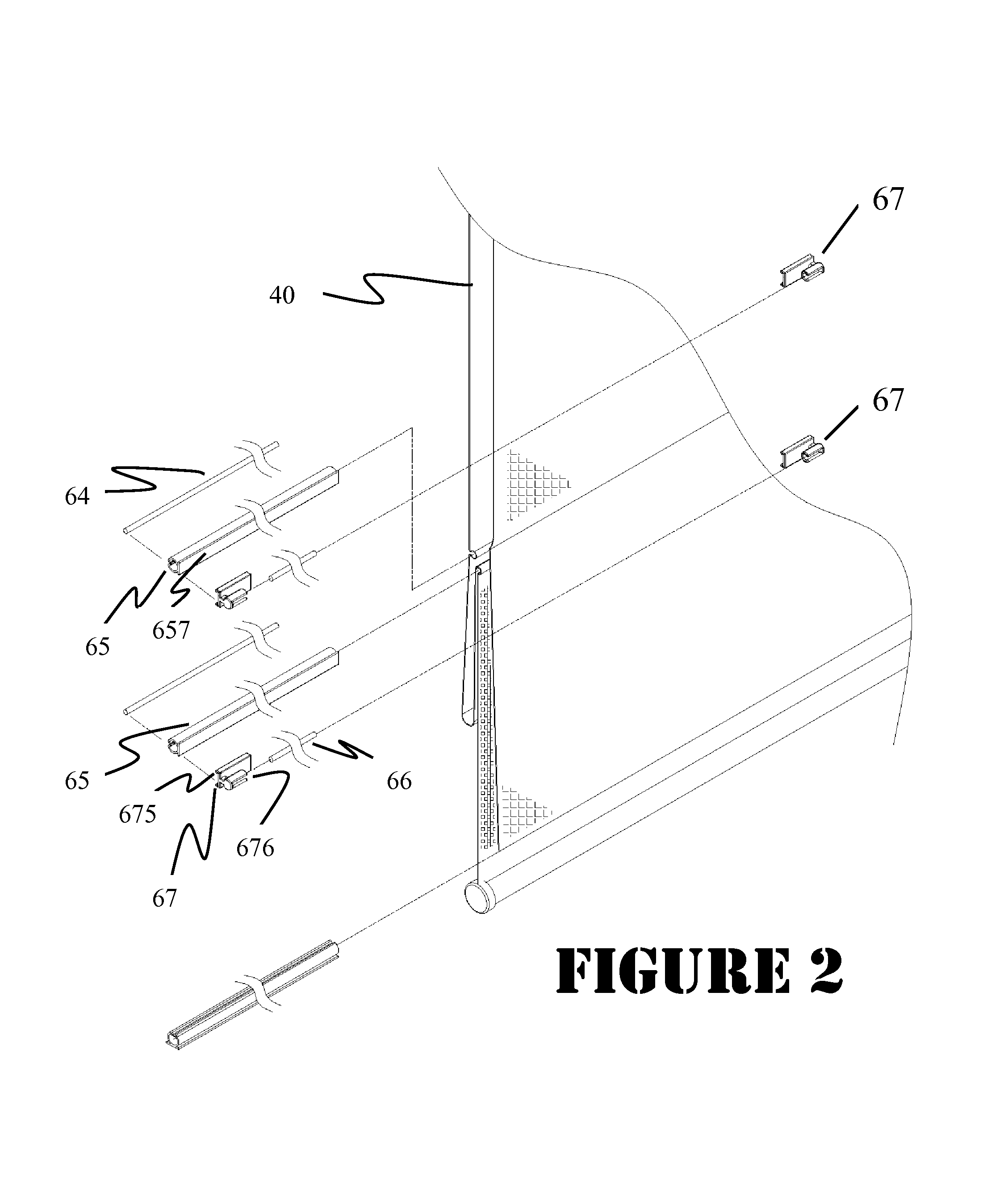

Roman Shade Window Curtain Having A Special Head Rail For Using A Roller Shade As Its Release/Retraction Control

ActiveUS20110067820A1Safety hazardFlexibility in light controlScreensExtensible doors/windowsMechanical engineering

Owner:PACIFIC HERITAGE HOME FASHIONS

Temperature controlled showerhead

ActiveUS8137467B2Improve cooling effectPrecise and stable temperature controlLiquid surface applicatorsSemiconductor/solid-state device manufacturingTemperature controlControl system

A temperature controlled showerhead for chemical vapor deposition (CVD) chambers enhances heat dissipation to enable accurate temperature control with an electric heater. Heat dissipates by conduction through a showerhead stem and fluid passageway and radiation from a back plate. A temperature control system includes one or more temperature controlled showerheads in a CVD chamber with fluid passageways serially connected to a heat exchanger.

Owner:NOVELLUS SYSTEMS

Temperature controlled showerhead

ActiveUS20090095219A1Precise and stable temperature controlRapid responseLiquid surface applicatorsSemiconductor/solid-state device manufacturingTemperature controlControl system

A temperature controlled showerhead for chemical vapor deposition (CVD) chambers enhances heat dissipation to enable accurate temperature control with an electric heater. Heat dissipates by conduction through a showerhead stem and fluid passageway and radiation from a back plate. A temperature control system includes one or more temperature controlled showerheads in a CVD chamber with fluid passageways serially connected to a heat exchanger.

Owner:NOVELLUS SYSTEMS

Temperature controlled showerhead

InactiveUS20090095218A1Precise and stable temperature controlRapid responseLiquid surface applicatorsChemical vapor deposition coatingTemperature controlControl system

A temperature controlled showerhead for chemical vapor deposition (CVD) chambers enhances heat dissipation to enable accurate temperature control with an electric heater. Heat dissipates by conduction through a showerhead stem and fluid passageway and radiation from a back plate. A temperature control system includes one or more temperature controlled showerheads in a CVD chamber with fluid passageways serially connected to a heat exchanger.

Owner:NOVELLUS SYSTEMS

Temperature controlled showerhead

ActiveUS8673080B2Improve cooling effectPrecise and stable temperature controlLiquid surface applicatorsElectric discharge tubesTemperature controlControl system

A temperature controlled showerhead for chemical vapor deposition (CVD) chambers enhances heat dissipation to enable accurate temperature control with an electric heater. Heat dissipates by conduction through a showerhead stem and fluid passageway and radiation from a back plate. A temperature control system includes one or more temperature controlled showerheads in a CVD chamber with fluid passageways serially connected to a heat exchanger.

Owner:NOVELLUS SYSTEMS

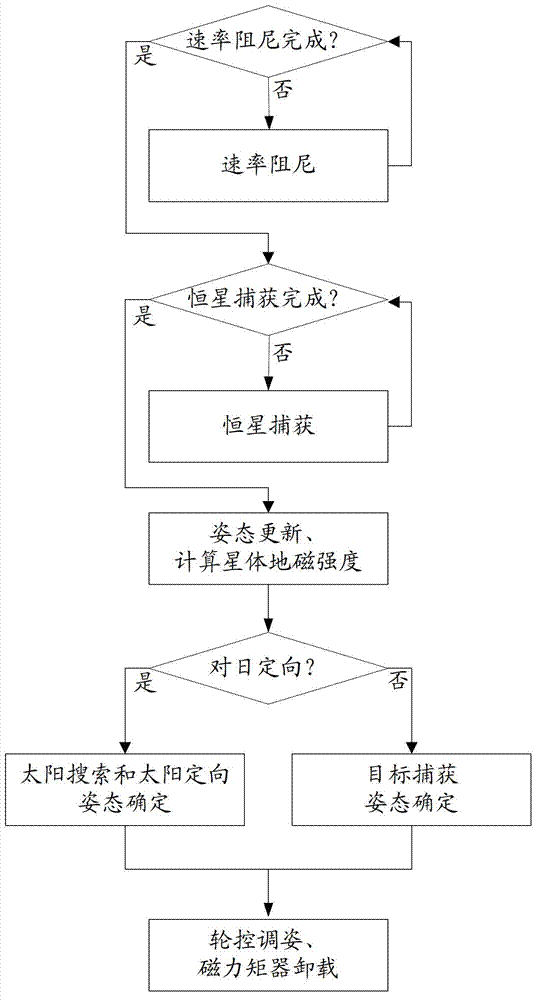

Full gesture capture method based on momentum wheel control

ActiveCN103092209AExtend your lifeImprove securityAttitude controlAdaptive controlMomentumOperability

The invention relates to a full gesture capture method based on momentum wheel control. The full gesture capture method based on the momentum wheel control includes following steps of rate damping, star capture, gesture updating and geomagnetic strength calculation of star noumenon, the sun search and the sun directional gesture confirming, aim capture gesture confirming, and wheel control adjusting gesture and magnetic torquer unloading. The full gesture capture method aims to solving the problem of spacecraft full gesture capture, is based on momentum wheel control, and engineer operability is strong.

Owner:BEIJING INST OF CONTROL ENG

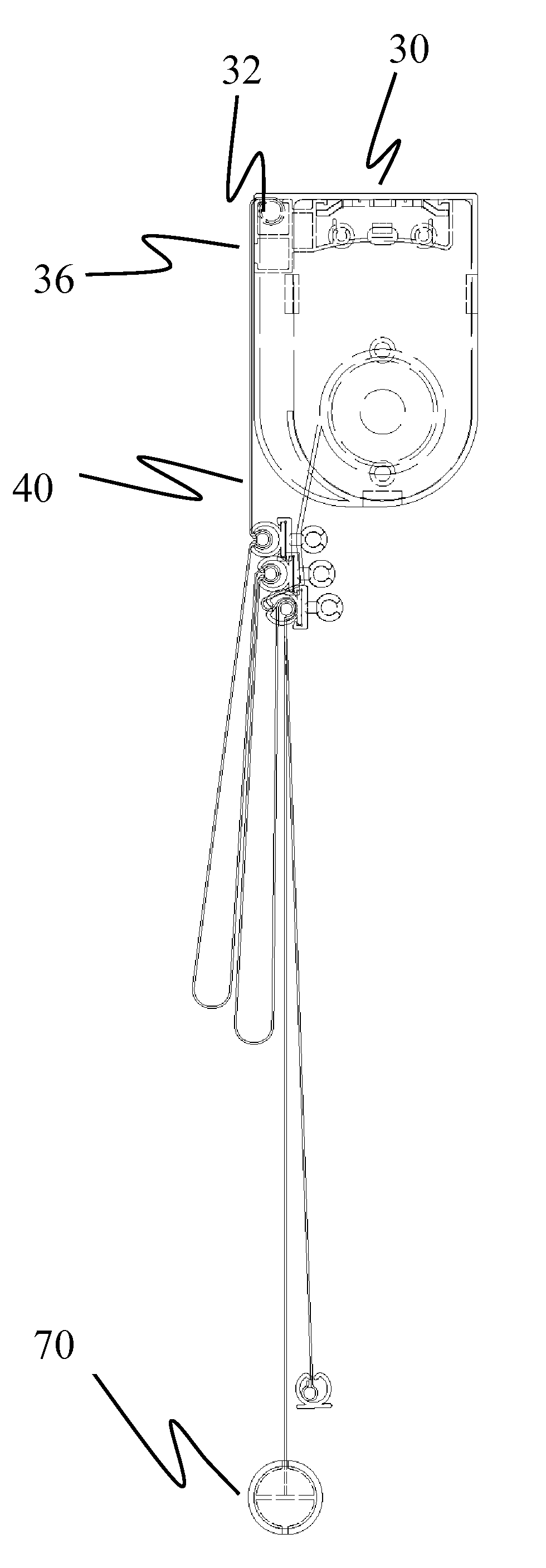

Roman shade window curtain having a special head rail for using a roller shade as its release/retraction control

ActiveUS8267144B2Safety hazardFlexibility in light controlScreensExtensible doors/windowsEngineeringMechanical engineering

Owner:PACIFIC HERITAGE HOME FASHIONS

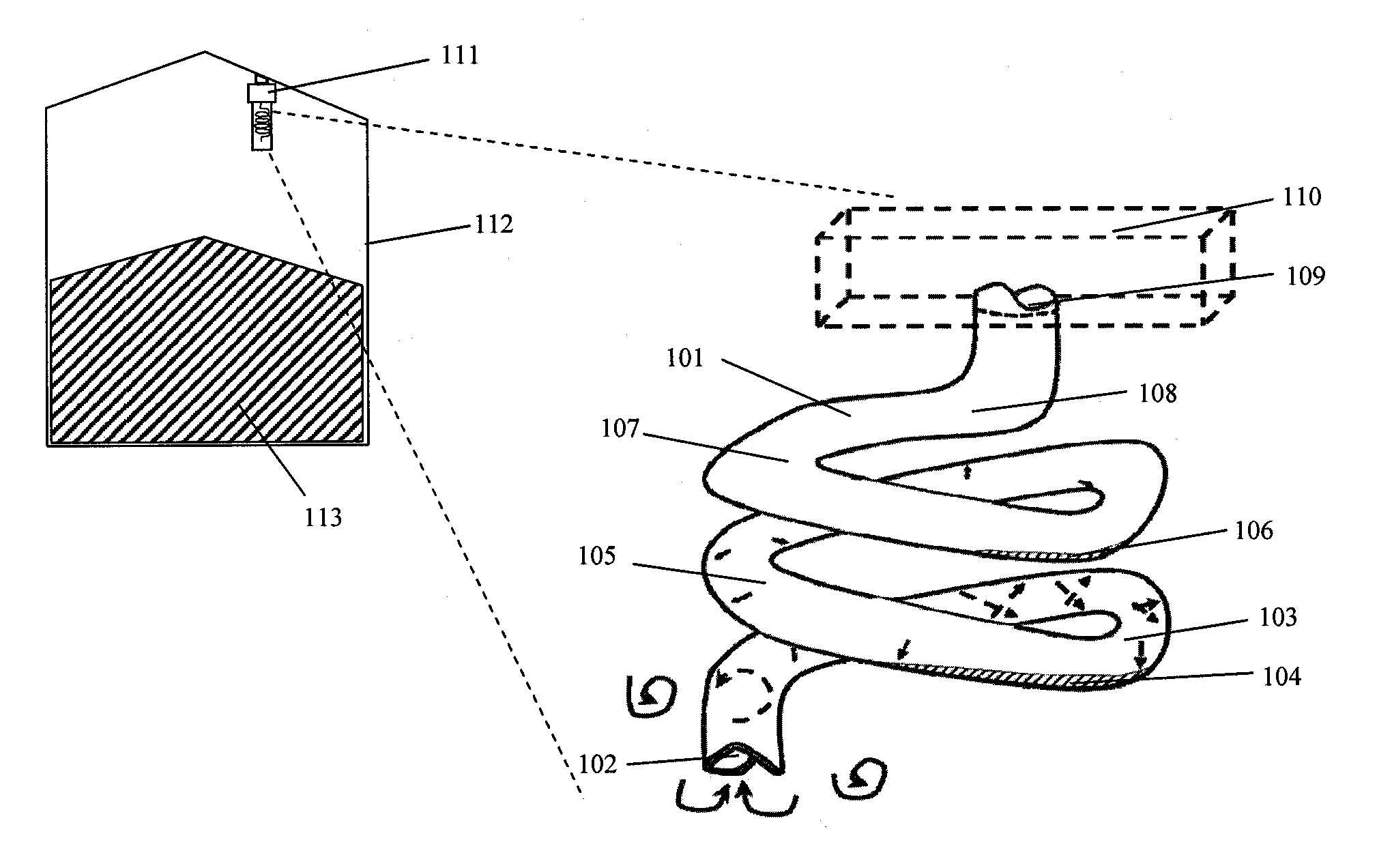

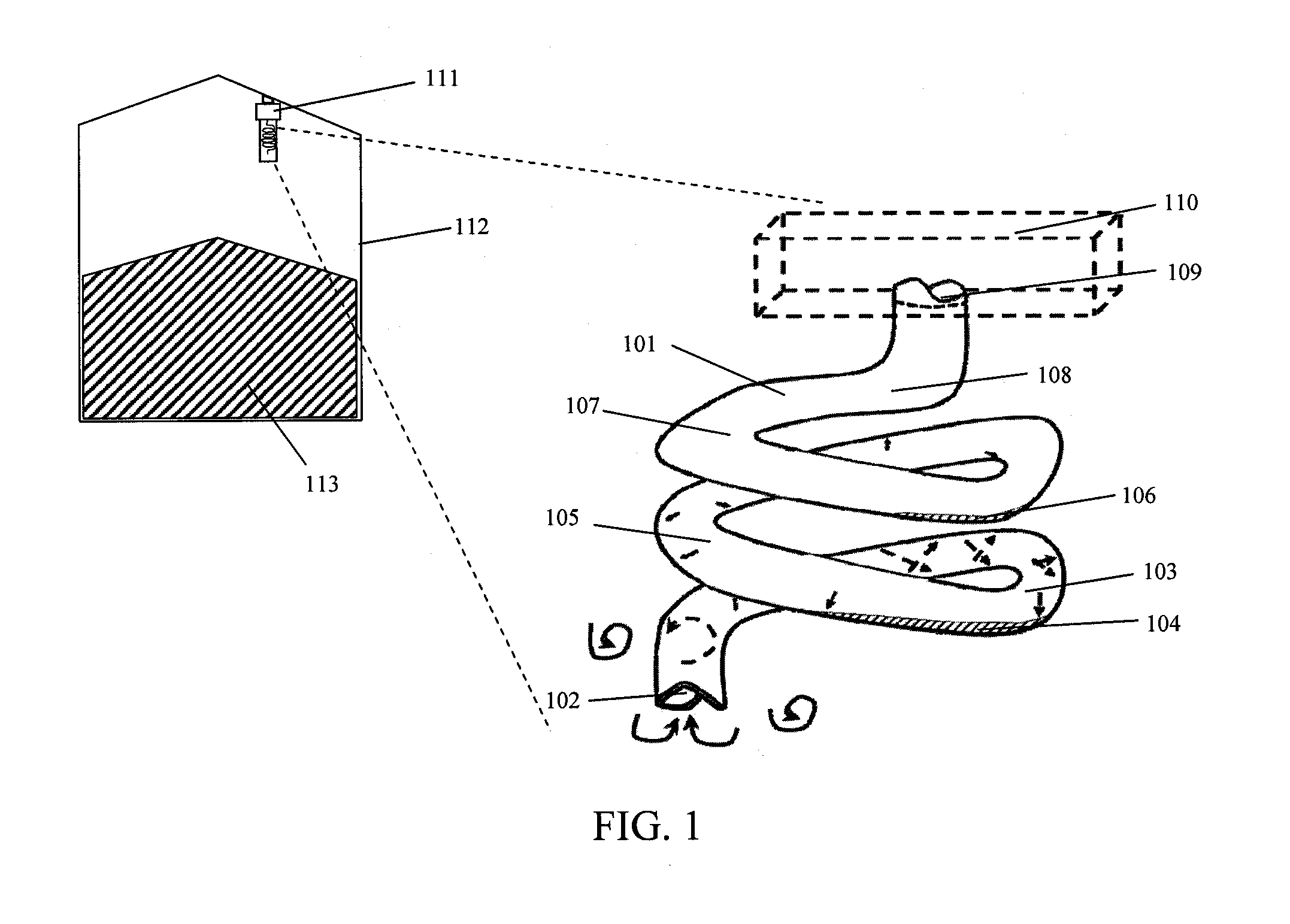

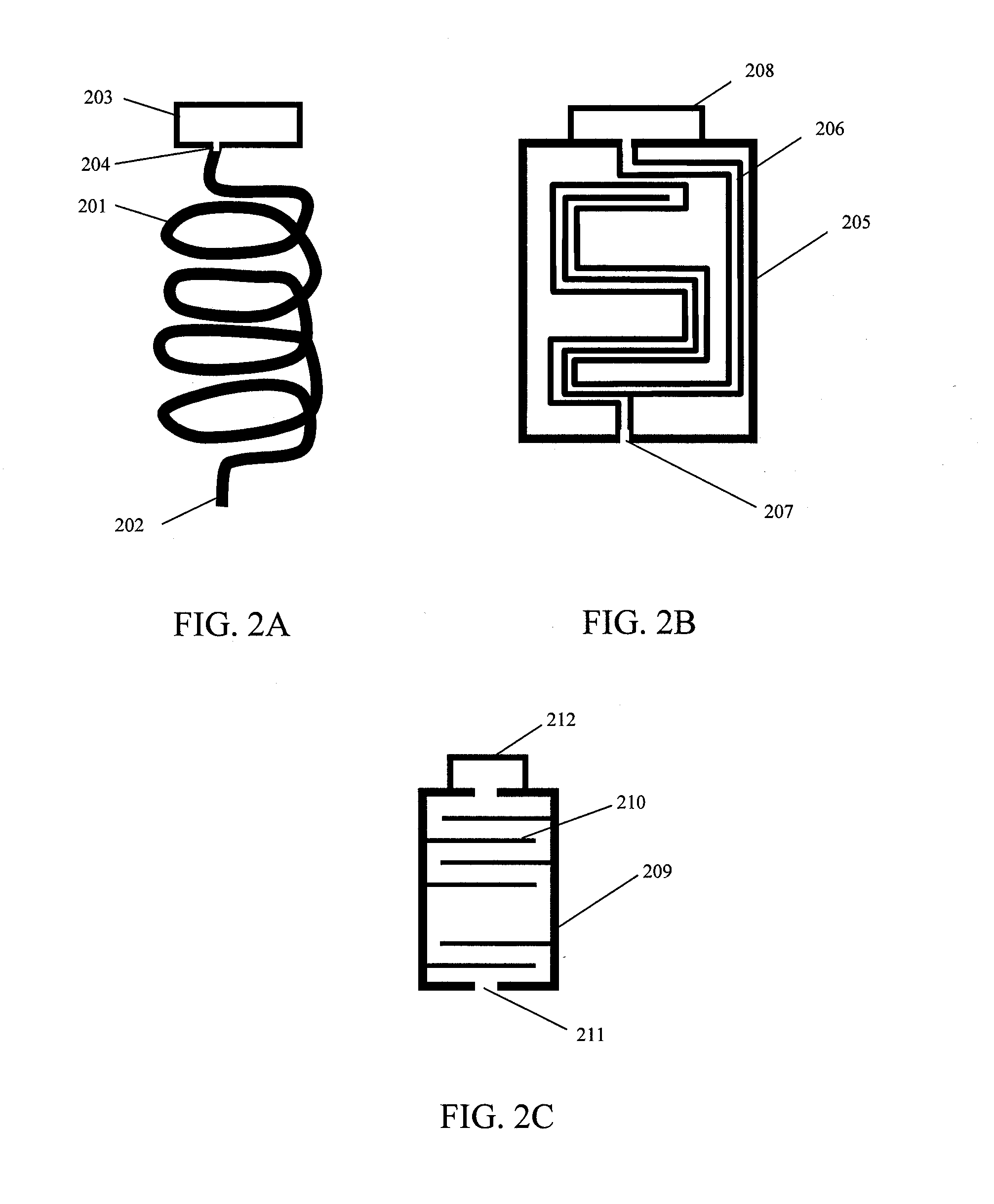

Bulk grain storage spoilage detection apparatus

ActiveUS20110241889A1Reduce personnel safety hazardsIncreasing overall workforce safetySamplingMaterial analysis by electric/magnetic meansGas detectorEngineering

