Water-cooled slag discharging device and method for realizing water circulation

A water circulation, water-cooled technology, applied in laser welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problem of fast slag discharge, rising water temperature, and the inability of the slag discharge trolley to be pulled out from the bottom of the machine tool when it passes through thermal deformation and other problems to achieve the effect of ensuring normal slag discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

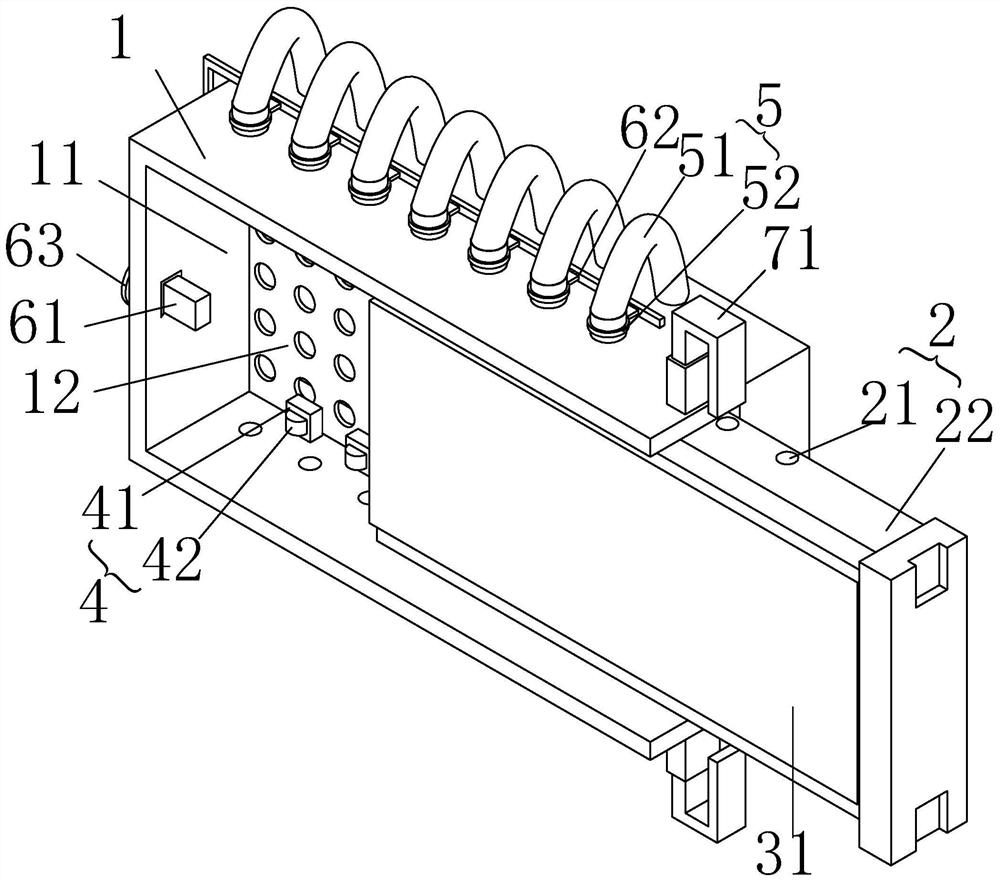

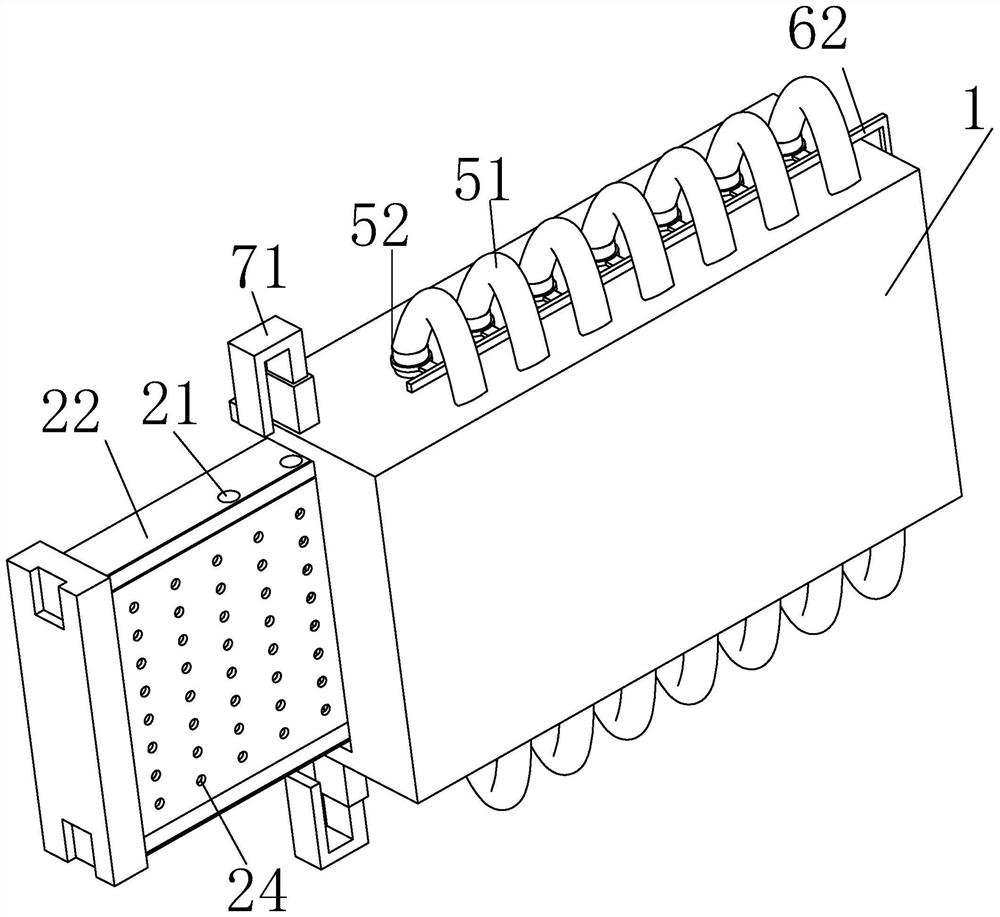

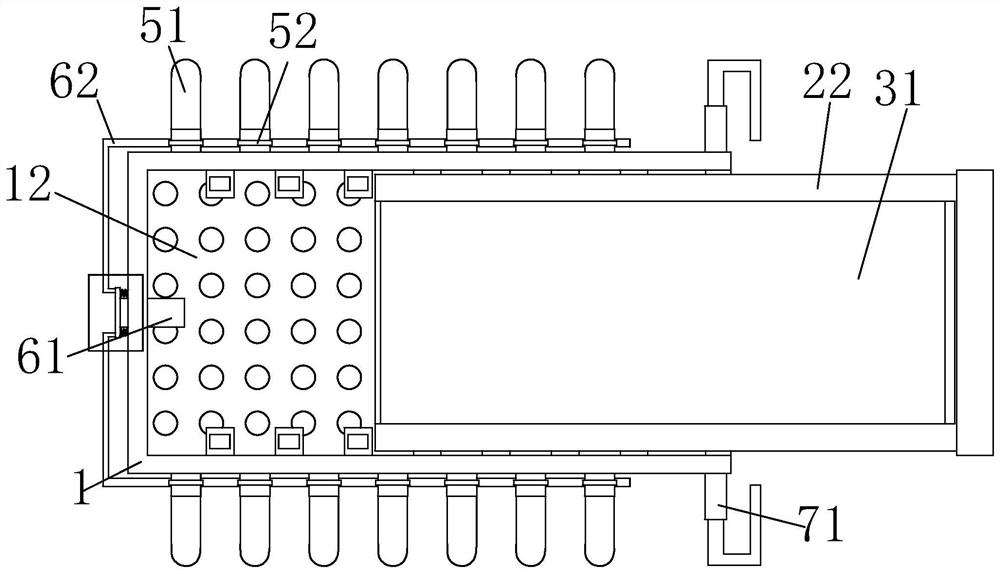

[0038] Such as Figure 1-Figure 6 As shown, a water-cooled slag discharge device that realizes water circulation includes a box body 1 and a bearing assembly 2. The box body 1 is provided with a sliding chamber 11 for storing and moving the loading assembly 2. The loading assembly 2 can be moved along the length direction of the box body 1. Disassemble and connect in the sliding cavity 11;

[0039] The bearing assembly 2 includes a support plate 22, on which a refractory plate 31 for resisting laser light and collecting residue is connected, and a water cooling cavity 23 for storing water is provided between the support plate 22 and the refractory plate 31, and the water cooling cavity 23 is along the refractory The board 31 is set in the width direction and extends along the length direction of the refractory board 31. The box body 1 is also provided with a water storage chamber 14 for storing excess water in the water cooling chamber 23. The water storage chamber 14 is locat...

Embodiment approach

[0071] Such as Figure 6-Figure 10 As shown, based on the above-mentioned water-cooled slagging device for realizing water circulation of the present invention, the present invention also provides another embodiment of the device, including:

[0072] Divide several water pipes 51 into two parts according to the sliding direction of the support plate 22 in the sliding chamber 11, and a part of the water pipes 51 close to the sliding terminal of the support plate 22 is still connected by the connecting rod 62 to control the baffle plate 52. One end of a part of the baffle plate 52 at the beginning of the sliding of the support plate 22 is connected with a moving rod 84, that is, the water pipe 51 near the beginning of the sliding of the supporting plate 22, and the moving rod 84 controls the baffle 52 to realize communication.

[0073] Both sides of the support plate 22 in the width direction are connected with two racks 81, and the two racks 81 are located in the middle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com