Preparation technology of selective resin for removing trace nitrate ion in water

A nitrate ion and preparation process technology, applied in the field of selective resin preparation technology, can solve problems such as unsatisfactory nitrate removal effect and poor removal effect, and achieve high selectivity, improved pore structure, and large exchange rate. The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

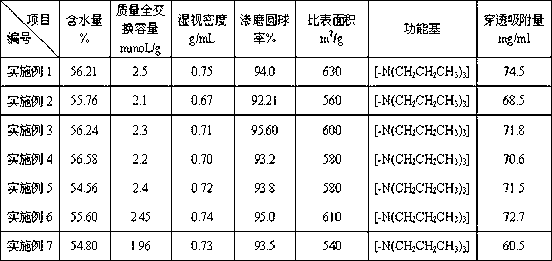

Examples

Embodiment 1

[0030] 1) Polymerization: Add 600 parts of pure water to a 2-liter polymerization reactor, add 3 parts of gelatin, 24 parts of magnesium sulfate, and 16 parts of sodium carbonate in sequence under stirring conditions, then raise the temperature to 50°C, and add 3 parts of methine Blue, stop stirring, add the oil phase mixed by 70 parts of styrene, 30 parts of divinylbenzene, 65 parts of toluene, 60 parts of white oil, and 0.7 parts of benzoyl peroxide. Close the reaction kettle, start stirring, adjust the particle size of the liquid beads to 0.125-0.8mm, raise the temperature to 79°C, keep it warm for 2 hours, raise the temperature to 85°C, keep it warm for 4 hours, raise the temperature to 95°C, and keep it warm for 6 hours. Wash, dry and sieve to obtain white balls of 0.315-0.71mm.

[0031] 2) Chloromethylation: Add 100 parts of white ball and 500 parts of chloromethyl ether prepared in step 1) into a 2-liter reactor, and after swelling for 1.5 hours, add anhydrous zinc chlo...

Embodiment 2

[0034] 1) Polymerization: Add 500 parts of pure water to a 2-liter polymerization reactor, and then add 3.5 parts of polyvinyl alcohol, 30 parts of disodium hydrogen phosphate, and 15 parts of trisodium phosphate under stirring conditions, then raise the temperature to 50 ° C, add 2 parts of methylene blue, stop stirring, add the oil phase mixed by 75 parts of styrene, 25 parts of divinylbenzene, 70 parts of toluene, 60 parts of isobutanol, and 0.8 parts of azobisisobutyronitrile. Close the reaction kettle, start stirring, adjust the particle size of the liquid beads to 0.125-0.8mm, raise the temperature to 79°C, keep it warm for 2 hours, raise the temperature to 85°C, keep it warm for 4 hours, raise the temperature to 95°C, and keep it warm for 6 hours. Wash, dry and sieve to obtain white balls of 0.315-0.71mm.

[0035] 2) Chloromethylation: Add 100 parts of white ball and 400 parts of chloromethyl ether prepared in step 1) into a 2-liter reactor, and after swelling for 1 hou...

Embodiment 3

[0038] 1) Polymerization: Add 600 parts of pure water to a 2-liter polymerization reactor, add 4 parts of polyvinyl alcohol, 30 parts of magnesium sulfate, and 20 parts of sodium carbonate in turn under stirring conditions, then raise the temperature to 50°C, and add 4 parts of Methylene blue, stop stirring, add the oil phase mixed by 75 parts of styrene, 30 parts of divinylbenzene, 75 parts of benzene, 70 parts of white oil, and 1 part of benzoyl peroxide. Close the reaction kettle, start stirring, adjust the particle size of the liquid beads to 0.125-0.8mm, raise the temperature to 79°C, keep it warm for 2 hours, raise the temperature to 85°C, keep it warm for 4 hours, raise the temperature to 95°C, and keep it warm for 6 hours. Wash, dry and sieve to obtain white balls of 0.315-0.71mm.

[0039] 2) Chloromethylation: Add 100 parts of white ball and 600 parts of chloromethyl ether prepared in step 1) into a 2-liter reactor, after swelling for 3 hours, add anhydrous zinc chlor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com