An apparatus is disclosed for facilitating spoilage detection in bulk grain storage bins via dust-free or substantially dust-free air sampling. Dust particles are passively removed from sampled air without the use of barrier filters or electrostatic screens, but instead through the use of a non-linear pathway that is open at one end and closed at the other end. A system is disclosed that incorporates a coiled pathway as an air inlet element combined with a carbon dioxide or other gas detector element to provide an integrated detector module suitable for permanent installation in a dusty bulk grain storage bin environment to provide spoilage gas measurements over time. The system may communicate data to a central data storage system via cellular telephone or long range radio frequency data transmission. Alerts and alarms are generated and transmitted electronically to users via email, SMS text, automated phone messages and other means.

Owner:BIN TECH L

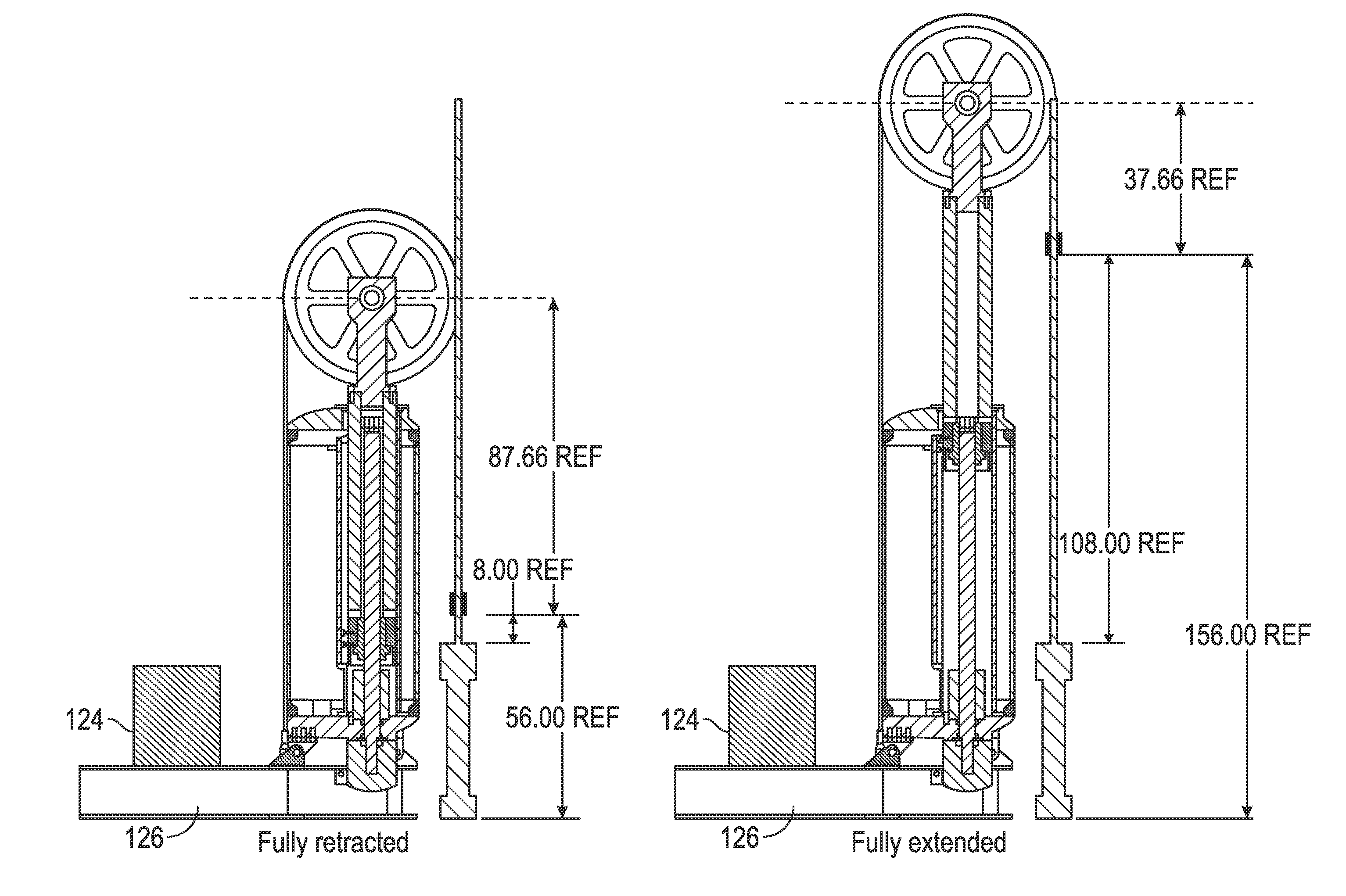

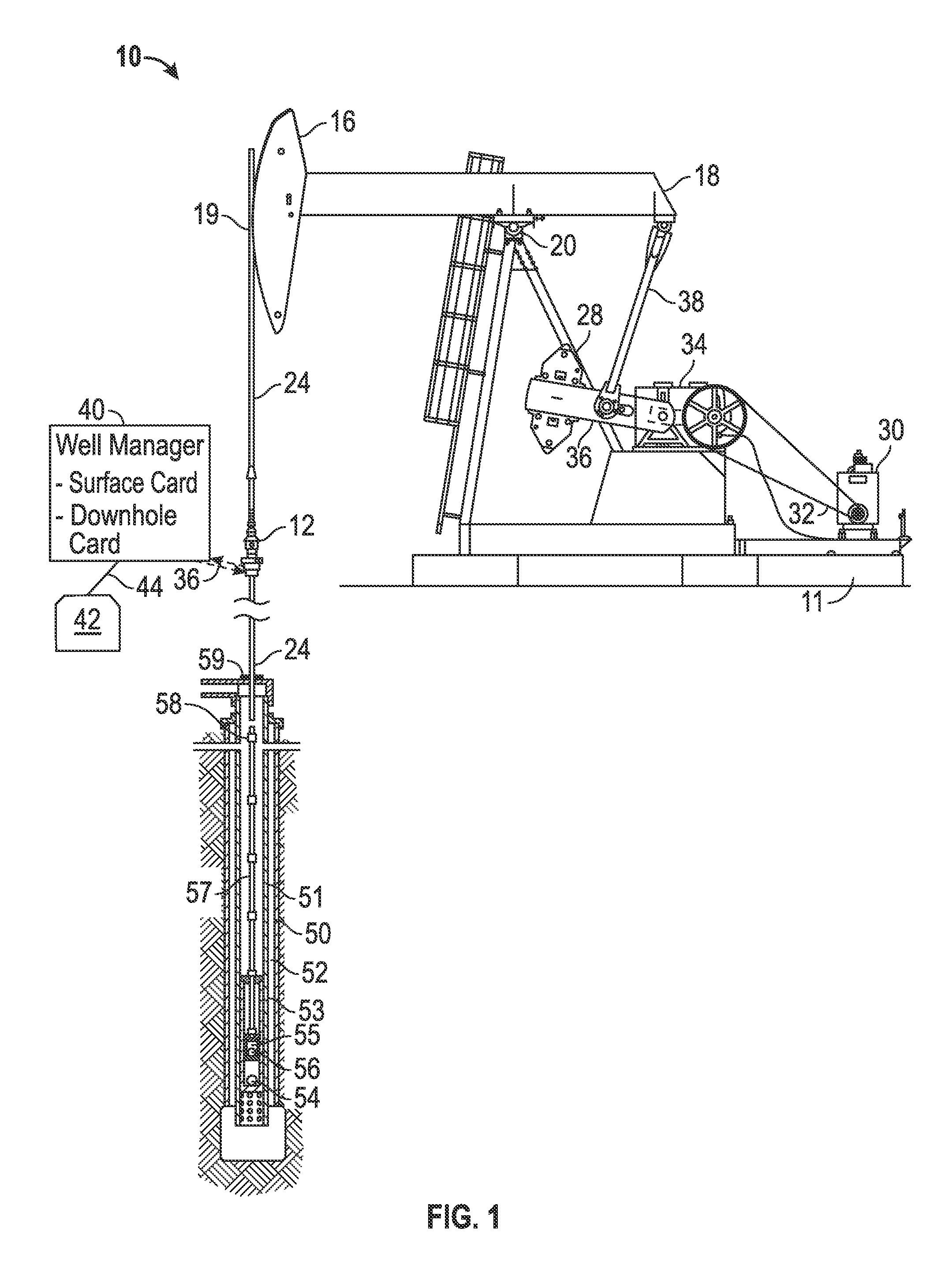

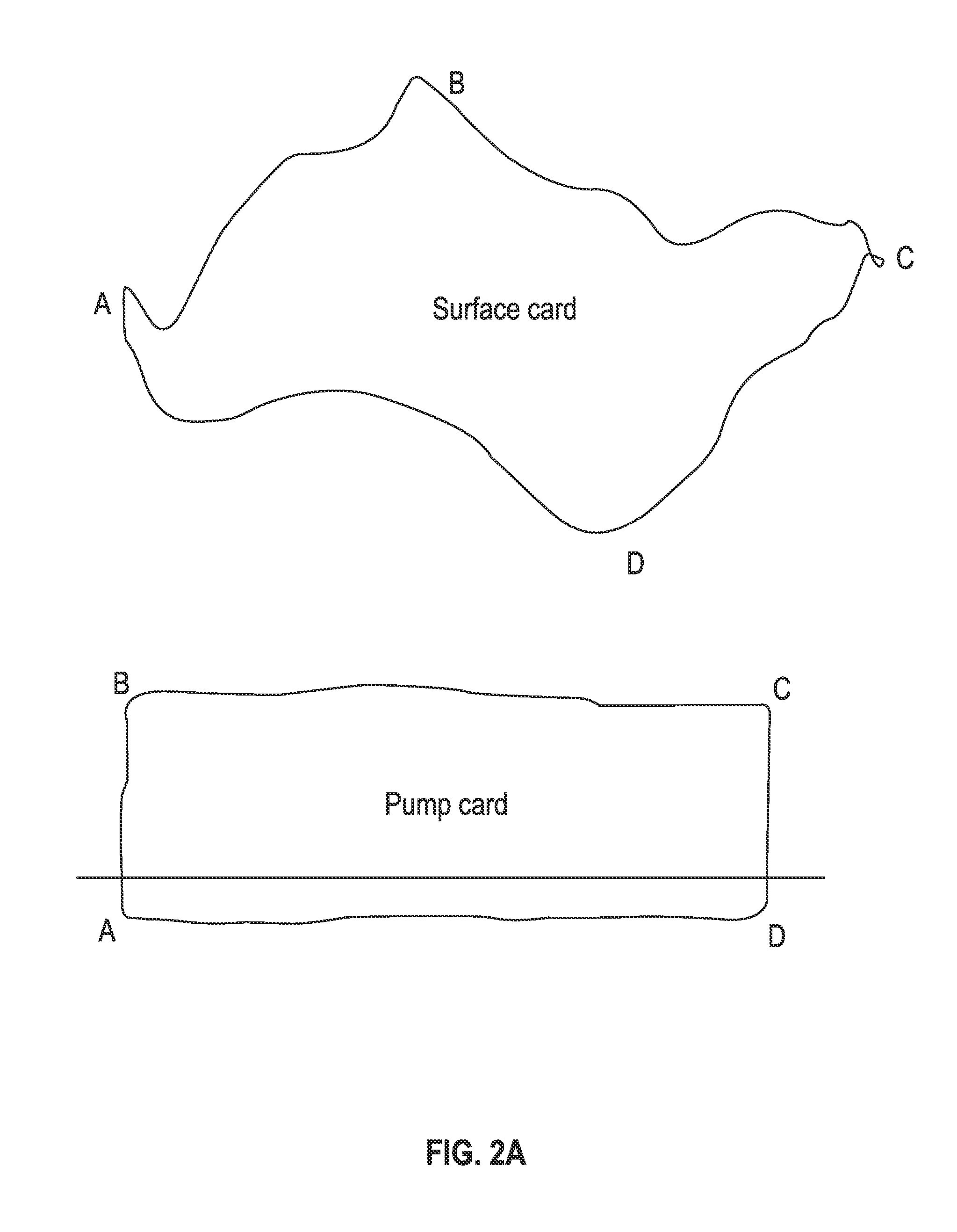

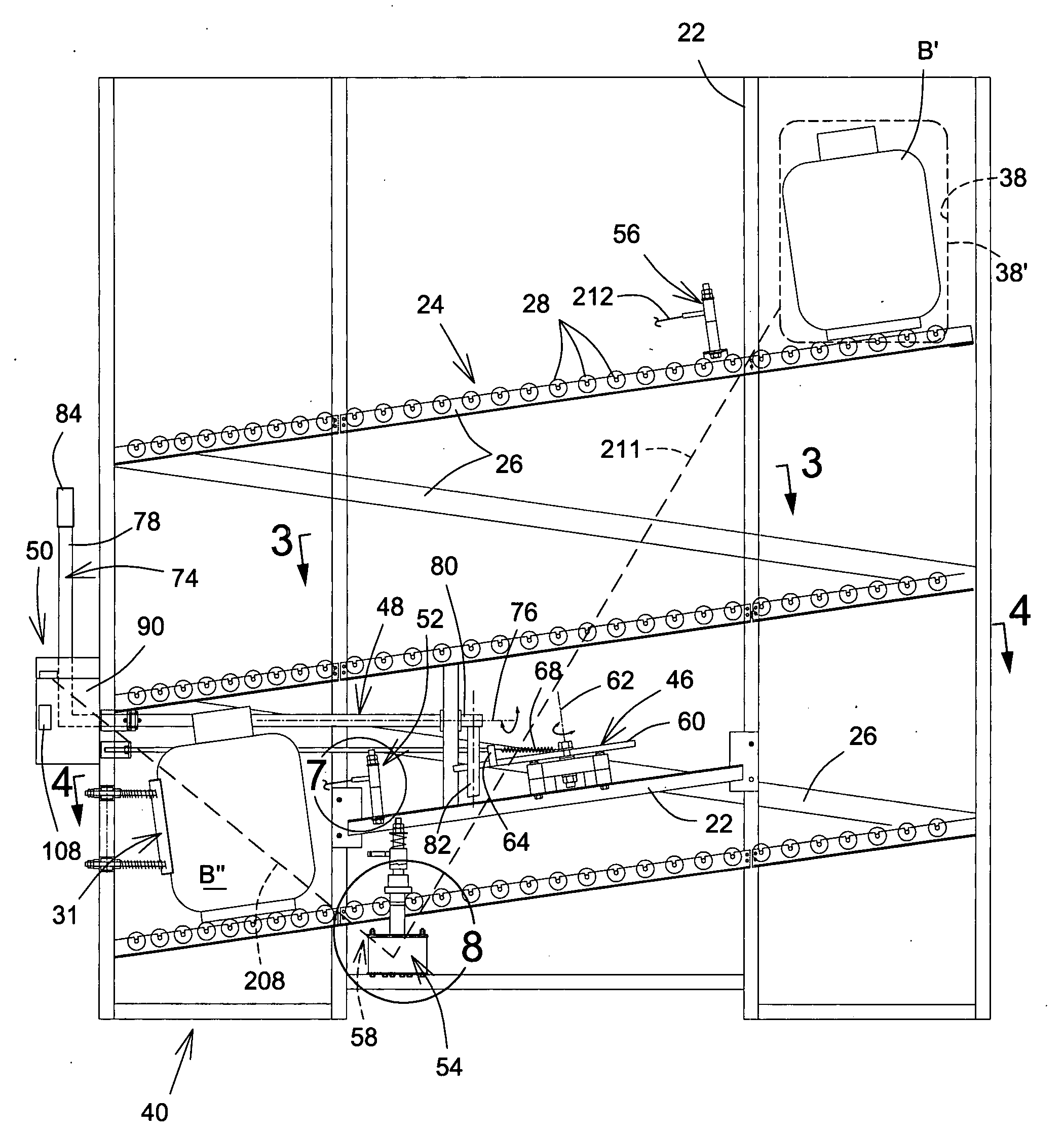

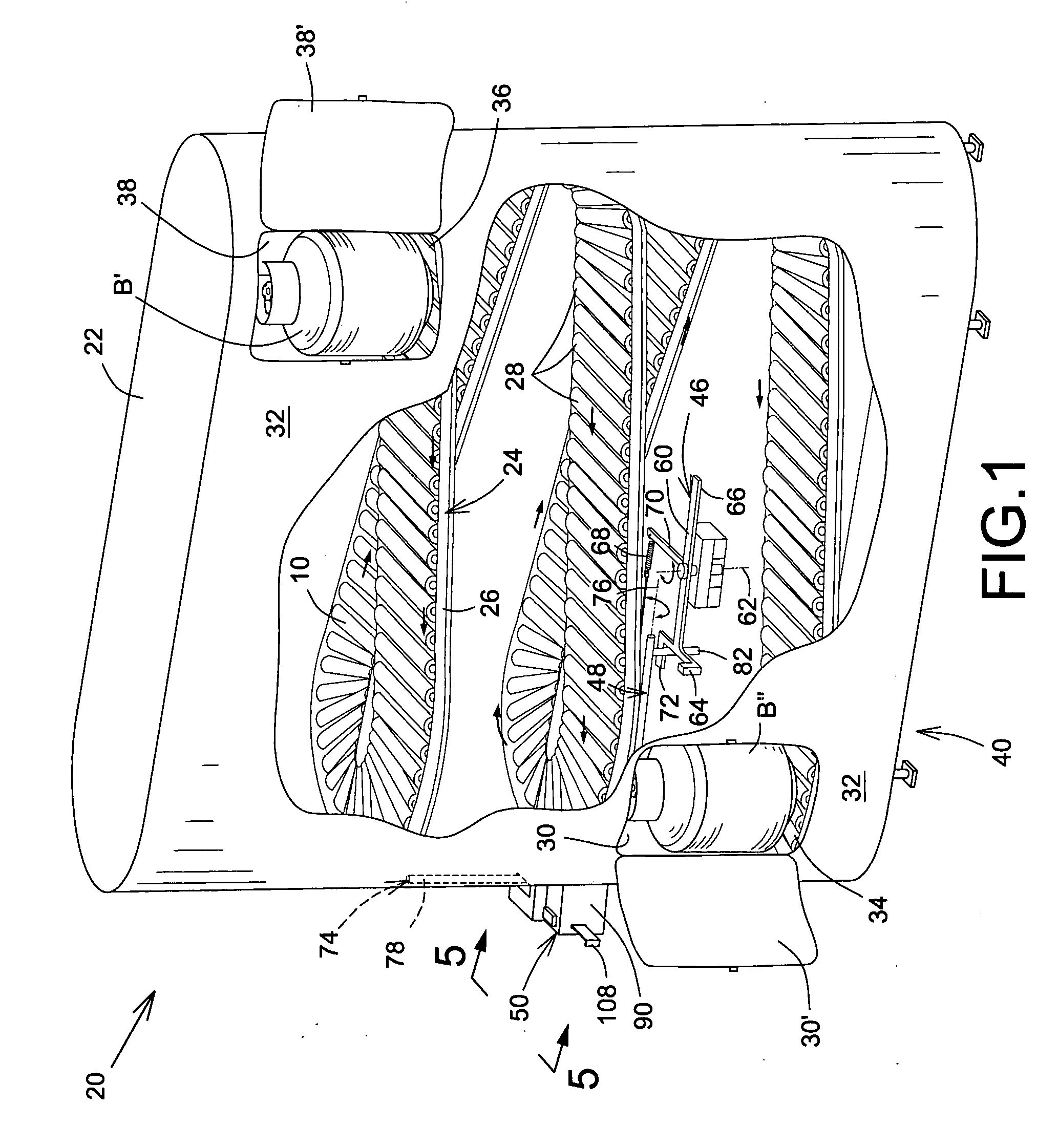

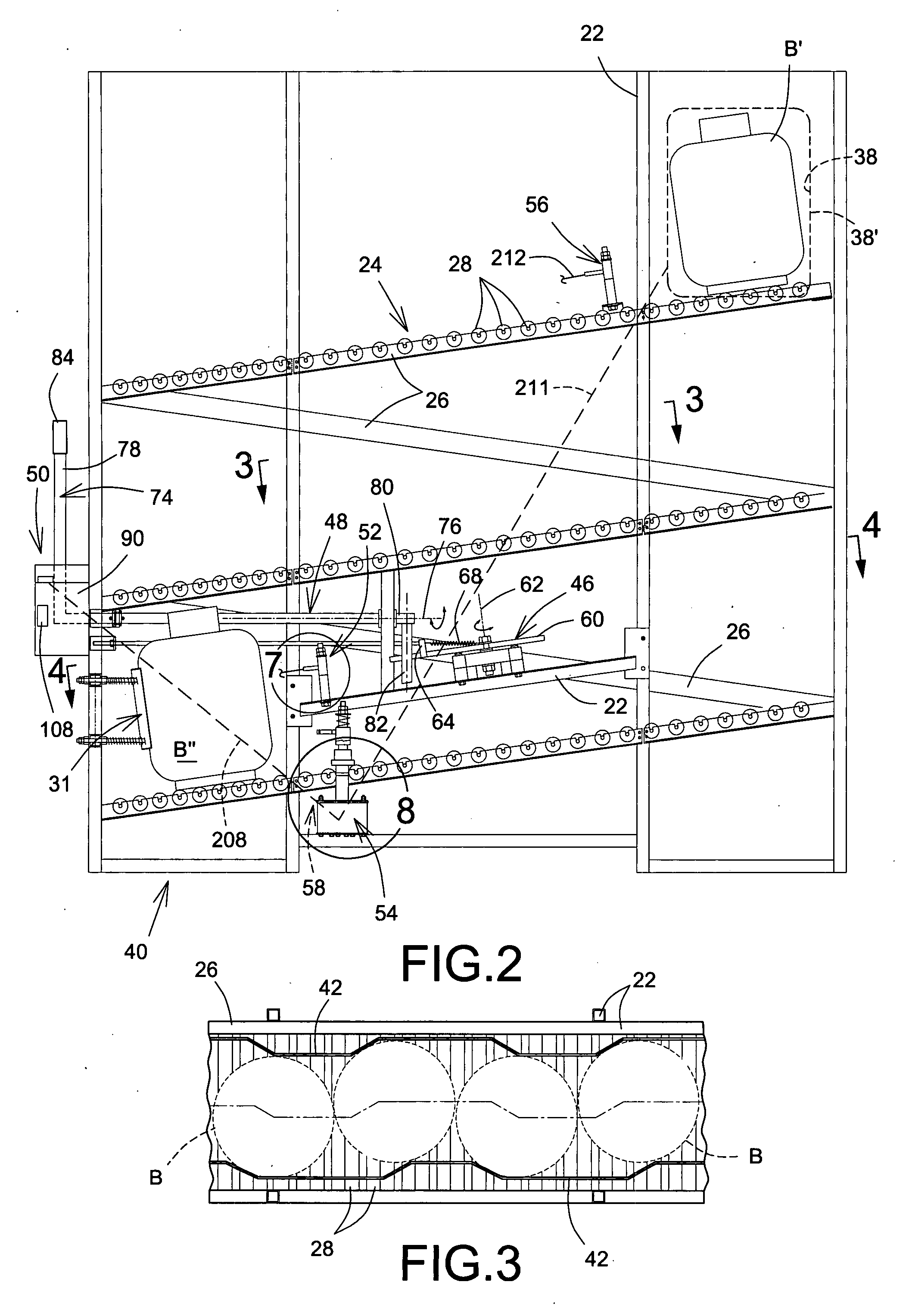

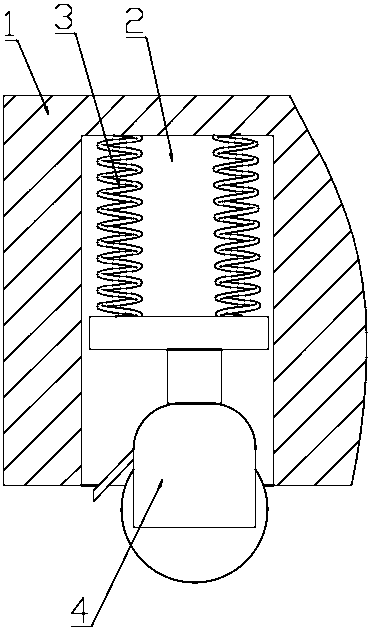

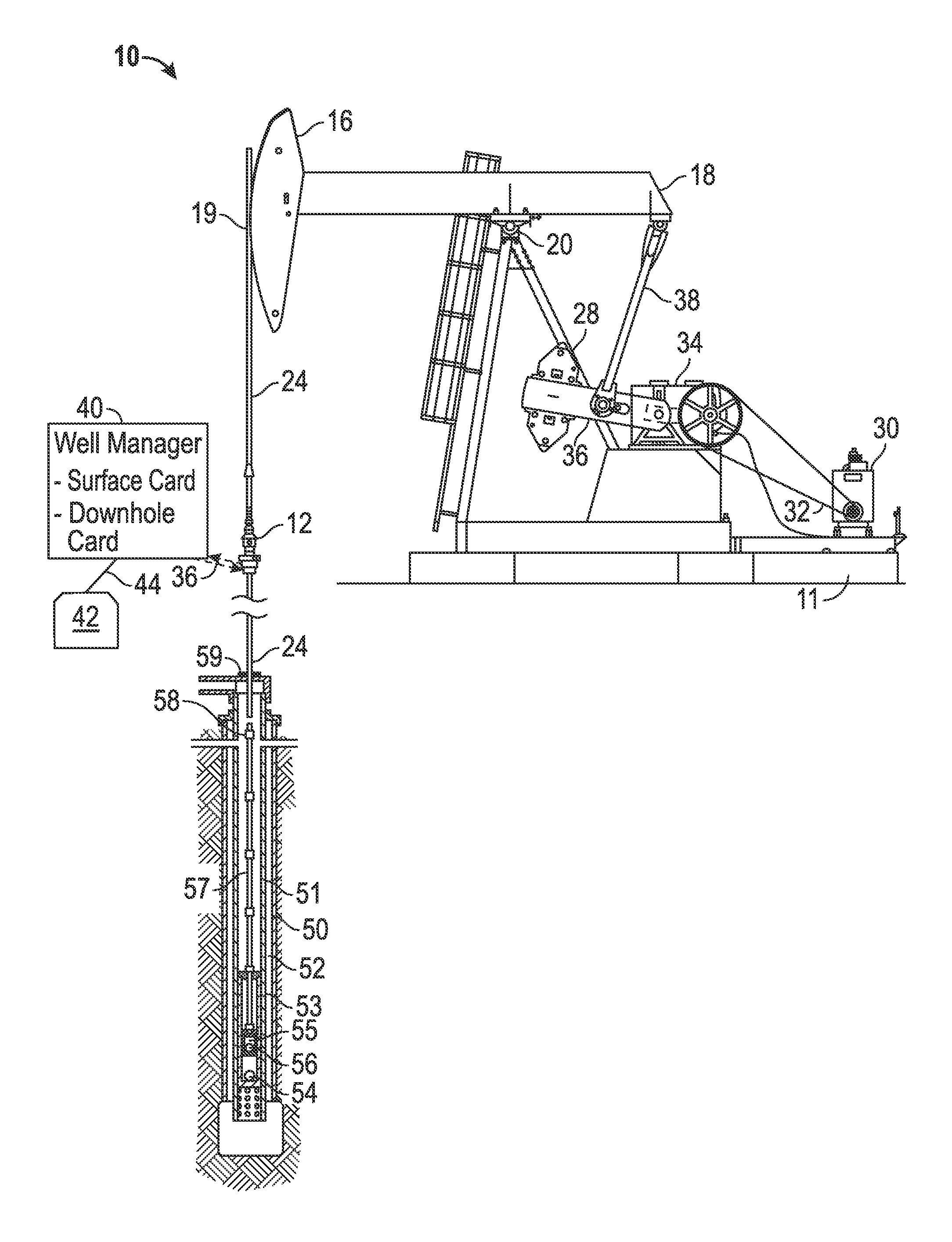

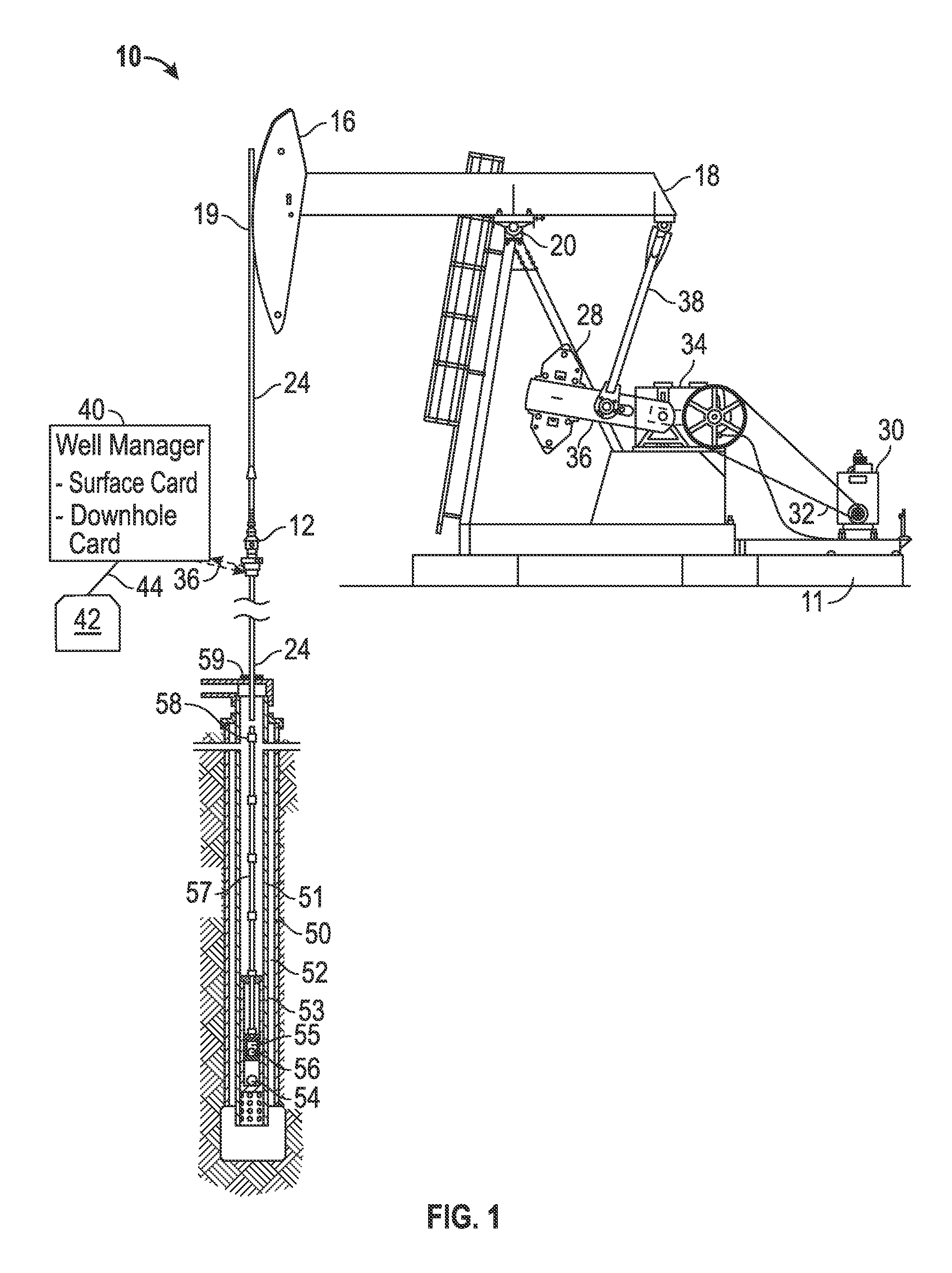

Low Profile Rod Pumping Unit with Pneumatic Counterbalance for the Active Control of the Rod String

ActiveUS20130306326A1Small environmental footprintEliminate potential safety hazardsConstructionsGearingEngineeringAutomation

Adaptable systems for a surface pumping unit that includes a low inertia pumping unit mechanism having a pneumatic counterbalance assembly are described, as well as methods for the use of such systems for subterranean fluid recovery. The system is capable of being integrated with well management automation systems, thereby allowing for response to active control commands, and automatically altering and / or maintaining a counterbalance force in the pumping unit by adding or removing air mass from a containment vessel associated with the pumping unit.

Owner:RAVDOS HLDG INC

Mercury-free catalyst applied to stationery bed for preparing chloroethylene and preparation method thereof

ActiveCN103551168AHigh activityHigh selectivityPhysical/chemical process catalystsPreparation by halogen halide additionDecompositionHigh activity

