Piercing terminal pressing clamping device

A piercing terminal and fixture device technology, which is applied in the direction of needle tip/slotted plate contact pieces used to penetrate insulating wires/cable core wires, and can solve the problems of shallow Y-shaped openings, high cost, and inability to fix wires, etc. , to achieve the effect of cost saving, low processing cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

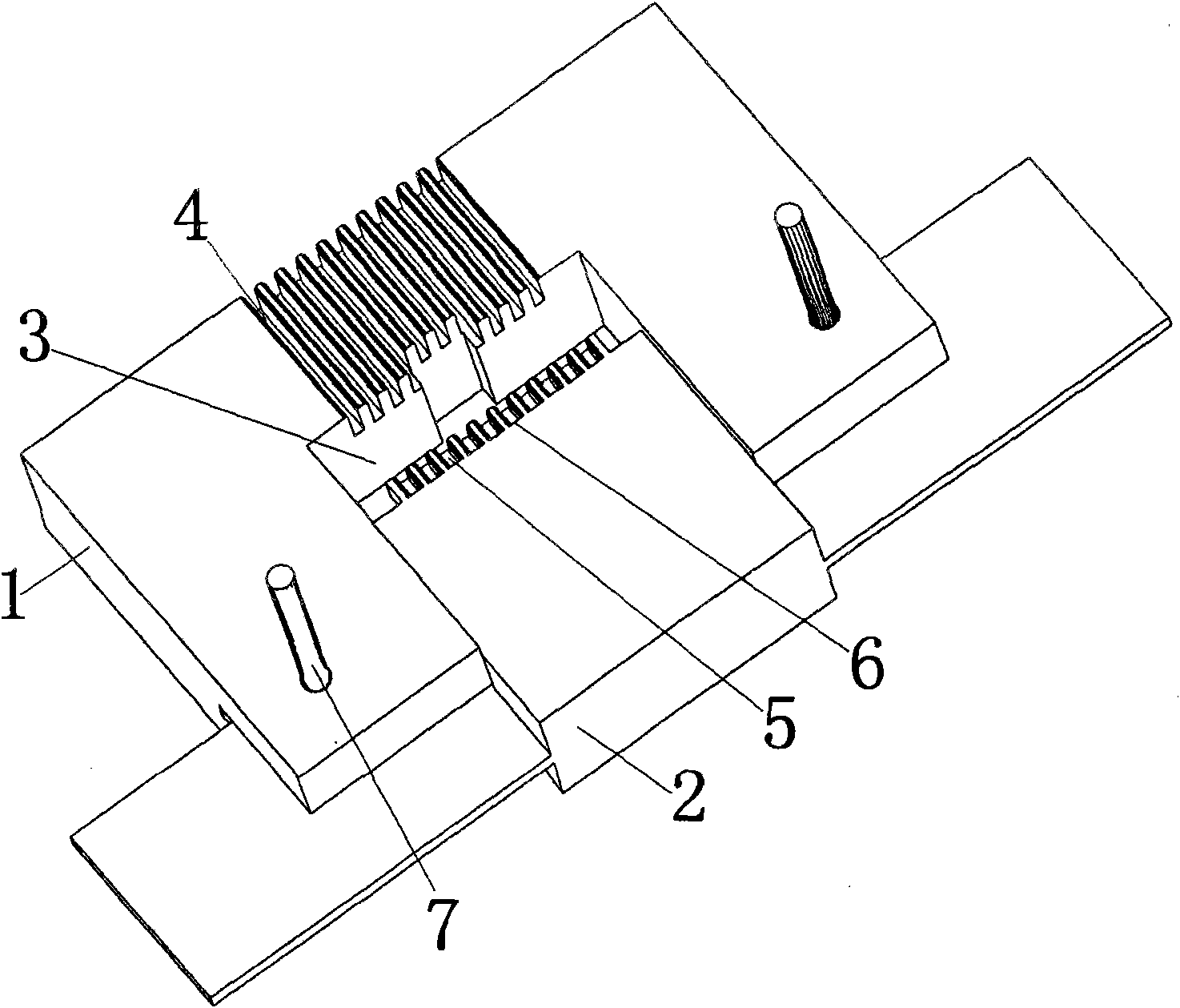

