Mixed light emitting diode (LED) lamp strip

An LED light bar and mixing technology, which is applied to the parts of lighting devices, semiconductor devices of light-emitting elements, lighting devices, etc., can solve the problem of low output rate of LED high brightness level and central chromaticity level, which is not conducive to improving the The market competitiveness of enterprises and the large differences in output conditions can reduce the cost of material procurement and the consumption of human and material resources, improve market competitiveness, and have a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the drawings and specific embodiments.

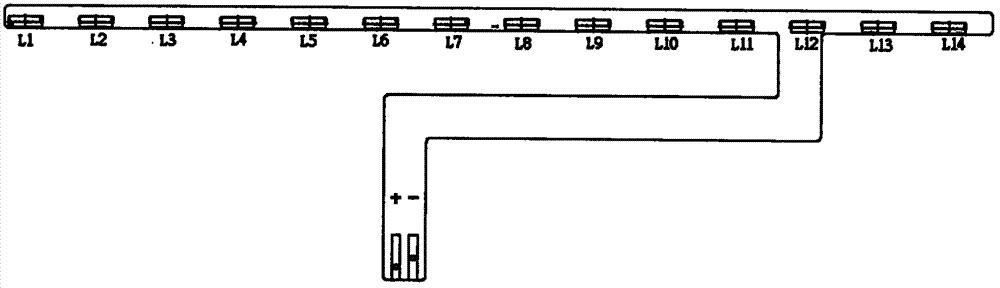

[0010] A mixed LED light bar, comprising a PCB board, and an LED group including a number of LED unit components arranged on the PCB board. The LED group consists of two different brightness LED unit components one and LED unit components two spaced apart Formed on PCB board. The first LED unit element and the second LED unit element are arranged on a horizontal line at intervals, and the distance between the unit elements and the unit elements is equal.

[0011] As shown in the figure, for example, single-numbered LEDs numbered L1, 3, 5, 7... use the same brightness LED unit one for printing; L2, 4, 6, 8... double-numbered LEDs use the same brightness The second LED unit is printed. The front LED single original has a higher brightness, and the rear LED single original ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com