The invention provides a mercury-free catalyst applied to stationery bed for preparing chloroethylene and a preparation method thereof. The catalyst takes activated carbon, pretreated by hydrochloric acid or sodium hydroxide water solution, as a carrier, and gold trichloride and ferric chloride as active components, and compared with the ordinary mercury-free catalyst, according to the preparation method of the catalyst, the gold trichloride is guaranteed not to be reduced and can be uniformly and firmly loaded on the surface of the activated carbon carrier by replacing nitrohydrochloric acid in the preparation of the catalyst with hydrogen peroxide and taking other metal chloride, capable of promoting the decomposition of the hydrogen peroxide, as auxiliaries. The catalyst has high activity and selectivity in the reaction of preparing chloroethylene in the stationery bed through acetylene hydrochlorination, and the preparation method is simple and efficient, and green and environment-friendly, and has important practical significance in the industrial application.

Owner:NANKAI UNIV

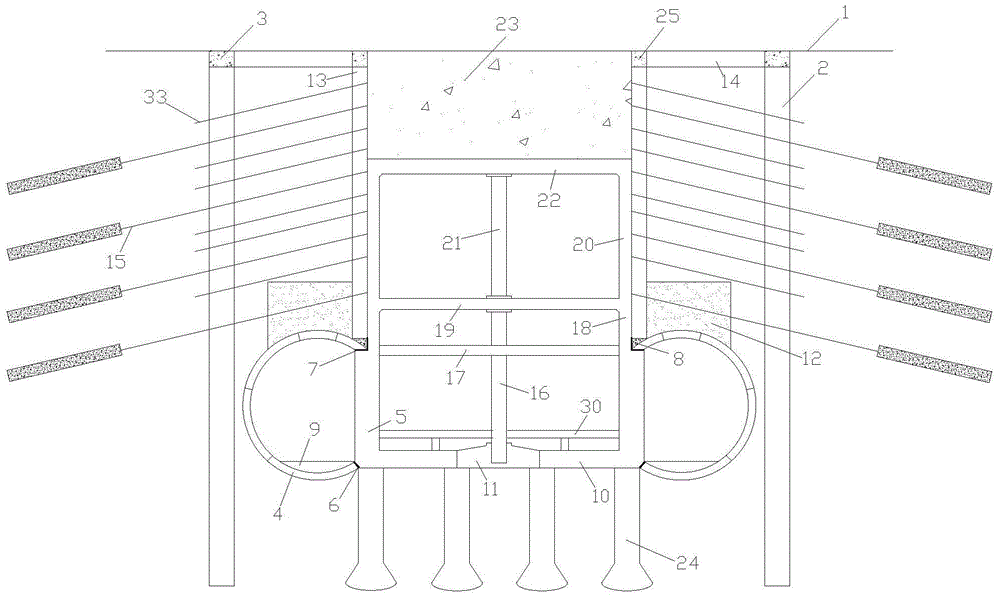

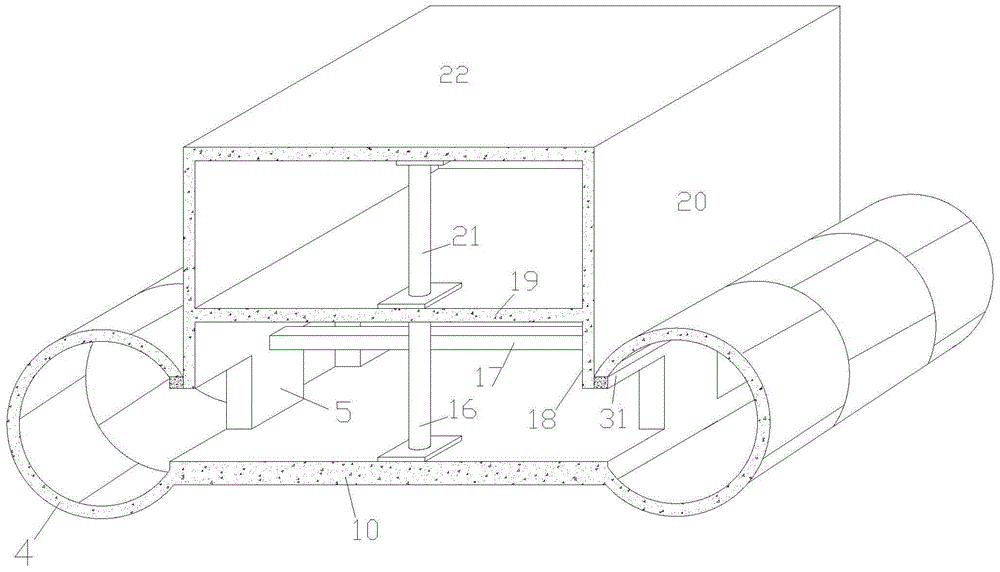

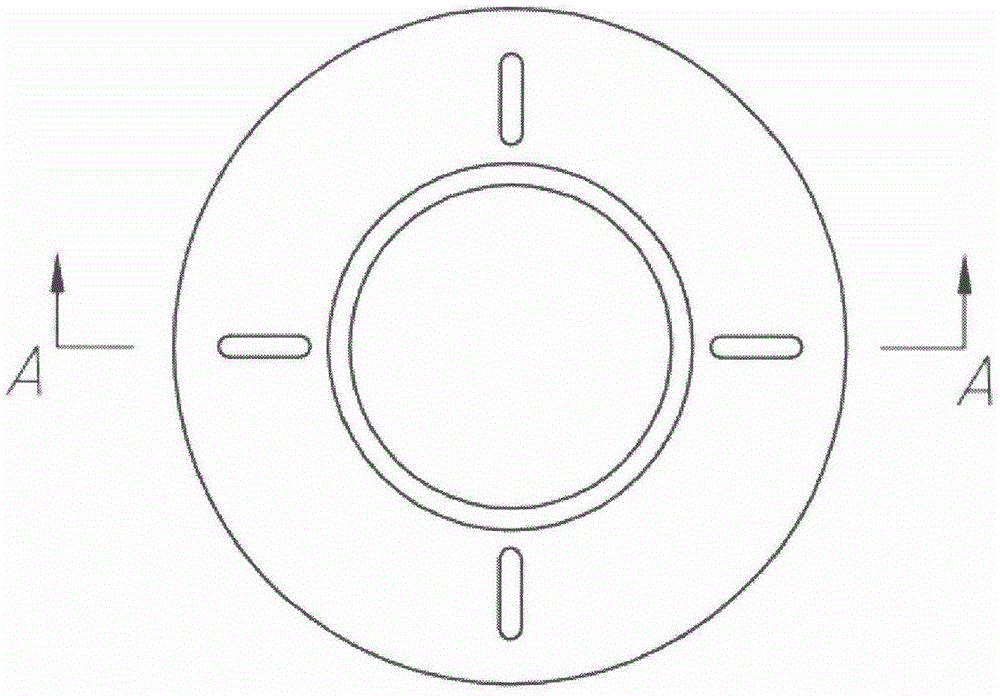

Open excavation construction method for expanding excavation of station on metro interzone shield tunnel foundation

InactiveCN105064397AReduce non-propulsion workImprove construction efficiencyArtificial islandsExcavationsStress systemSlurry wall

An open excavation construction method for expanding excavation of a station on a metro interzone shield tunnel foundation method includes the steps that uplift piles, wall columns, a base plate, a middle stand column foundation and transverse supporting beams between the wall columns are constructed in a transverse channel, wherein the base plate is connected with the bottoms of the wall columns, water prevention treatment is conducted, and the wall columns and duct pieces are connected, so that a sealed stress system is formed; soil over the tunnel is subjected to grouting reinforcement, an excavation retaining structure of a station body foundation bit is built, and the top end of the structure is connected with an external campshed or an underground diaphragm wall through a connection beam; slopes are supported through a composite soil nailing supporting technology, foot locking supports are erected at the pile foots, after excavation is conducted on the bottom of a foundation pit, residual duct pieces are removed, connection beams between the wall columns are constructed, and the connection beams are firmly connected with the duct pieces; the transverse support system is constructed. The method is reasonable, feasible and high in maneuverability. By means of application of the method, great economic benefits, social benefits and environmental benefits are achieved. The method has significant engineering application value and development prospects.

