Preparation method of multistage porous Rh nanosheet

A technology of nanosheets and hydroxyethylidene diphosphonic acid, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of slow methanol oxidation reaction at the anode and hinder the commercialization of ADMFCs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

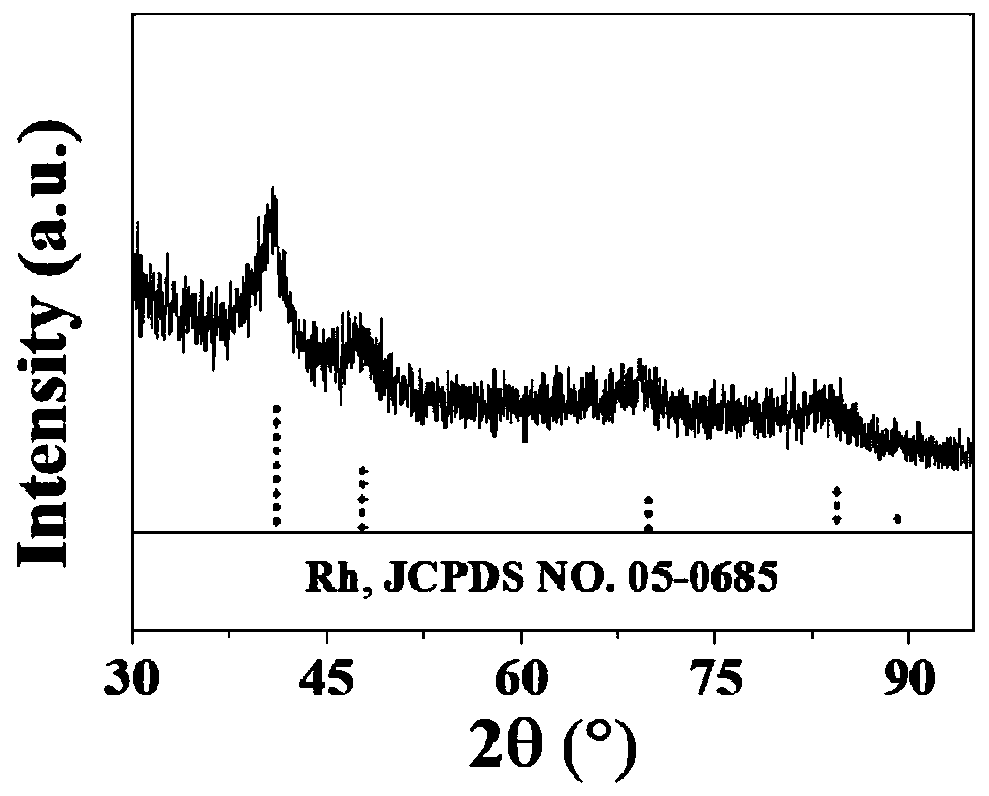

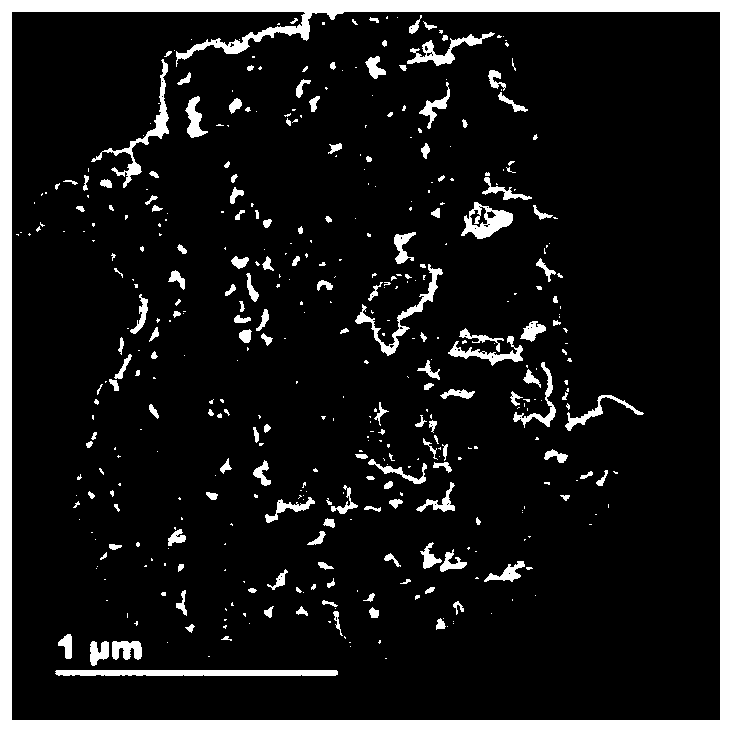

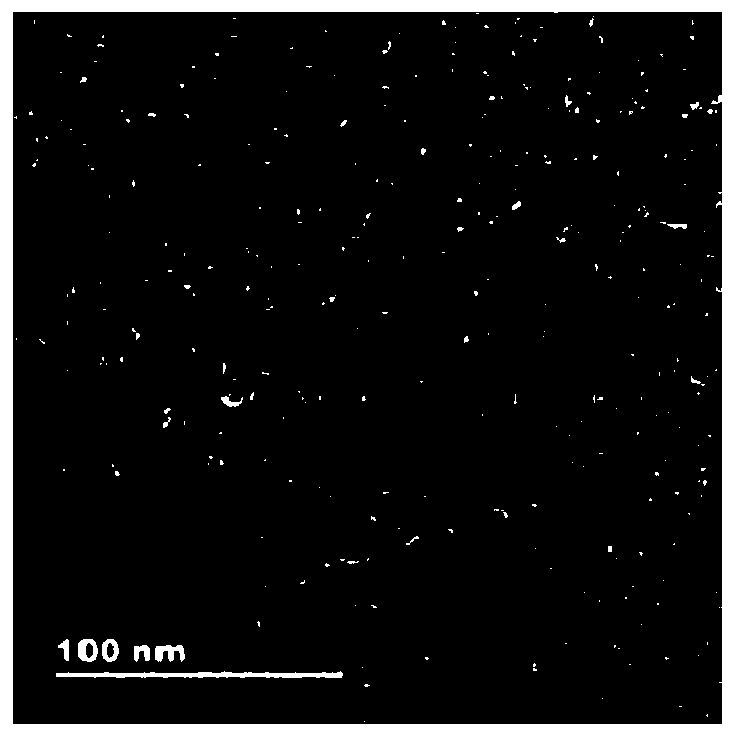

[0021] 1mL0.08mol / L of RhCl 3 aqueous solution, 1 mL of 0.5 mol / L aqueous solution of hydroxyethylidene diphosphonic acid, and 8 mL of deionized water were mixed evenly, and the resulting mixture was allowed to stand for 1 to 2 minutes to allow Rh 3+ Complexation with hydroxyethylidene diphosphonic acid to form HEDP-Rh 3+ complex; then add 25mL of ethanol, and add 2mL of 2mol / L NaOH aqueous solution to adjust the pH to 12-14, so that HEDP-Rh 3+ The complex compound was precipitated; finally, 5 mL (0.09 mol) of ethylene glycol was added, and the reduction reaction was carried out at 160° C. in the reaction kettle for 3 hours, centrifuged, washed, and vacuum-dried to obtain the product. Depend on figure 1 It can be seen that the obtained product is Rh. Depend on figure 2 It can be seen that the obtained product is a two-dimensional porous sheet structure. pass image 3 On closer inspection, we can see that Rh nanosheets are assembled from two-dimensional Rh nanocrystals w...

Embodiment 2

