Nano magnesium cobaltate as well as preparation method and application thereof

A technology of nano-cobalt and magnesium cobaltate, applied in nanotechnology, chemical instruments and methods, cobalt compounds, etc., can solve the problem of low capacity of magnesium cobaltate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0043] As an implementation manner of the embodiments of the present invention, the millimolar ratio of the magnesium source, cobalt source, precipitation agent and structure synthesis agent is 1-10:2-10:1-15:1-5.

[0044] According to MgCo 2 o 4 It can be seen from the chemical formula that in the unit cell of the material, the ratio of Mg to Co atoms is 1:2, so the millimolar ratio of adding magnesium to cobalt source is the most suitable of 1:2. Based on this, excessive or too little of a certain source may lead to the generation of other impurities (magnesium hydroxide, cobalt hydroxide), which will affect the synthesis of magnesium cobaltate crystals, and the purity of the material is not high.

[0045] The precipitant is mainly hydrolyzed to produce hydroxide ions, which combine with magnesium and cobalt ions to undergo a precipitation reaction, so that a precursor can be deposited on the foamed nickel, and the precursor can be further oxidized into magnesium cobaltate ...

Embodiment 1

[0070] Embodiment 1 provides a kind of nano-magnesium cobaltate and its preparation method and application, and the method is as follows:

[0071] 1. Weigh 0.2564g magnesium nitrate (1mmol), 0.5820g cobalt nitrate (2mmol), 0.3g urea (5mmol), and 0.074g ammonium fluoride (2mmol) and dissolve them in 50ml of deionized water, stir for 1 hour to obtain a uniform mixture solution.

[0072] 2. Nickel foam (1×4cm 2 ) were ultrasonicated with 3 mol / L dilute hydrochloric acid, acetone, absolute ethanol, and deionized water for 15 minutes, and dried at a temperature of 50° C. for 70 minutes.