Owner:BEIJING UNIV OF TECH

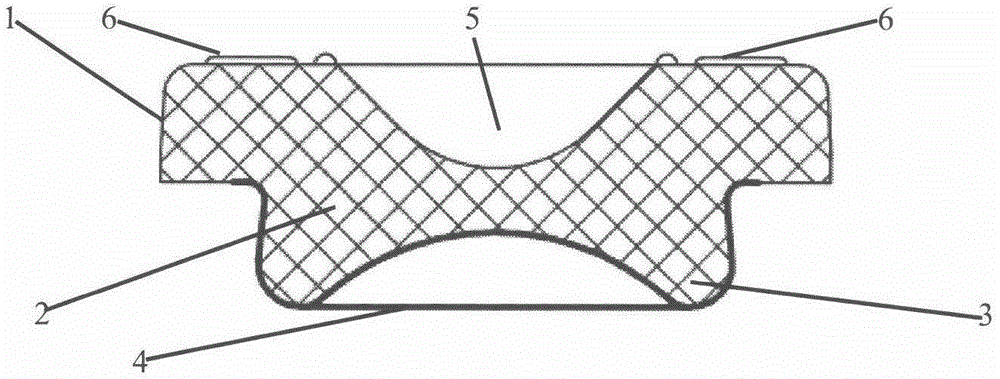

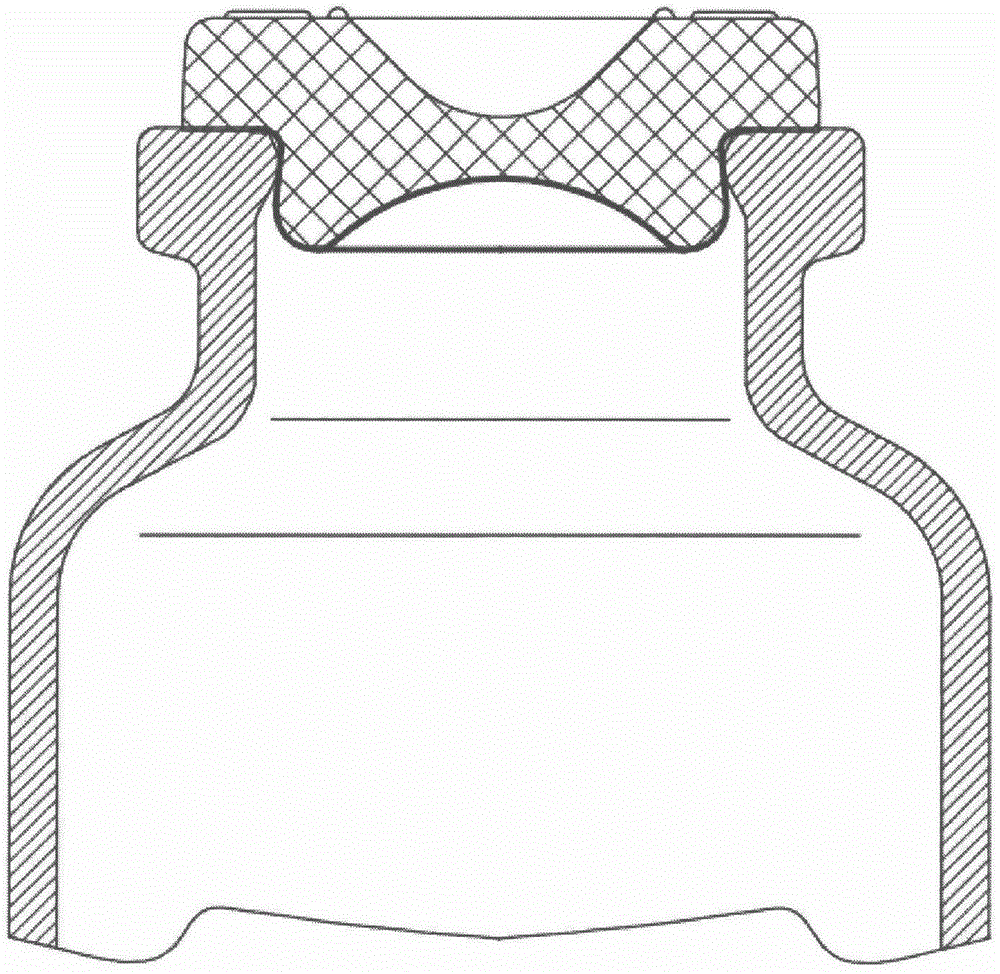

Laminating rubber plug and production method thereof

InactiveCN105662859APrevent jumpingEasy to cleanPharmaceutical containersMedical packagingAfter treatmentVulcanization

The invention discloses a laminating rubber plug which comprises a rubber plug crown part and a rubber plug neck part, wherein the bottom surface of the rubber plug neck part is a spherical arc surface; the surface of the plug neck is covered with a film; the laminating part stretches from the surface of the plug neck to the plane position of the plug crown part sealed with a bottleneck; the plug column part of the rubber plug neck part has a small top and a big bottom; and spherical concave pinpricks are formed in the top surface of the rubber plug crown part, and protuberances are arranged around the pinpricks. The invention also discloses a production method of the laminating rubber plug, which comprises four steps of piece squeezing, piece punching, vulcanization and after-treatment. Due to the technical scheme, direct contact between the rubber plug and tablets can be prevented, the medicine is prevented from permeating and being precipitated and dissolved out for sure, the air tightness can be guaranteed, the plug jump can be avoided in automatic encapsulation, and exceeding fragmentation caused by a non-standard needle can be prevented; and moreover, secondary vulcanization is reduced in the production method, the silicification technology is not adopted, the materials and secondary pollution are reduced, and the original characteristics of the film materials are guaranteed.

Owner:JIANGSU HUA LAN PHARMA NEW MATERIALS LTD BY SHARE LTD

Waterborne leveling agent for dyeing ultrafine fiber PU synthetic leather

The invention discloses a waterborne leveling agent for dyeing ultrafine fiber PU synthetic leather, which relates to the technical field of synthetic leather. The waterborne leveling agent is prepared from the following raw materials in parts by weight: 25 to 35 parts of methoxy polyethylene glycol, 10 to 15 parts of sodium polyacrylate, 1 to 5 parts of hydrogenated ricinoleic acid, 1 to 5 partsof gamma-polyglutamic acid, 1 to 5 parts of N-hydroxyethyl acrylamide, 0.5 to 3 parts of 2-Amino-2-(hydroxymethyl)-1,3-propanediol, 0.5 to 3 parts of povidoneK30, 0.05 to 0.5 part of vinyl trimethoxysilane, and 0.05 to 0.5 part of titanate coupling agent TMC-WT. The leveling agent of the invention belongs to the waterborne leveling agent; and by adopting the waterborne leveling agent, the staining rate of the dye on the synthetic leather can be significantly increased, the color difference can be reduced, the uniformity in dyeing the synthetic leather can be realized, a K / S value at 460nm isgreater than 4, and a DEcmc value is smaller than 0.3.

Owner:马多浩

One part, solids containing decontamination blend composition

ActiveUS20080176943A1Safety hazardLess-restrictive packaging and handling and shipping qualityBiocideDead animal preservationPollutantNerve gases

A one part, solids containing decontamination blend composition comprises a solid acetyl donor coated with a compound that protects it from hydrolysis, a peroxygen source, optionally a catalyst, optionally a surfactant, and optionally a buffer. The decontamination blend composition is generally in a dry powder, particle, etc form or in a tablet, pill, etc form and is complete in and of itself in that no additional compounds are required prior to use and is readily distributed as a one package system. Upon the addition of water, a peroxygen compound such as hydrogen peroxide is formed, and peracetic acid is generated under alkaline conditions. The decontamination blend composition is particularly suitable for oxidizing various chemical and biological compounds thereby eradicating the same in situ as on surfaces, clothes, articles, and the like. Representative contaminants include mustard gas, nerve gas, bacterial toxins, anthrax, bird flu, and the like.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY +1

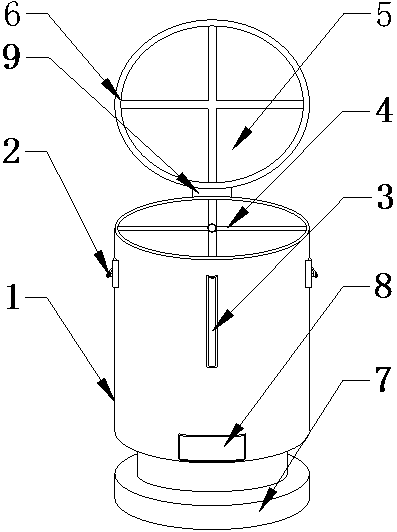

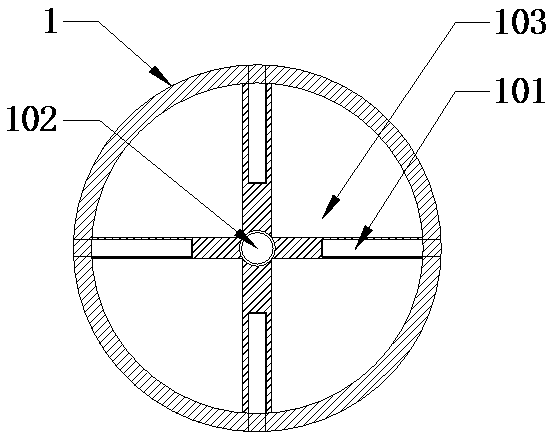

Classification garbage can

InactiveCN109533706AImprove classification performanceEmbody practicalityRefuse receptaclesFire preventionComputer science

The invention discloses a classification garbage can. The classification garbage can comprises a classification garbage can main body, a classification garbage can sealing top cover and a base, wherein a classification garbage can handle is movably connected to one side of the top of the classification garbage can main body, hidden type cigarette end placing boxes are embedded into the middle of the top of the classification garbage can main body, a hidden drawer is embedded into the bottom of the classification garbage can main body, the bottom end of the classification garbage can main bodyis movably connected with the base, the base can enable the classification garbage can main body to rotate, so that the classification garbage can is more convenient to use, and the flexibility of theclassification garbage can main body is improved; due to the fact that the four cigarette end placing boxes are arranged, the fire caused by the fact that cigarette ends are not extinguished is wellprevented, the safety performance of the classification garbage can is enhanced, the fire prevention capability of the classification garbage can is improved, and the safety of the classification garbage can is embodied; the classification garbage can is convenient to use and suitable for the technical field of environmental protection products, and has a wide development prospect in the future.

Owner:深圳景丹软件科技有限公司

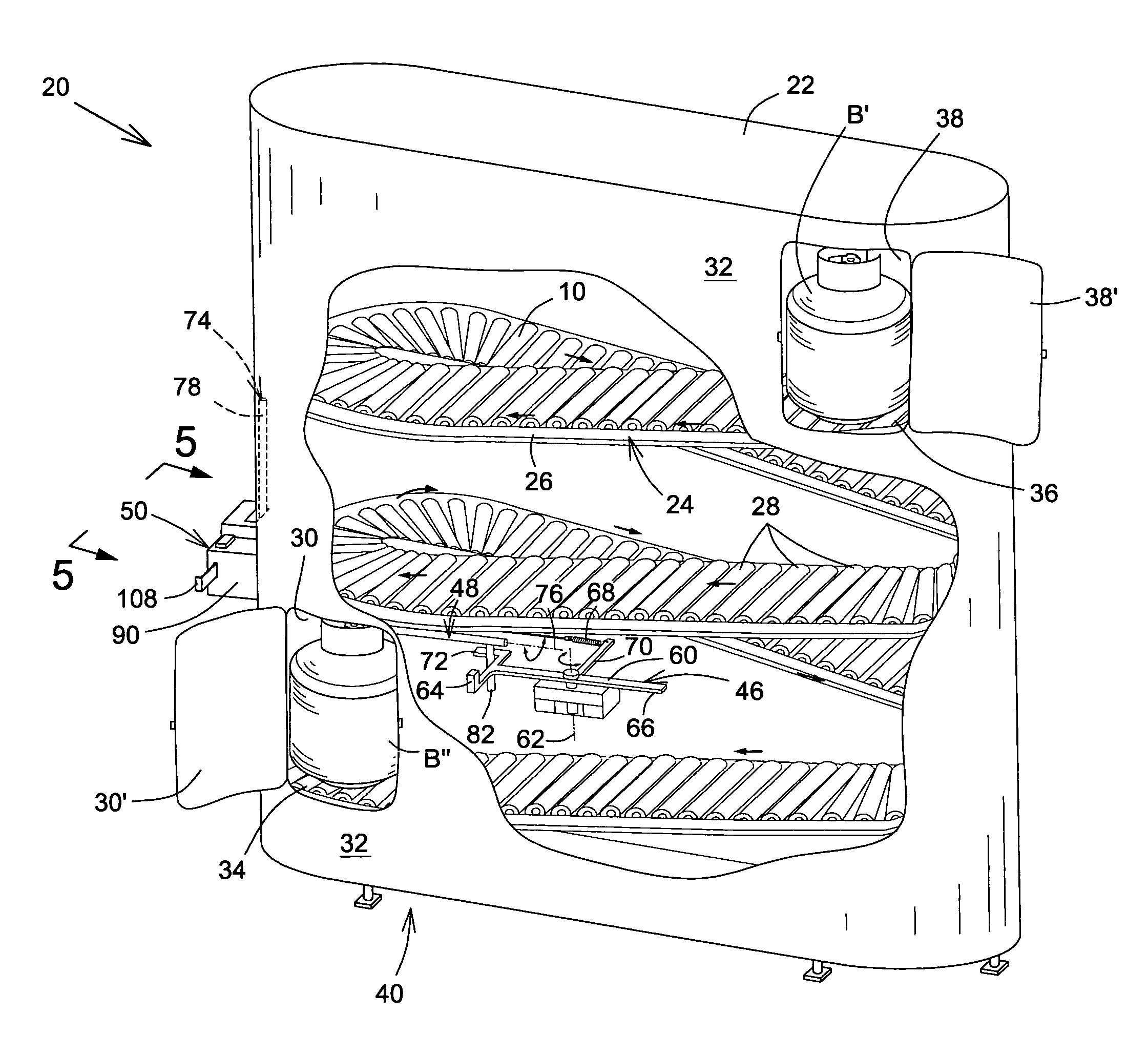

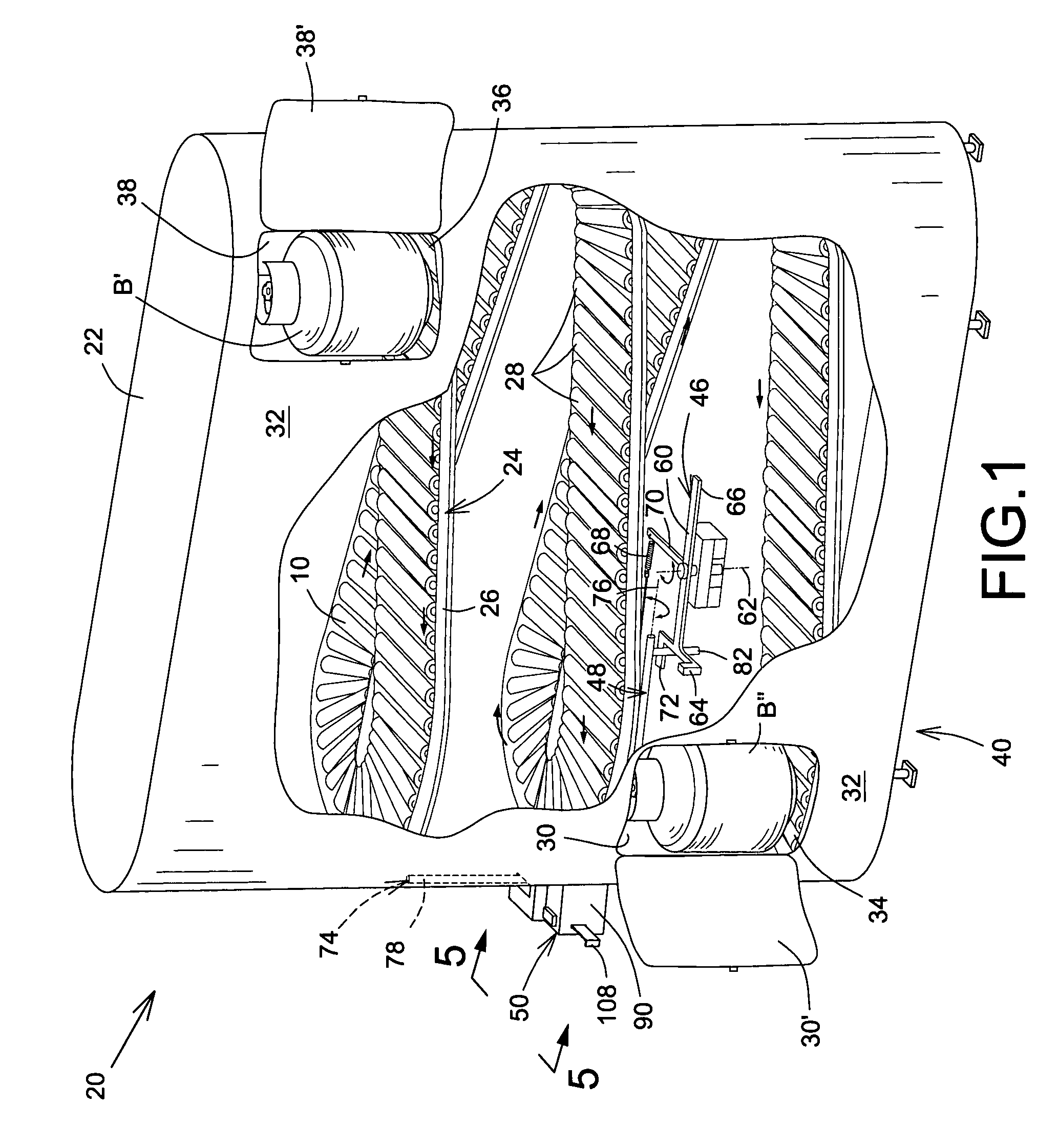

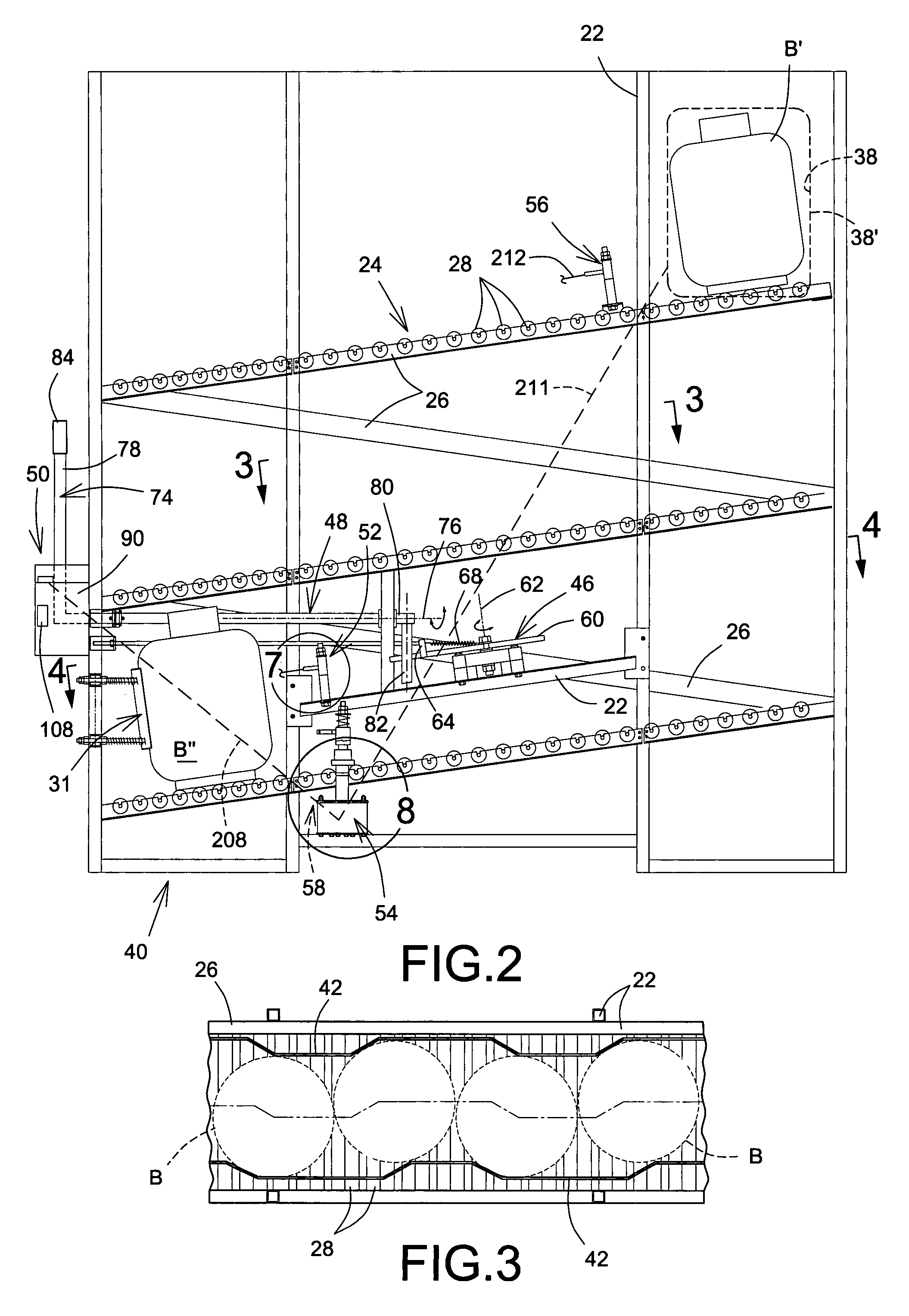

Mechanical gas bottle dispensing machine

ActiveUS20090084810A1Prevent operationSafety hazardSmall article dispensingRod article dispensingEngineeringBottle