[0023] 1mL0.08mol / L of RhCl 3 aqueous solution, 0.5mL of 0.5mol / L hydroxyethylidene diphosphonic acid aqueous solution, and 8.5mL of deionized water were mixed evenly, and the resulting mixture was allowed to stand for 1 to 2 minutes to allow the Rh 3+ Complexation with hydroxyethylidene diphosphonic acid to form HEDP-Rh 3+ complex; then add 15mL ethanol, and add 2mL 2mol / L NaOH aqueous solution to adjust the pH to 12-14, so that HEDP-Rh 3+ The complex compound was precipitated; finally, 10mL (0.18mol) ethylene glycol was added, and the reduction reaction was carried out at 150°C in the reaction kettle for 5 hours, centrifuged, washed, and vacuum-dried to obtain multi-level porous Rh nanosheets (see Figure 4 ).

Embodiment 3

[0025] 1mL0.08mol / L of RhCl 3 aqueous solution, 1.5 mL of 0.5 mol / L aqueous solution of hydroxyethylidene diphosphonic acid, and 7.5 mL of deionized water were mixed evenly, and the resulting mixture was allowed to stand for 1 to 2 minutes to allow Rh 3+ Complexation with hydroxyethylidene diphosphonic acid to form HEDP-Rh 3+ complex; then add 30mL ethanol, and add 2mL 2mol / L NaOH aqueous solution to adjust the pH to 12-14, so that HEDP-Rh 3+ The complex compound was precipitated; finally, 4 mL (0.07 mol) of ethylene glycol was added, and the reduction reaction was carried out at 170 °C in the reactor for 3 hours, centrifuged, washed, and vacuum-dried to obtain multi-level porous Rh nanosheets (see Figure 5 ).

[0026] In order to prove the beneficial effects of the present invention, the inventors used the multi-level porous Rh nanosheets prepared in Example 1 (abbreviated as Rh nanosheets) to electrocatalyze the methanol oxidation oxidation reaction at 30 ° C, and adopted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com