Intermediate storage bin type multifunctional powder feeding system for steel ball coal mill

A technology of steel ball coal mills and intermediate storage bins, which is applied in the direction of block/powder fuel preparation, block/powder supply/distribution, combustion methods, etc., and can solve the problem of fuel supply security that affects the economy of coal-fired procurement in power plants , limited range of coal type adaptation, large fluctuations, etc., to achieve the effect of broadening the scope of coal-fired procurement, providing operating benefits, and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

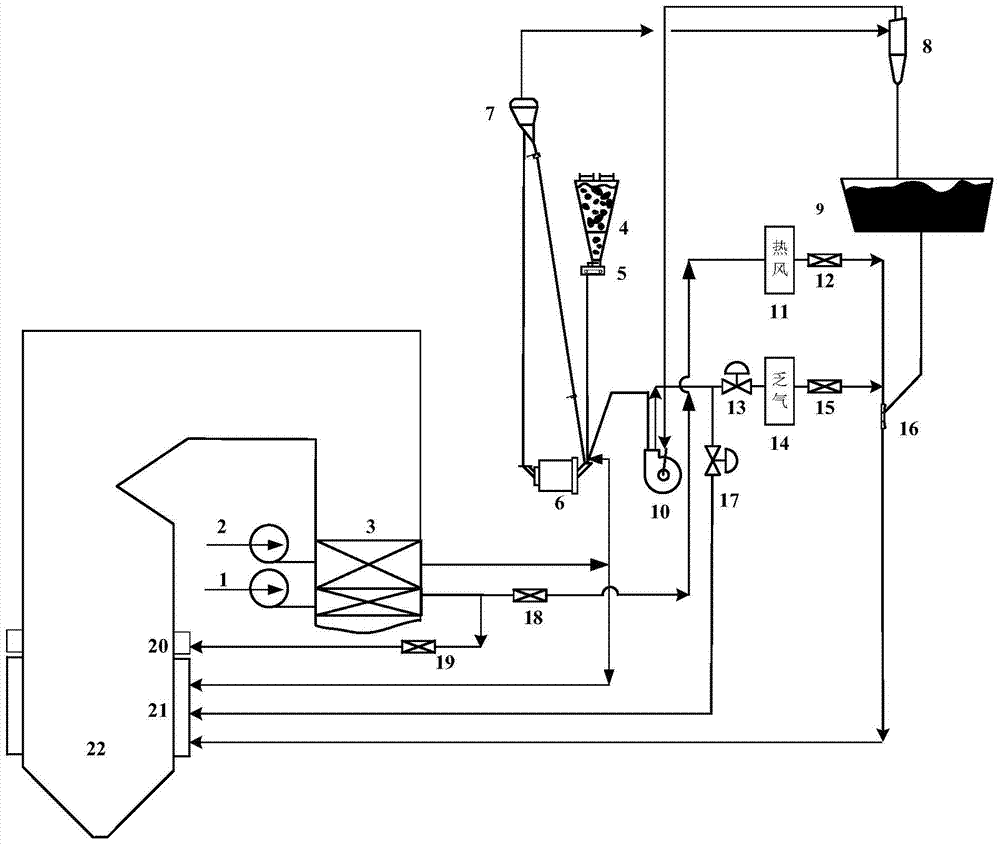

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] see figure 1 , the steel ball coal mill intermediate storage warehouse type multifunctional powder feeding system of the present invention includes a primary fan 1, a blower fan 2, an air preheater 3, a coal bunker 4, a coal feeder 5, a coal mill 6, and a coarse powder separator 7 , fine powder separator 8, powder bin 9, powder exhaust fan 10, primary air box 11, primary air branch pipe hot air regulating door 12, powder feeding exhaust air isolation door 13, exhaust air bellows 14, primary air branch exhaust air regulating door 15, Air powder mixer 16, boiler tertiary air pipe isolation door 17, powder feeding hot air main pipe adjustment door 18, high-speed OFA air volume adjustment door 19, high-speed OFA nozzle 20, main burner 21 and boiler 22.

[0018] Wherein, in the boiler system, the coal bunker 4 is used to supply coal to the coal feeder 5, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com