Owner:BORZYM ANDRZEJ

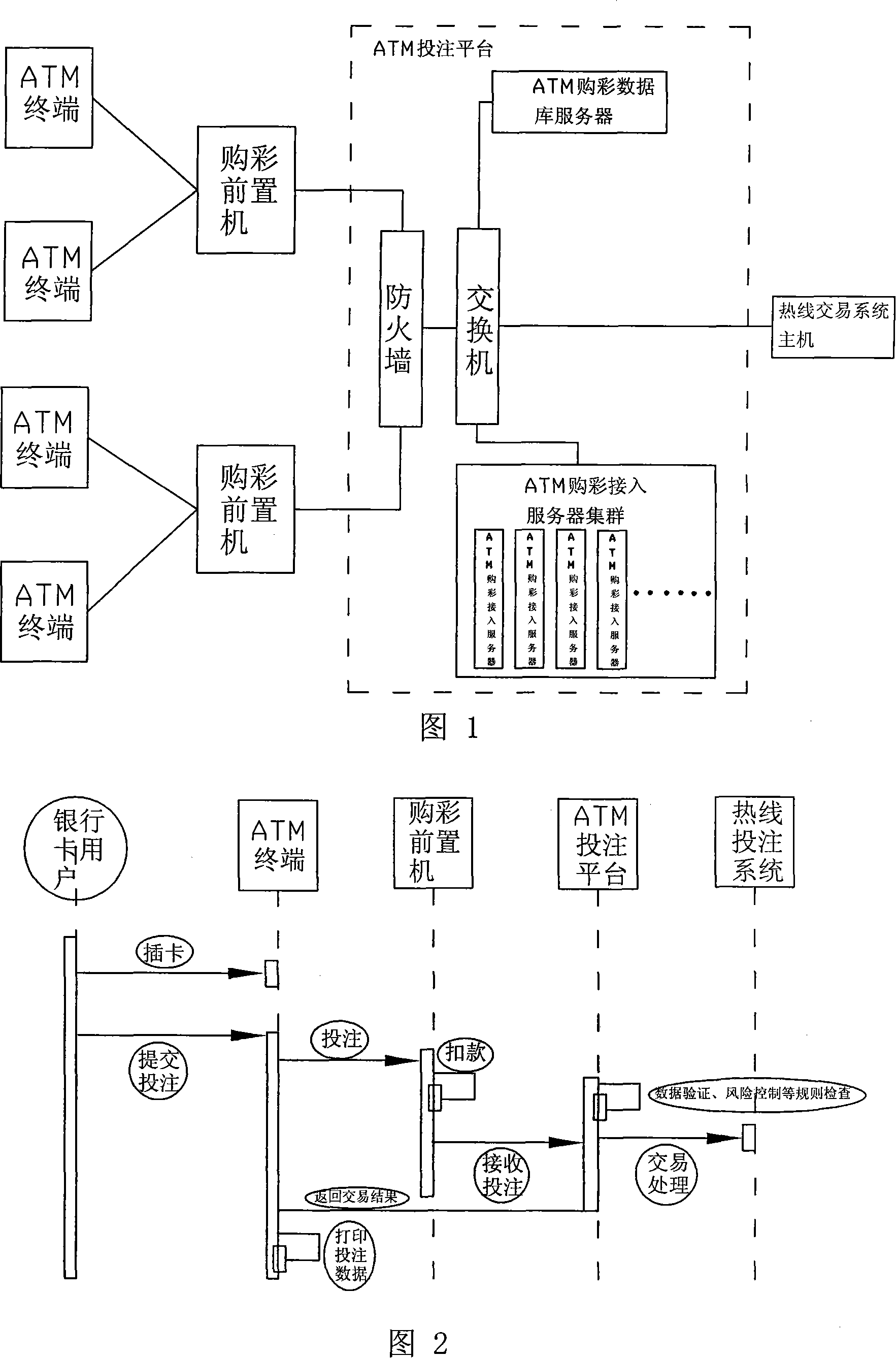

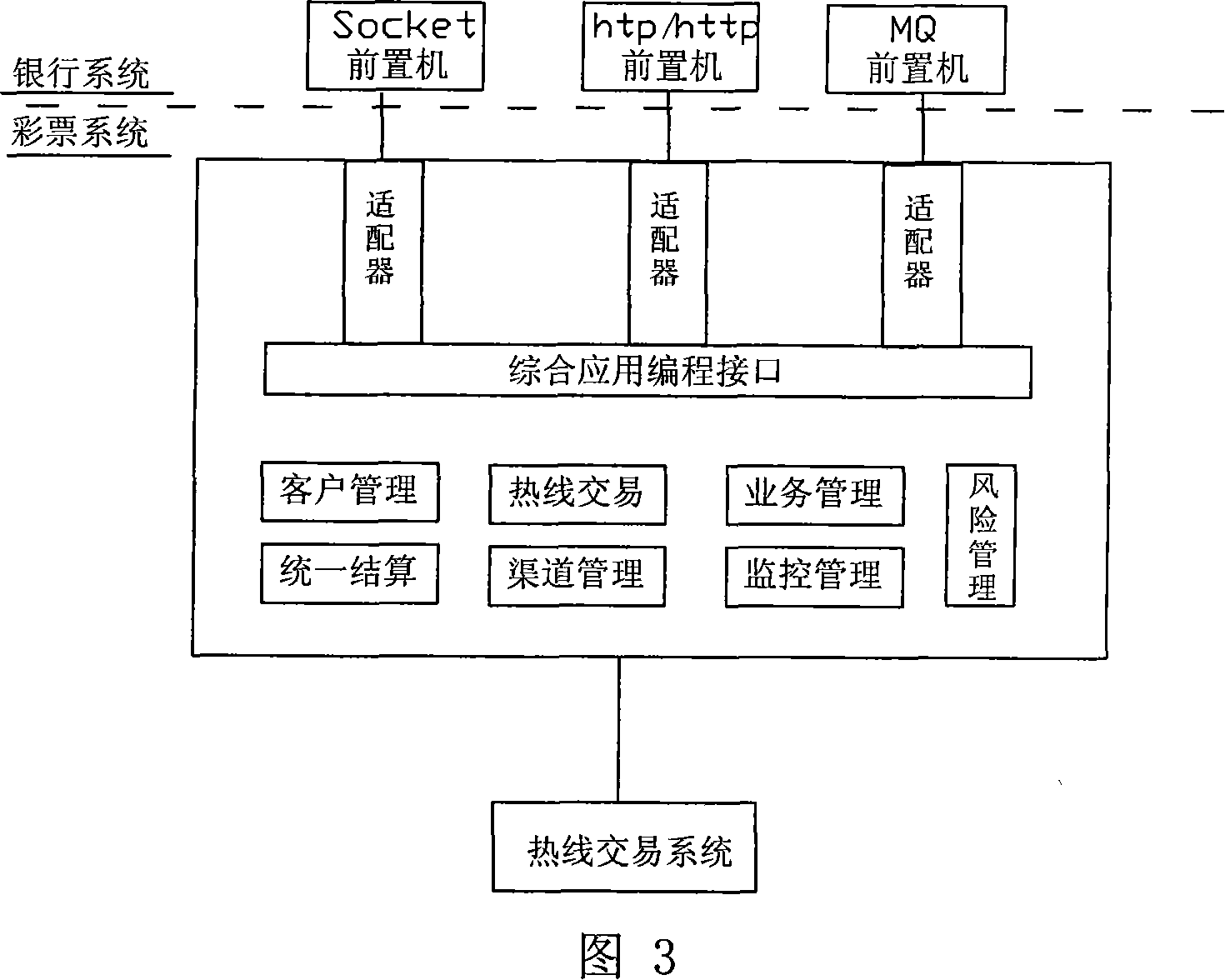

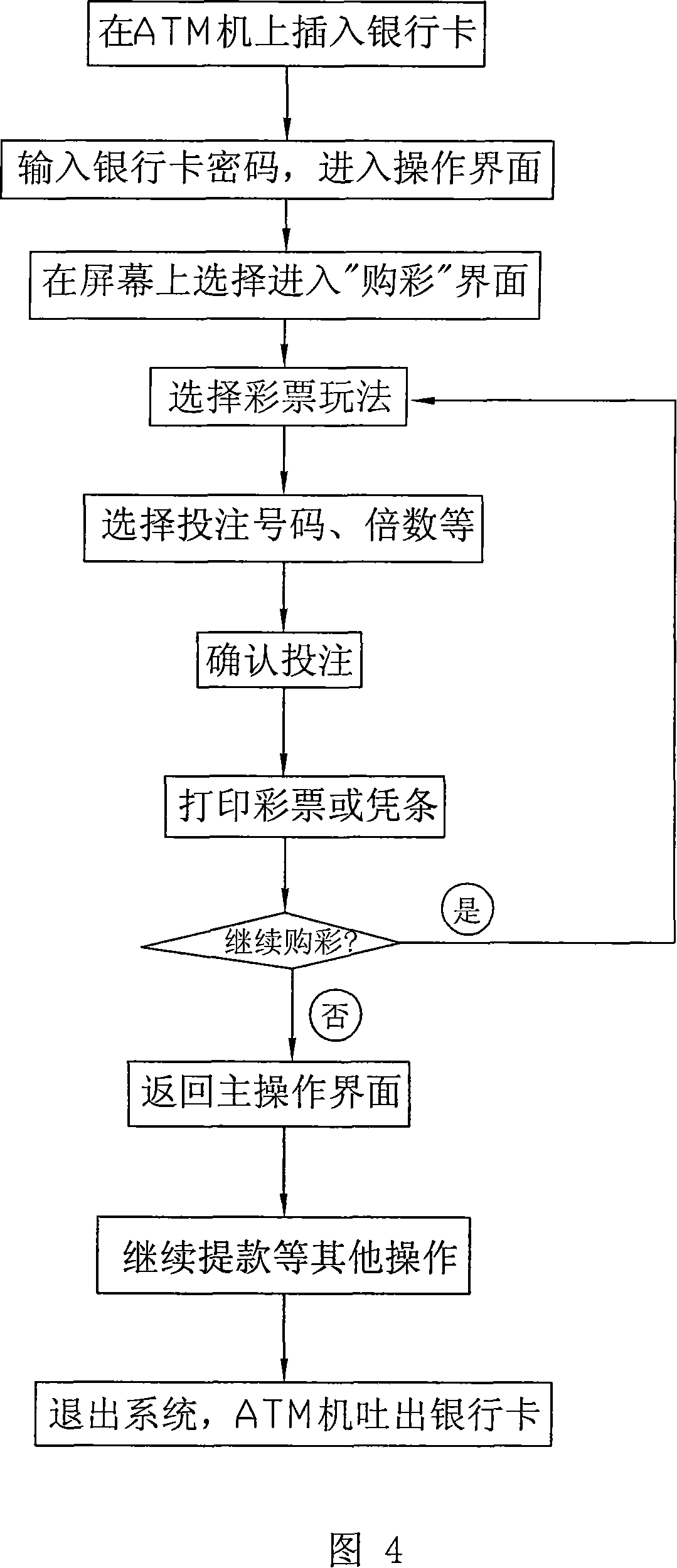

Bank self-help lottery ticket distribution system and its method

InactiveCN101236670ASolve technical problems of electronic transactionsReduce the issuance of currencyComplete banking machinesLottery apparatusDistribution systemHotline

The present invention discloses a bank self-service lottery sale system and a method thereof. The system mainly comprises a bank ATM terminal, a lottery purchase front end computer, an ATM bet platform and a hotline bet system. The ATM terminal transmits lottery data input on the ATM terminal by a user to the lottery purchase front end computer; the lottery purchase front end computer gathers the lottery purchase information of the user through the ATM terminal and deducts lottery money amount from a bank card of the user; the lottery purchase front end computer sends the lottery information including user information to the ATM bet platform for betting; the bet information confirmed by the ATM bet platform is returned to the ATM terminal, and the bet information is sent to the hotline bet system; a bet result is displayed by the ATM terminal. The present invention is used to realize electronic lottery transaction and reduce lottery print waste caused by lottery transaction. The bank card bundled with lottery purchase is safe and fast in transaction, simple in purchase and award cashing procedures, monitors every transaction in real time, and has high supervision property.

Owner:深圳环彩普达科技有限公司

Lifting type intelligent traffic channelizing device

ActiveCN110593154AIncrease frictionReduce weightGeneral water supply conservationTraffic signalsIntelligent transportWind power

The invention discloses a lifting type intelligent traffic channelizing device, and relates to the field of traffic. The device mainly solves the problem that when a traffic light on a road is damaged, a convenient-to-move traffic light is inconvenient to fix when being used for directing the traffic. The device mainly comprises a moving base, wherein a limiting mechanism, a drainage mechanism, avisual inspection mechanism, a control mechanism, a fixing mechanism and an intelligent lifting mechanism are arranged on the moving base; a proper amount of water is added into a water containing box, a telescopic spring is compressed, and universal wheels are retracted into circular grooves, so that the lower surface of the moving base is directly contacted with the ground, the moving is prevented, and the fixing is facilitated; and the height of the traffic light is adjusted by detecting the size of the wind power. The lifting type intelligent traffic channelizing device has the beneficialeffects that the device can be quickly fixed, the use is convenient, the wind resistance can be reduced conveniently, and the use is safer.

Owner:翟维

System and method of chamber destruction of bomb

The invention discloses a system and method to destroy bomb in underground chamber that is made up of destroying underground chamber located in wall rock and the bottom has impacting resistance material layer, adit and communicating laneway that has laneway structure. The destroying underground chamber connects to adit through laneway. After setting the system, laying the bomb and blasting charge into the underground chamber to take remote detonation and take forced draught after detonating to release the waste gas into atmosphere and the harmful gas thickness would be lowered to safe range. The system would destroy 200kg detonator equivalent weight bomb, and the bow wave would not harm human over 200m distance. Even in the area of popuousness.