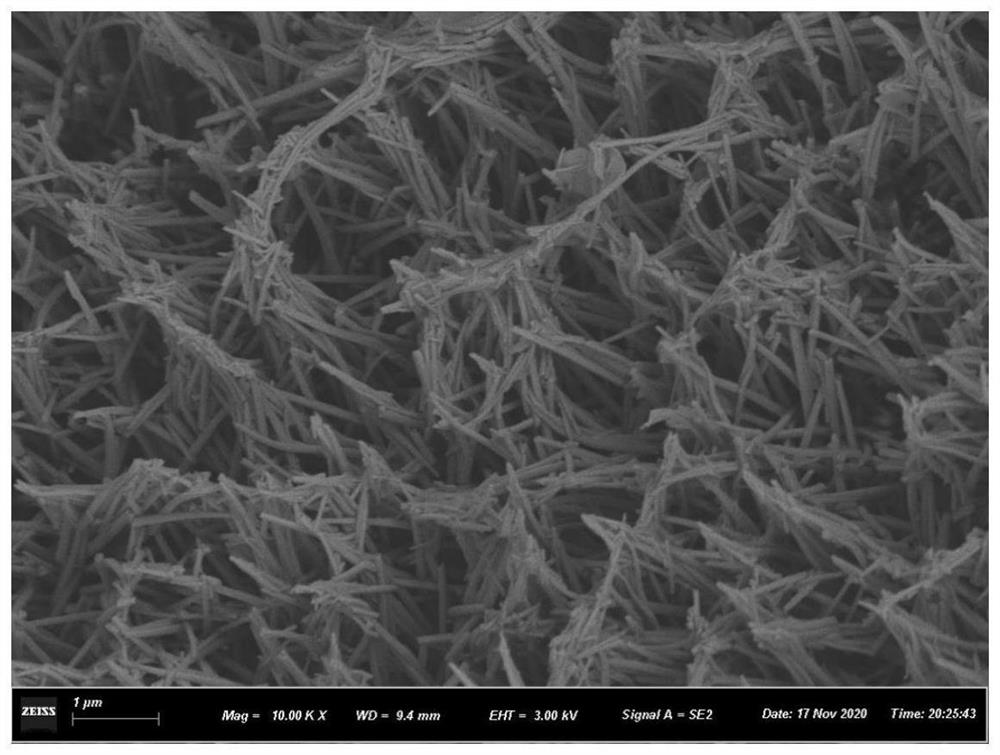

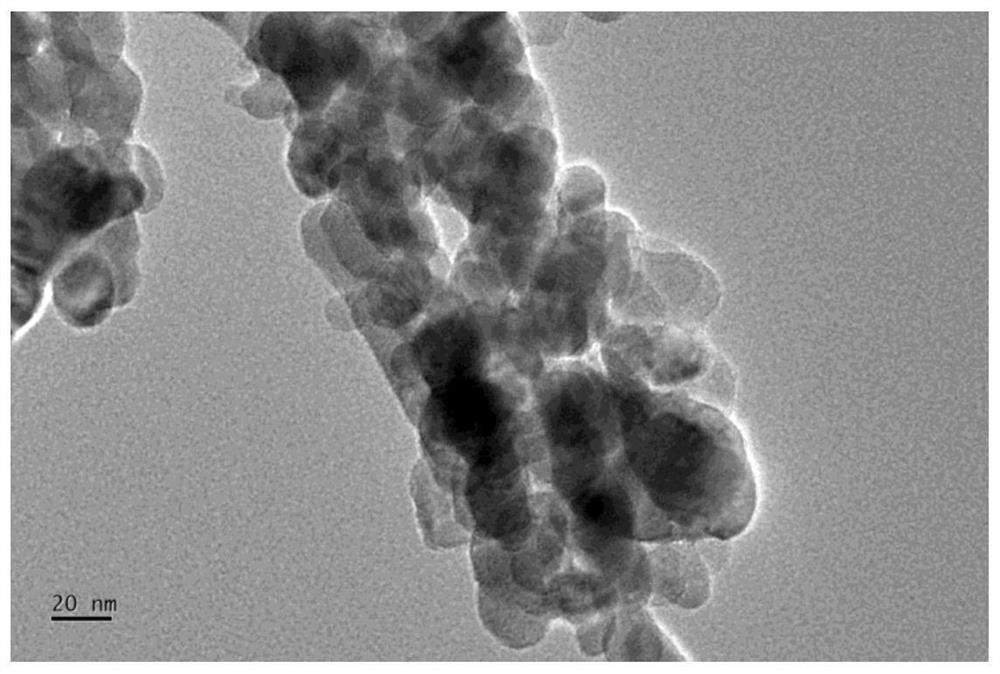

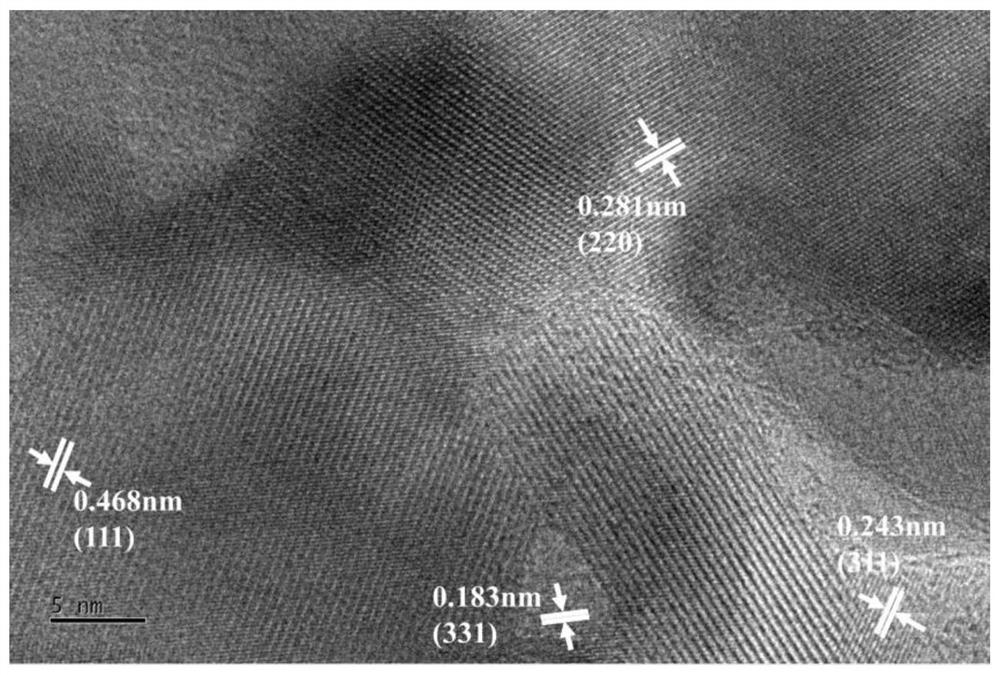

[0073] 3. Transfer the mixed solution obtained in step 1 and the nickel foam obtained in step 2 to a 100ml reactor, and conduct hydrothermal treatment at 120°C for 6 hours. After cooling down to room temperature naturally, wash with absolute ethanol and deionized water for 3 times, and then dried at 60°C for 5 hours to obtain a magnesium cobaltate precursor.

[0074] 4. Heat the precursor obtai...

Embodiment 2

[0076] Embodiment 2 provides a kind of nano-magnesium cobaltate and its preparation method and application, the method is as follows:

[0077] 1. Weigh 0.322g magnesium acetate (1.5mmol), 0.53g cobalt acetate (3mmol), 0.54g oxalic acid (6mmol), and 0.056g ammonium fluoride (1.5mmol) and dissolve them in 50ml of deionized water, stir for 1 hour to obtain Mix the solution evenly.

[0078] 2. Nickel foam (2×3cm 2 ) respectively with 3mol / L dilute hydrochloric acid, acetone, absolute ethanol, and deionized water for 20 minutes, and dried at a temperature of 60°C for 65 minutes.

[0079] 3. Transfer the mixed solution obtained in step 1 and the nickel foam obtained in step 2 to a 100ml reactor, and conduct hydrothermal treatment at 125°C for 5 hours. After cooling down to room temperature naturally, wash with absolute ethanol and deionized water for 4 times, and then dried at 60°C for 5 hours to obtain a magnesium cobaltate precursor.

[0080] 4. Heat the precursor obtained in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com