Laminating rubber plug and production method thereof

A film-coated rubber stopper, rubber stopper technology, applied in the field of film-coated rubber stoppers and its production, can solve problems affecting drug safety, environmental pollution, rubber stopper penetration, etc., to ensure the uniformity of film extension, reduce puncture force, The effect of preventing rubber stopper from sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

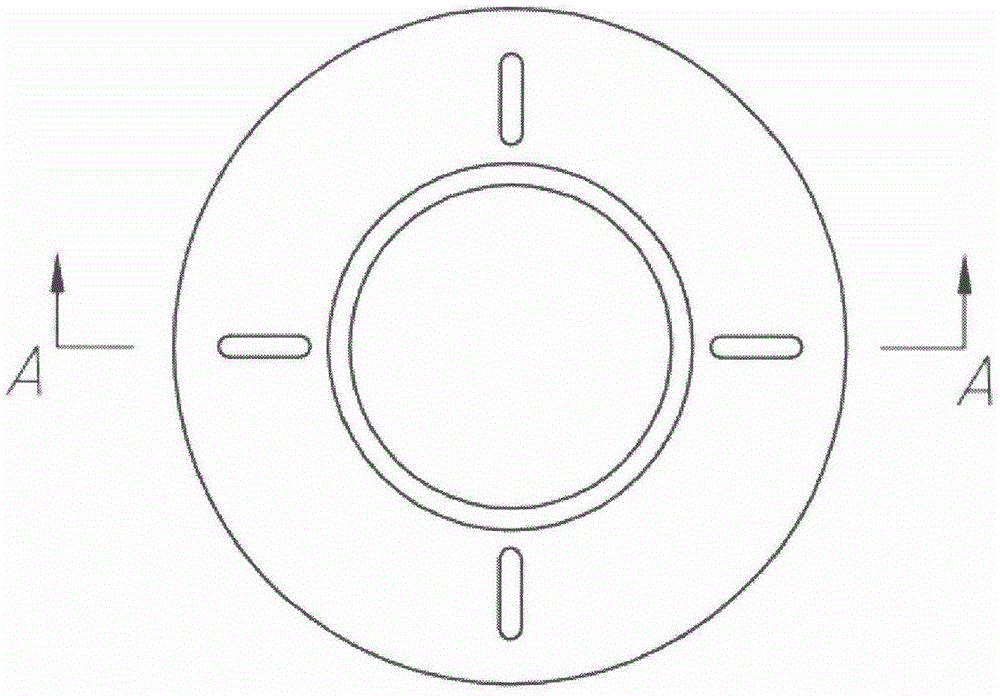

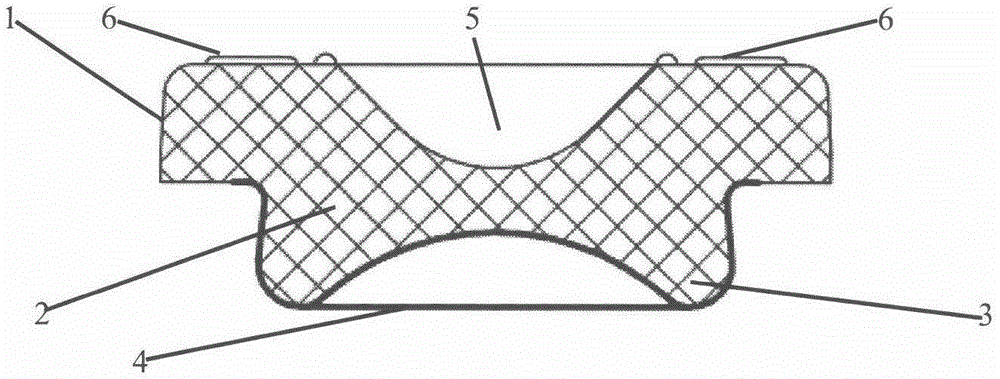

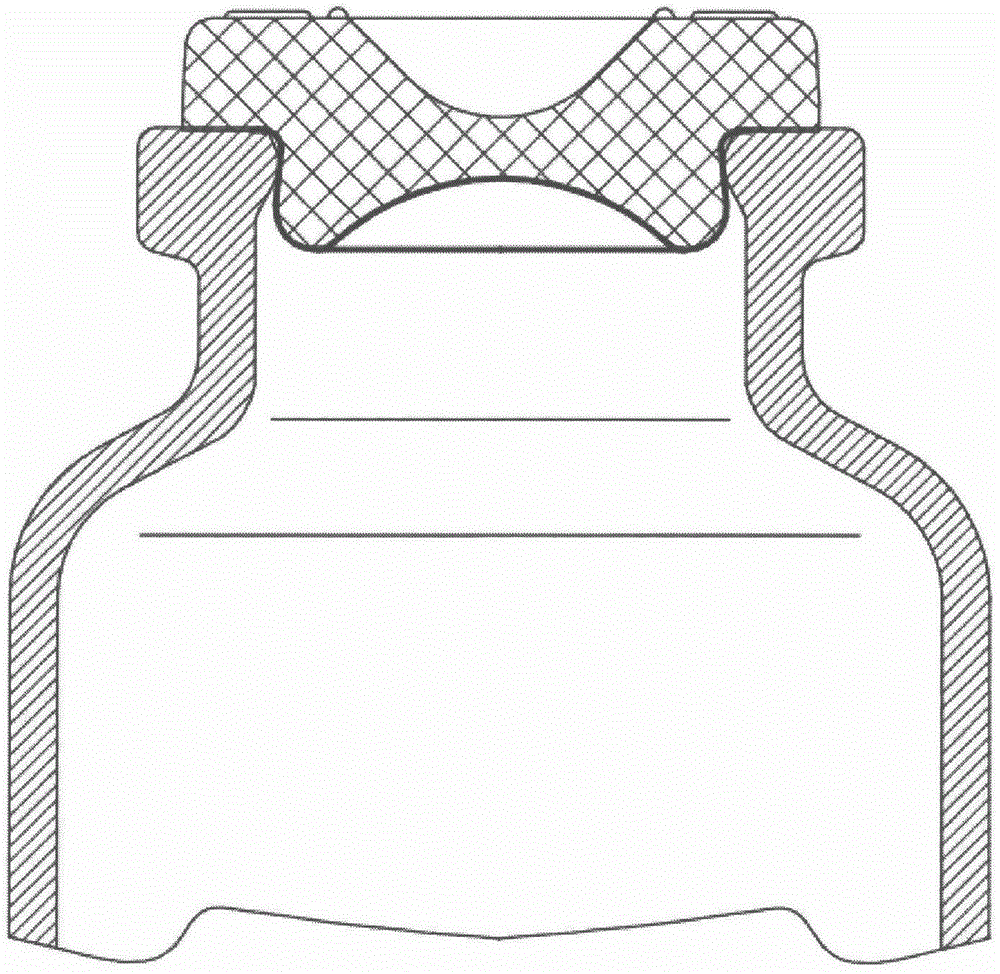

[0025] Embodiment one: if figure 1 It is the top view of the coated rubber plug, figure 2 Schematic diagram of the cross-sectional structure of the coated rubber plug, image 3 As shown in the cross-sectional diagram of the combination of the film-coated rubber stopper and the packaging bottle, the rubber stopper includes a rubber stopper crown (1) and a rubber stopper neck (2). The rubber stopper neck (2) adopts a spherical arc surface design, and the rubber stopper The plug part (3) of the plug neck (2) is small at the top and large at the bottom, the bottom surface of the rubber plug neck (2) is a spherical arc surface, and the coating part of the film-coated rubber plug is designed with a spherical arc surface to ensure The uniformity of film extension, uniformity of thickness, and uniformity of drug shielding ensure the safety of the preparation. The design of the plug part (3) with a small upper part and a larger lower part can ensure that the plug will never jump duri...

Embodiment 2

[0026] Embodiment two: if figure 1 It is the top view of the coated rubber plug, figure 2 Schematic diagram of the cross-sectional structure of the coated rubber plug, image 3 As shown in the schematic cross-sectional view of the combination of the film-coated rubber stopper and the packaging bottle, a ring protrusion can also be provided around the needle-punched hole (5) in the film-coated rubber stopper. The ring protrusion is higher than the plane of the rubber plug, which not only prevents the rubber plug from sticking, but also facilitates the stability of the suction plug when the rubber plug is removed.

[0027] The production method of film-coated rubber stopper of the present invention, step is as follows:

[0028] Step 1. Extrusion

[0029] Use an extruder to extrude the mixed rubber material into a rubber sheet;

[0030] Step two, film

[0031] Put the rubber sheet extruded in step 1 on the film, press it, and then put the rubber sheet pressed with the film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com