Owner:GUANGDONG HONGDA BLASTING

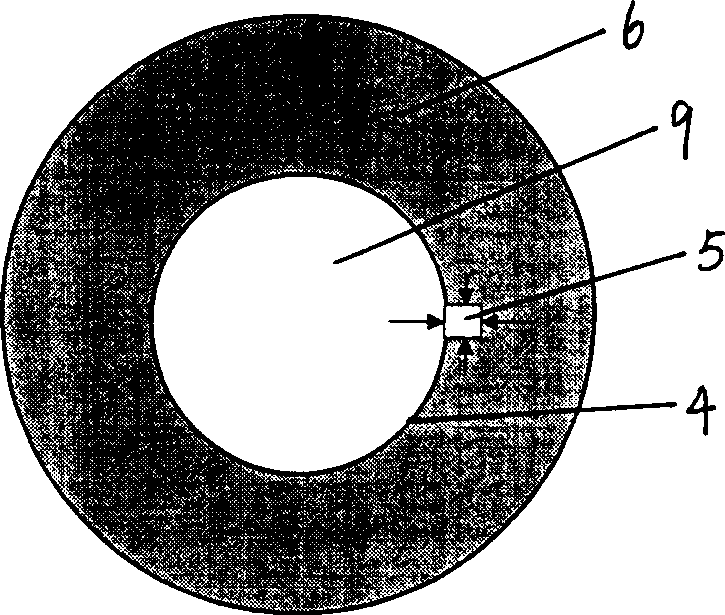

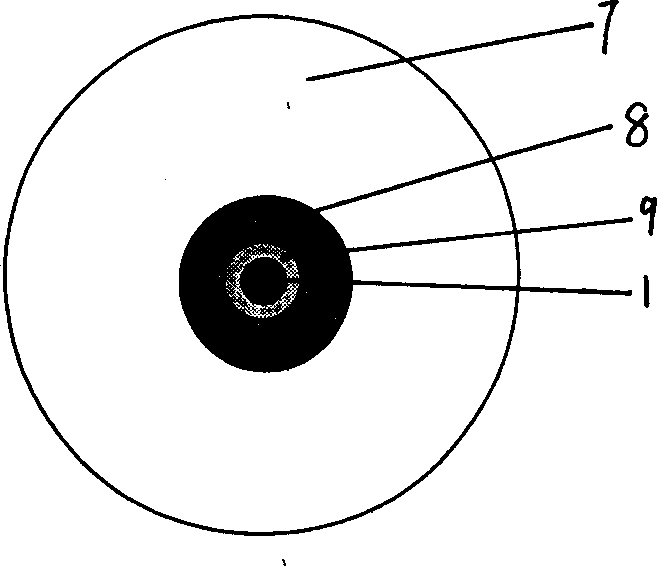

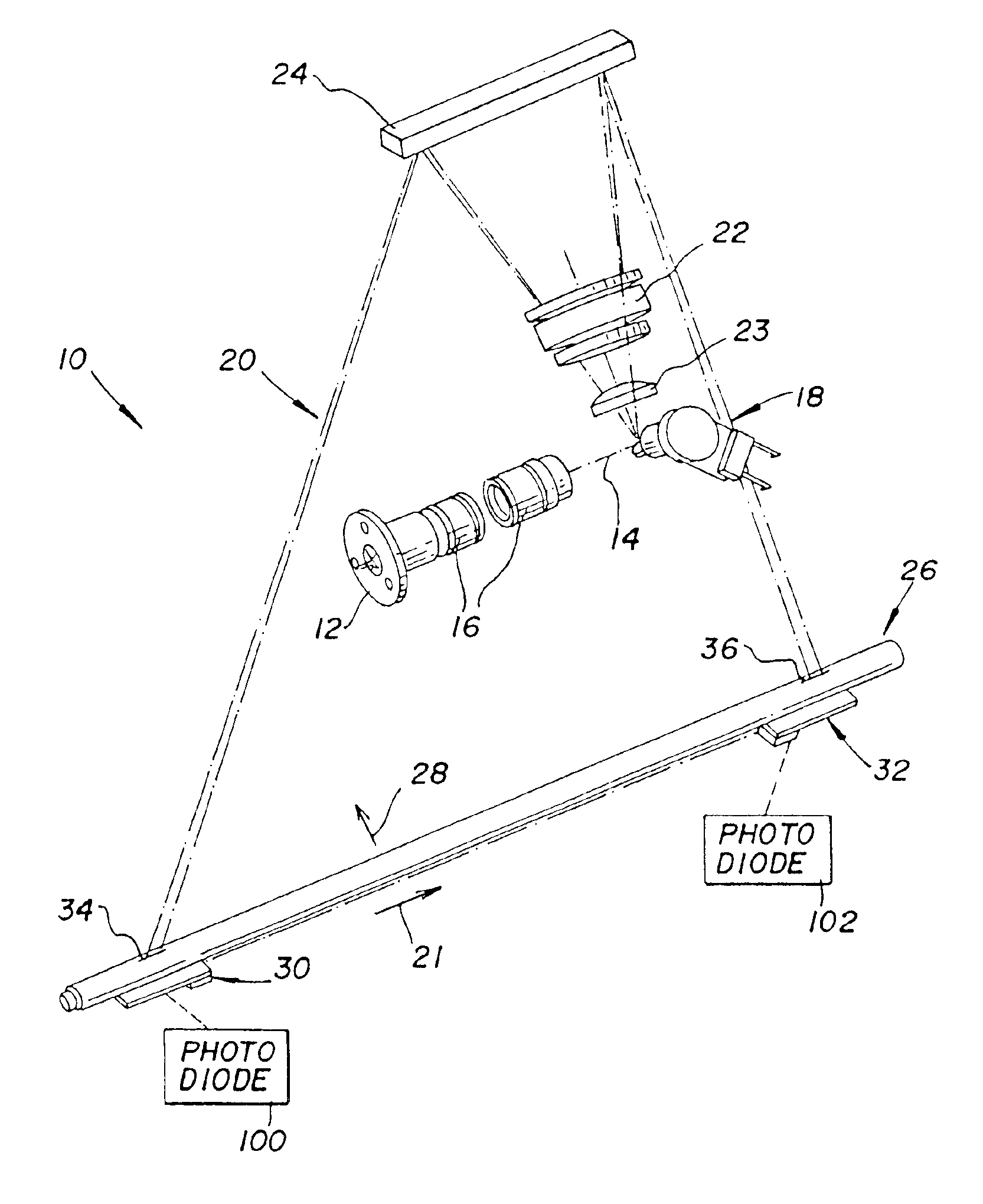

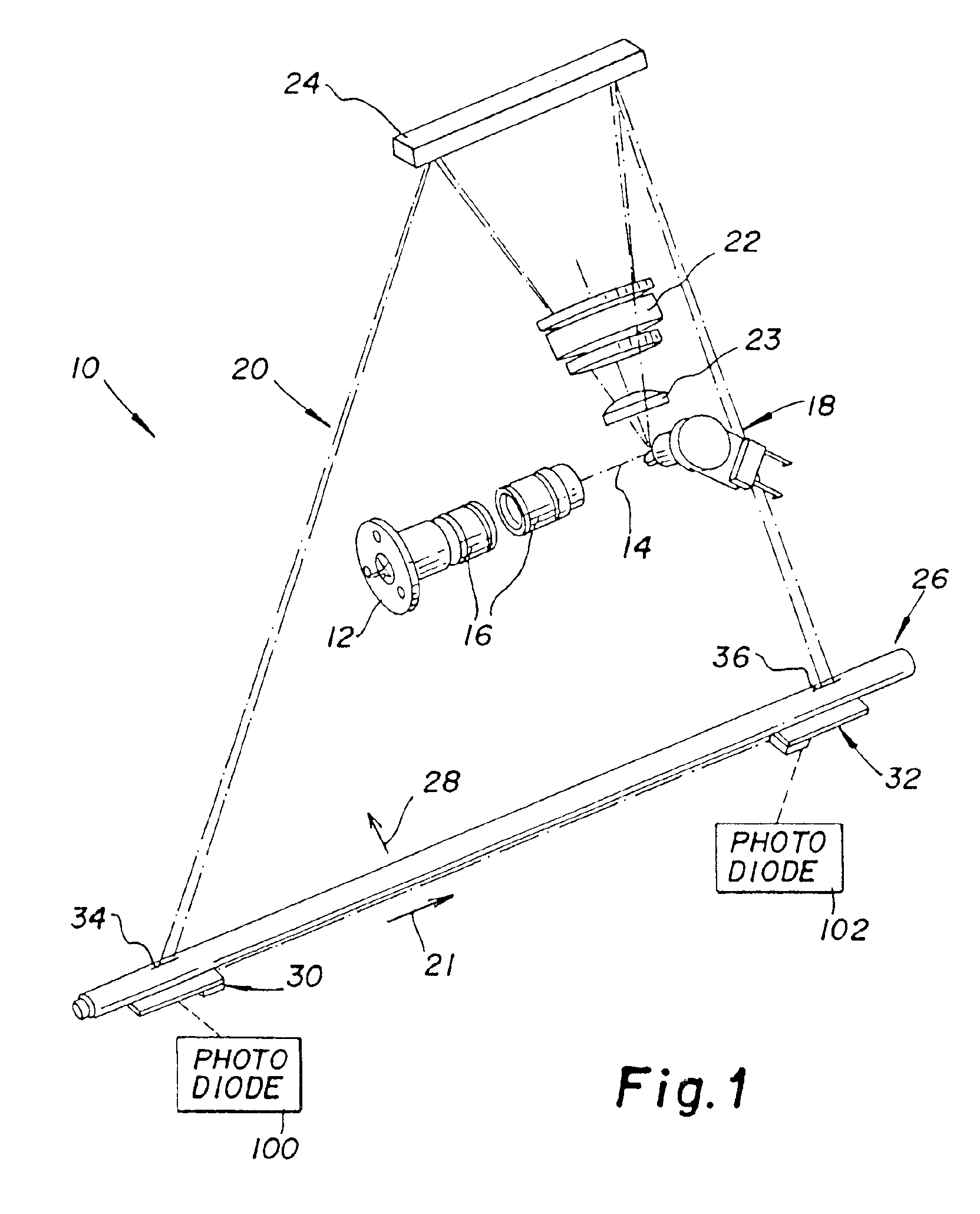

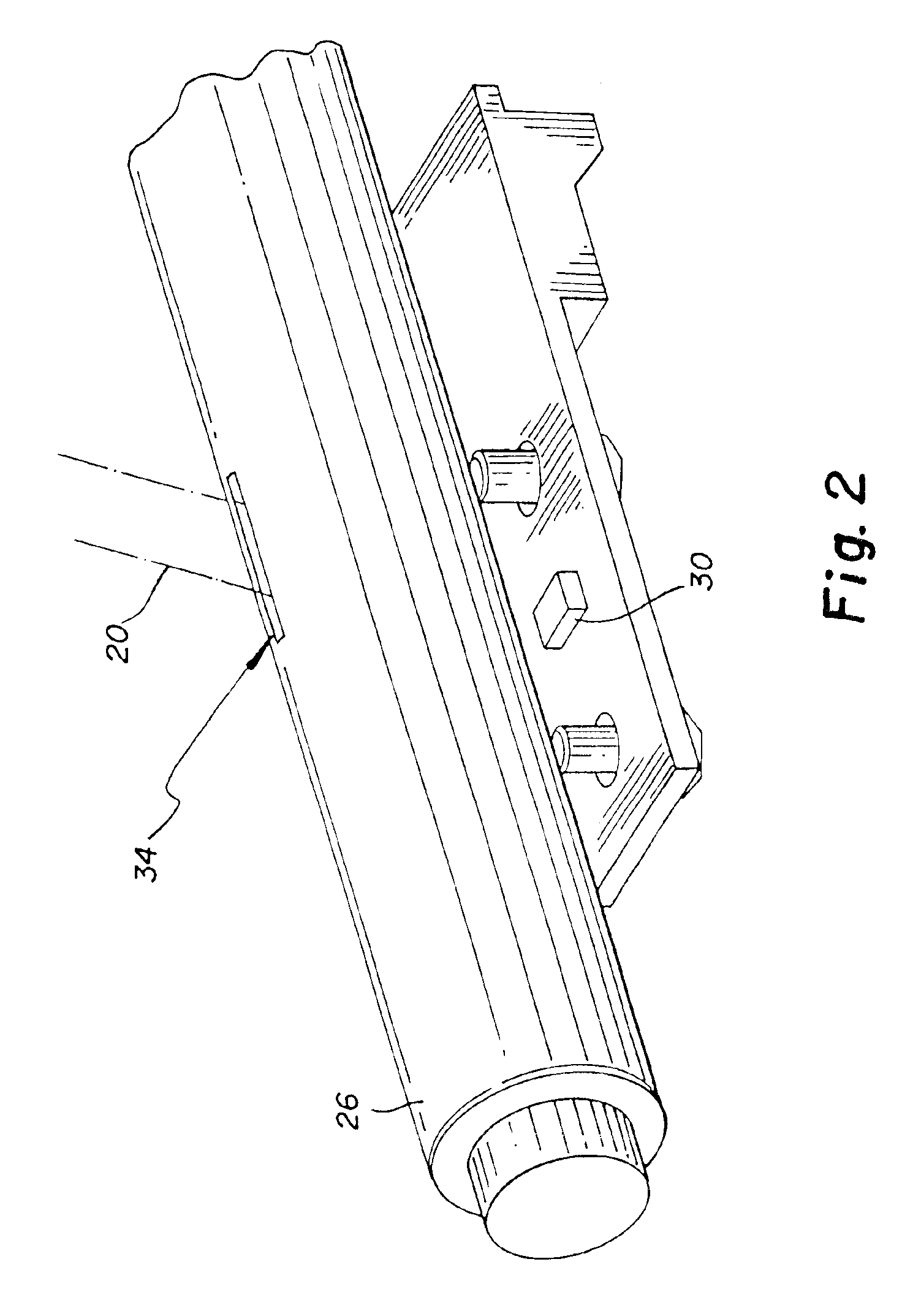

Scanline alignment sensors

InactiveUS6911647B2Safety hazardPrecise alignmentBeam/ray focussing/reflecting arrangementsMaterial analysis by optical meansPhotovoltaic detectorsPhotodetector

An optical imaging system comprising: an optical assembly for producing a laser beam scanline at an imaging region; first and second photodetectors located at the imaging region at the first and second ends of a produced laser beam scanline; and a visual indicator system coupled to the first and second photodetectors to visually indicate detection of the first and second ends of the laser beam scanline.

Owner:CARESTREAM HEALTH INC

Low profile rod pumping unit with pneumatic counterbalance for the active control of the rod string

ActiveUS9115574B2Small footprintSafety hazardConstructionsFlexible member pumpsEngineeringAutomation

Adaptable systems for a surface pumping unit that includes a low inertia pumping unit mechanism having a pneumatic counterbalance assembly are described, as well as methods for the use of such systems for subterranean fluid recovery. The system is capable of being integrated with well management automation systems, thereby allowing for response to active control commands, and automatically altering and / or maintaining a counterbalance force in the pumping unit by adding or removing air mass from a containment vessel associated with the pumping unit.

Owner:RAVDOS HLDG INC

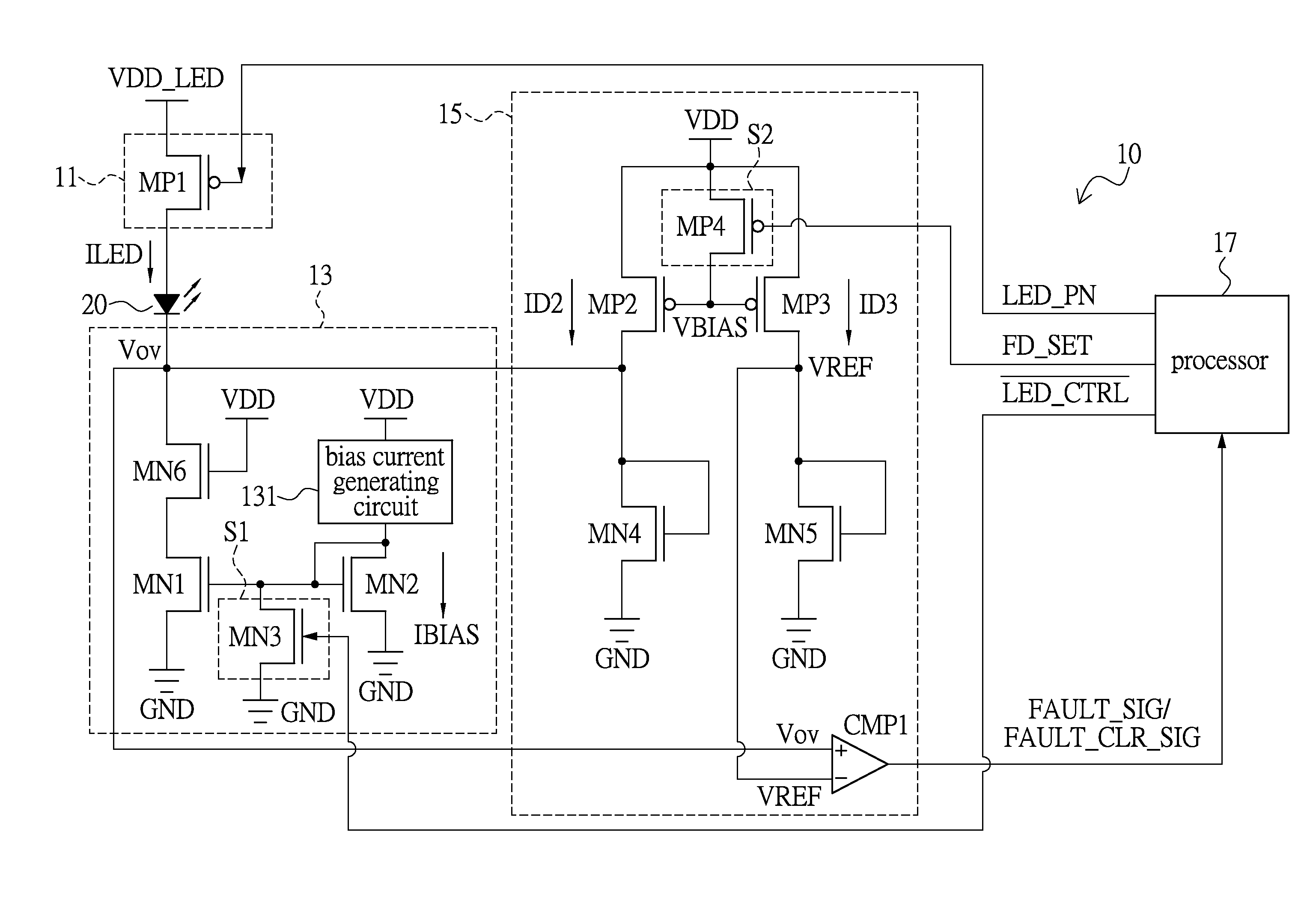

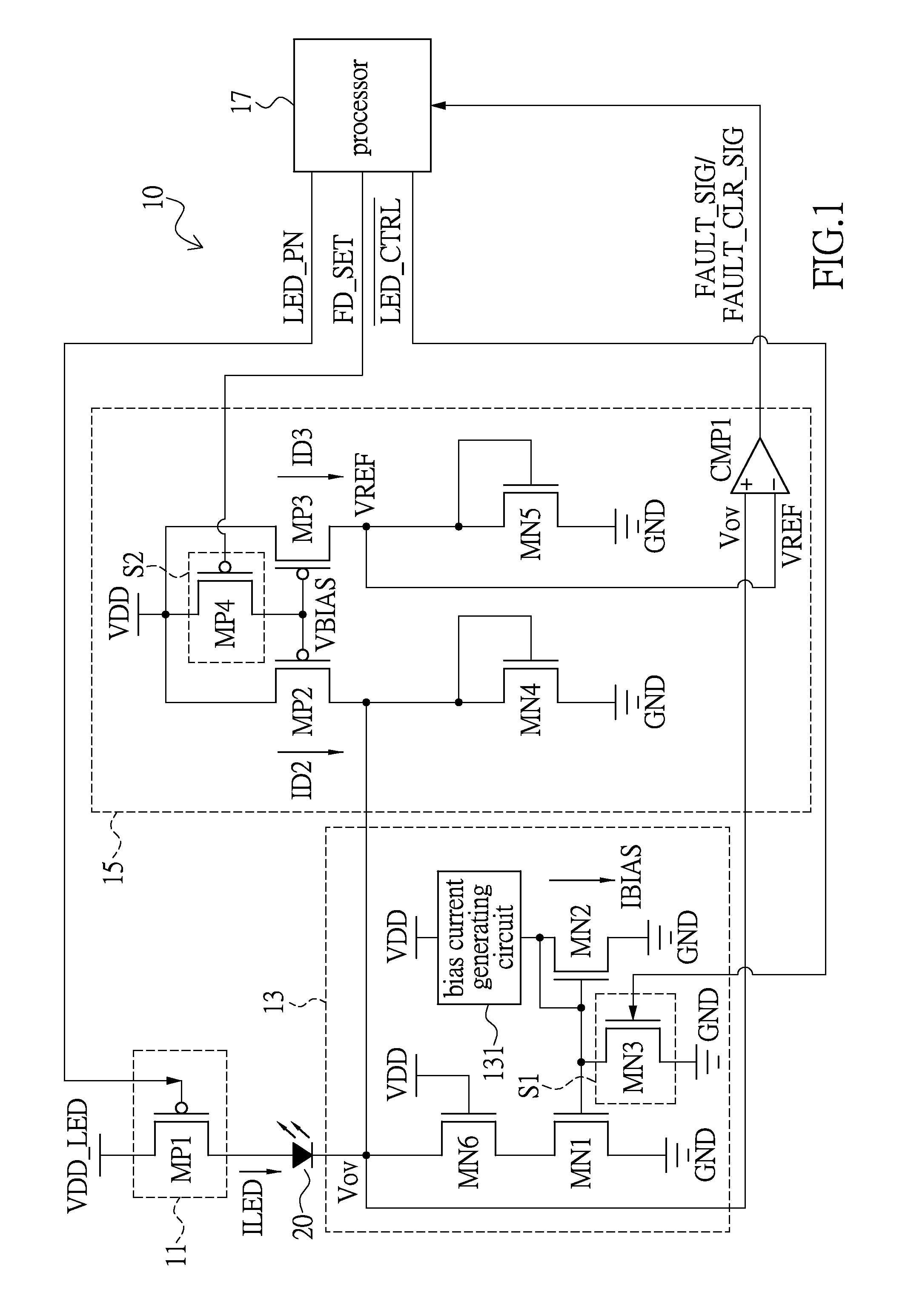

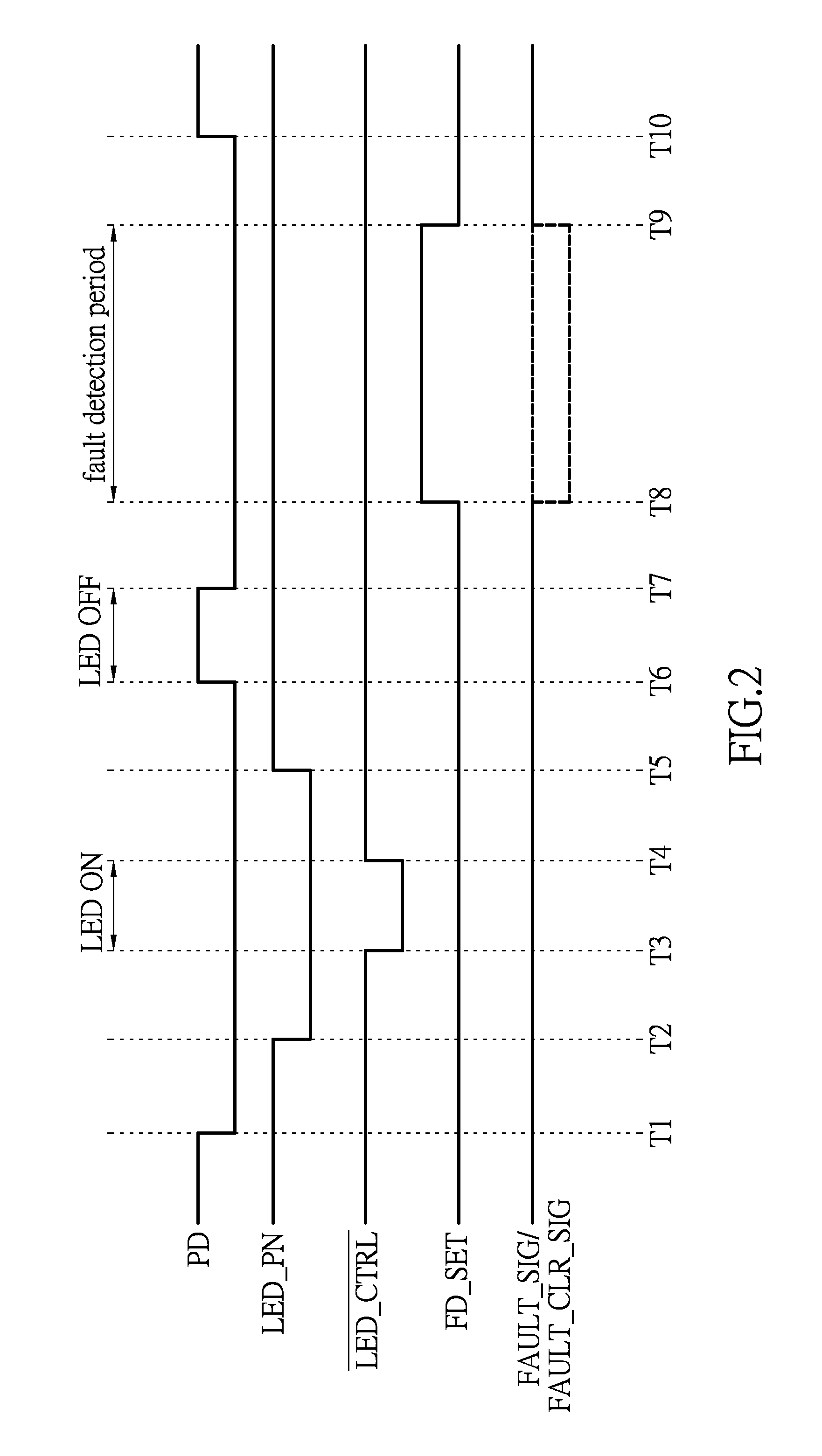

Driving circuit with fault detection and optical input device having the same

ActiveUS20150338931A1Effective security protectionLow costInput/output for user-computer interactionDiode testingDriving currentDriver circuit

The present disclosure provides a driving circuit, which includes a switch, a driver unit, a fault detection circuit, and a processor. The switch is coupled between a power terminal and an anode of a light emitting diode (LED) of a light source. The driver unit is coupled between a cathode of the LED and a ground for generating a driving current according to a control signal. The fault detection circuit operatively detects whether the cathode of the LED is shorted and generate a fault signal when detected that the cathode of the LED is shorted. The processor initiates a fault detection period, during which the processor turns off the switch and the driver unit causes the cathode of the LED to be floating while activates the fault detection circuit to detect whether the cathode of the LED is shorted.

