Methanol diesel oil additive and methanol diesel oil

An additive and diesel technology, which is applied in the petroleum industry, liquid carbon-containing fuel, fuel, etc., can solve the problems of limiting the use range of methanol diesel, poor swelling, high corrosion, etc., and achieves wide performance, good environmental protection, and reduced pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

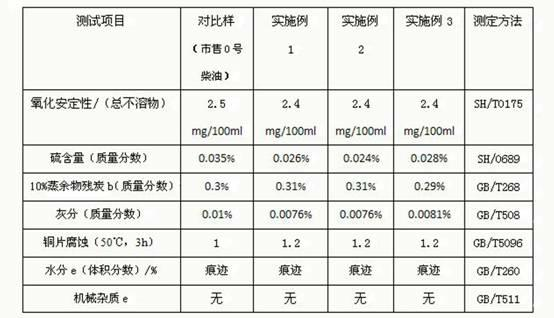

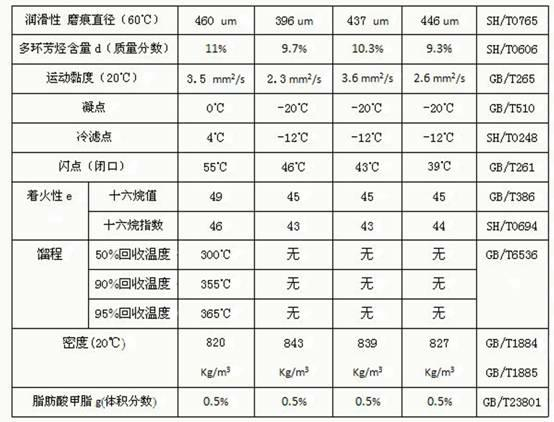

Embodiment 1

[0014] The methanol diesel additive is composed of the following components in parts by weight: 0.04 parts of ferrocene, 2 parts of acetone, 4 parts of dimethyl carbonate, 3 parts of isobutanol and 2 parts of toluene.

[0015] The methanol diesel added with the above-mentioned methanol diesel additive is composed of the following components in parts by weight: 0.04 parts of ferrocene, 2 parts of acetone, 4 parts of dimethyl carbonate, 3 parts of isobutanol, 2 parts of toluene, and 70 parts of diesel oil 1. 20 parts of methanol, the preparation method of which is: weighing each component according to the parts by weight of each component, and then mixing and stirring to obtain it.

Embodiment 2

[0017] The methanol diesel additive is composed of the following components in parts by weight: 0.06 parts of ferrocene, 4 parts of acetone, 4 parts of dimethyl carbonate, 2 parts of isobutanol and 3 parts of toluene.

[0018] The methanol diesel added with the above-mentioned methanol diesel additive is composed of the following components in parts by weight: 0.06 parts of ferrocene, 4 parts of acetone, 4 parts of dimethyl carbonate, 2 parts of isobutanol, 3 parts of toluene, and 70 parts of diesel oil 1. 25 parts of methanol, the preparation method of which is as follows: weighing each component according to the parts by weight of each component, and then mixing and stirring to obtain it.

Embodiment 3

[0020] The methanol diesel additive is composed of the following components in parts by weight: 0.07 parts of ferrocene, 5 parts of acetone, 4 parts of dimethyl carbonate, 2 parts of isobutanol and 2 parts of toluene.

[0021] The methanol diesel added with the above-mentioned methanol diesel additive is composed of the following components in parts by weight: 0.07 parts of ferrocene, 5 parts of acetone, 4 parts of dimethyl carbonate, 2 parts of isobutanol, 2 parts of toluene, and 70 parts of diesel oil 1. 23 parts of methanol, the preparation method of which is as follows: weighing each component according to the parts by weight of each component, and then mixing and stirring to obtain it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com