Halogen-free flame retardant composite belt

A technology of flame-retardant composite and composite tapes, which is applied in the directions of synthetic resin layered products, layered products, metal layered products, etc., can solve the problems that the products cannot fully meet the actual needs, and achieve the effect of improving the wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

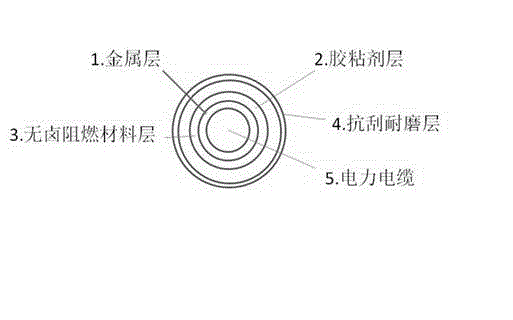

[0017] The structure of the present invention will be further described below in conjunction with the drawings.

[0018] Such as figure 1 As shown, the metal composite belt of the present invention is a composite structure of a copper layer or aluminum-plastic layer 1 and a biaxially stretched halogen-free flame-retardant polynylon composite material layer 3. The copper layer or aluminum-plastic composite material layer 1 and a halogen-free flame-retardant nylon composite material layer 3 It is formed by bonding and heating the adhesive layer 2. The halogen-free flame-retardant nylon composite material has a scratch-resistant and wear-resistant layer.

[0019] In the present invention, the metal layer 1 is obtained by cold rolling, the total thickness of the composite belt is 0.028 to 0.308 mm, wherein the thickness of the metal layer 1 is 0.02 to 0.2 mm, and the biaxially oriented halogen-free flame-retardant nylon composite material layer 3 The thickness is 0.008-0.058mm, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com