Owner:PIXART IMAGING PENANG

Mechanical gas bottle dispensing machine

InactiveUS7975875B2Safety hazardReduce stepsSmall article dispensingRod article dispensingGas cylinderEngineering

Owner:BORZYM ANDRZEJ

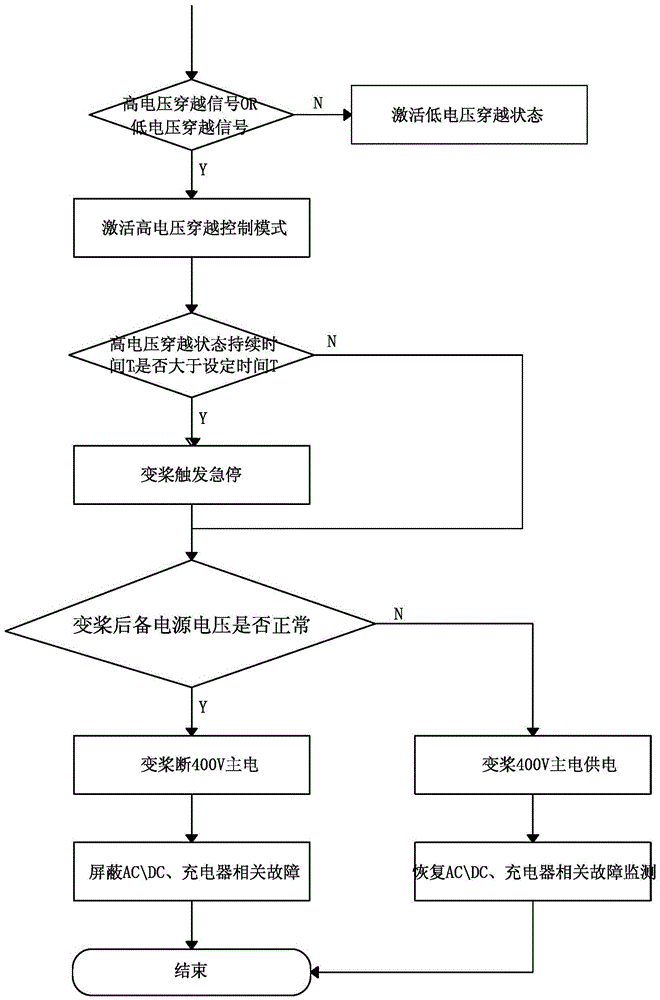

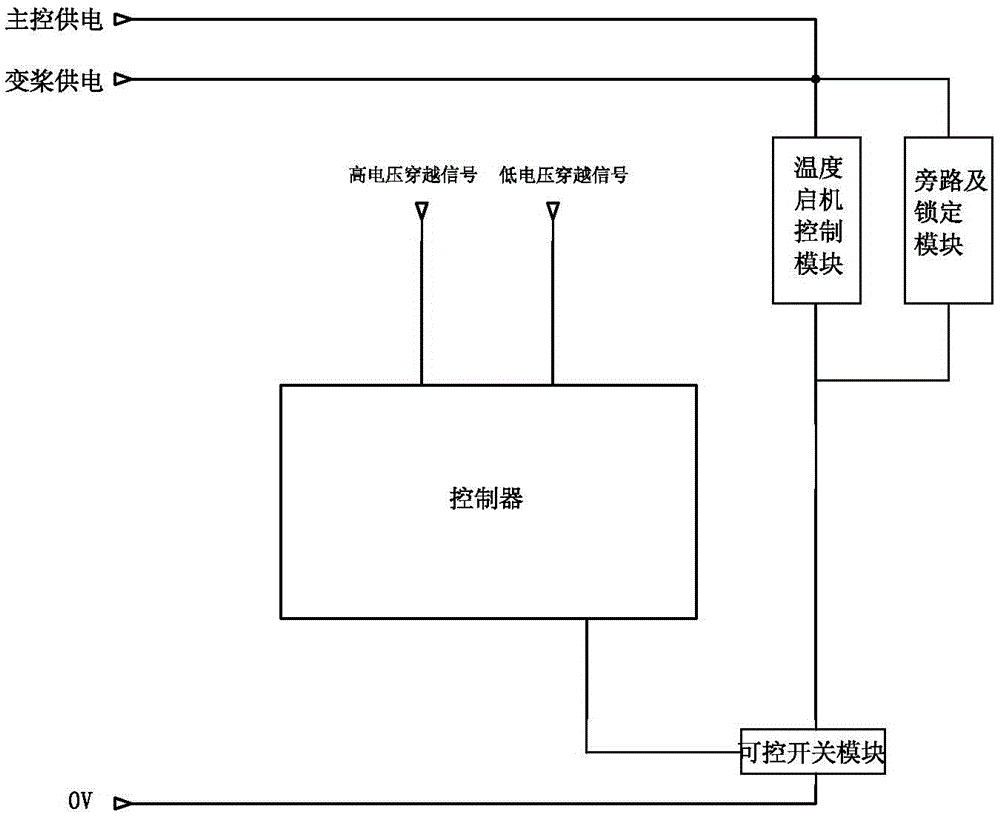

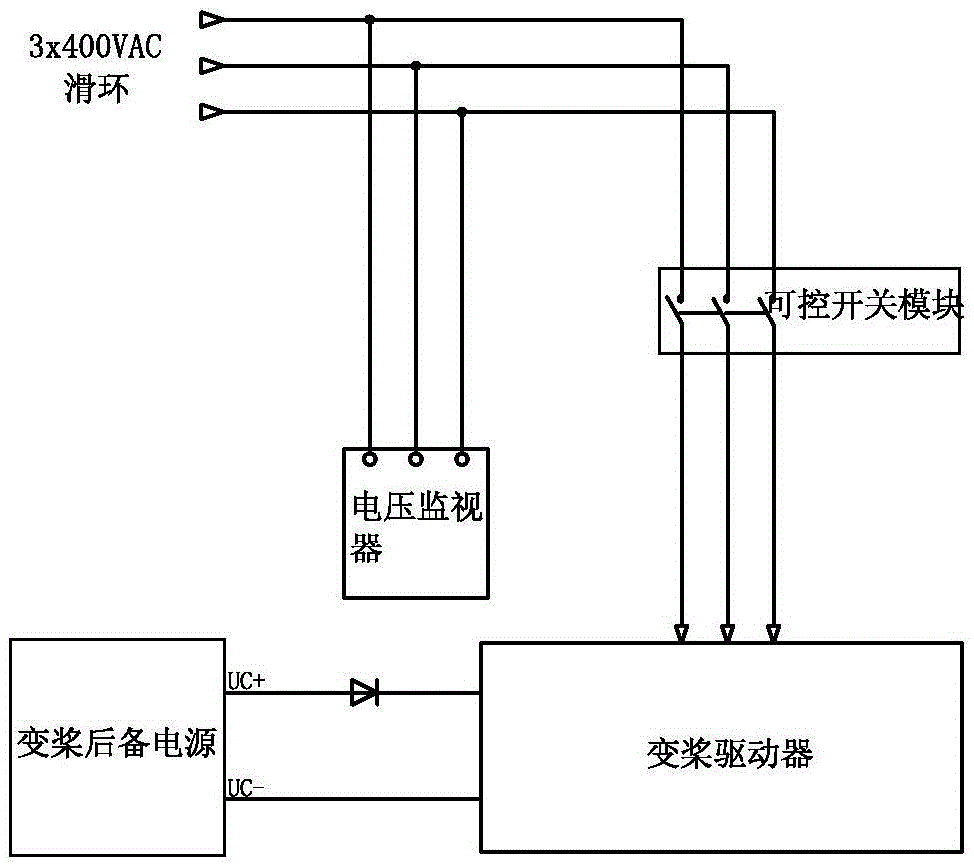

Wind power generating set high voltage ride-through control method

ActiveCN105610184ASafety hazardRealization of high voltage ride throughSingle network parallel feeding arrangementsWind energy generationPower gridGenerating unit

The invention relates to a wind power generating set high voltage ride-through control method. Based on high voltage ride-through signals fed back by a voltage monitor, a controllable switch module can be controlled to cut off power supply of a power grid for a pitch system; under a situation that the pitch system is disconnected from the power grid, a voltage withstanding device such as the voltage monitor is utilized to withstand transient high voltage for at least 2 seconds, so that high voltage ride-through can be realized under the condition that a wind power generating set is connected with the power grid; and therefore, huge impact on the power grid and accidents endangering the safety of the wind power generating set can be avoided.

Owner:CHENGDU FORWARD TECH

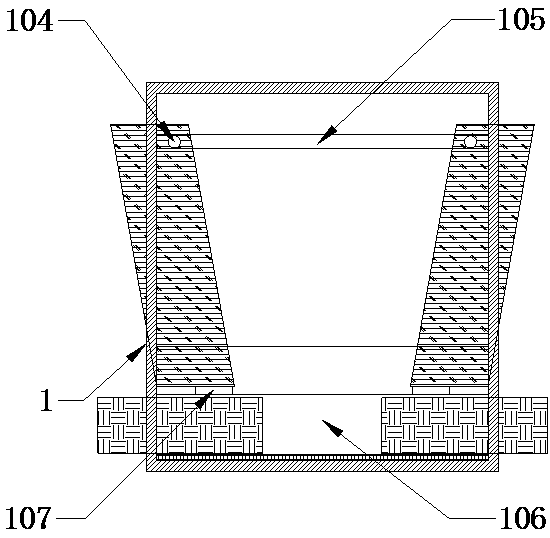

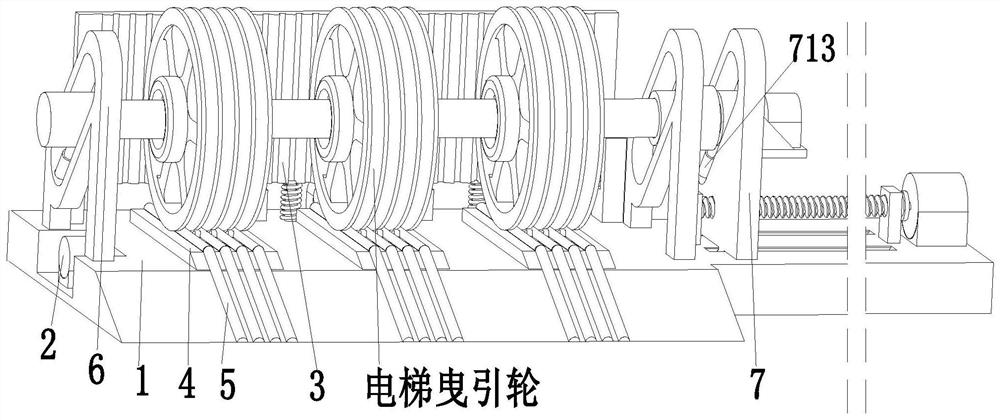

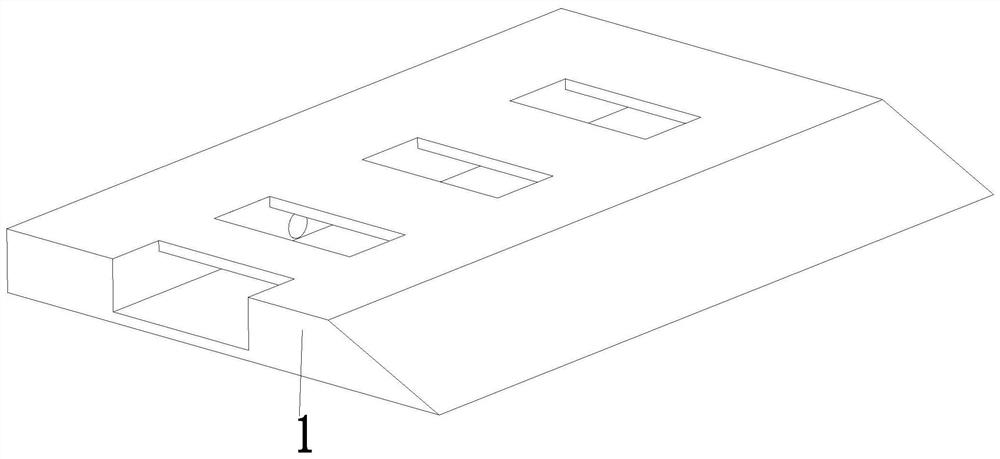

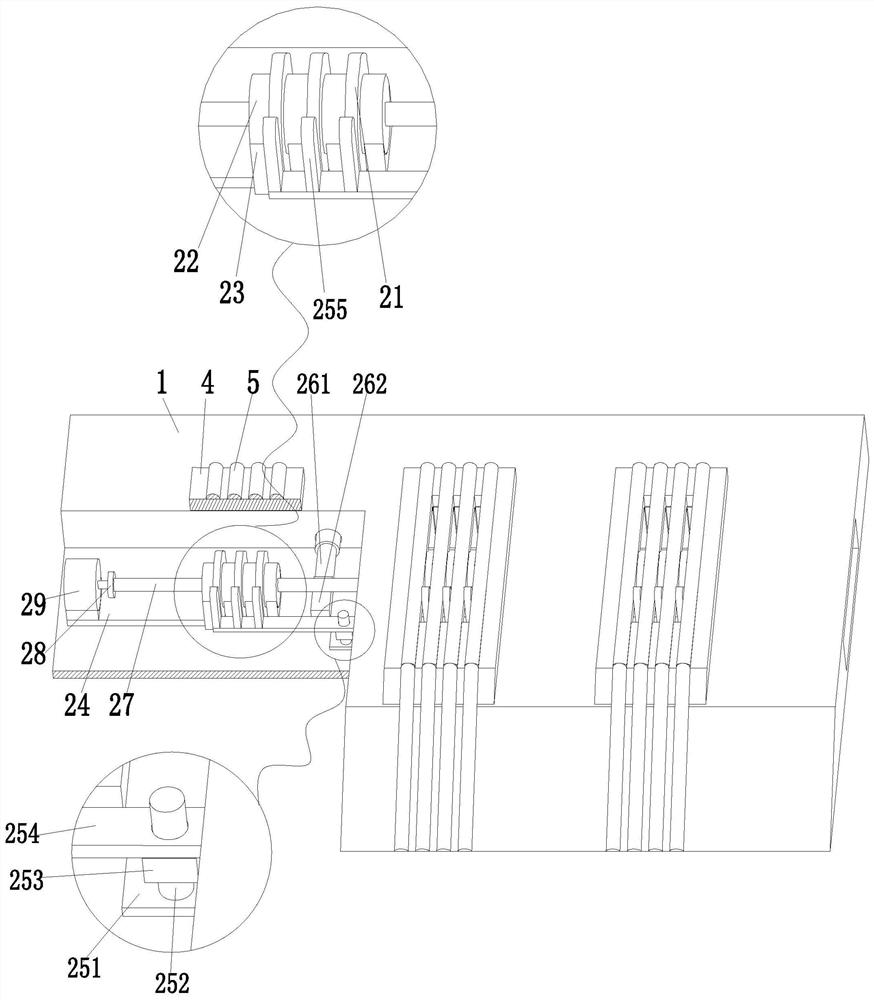

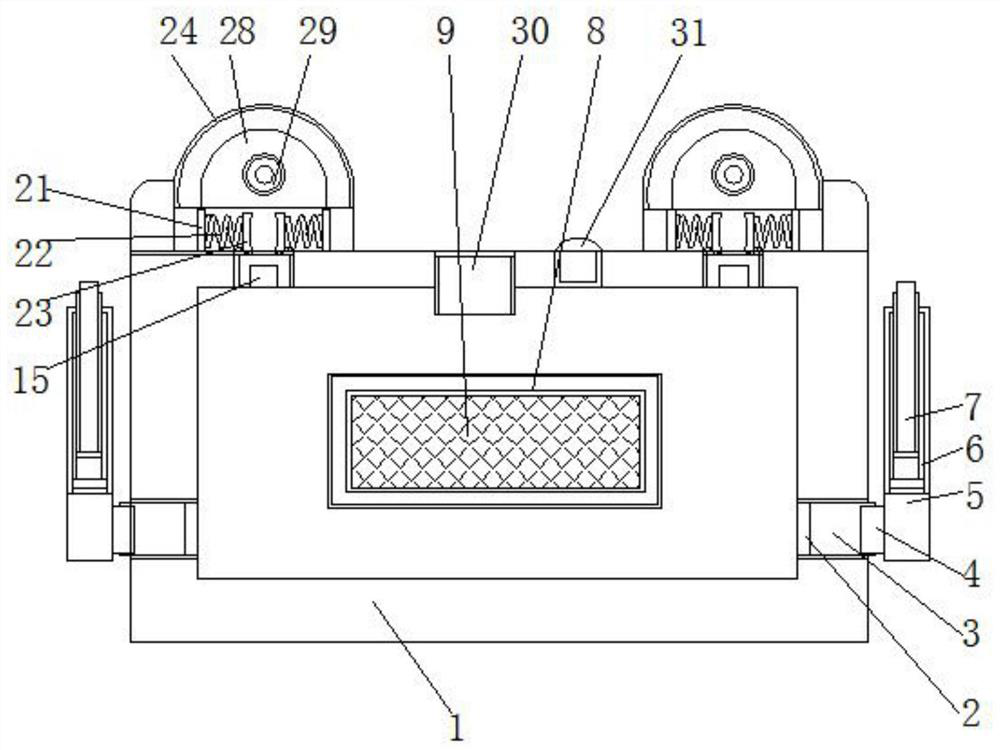

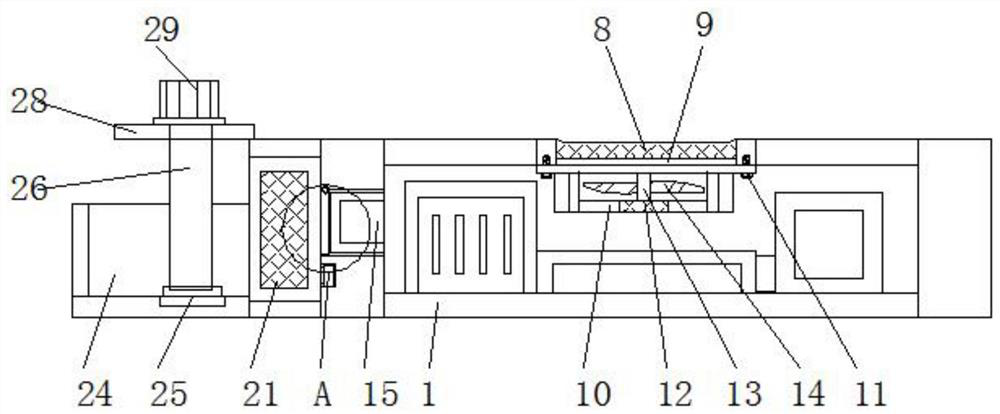

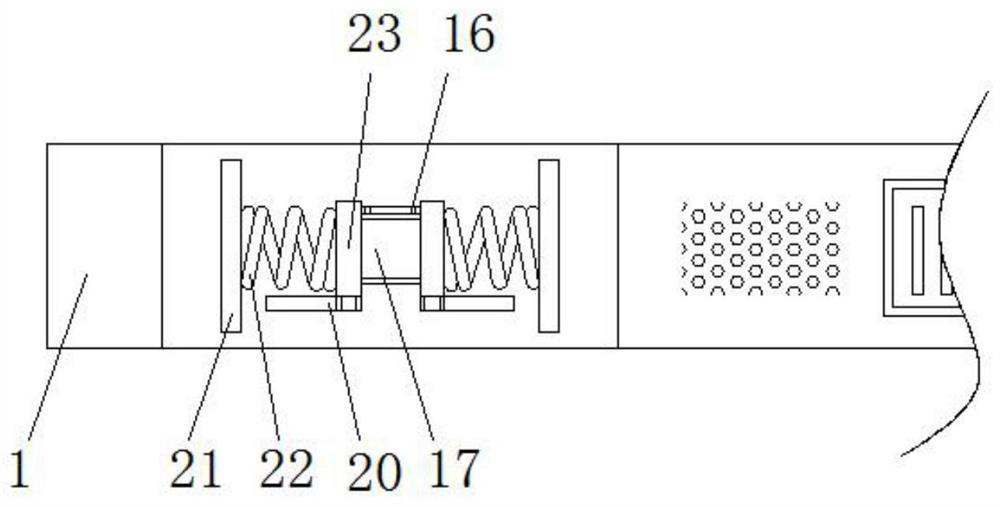

Elevator traction wheel manufacturing and processing device and manufacturing and processing method