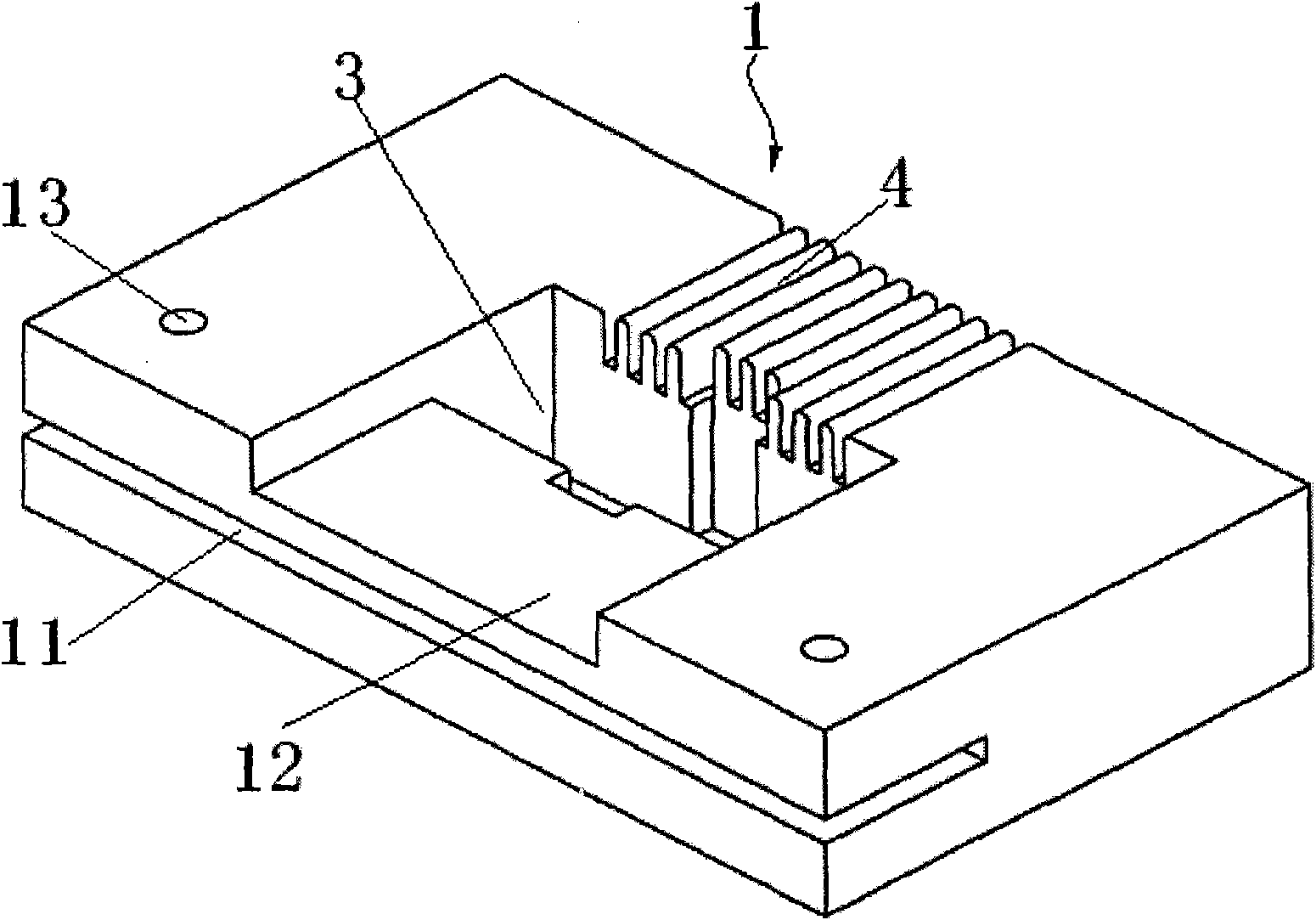

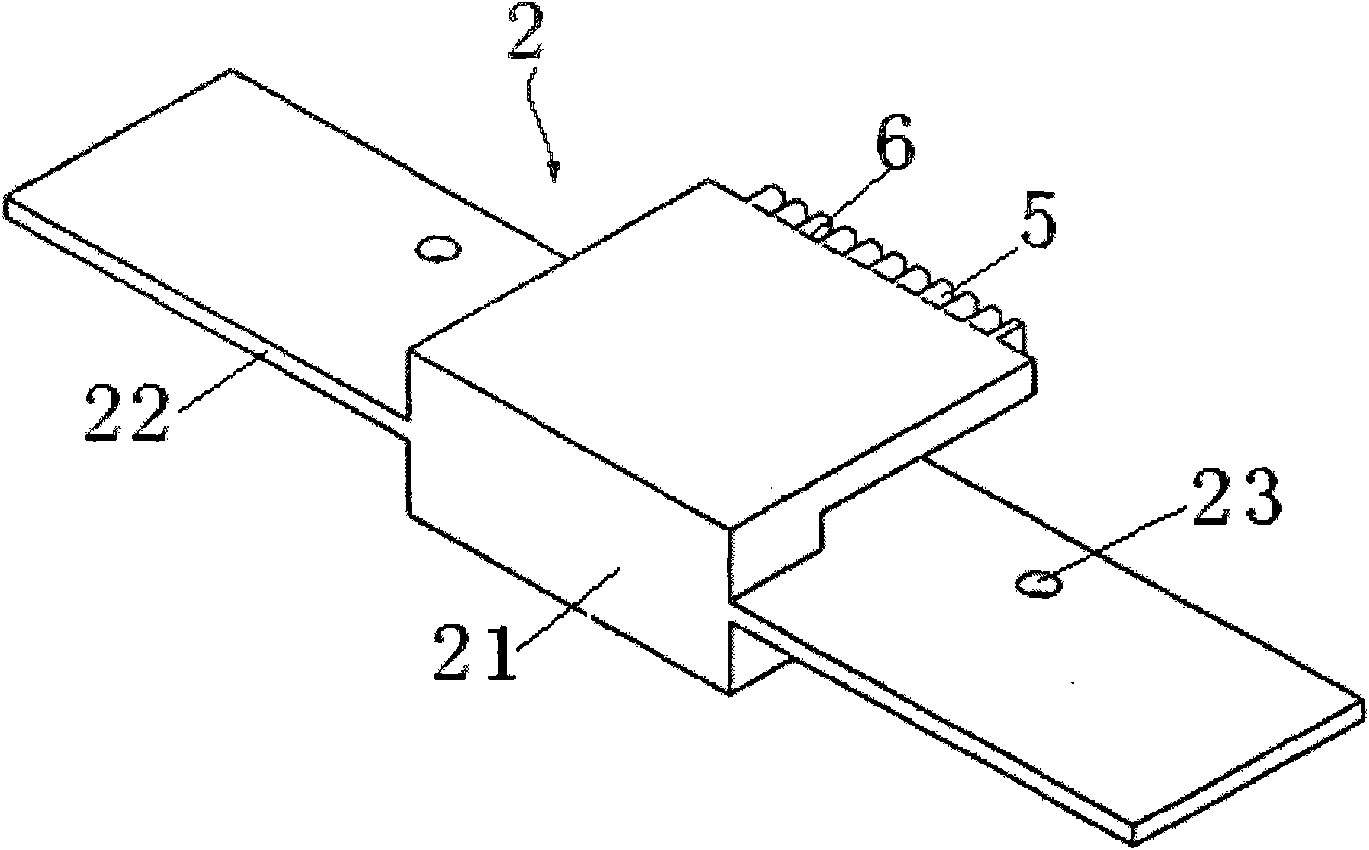

[0033] Such as figure 1 As shown, the puncture-type terminal crimping fixture device of the present invention includes a base 1 and a positioning member 2, the base 1 is provided with a positioning groove 3, and the positioning groove 3 penetrates from the upper surface to the lower surface of the base 1, so The shape of the positioning groove 3 is adapted to the shape of the main body of the terminal. The upper surface of the base on the side where one side wall of the positioning groove 3 is located is provided with a number of main wire slots 4 perpendicular to the positioning slot 3. The width of the main wire slot 4 and the wire diameter Compatible; the positioning part 2 is arranged on the other upper surface of the base relative to the side where the main wire groove is located, and a side end surface of the positioning part 2 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com