InactiveCN111922853AImprove grinding efficiencyAvoid problems such as reduced service lifeGrinding drivesGrinding machinesStructural engineeringMachine

The invention relates to an elevator traction wheel manufacturing and processing device and a manufacturing method. The elevator traction wheel manufacturing and processing device comprises a base, arotating mechanism, a polishing mechanism, placing tables, a limiting bar, a height adjusting mechanism and a driving mechanism. The base is in a trapezoid structure with the upper end of the front side inclined backwards. A mounting groove is formed in the middle of the base. The rotating mechanism is arranged in the mounting groove. The polishing mechanism is arranged on the upper rear side of the upper end surface of the base. The placing tables are uniformly mounted on the upper end surface of the base. The upper end surfaces of the placing tables and the inclined surface of the base are detachably provided with the limiting bar. The height adjusting mechanism is arranged on the upper end surface of the base and is located on the left and right sides of the upper end surface of the base. The driving mechanism is arranged on the right side of the height adjusting mechanism. The elevator traction wheel manufacturing and processing device and the manufacturing method can solve the problems of incapability of removing burrs on the inner wall of a rope groove of an elevator traction wheel in the existing process of polishing the traction wheel by using a traction wheel polishing machine, and only one elevator traction wheel can be polished at a time.

Owner:缪心怡

Set top box with data line arrangement mechanism

InactiveCN113038206AImprove reception performanceEasy to installSelective content distributionPower switchingStructural engineering

The invention discloses a set top box with a data line arrangement mechanism, and the set top box comprises a shell and a screw; the shell is internally provided with a clamping groove, the right side of a connecting block is provided with a first rotating shaft, the interior of an antenna shell is provided with a sliding groove, the left side of a signal rod is provided with a dustproof net, and a fan shell is arranged below a heat dissipation opening; a sliding block is arranged in a sliding way, a fixed plate is arranged above a sliding rail, a clamping plate is arranged on the right side of a reset spring, a bottom groove is formed in the right side of a storage box, a wire outlet is formed in the right side of a rotating column, a rotating button is arranged above a top plate, and a power switch is arranged on the right side of a USB interface. The set top box with the data line arrangement mechanism is provided with the storage box, and data lines are stored and arranged through the storage box, so that the situation that the lines are disordered, the whole environment looks very disordered, a plurality of lines are knotted, certain potential safety hazards exist, cleaning is inconvenient, and dirt is easily hidden is avoided.

Owner:SHENZHEN CHUANGYINGXIN IND CO LTD

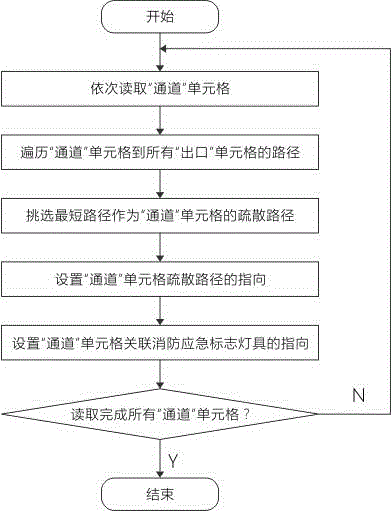

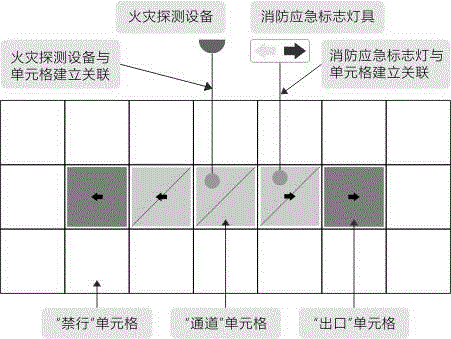

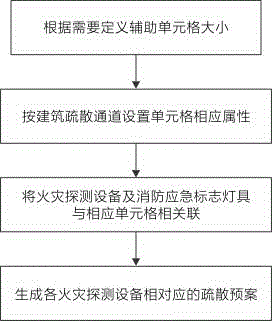

Method for automatically generating evacuation plan through gridding

InactiveCN105989563AImprove work efficiencyLow implementation costData processing applicationsEvacuation planFire protection

The invention belongs to the intelligent fire protection emergency lighting and evacuation indication system field and provides a method for automatically generating an evacuation plan through gridding. The method includes the following steps that: 1) a grid composed of polygon cells is drawn; 2) attributes such as ''pass forbidden'', ''channel'' and ''exit'' are set for the cells in the grid, and evacuation channels and exits in a building are described; 3) control points of fire detection devices and fire protection emergency indication lights are dragged onto the cells, so that correlations are established; and 4) evacuation paths between ''channel'' cells and a nearest ''exit'' cell are obtained through a software algorithm, and the ''channel'' cells are set to point to the ''exit'' cell; and 5) an evacuation plan correlated with the fire protection emergency indication lights is generated according to the pointing directions of the ''channel'' cells.

Owner:刘洋

Vacuum freeze-drying processing method of fresh ginsengs

InactiveCN108634157AExtended shelf lifeGuaranteed freshnessFood preservationFreeze-dryingAdditive ingredient

The present invention discloses a vacuum freeze-drying processing method of fresh ginsengs. The vacuum freeze-drying processing method comprises steps of material selecting, deep washing and screening, instant high temperature sterilizing, pre-freezing, one-step vacuum freeze drying, moisture preventing and packaging. The processed fresh ginsengs are subjected to the instant high temperature sterilizing and one-step vacuum freeze drying to maximally retain nutrients of ginsenosides, polysaccharides, flavonoids, vitamins, etc., and to enable many easily volatile and heat-sensitive natural ingredients originally unique to the fresh ginsengs to both be very well preserved. Besides, the shapes of the original fresh ginsengs are preserved; the ginsengs are unique in smell and fresh in color, and have characteristics of being clean and sterile, eaten directly, and crisp in mouthfeel; and the whole processing method optimizes technological processes, shortens processing processes, effectivelyimproves processing efficiency, reduces production costs, and effectively extends the shelf life of the fresh ginsengs.

Owner:广东天葆堂健康科技产业有限公司

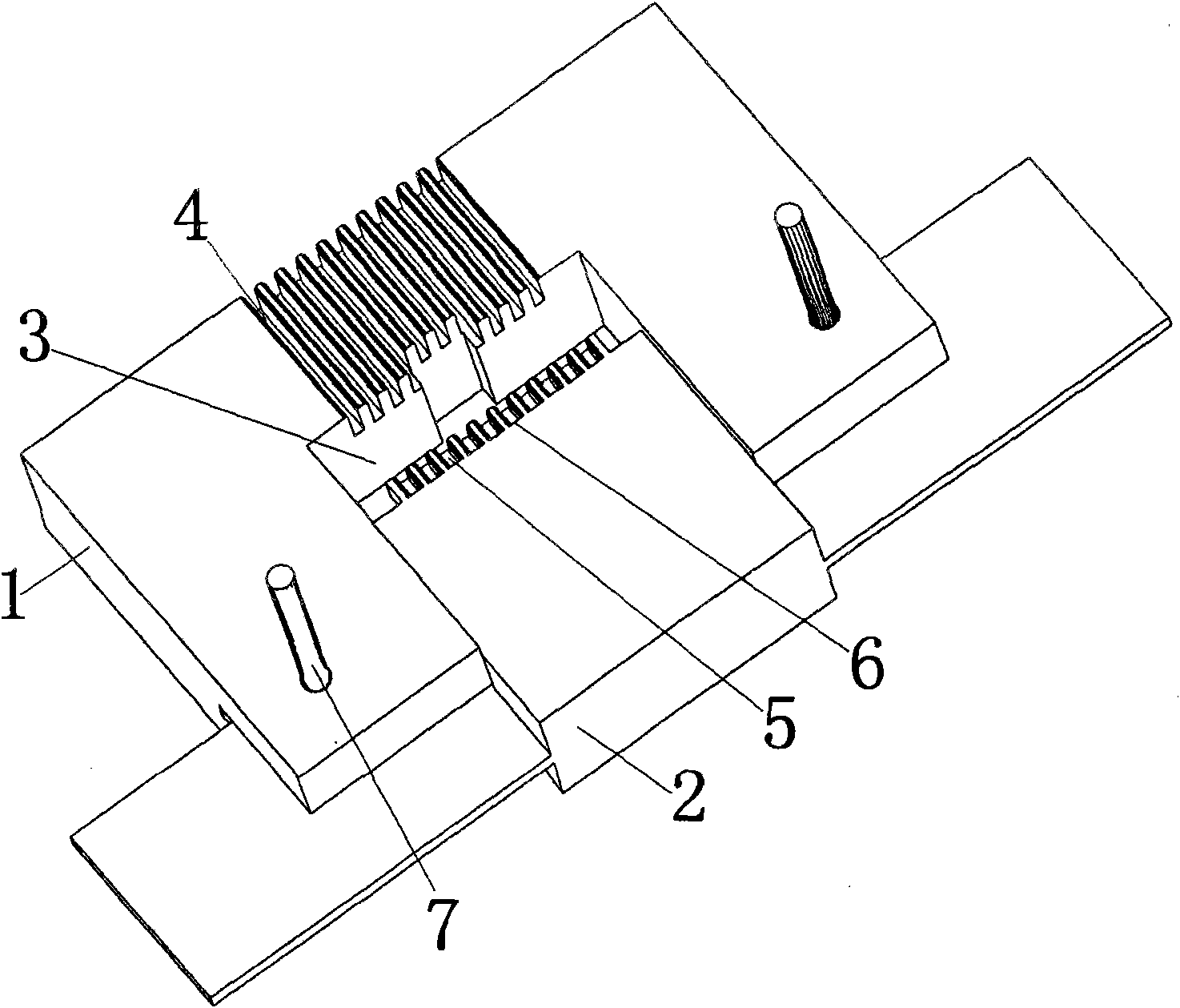

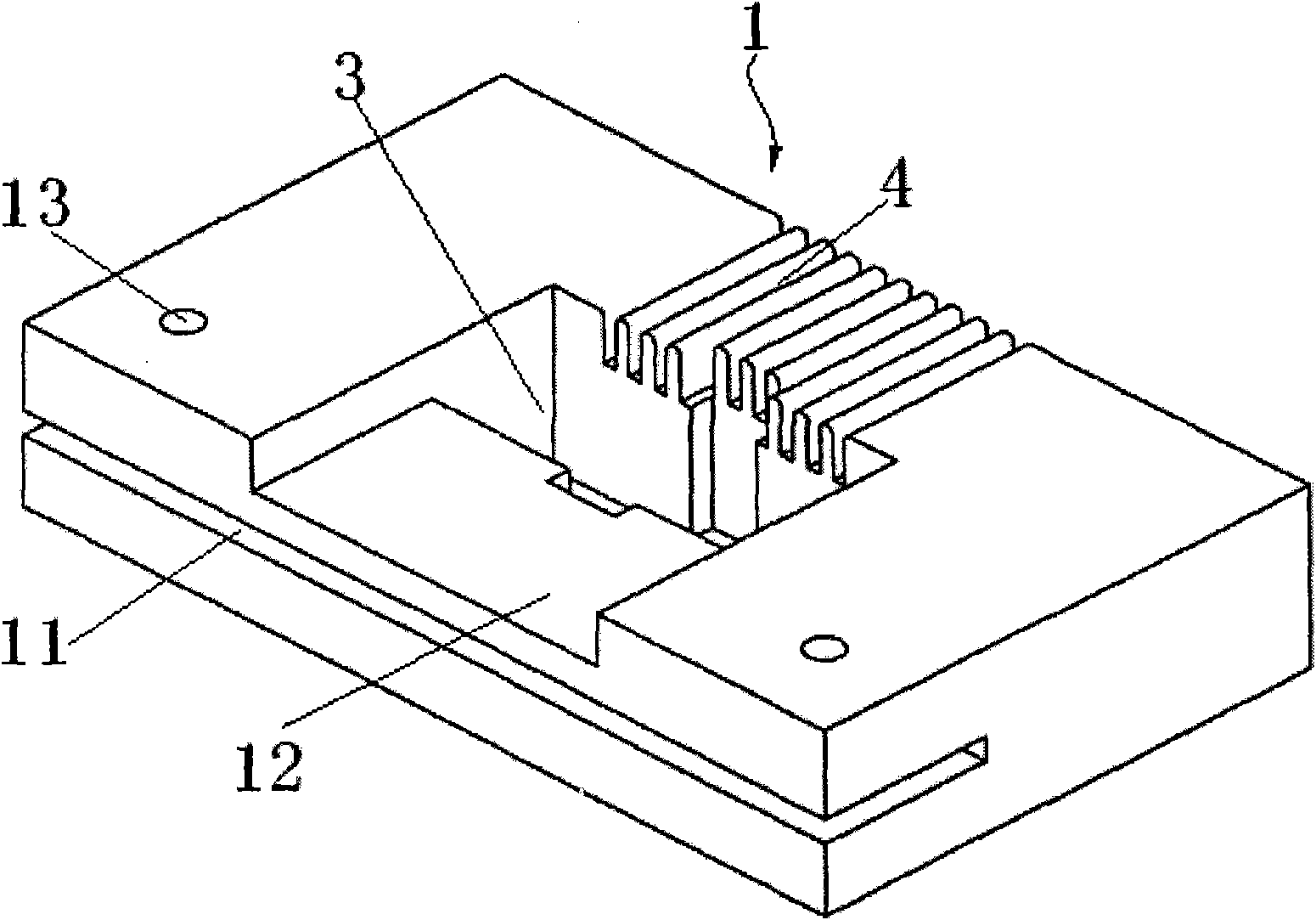

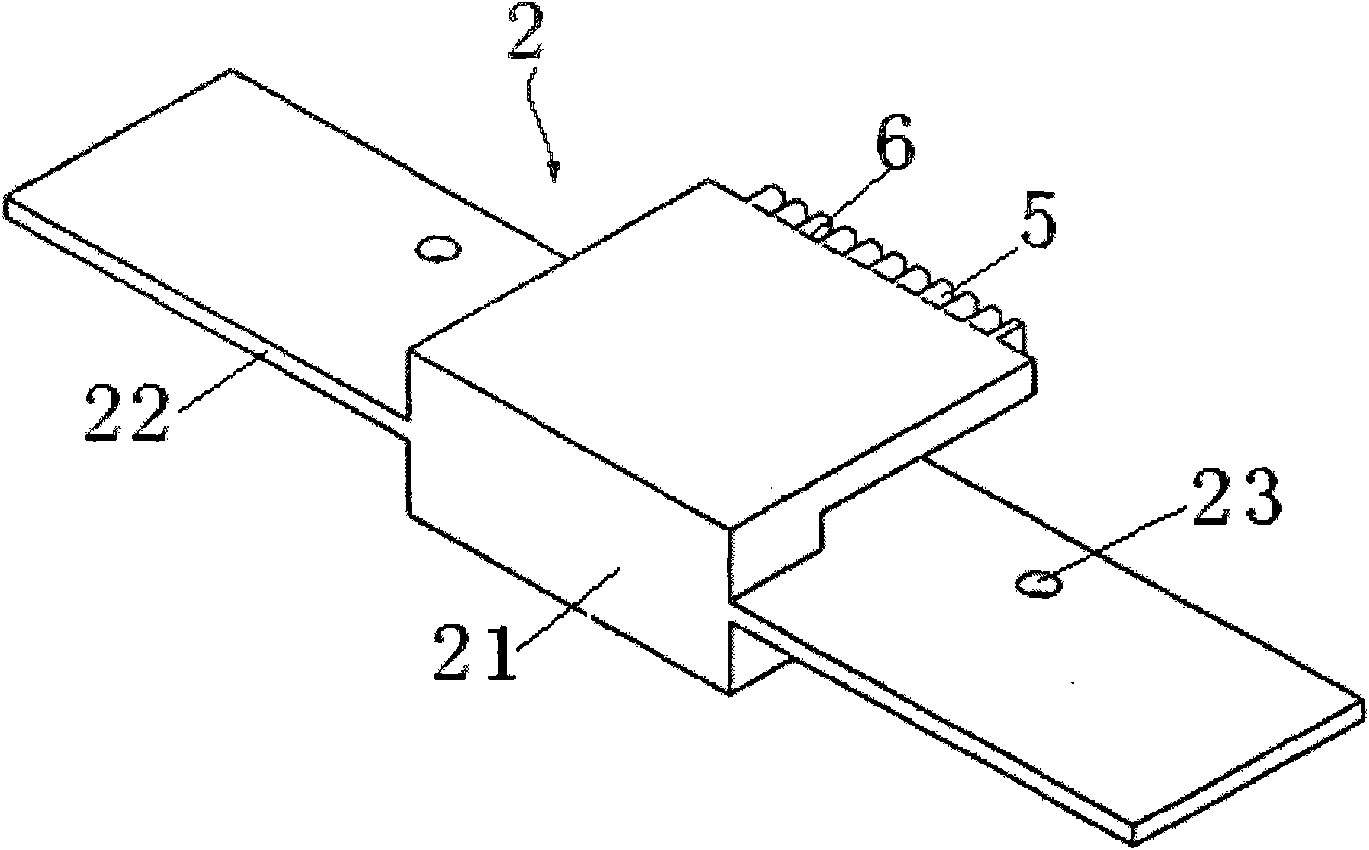

Piercing terminal pressing clamping device

ActiveCN101630777AReduce processing costsLow costContact members penetrating/cutting insulation/cable strandsEngineeringMechanical engineering

The invention discloses a piercing terminal pressing clamping device, comprising a base and a positioning piece, wherein, a positioning groove is arranged on the base and penetrates through the base from the upper surface to the lower surface, the shape of the positioning groove adapts to the shape of a terminal body, a plurality of main wire casings which are perpendicular to the positioning groove are arranged on the upper surface of the base on one side on which one side wall of the positioning groove is positioned, and the width of each main wire casing adapts to the diameter of a guide line; the positioning piece is arranged on the other upper surface of the side on which the main wire casings are positioned and to which the base corresponds, one lateral end face of the positioning piece is provided with auxiliary wire casings, each auxiliary wire casing and each main wire casing are opposite to and matched with each other on the same plane, a positioning face is arranged on the end of each auxiliary wire casing, and the positioning groove is positioned between the main wire casings and the auxiliary wire casings. The invention has the advantages of low manufacturing cost and easy and pellucid operation of processing method, and can not cause potential safety hazard to operators, etc.

Owner:上海元一电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com